Hidden Dangers of Modifying Leaf Blower Tubes

- April 22, 2024

- 0 comment

Discover the risks of modifying leaf blower tubes and their impact on engine performance and safety. Learn why sticking to manufacturer settings is crucial.

Leaf blowers are essential tools for garden maintenance, effectively clearing leaves and debris. However, altering the blower tube can have severe consequences on the blower’s engine and overall functionality. Modifying these components to increase airflow might seem like a quick fix to boost performance, but such changes can lead to engine damage and decreased efficiency. In this article, we delve into the reasons why adhering to manufacturer settings is not only crucial for maintaining the longevity of your tool but also for ensuring it operates safely and effectively.

Why Modifying Blower Tubes is Risky

The blower tube is crucial to the proper operation of leaf blowers, whether they are handheld or backpack models and across all brands like Stihl, Husqvarna, Echo, or Ryobi. The tube’s design and size are specifically engineered to balance the airspeed and volume (measured in cubic feet per minute, or CFM) that passes through it.

Some users attempt to modify the blower tube’s exit point, often narrowing it to increase the air speed—akin to placing a thumb over a garden hose nozzle to spray water further. While this might seem effective at first, as it can indeed increase the speed of air exit, it simultaneously reduces the volume of air (CFM). This reduction forces the engine to work harder than its designed limit, significantly increasing the risk of engine damage.

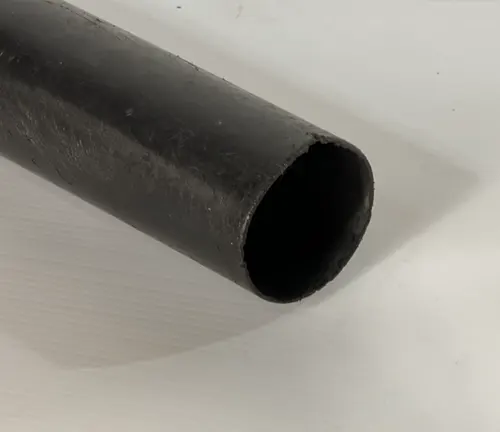

Experiment Demonstrating the Risks

To highlight the potential dangers of modifying blower tubes, an experiment was conducted comparing the operational speeds of a blower with a standard tube versus one modified with duct tape to restrict airflow:

Original Tube

The blower operated at a safe and steady 7,300 RPM, adhering to the manufacturer’s recommended operational specifications.

Modified Tube

When tested, the RPM alarmingly increased to 9,020, significantly exceeding the safe operational limits recommended by the manufacturer. This poses a severe risk of engine damage due to overstressing components.

This increase in RPM can lead to what is termed an “overspeed seizure,” particularly affecting the blower’s crankshaft bearings. These bearings are designed to function within specific speed thresholds, and operating beyond these limits can cause the bearings to break down or disintegrate, potentially leading to catastrophic engine failure. This experiment underscores the critical importance of following manufacturer guidelines and avoiding unauthorized modifications that could impair equipment functionality and safety.

Technical Implications of Increased RPM

Running a leaf blower with increased RPM due to tube modification can lead to several issues:

- Overspeed Seizure: The most critical concern is overspeed seizure, affecting not just the piston or cylinder but predominantly the crankshaft bearings. These components are specifically designed to withstand certain operational thresholds. Exceeding these speeds can lead to mechanical failures and complete engine seizures.

- Heat Build-up: Higher RPMs generate excessive heat. This heat accumulation can swiftly degrade the engine’s internal components. Over time, this can reduce the efficacy of lubricants, potentially causing them to fail in providing necessary lubrication and cooling. Additionally, the increased temperature can alter the metallurgical properties of the engine parts, making them more susceptible to wear and damage.

- Increased Wear: With the engine running at higher speeds, the wear and tear on essential components such as the crankshaft and its bearings accelerate. This not only shortens the overall lifespan of the leaf blower but also increases the frequency and potentially the cost of necessary repairs and maintenance.

Best Practices for Leaf Blower Usage

To maximize the effectiveness and extend the lifespan of your leaf blower, consider these best practices:

- Avoid Modifications: Stick to the manufacturer’s guidelines and use the blower as intended. Alterations, particularly to the blower tube, can seem beneficial for increasing power or efficiency in the short term but often lead to significant long-term damage.

- Regular Maintenance: Regular checks and maintenance are crucial. Ensure the blower and its components, especially the tube and exit points, are clear of debris, which can restrict airflow and reduce efficiency. Cleaning the blower after each use prevents build-up that could affect performance.

- Consult Professionals: If you encounter performance issues or are unsure about the proper maintenance procedures, consult a professional. This ensures that your equipment is assessed and serviced correctly, helping to maintain its functionality and extend its useful life.

Conclusion

Modifying the blower tube might appear to offer more power or efficiency in clearing debris, but it actually compromises the machine’s design and can lead to significant engine damage. The recommendation is clear: adhere to using the blower as designed and avoid any modifications to ensure it runs safely and effectively. Always use the tube that comes with your blower and resist the temptation to alter it in any way. This approach will help maintain the blower’s lifespan and prevent unexpected breakdowns.

FAQs

- Can narrowing the tube on a leaf blower increase its efficiency?

Modifying the tube to be narrower can increase air speed but decrease the volume of air (CFM) being moved, which might not be as effective for blowing larger debris. - What are the risks of modifying a leaf blower tube?

Restricting the blower tube can cause the engine to run at higher RPMs than it’s designed for, potentially leading to overheating and engine damage. - Is it better to increase the speed or the volume (CFM) of air in a leaf blower?

It depends on the task. Higher speed (MPH) can blow debris further, which is good for dry leaves and surfaces, while higher volume (CFM) is better for moving larger or wet debris. - How can modifications to a leaf blower tube affect its warranty?

Modifications can void the warranty if they lead to damage or are not approved by the manufacturer. - Can DIY modifications improve the performance of a leaf blower?

While some DIY enthusiasts may find slight improvements by modifying leaf blower tubes, these changes can often lead to unintended consequences like reduced equipment life or voided warranties. - What should be considered before modifying a leaf blower’s tube?

Before modifying, consider the specific needs for air speed versus volume, and the material you’ll be clearing, and check the manufacturer’s guidelines to avoid damaging your blower or voiding its warranty. - How does changing the tube diameter affect leaf blower noise?

Smaller tube diameters can increase the velocity and noise level of the blower, which might require additional hearing protection during operation. - Can tube modifications lead to increased fuel consumption?

Yes, by increasing the RPM and the engine’s workload, there might be a noticeable increase in fuel consumption. - What materials are safe to use for modifying leaf blower tubes?

It’s important to use materials that can withstand the air speed and volume without deteriorating, such as certain metals or durable plastics. - Are there any professional adjustments recommended instead of DIY modifications?

Professional adjustments or accessories approved by the blower’s manufacturer are recommended over DIY modifications to ensure safety and efficiency without risking damage.

Do you have thoughts or personal experiences with modifying leaf blower tubes? We’d love to hear them! Share your insights or questions in the comments below and join the conversation. Happy blowing!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment