The World’s Strongest Fiber for Chain Saw Safety

- April 26, 2023

- 0 comment

Engtex, a Swedish textile company from Mullsjö, has transformed significantly since its early days in clothing production. In the 1970s, recognizing the need to adapt to shifting market trends, the company pivoted to industrial textiles and introduced innovative solutions like chainsaw protection pants. This move not only secured their position in the market but also set new standards in chainsaw safety. Today, Engtex is celebrated as a leading manufacturer of chainsaw safety textiles, leveraging advanced materials like Dyneema to create durable and reliable products. With their focus on chainsaw safety gear materials and fiber technology, Engtex continues to experience remarkable growth. In this article, we’ll explore the innovations behind Engtex’s products and what sets them apart in the competitive chainsaw safety market.

Reduced Weight by 50% While Increasing strength

Engtex has made remarkable strides in advancing chainsaw protection technology, prioritizing both safety and user comfort. By transitioning from polyester fibers to high-performance materials like Dyneema, their chainsaw protection textiles now offer significantly stronger protection while reducing weight and thickness by 50%. This innovation not only enhances safety but also improves comfort, with thinner designs allowing better airflow and moisture transport. The latest generation of Engtex’s chainsaw protection pants demonstrates these advancements, standing out as a game-changer compared to the bulkier models of the 80s and 90s. While high-performance fibers like Dyneema come at a premium, their unmatched durability and effectiveness make them a worthwhile investment especially when protecting your legs or even saving your life. With innovations like these, Engtex continues to lead in chainsaw safety gear, combining cutting-edge materials with thoughtful design.

Fiber is 15 times More Durable Than Steel

When it comes to chainsaw protection, Dyneema® stands out as the leading fiber available on the market today. Manufactured by a Dutch company, Dyneema® is often referred to as “the world’s strongest fiber.” Known for its exceptional strength and versatility, it’s used in applications ranging from super-strong ropes and textile fibers to military protective gear capable of withstanding bullets and fragments. This makes it a superior choice for chainsaw safety compared to materials like Kevlar.

The Secret Lies in the Method of Weaving

Have you ever wondered why chainsaw protection pants are so effective? The answer lies in their innovative weaving method. When a chainsaw chain strikes the pants, it encounters tightly interwoven fibers designed to stick to the sprocket and stop the chain almost instantly. This advanced fiber technology is what makes modern chainsaw-resistant clothing so reliable. Engtex CEO Patrik Johansson compares this technique to the weaving method used for bed sheets, where interlocked threads make it impossible to pull out a single thread without disrupting the entire structure.

Similarly, the fibers in chainsaw protection pants are strategically interwoven to create a tough, impenetrable barrier. This weaving technique, combined with high-performance materials like Dyneema, is a key factor in the effectiveness and reliability of chainsaw safety gear. It’s innovations like these that keep Engtex at the forefront of the chainsaw safety gear materials market.

Did you know that the effectiveness of saw protection fabrics lies in a unique weaving technique called “warp knitting”? Unlike the crosswise weaving used for bed sheets, this method involves a thread structure with two layers of strong Dyneema® threads laid perpendicular to each other, bonded by a third layer that knits them together. This innovative design allows each thread to be easily removed, no matter its orientation.

When a chainsaw chain strikes this fabric, it rips apart a significant number of super-strong threads. These threads quickly entangle with the chain and sprocket, bringing the chain to an almost instantaneous stop. This advanced fiber technology, coupled with the incredible strength of Dyneema®, is a key factor in preventing serious injuries.

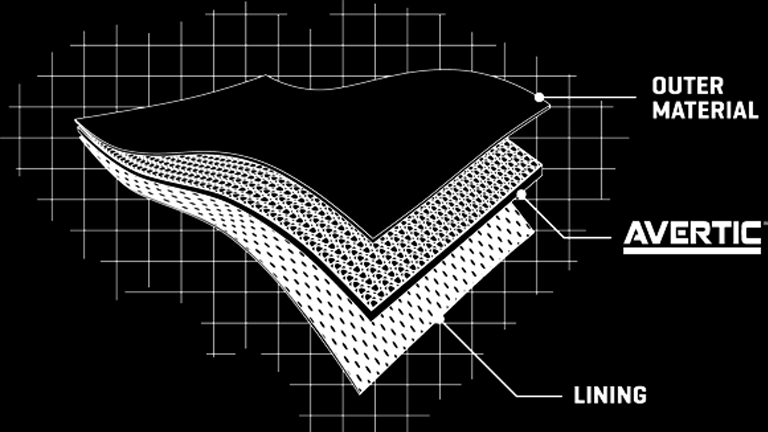

Brand’s Own Chainsaw Protection Textile

The protective pads in chainsaw pants, branded as Avertic® by Engtex, play a vital role in ensuring safety and comfort. Known for their lightweight design and exceptional breathability, Avertic® pads are used by leading manufacturers like STIHL in Germany to enhance the quality of their protective gear. These pads, made with advanced materials, provide reliable cut resistance, reducing the risk of injury when operating chainsaws. By incorporating innovations like Avertic®, Engtex continues to set the standard for chainsaw safety gear materials.

Classes of ChainSaw Protection

Many institutions regularly test the saw protection capacity of protective pants. One of the most well-known testing and research institutions is KwF (Kuratorium für Waldarbeit & Forsttechnik) in Germany, which conducts thorough testing of various protective products. Here’s a quick example of a Stihl test from KwF’s testing facility:

Saw protection pants have three distinct classes of protection, each with unique requirements and testing procedures. The standardized calibration pads used in all saw protection tests are trimmed to the same specifications using pads created by Engtex. These pads feature complete saw protection and have uniform characteristics.

Each class of saw protection requires that the chain must not damage the innermost fabric layer of the pants after it has stopped. There are three different classes of protection based on the speed of the saw chain:

- Class 1: can withstand a saw chain speed of 20 meters/second (65.6 ft/sec)

- Class 2: can withstand a saw chain speed of 24 meters/second (78.7 ft/sec)

- Class 3: can withstand a saw chain speed of 28 meters/second (91.9 ft/sec)

Did you know that saw protection tests are done differently in Europe and the United States? In Europe, the tests are conducted on the pants leg at a 45-degree angle, while in the United States, the tests are made at a 90-degree angle and cross over the leg. This difference in testing methodology can impact the effectiveness of the saw protection, as the angle and direction of the saw chain can affect how it interacts with the fabric. As a result, it’s important to carefully consider the testing standards used when evaluating saw protection products. By understanding these differences, consumers can make more informed decisions when selecting the right saw protection for their needs.

6 layers

The most effective saw protection pants on the market today use the Avertic Pro or Avertic Pro Lite fabric. The Avertic Pro Lite fabric weighs a mere 99 grams per square meter and requires six layers for protection class 1 or eight layers for protection class 2.

The Growing Market for Chainsaw Protection

The future of saw chain protection looks bright, according to industry experts. With new markets emerging in countries like Eastern Europe and Russia, there is a growing need for protective clothing that has not been previously used. Germany is also seeing a rise in chainsaw use, leading to an increased demand for protective clothing. In the United States, there is a growing market for saw protection clothing, especially among younger generations who prioritize safety. Manufacturers are responding by designing clothing that is both functional and fashionable, offering consumers more options to stay safe on the job. As the demand for saw protection clothing continues to increase, companies like Engtex are expanding to larger production facilities to meet the needs of their customers.

It all begins with the laying of the warp, where the fibers are positioned with the required spacing for the final product. In a massive rack, over 1000 thread spools are available. Thin fibers are directed from the spools towards the collecting reel, where they are wound up at an impressive speed of 60 km/h (37 mph). Each spool has 10 km (10,000 meters/32,800 ft) of fiber. The warp I observed had almost 1200 threads.

After the warp is set up, it’s taken to the machines where the actual weaving or knitting is done. The machines work rapidly with needles, knitting the two layers of Dyneema fibers into a consistent weave. The final product is rolled up and sent to clothing manufacturers, who cut and add the desired number of protective layers to their pants, boots, or gloves. Thanks to the hard work of Engtex’s product developers in Mullsjö, the next time you use your chainsaw and avoid injury, you can be grateful for the high-quality protective materials that keep you safe.

Conclusion

In conclusion, Engtex has significantly advanced the field of chainsaw safety by developing cutting-edge textiles that leverage the world’s strongest fiber, Dyneema. This innovation has resulted in protective gear that not only offers unmatched durability and resistance—being fifteen times stronger than steel—but also enhances user comfort and efficiency. The sophisticated weaving techniques employed ensure that these garments effectively halt chainsaw blades, providing crucial safety to users. As the demand for more robust and comfortable protective clothing grows globally, Engtex’s pioneering efforts continue to set industry benchmarks, ensuring that safety remains a paramount concern in the increasingly mechanized and risky environment of forestry work.

FAQs

- What is the world’s strongest fiber used in chainsaw safety gear?

Dyneema is currently the strongest fiber used in chainsaw safety equipment. It’s renowned for its exceptional strength-to-weight ratio, being 15 times stronger than steel. - How does Dyneema enhance the safety of chainsaw protective clothing?

Dyneema enhances safety by providing superior cut resistance and durability without adding bulk. This ensures that the protective gear is not only effective at stopping chainsaw blades but also comfortable and lightweight, which increases user mobility and reduces fatigue. - What makes Engtex’s chainsaw protective gear different from others in the market?

Engtex’s gear stands out due to its innovative use of Dyneema and unique weaving techniques that integrate multiple protective layers into a cohesive fabric that is effective at stopping chainsaw blades almost instantaneously upon contact. - Can the protective gear made with Dyneema be washed or does it require special care?

Yes, the protective gear can be washed. However, it is recommended to follow specific care instructions provided by the manufacturer to ensure the longevity and continued effectiveness of the fiber. - What are the classes of protection available in Engtex’s chainsaw safety gear and what do they signify?

Engtex’s chainsaw safety gear comes in three classes of protection: Class 1 (20 m/s), Class 2 (24 m/s), and Class 3 (28 m/s). Each class signifies the maximum speed of a chainsaw chain that the gear can withstand without the chain penetrating the innermost layer of the fabric. - Is Engtex’s chainsaw protective clothing suitable for professional lumberjacks as well as casual users?

Yes, Engtex designs protective clothing that caters to both professional lumberjacks and casual users, emphasizing not only protection but also comfort and style, making it suitable for a wide range of activities and experience levels. - How does the cost of Dyneema-based protective gear compare to other materials like Kevlar?

Protective gear made with Dyneema tends to be more expensive than those made with materials like Kevlar due to its superior strength and advanced protective features. However, the investment is generally seen as worthwhile for the enhanced safety and durability it offers. - Where can consumers purchase Engtex chainsaw protective gear and what should they look for when buying?

Engtex chainsaw protective gear can be purchased through various distributors and retailers, both online and in physical stores. Consumers should look for gear that specifically mentions the use of Dyneema and check that it meets the safety standards and class requirements for their specific chainsaw use needs.

John Carlos

Forestry AuthorThe beauty of logging isn't just about felling trees. It's about understanding nature, mastering the art of chainsaws, and respecting the environment. I believe in sharing my experiences and knowledge, ensuring that we move towards a sustainable future together.

Leave your comment