Can a Chainsaw Chain Be Put on Backwards? How to Fix

- February 6, 2024

- 0 comment

Owning and operating a chainsaw requires not only skill and safety measures but also an understanding of its components and assembly. One question that often arises among both novice and seasoned chainsaw users is: Can a chainsaw chain be put on backwards? This article aims to address this question comprehensively, explore the implications of such an error, and provide guidance for proper chainsaw chain installation.

Understanding the Chainsaw Chain

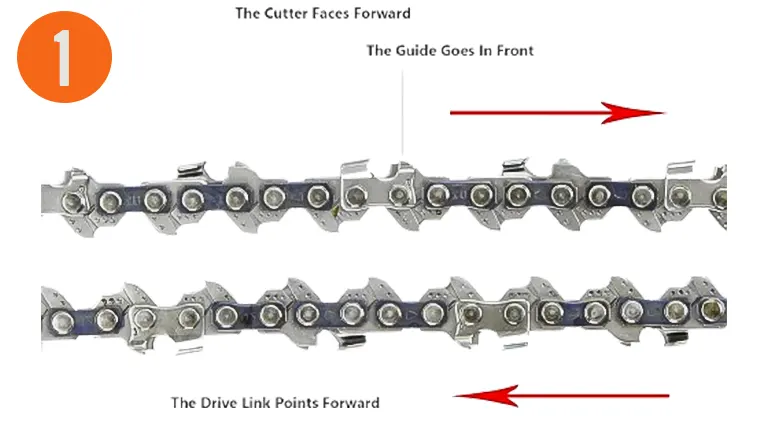

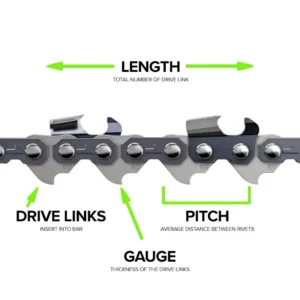

Before delving into the orientation of a chainsaw chain, it’s crucial to understand its structure. A chainsaw chain consists of a series of sharp cutting teeth and drive links. The cutting teeth are responsible for the actual wood cutting, while the drive links fit into the chainsaw’s guide bar, allowing smooth movement around it.

The Possibility of Incorrect Installation

To answer the question directly: Yes, a chainsaw chain can indeed be put on backwards. This mistake is more common than one might think, especially among individuals who are new to using or maintaining a chainsaw. When a chain is installed backward, the saw’s effectiveness is significantly reduced, leading to frustration and increased physical exertion during cutting tasks.

Signs of a Backward Chain

Understanding the signs of an incorrectly installed chain is crucial for efficient chainsaw operation. Here are some indicators:

Ineffective Cutting

The most apparent sign is that the chainsaw doesn’t cut effectively. If you find yourself applying excessive pressure to achieve a cut, or if the saw produces fine sawdust instead of coarse chips, the chain might be backward.

Visible Orientation of the Cutting Teeth

Examining the chain can quickly pinpoint the problem. The cutting teeth should be oriented forward, aligning with the chain’s direction of movement. If they face backward, they’re not positioned to cut the wood effectively.

Increased Vibration or Kickback

A chain installed backward won’t interact correctly with the wood, potentially causing unusual vibrations or a dangerous increase in kickback, making it crucial to ensure proper chain installation for safe and efficient chainsaw use.

Consequences of a Backward Chain

Operating a chainsaw with the chain backward is detrimental not only to the chainsaw’s performance but also to safety. Key consequences include:

Reduced Efficiency

A backward chain compromises cutting efficiency, demanding more power—whether fuel or battery—to operate the chainsaw, resulting in wasted energy and reduced productivity.

Increased Wear

When a chain is mounted incorrectly, not only does the improper orientation subject the chain and the chainsaw to abnormal stress and friction, but it also disrupts the proper seating of the drive links around the drive sprocket. This misalignment can lead to premature wear and tear on the sprocket itself, in addition to the chain and the chainsaw, potentially necessitating costly replacements. Such undue strain accelerates wear on these crucial components, shortening the overall lifespan of your equipment and impacting its performance.

Safety Hazards

A backward chain significantly raises the danger of kickback, a leading cause of chainsaw-related accidents. Additionally, operators might apply excessive force during use, increasing the risk of accidents or injuries due to loss of control. Ensuring the correct installation of the chainsaw chain is paramount for safe and effective operation.

Correcting and Avoiding the Mistake

To ensure safe and efficient chainsaw operation, follow these steps for correct chain installation and maintenance:

1. Chain Installation

Proper chain installation is paramount for the efficient and safe operation of your chainsaw. Begin this process by consulting your chainsaw’s user manual, which provides specific instructions tailored to your model. Attention to detail is crucial during installation; ensure that the cutting teeth are correctly oriented forward, matching the direction of the chain’s rotation during use. This alignment is essential for effective cutting. Additionally, make sure that the drive links are properly seated in the guide bar. When these links are snug and correctly aligned, it ensures smooth movement of the chain around the bar and prevents operational issues.

2. Regular Maintenance

Consistent maintenance is key to the longevity and performance of your chainsaw. Regular inspections of the chain’s tension and sharpness are fundamental to a well-functioning chainsaw. A chain that is correctly tensioned and sharp is less likely to be installed incorrectly and ensures optimal cutting performance. Do not overlook the importance of chain sharpness; a dull chain not only hampers efficiency but can also pose safety risks. Regular sharpening keeps the chain in top condition, promoting safe and effective operation.

3. Marking the Chain

A simple yet effective strategy to avoid installation errors is to mark your chain. Use a permanent marker or paint to apply a distinctive mark on the top of your chain. This mark acts as a quick visual reference, indicating the correct direction of the chain, especially useful during reinstallation. This practice reduces the likelihood of backward installation, streamlining the maintenance process and ensuring the chainsaw is always ready for efficient and safe operation.

Here is a video of testimony on what happens when you put the chainsaw blade backward.

Maintenance Best Practices

To ensure the longevity and optimal performance of your chainsaw, adopting a routine maintenance schedule is crucial. This not only prevents the common mistake of installing the chain backward but also enhances the overall functionality of your equipment. Here are key maintenance tips:

- Regular Chain Checks: Inspect your chainsaw chain regularly for correct orientation, sharpness, and tension. After every use is ideal, but at a minimum, check before any significant period of use. This ensures that the chain is ready for efficient cutting and minimizes wear on the chainsaw.

- Cleaning and Storing: After use, clean the chainsaw thoroughly to remove any debris, sap, or dust that has accumulated on the chain, bar, and around the motor or engine housing. Use a soft brush or cloth for cleaning and apply proper lubricant to the chain and bar to prevent rust. Store your chainsaw in a dry, clean place away from the reach of children. Moisture can cause the metal parts to rust, and dust accumulation can clog the chainsaw’s moving parts, leading to premature wear.

- Sharpness Maintenance: A sharp chain is safer and more efficient. Use a chainsaw file or a professional sharpening service to keep the teeth razor-sharp. Dull chains require more force to cut, increasing the risk of accidents and wear on the chainsaw.

- Tension Adjustment: Proper chain tension is vital. A chain that’s too tight or too loose can lead to poor cutting performance and increase the risk of the chain coming off the bar. Refer to your chainsaw’s manual for instructions on how to adjust the chain tension correctly.

Safety Precautions

Safety should always be the foremost concern when operating a chainsaw. A backward chain not only compromises the efficiency of your work but also poses significant safety risks. Here are essential safety measures to observe:

- Wear Protective Gear: Always wear appropriate safety gear, including safety goggles, gloves, ear protection, and sturdy boots. Protective clothing can prevent injuries from flying debris, noise-induced hearing loss, and accidental cuts.

- Never Modify the Chain: Modifying a chain’s design or attempting repairs while the chainsaw is on can lead to catastrophic failures. Always ensure the chainsaw is off and fully cooled down before performing any maintenance or adjustments.

- Be Aware of Kickback: A backward chain increases the likelihood of kickback, one of the most dangerous hazards when using a chainsaw. Understand how to handle and reduce kickback risks by using chainsaws with built-in safety features and by maintaining proper form and grip during use.

- Regular Training: If you’re new to using a chainsaw or it’s been a while since you last used one, consider undergoing a safety training course. Familiarize yourself with your specific chainsaw model’s safety features and operational guidelines.

Incorporating these maintenance best practices and safety precautions into your chainsaw use routine can significantly reduce the risk of accidents and ensure your equipment remains in top condition for years to come. Remember, taking the time to maintain and safely operate your chainsaw can save time, money, and potentially prevent serious injuries.

Conclusion

While a chainsaw chain can indeed be put on backward, understanding the structure of the chain, recognizing the signs of incorrect installation, and adhering to proper maintenance and installation procedures can prevent this mistake. Ensuring the correct orientation of the chainsaw chain not only enhances cutting efficiency but also significantly contributes to the safe operation of this powerful tool. Always prioritize safety and efficiency by taking the time to inspect and correctly install your chainsaw chain.

FAQs

- How can I tell if my chainsaw chain is on backward?

Check the orientation of the cutting teeth. They should face forward towards the direction of rotation. If the teeth are facing backward, the chain is installed incorrectly. Also, if the chainsaw produces fine sawdust instead of coarse chips or requires excessive pressure to cut, these are signs that the chain might be on backward. - What should I do if I accidentally put the chainsaw chain on backward?

Turn off the chainsaw and allow it to cool down. Then, remove the chain and reinstall it correctly, ensuring that the cutting teeth face forward. Always refer to your chainsaw’s user manual for specific guidance on chain installation. - Can installing a chainsaw chain backward damage the chainsaw or the chain itself?

Yes, operating a chainsaw with the chain installed backward can lead to increased wear on both the chain and the chainsaw. It’s inefficient and can lead to unnecessary strain on the chainsaw’s motor or engine. - Is it safe to use a chainsaw with the chain installed backward?

No, it’s not safe. Besides being inefficient, it increases the risk of kickback, which can lead to serious injuries. Always ensure the chain is installed correctly before using the chainsaw. - How often should I check the orientation of my chainsaw chain?

It’s good practice to check the orientation each time you install the chain or perform maintenance on your chainsaw. Ensuring the correct orientation from the start can save you time and prevent safety hazards. - Are there any tips to prevent installing the chainsaw chain backward?

Yes, consider marking the top of your chain with a permanent marker or paint in a specific color to quickly identify the correct direction. Also, making a habit of checking the direction of the cutting teeth before each installation can prevent this mistake. - Will a chainsaw still cut if the chain is installed backward?

A chainsaw with the chain installed backward will have significantly reduced cutting efficiency. It may still cut to some extent, but it will require more effort, and the result will be unsatisfactory, with fine sawdust instead of coarse chips. - How can incorrect chain orientation affect the lifespan of my chainsaw?

Incorrect chain orientation can lead to increased and uneven wear on the chain and the chainsaw’s guide bar. Over time, this can shorten the lifespan of these components and lead to the need for more frequent repairs or replacements.

Jump into the discussion below and become an integral part of our chainsaw-savvy circle. Whether you’re a seasoned lumberjack or a newcomer to the world of chainsaws, your insights are invaluable. Share your tips, hurdles, and successes to enlighten and encourage fellow chainsaw users. Every nugget of wisdom contributes to building a robust and informed community for chainsaw enthusiasts everywhere. Let’s sharpen our collective knowledge and enhance our chainsaw mastery together!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment