Chainsaw Protection Worlds Strongest

- March 27, 2023

- 0 comment

Engtex, a Swedish textile company headquartered in Mullsjö, has evolved significantly since its beginnings in clothing production. By the 1970s, the company recognized the need for the Swedish textile industry to adapt to shifting market demands. In response, Engtex pivoted toward industrial textiles, creating innovative products like cut-resistant chainsaw pants. These chainsaw protective gear items quickly became a hit, establishing Engtex as a leader in high-performance chainsaw safety clothing.

Today, Engtex is a top manufacturer of chainsaw protection textiles, with their products seeing significant market growth. This text will delve into the market dynamics and highlight what sets Engtex’s ultra-strong chainsaw gear apart from the competition. Their commitment to creating top-rated chainsaw protection ensures they remain a trusted name in chainsaw safety equipment worldwide.

Halved weight – Increased strength

Engtex has consistently pushed the boundaries of chainsaw protective gear with significant advancements. By replacing polyester fibers with stronger, more advanced materials, they’ve created cut-resistant chainsaw pants that are not only more effective but also lighter and thinner reducing weight and thickness by half. This innovation enhances comfort with improved airflow and moisture transport, making the gear more practical for extended use. The latest generation of their premium chainsaw safety clothing has left users impressed, especially compared to bulky designs from the 80s and 90s. While the top-tier fiber materials that provide the world’s strongest chainsaw protection come at a higher cost, the investment is justified when it’s about safeguarding your legs or your life. High-performance chainsaw gear is more than an expense; it’s a necessity.

Fiber is 15 Times Stronger than Steel

Dyneema®, produced by a Dutch company, is renowned as “the world’s strongest fiber,” boasting a strength-to-weight ratio 15 times greater than steel. This ultra-strong material is utilized in various high-performance applications, including super-strong ropes, textile fibers, and military protective gear capable of withstanding bullets and shrapnel, similar to Kevlar. When discussing chainsaw protective gear with Engtex CEO Patrik Johansson, he noted that while Kevlar is a robust material approximately five times stronger than steel it shares a structural similarity with cellulose fibers, which chainsaws are specifically designed to cut. This characteristic renders Kevlar less suitable for chainsaw protection. In contrast, Dyneema’s unique properties make it ideal for crafting high-performance chainsaw safety clothing, such as cut-resistant chainsaw pants, offering superior protection and durability.

The Weaving Method is the Secret

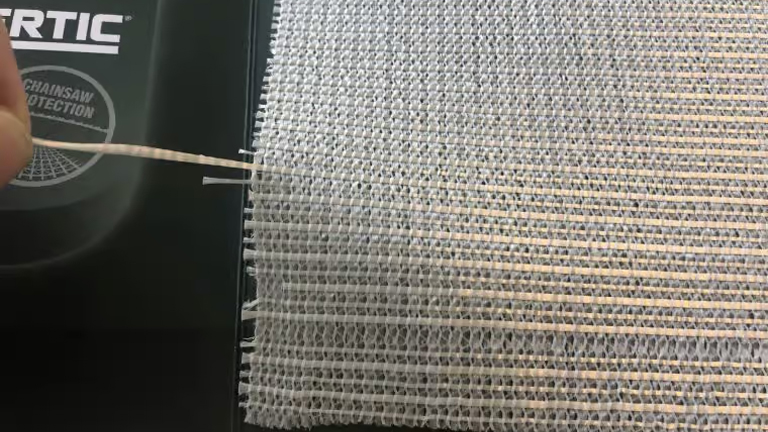

The effectiveness of chainsaw protective gear lies in its innovative weaving method. When a chainsaw chain contacts the pants, it pulls out numerous fibers that clog the sprocket, halting the chain. Engtex CEO Patrik Johansson explains this using an analogy: traditional bed sheets are made with interwoven threads that lock together, preventing single threads from being pulled out.

In contrast, Engtex’s chainsaw protection textiles use a specialized technique called warp knitting. Unlike crosswise weaving, warp knitting involves two perpendicular layers of Dyneema® threads, the world’s strongest fiber, held together by a third layer that knits them securely. This design allows individual threads to be easily removed regardless of their orientation. When a chainsaw hits the fabric, the chain tears through the super-strong threads. These threads entangle rapidly with the chain and sprocket, causing an almost instant stop. This high-performance chainsaw gear design is a cornerstone of cut-resistant chainsaw pants, offering unmatched chainsaw safety clothing for professionals.

Own Brand for Chainsaw Protecting Textile

The protective pads in chainsaw pants are crucial for safety. Engtex, the manufacturer of these pads, brands them as AVERTIC® to highlight their quality. Notably, companies like STIHL in Germany incorporate AVERTIC® into their protective clothing, underscoring its superior performance in chainsaw safety equipment. By using AVERTIC® pads, manufacturers ensure their chainsaw protective gear meets high standards of protection and durability. This collaboration between Engtex and leading brands results in top-rated chainsaw protection for users worldwide.

Three Different Classes of Chain Saw Protection

Chainsaw protection pants undergo rigorous testing to ensure their effectiveness, with institutions like Germany’s Kuratorium für Waldarbeit & Forsttechnik (KwF) leading the way. For example, KwF’s testing facilities assess saw protection pants using standardized calibration pads made by Engtex. These pads, branded as AVERTIC®, are designed to provide consistent testing conditions with uniform characteristics.

Saw protection pants are classified into three levels, each with distinct requirements for stopping a chainsaw before it damages the innermost fabric layer:

- Class 1: Withstands a chain speed of 20 m/s (65.6 ft/s).

- Class 2: Withstands a chain speed of 24 m/s (78.7 ft/s).

- Class 3: Withstands a chain speed of 28 m/s (91.9 ft/s).

Tests in Europe are conducted at a 45-degree angle on the pants leg, while in the U.S., they are performed at a 90-degree angle across the leg. This ensures the pants meet regional safety standards and provide reliable protection.

Six layers

The most effective saw protection pants on the market today use the Avertic Pro or Avertic Pro Lite fabric. The Avertic Pro Lite fabric weighs a mere 99 grams per square meter and requires six layers for protection class 1, or eight layers for protection class 2.

The Growing Market for Chainsaw Protection

The demand for chainsaw protective gear is steadily increasing worldwide, with exciting growth opportunities on the horizon. According to Patrik Johansson, CEO of Engtex, countries like those in Eastern Europe and Russia where protective clothing hasn’t traditionally been used are beginning to adopt chainsaw safety equipment. Similarly, in Germany, a rise in chainsaw use has driven demand for cut-resistant chainsaw pants and related safety products.

In the United States, younger, safety-conscious generations are fueling a growing market for chainsaw protection textiles. Manufacturers have responded by designing clothing that combines both safety and style, making high-performance chainsaw gear more appealing to users. To meet this rising demand, Engtex is planning a move to a larger production facility, highlighting their commitment to innovation and capacity expansion.

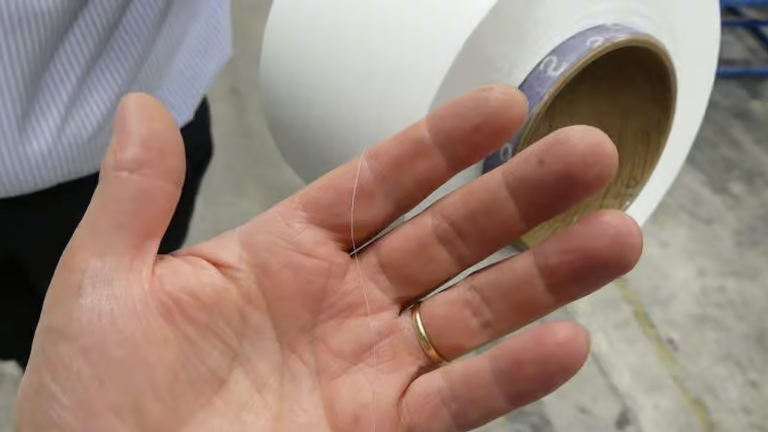

The production of Engtex’s AVERTIC® fabrics begins with precision. Over 1,000 thread spools, each holding 10 km (32,800 ft) of fiber, are arranged on a massive rack to create the warp. The fibers are aligned and collected at speeds of up to 60 km/h (37 mph) before being transferred to knitting machines.

Using advanced technology, these machines knit two layers of Dyneema®, the world’s strongest fiber, into a consistent weave. The final product is rolled up and sent to manufacturers, where it’s crafted into chainsaw safety clothing, boots, or gloves, with the required number of protective layers for each application.

Thanks to Engtex’s relentless innovation, the next time you use your chainsaw safely, you can credit their ultra-strong chainsaw gear for keeping you protected. The future of top-rated chainsaw protection looks safer and brighter than ever.

Here is a video where you can see the manufacturing and some cutting tests:

Frequently Asked Questions

- What are the main applications of Dyneema®?

Dyneema® is used in a wide range of applications, including personal protective equipment (e.g., cut-resistant gloves and body armor), maritime and industrial ropes, sports equipment (e.g., fishing lines, archery strings), and even lightweight outdoor gear like tents and backpacks. - Is Dyneema® resistant to chemicals and UV rays?

Dyneema® is highly resistant to chemicals and UV radiation, making it ideal for outdoor and marine applications where exposure to harsh environments is common. - Can Dyneema® be used for ballistic protection?

Yes, Dyneema® is used in the production of body armor and other ballistic protection solutions due to its high strength and low weight, providing excellent protection against ballistic threats. - Is Dyneema® environmentally friendly?

Dyneema® has a relatively low carbon footprint and can be recycled, making it a more sustainable choice compared to some other materials. - Can Dyneema® be dyed or colored?

Dyneema® is inherently white, but it can be dyed or colored during the production process to achieve different visual appearances or enhanced UV protection. - How does Dyneema® compare to other high-strength fibers like Kevlar®?

Dyneema® and Kevlar® are both high-strength fibers, but they have different properties and strengths. Dyneema® is known for its superior strength-to-weight ratio, while Kevlar® offers excellent heat resistance. - Is Dyneema® resistant to moisture and water?

Dyneema® has excellent resistance to moisture, and it doesn’t absorb water, which helps it maintain its strength and durability in wet environments.

John Carlos

Forestry AuthorThe beauty of logging isn't just about felling trees. It's about understanding nature, mastering the art of chainsaws, and respecting the environment. I believe in sharing my experiences and knowledge, ensuring that we move towards a sustainable future together.

Leave your comment