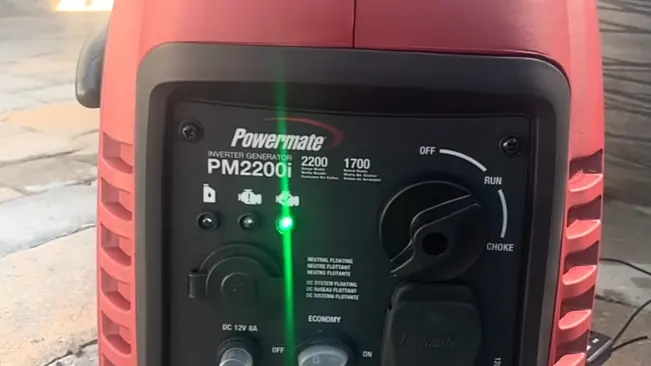

Generator Break-In: A Step-by-Step Guide for Optimal Performance

- January 29, 2024

- 0 comment

Generators are a crucial investment for both residential and commercial uses, providing power in emergencies or when off-grid. To ensure optimal performance and longevity, it’s important to properly break in a new generator. This article delves into what generator break-in entails and its significance.

Why Break-In Your Generator?

The process of breaking in a generator is a critical step often overlooked, yet it plays a fundamental role in determining the efficiency and longevity of the unit. Much like training an athlete for peak performance, breaking in a generator involves a series of initial operation steps that ensure the internal components, especially the engine, are adequately lubricated and conditioned for future use. This process helps in smoothing out any rough edges in the internal mechanisms, facilitating better fuel efficiency, and reducing the likelihood of engine wear and tear.

Some may argue that this step is superfluous, but in reality, a properly executed break-in routine is a proactive measure that can significantly enhance the generator’s operational life. By gently easing the generator into its functional capacity, rather than thrusting it into full-load operation from the start, you allow for the gradual settling of components. This not only optimizes performance but also mitigates the risk of early breakdowns, thus ensuring that your generator remains a reliable source of power for a longer period. Hence, disregarding the break-in period can lead to premature malfunctions and diminished efficiency, underscoring the importance of this foundational step in the life cycle of your generator.

Selecting the Right Generator for Break-In

Selecting the appropriate generator for a successful break-in process is a task that requires careful consideration and understanding of various factors. The market offers a wide range of portable generators, each designed with specific features and capabilities to suit different needs. For instance, small, portable models are ideal for occasional home use or outdoor activities like camping, providing enough power for necessities.

On the other hand, larger, more powerful generators are tailored for professional environments such as construction sites, where they need to handle heavy loads consistently. When choosing a generator, it’s essential to consider the power output and capacity, ensuring it aligns with your anticipated energy requirements. Furthermore, the type of fuel the generator uses – whether gasoline, diesel, or propane – significantly impacts the break-in process, as each fuel type has its characteristics and requirements. The choice should also factor in aspects like noise levels, fuel efficiency, and ease of maintenance, aligning with your specific usage scenarios and preferences.

Preparation and Setup for Optimal Generator Break-In

After selecting the right generator, the focus shifts to preparing it for an effective break-in process, which is crucial for ensuring long-term performance and reliability.

This stage involves a series of pre-break-in checks, an often overlooked but vital step in the break-in process. These checks entail a thorough inspection of the generator for any possible shipping damage, ensuring that all components, including bolts and connections, are intact and securely fastened. It’s also essential to verify the oil and fuel levels, using the types recommended in the manufacturer’s manual.

This is crucial as using the wrong type of oil or fuel can adversely affect the break-in process and the generator’s overall performance.

Setting up the generator in a safe, well-ventilated area is another critical aspect, as it ensures safety during operation, especially during the initial break-in period. Following the manufacturer’s guidelines on load capacities and operating procedures during the setup will not only smooth out the break-in process but also lay the groundwork for the generator’s efficient operation,

preventing issues like overheating and ensuring a prolonged lifespan. Proper setup and preparation are the keys to unlocking the full potential of your generator, making it a reliable and efficient power source for your needs.

The Break-In Process: A Step-by-Step Guide

Initial Startup

Step 1. Reading the Manual

Before anything else, thoroughly read the generator’s manual. It provides specific instructions for startup procedures, safety guidelines, and maintenance tips tailored to your model.

Step 2. Setting Up in a Safe Location

Ensure the generator is placed in a well-ventilated, open area to prevent the buildup of exhaust fumes. It should be on a stable, flat surface, away from windows, doors, and vents to ensure safety and proper operation.

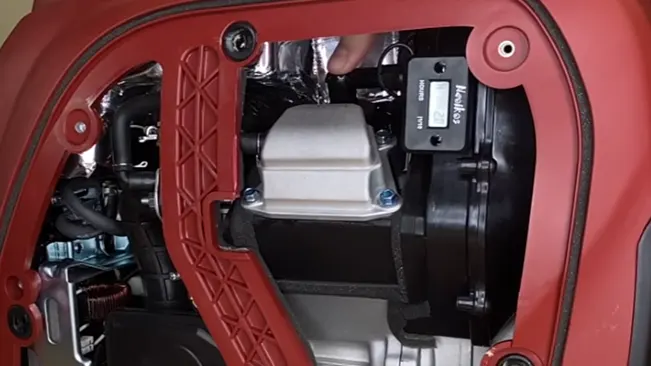

Step 3. Checking Fuel and Oil Levels

Confirm that the generator has the correct type and amount of oil and fuel as specified in the manual. The right oil and fuel are crucial for the smooth running of the engine and to avoid damage.

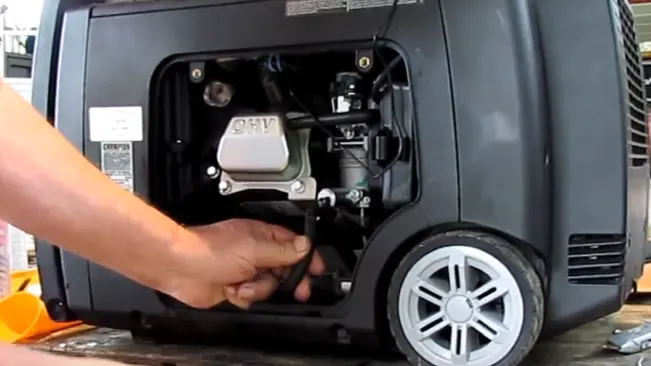

Step 4. Inspecting the Generator

Perform a visual inspection to check for any loose parts, damage, or leaks. Ensure all connections are secure and that the generator shows no signs of wear or damage from shipping.

Step 5. Connecting the Battery

If your generator has an electric start, connect the battery carefully, ensuring the connections are tight and secure.

Step 6. Turning on the Fuel Valve

Switch the fuel valve to the ‘on’ position to allow fuel to flow to the engine. This step is essential for the generator to start.

Gradual Load Application

- Initial Light Load Start by connecting a small appliance (e.g., a light bulb or a fan) to the generator. This load should be about 20-25% of the generator’s total capacity.

- Incremental Increase After running smoothly with the light load for about an hour, gradually increase the load. Add more appliances or switch to slightly heavier ones, like a coffee maker or television.

- Close Monitoring As the load increases, closely monitor the generator for any unusual sounds (knocking, rattling), smoke, unusual smells, or significant voltage fluctuations.

- Consistent Observation Keep an eye on the generator’s response to the load. It should run without struggling, excessive noise, or vibration.

- Taking Breaks Allow the generator to run at each new load level for a sufficient period before increasing it further, ensuring internal components adjust properly.

- Reaching Full Capacity Gradually bring the generator to its full load capacity, following the manual’s recommendations. This process might take several hours or days, depending on the generator’s size.

- Final Assessment Once at full capacity, assess the generator’s performance to ensure it handles the maximum load efficiently and without issues.

Essential Tips During the Break-In Period

Oil and Fuel Management

Frequency of Checks Routinely check the oil level in your generator, ideally before each use. This is crucial as running a generator with low oil can cause significant engine damage.

Oil Change Schedule Follow the manufacturer’s guidelines for oil change intervals. Typically, new generators require an oil change after the first 25-30 hours of operation (post break-in) and every 50-100 hours thereafter.

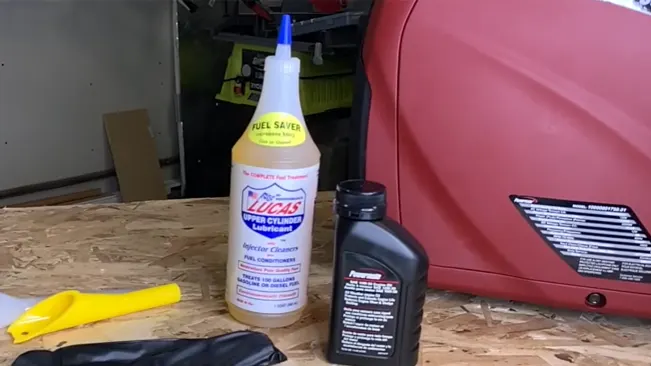

Choosing the Right Oil Ensure you’re using the type of oil recommended in your generator’s manual. Factors like operating temperature and engine type can influence the choice of oil.

Proper Oil Disposal When changing the oil, dispose of the old oil responsibly. Do not pour it down

drains or onto the ground. Use a certified oil-disposal facility.

Using the Correct Fuel Type

Fuel Specifications Always use the fuel type specified by the generator’s manufacturer. Common types include gasoline, diesel, and propane.

Fuel Quality: Use fresh, high-quality fuel. Old or contaminated fuel can lead to engine problems, reduced efficiency, and increased maintenance.

Fuel Additives Consider using fuel stabilizers, especially if the generator will not be used for extended periods. Stabilizers can prevent fuel degradation and engine clogging.

Fuel Storage: Store fuel in a clean, safe, and approved container. Keep it away from heat sources and regularly check for leaks or damage to the container.

Regular Fuel System Maintenance

Fuel Filter Inspection Regularly inspect and replace the fuel filter as needed to ensure clean fuel delivery to the engine.

Fuel Line Checks: Check the fuel lines for cracks or leaks. Damaged fuel lines can lead to fuel loss and safety hazards.

Carburetor Maintenance For generators with carburetors, periodic cleaning and adjustment may be necessary to ensure proper fuel-air mixture and efficient operation.

Temperature and Performance Monitoring

Regular Checks Consistently monitor the temperature of your generator during operation. Most models come with a built-in thermometer or temperature gauge for this purpose.

Overheating Prevention Be alert for any signs of overheating. High temperatures can indicate issues like low oil levels, cooling system malfunctions, or excessive load.

Optimal Operating Temperature Familiarize yourself with the optimal operating temperature range specified in your generator’s manual and ensure it operates within these limits

Performance and Sound Observation

Performance Changes Pay attention to any variations in the generator’s performance, such as fluctuations in power output or difficulty in starting.

Unusual Noises Listen for any abnormal sounds like knocking, rattling, or hissing, which can indicate mechanical issues.

Immediate Action If you notice any abnormal temperature readings, performance shifts, or unusual sounds, turn off the generator and perform a thorough inspection or consult a professional.

Maintenance and Care Post Break-In

First Maintenance Post Break-In

Following the generator’s break-in period, a detailed maintenance check is crucial. This includes replacing the engine oil to eliminate debris from initial wear, ensuring smooth engine operation. A thorough inspection of engine components, electrical connections, and the fuel system is also essential to address any early signs of wear or issues.

Additionally, cleaning or replacing the air filter is vital for maintaining efficient engine performance. Checking the fuel system for leaks or wear, and ensuring a clean fuel filter, is critical to prevent engine damage and maintain optimal functionality. This post break-in maintenance is key to securing the generator’s long-term reliability and efficiency.

Ongoing Maintenance

Ongoing maintenance is crucial for a generator’s longevity and performance. It involves scheduling regular engine inspections as recommended by the manufacturer to preemptively address any issues. Changing the oil regularly is essential for engine health, ensuring smooth and efficient operation. The air filters should also be cleaned or replaced frequently to avoid clogging and maintain engine efficiency.

Regular checks of the fuel system are necessary to identify and fix any leaks or blockages, and the fuel filter should be replaced as needed. Additionally, routine inspections of other components like spark plugs, electrical connections, and the cooling system are important to ensure they are in good condition and functioning properly. Adhering to these maintenance practices helps in keeping the generator reliable and ready for use while preventing major issues and costly repairs in the future.

Troubleshooting Common Issues During Break-In

Identifying Problems

It’s vital to monitor your generator for early signs of trouble to maintain its efficiency and prevent major issues. Listen for unusual noises like grinding or clanking, which could indicate internal problems. Watch for abnormal vibrations or shaking, signaling potential mechanical imbalances.

Regularly check for oil or fuel leaks, as these can affect performance and safety. Keep an eye on the engine’s behavior for any irregularities in power output or starting issues, which might suggest engine problems. Also, be vigilant for overheating, a common issue that can arise from cooling system failures or overloading. Promptly addressing these signs is key to ensuring the reliable and efficient operation of your generator.

Conclusion

conclusion, the process of properly breaking in your generator cannot be overstated in its importance for ensuring the machine’s longevity and optimal performance. This initial phase sets the foundation for how your generator will operate in the long run. By adhering to the recommended break-in procedures, you effectively condition the engine and other mechanical parts, reducing the likelihood of premature wear and tear.

The break-in period also allows you to identify and rectify any manufacturing flaws or issues before they escalate into more significant problems. Post-break-in, establishing a regimen of regular maintenance is crucial. This includes routine checks and timely servicing, ensuring that your generator remains in peak condition, ready to deliver reliable power whenever it’s needed. Investing time and effort in these early stages of your generator’s life can significantly reduce the risk of costly repairs and downtime in the future. In essence, a well-executed break-in and consistent maintenance plan are invaluable practices that guarantee your generator remains a dependable source of power for many years.

FAQs

- What is the purpose of breaking in a generator?

Breaking in a generator conditions its engine and internal components, ensuring efficient operation and prolonging its lifespan. - How often should I change the oil in my generator?

Typically, change the oil after the first 25-30 hours of operation (post break-in) and then every 50-100 hours of use, but always refer to your generator’s manual for specific guidelines. - Can I use any type of fuel for my generator?

No, you should use the specific type of fuel recommended by the generator’s manufacturer, such as gasoline, diesel, or propane. - How do I know if my generator is overheating?

Most generators have a temperature gauge. Overheating may be indicated by a high reading on this gauge or physical signs like smoke or a burning smell. - What should I do if my generator starts making unusual noises?

Turn off the generator and inspect it for issues. Consult the manual or a professional if necessary. - Is it necessary to run a generator at full capacity during the break-in period?

No, it’s recommended to start with a light load and gradually increase to about 50-75% of its capacity during the break-in period. - How do I properly store my generator when it’s not in use?

Store it in a dry, well-ventilated area. Drain or stabilize the fuel and disconnect the battery if it’s not going to be used for a long period. - Can I operate my generator in any weather condition?

Generators should be operated in a dry area to avoid electrical hazards. Some generators are designed for harsher conditions, but always check the manufacturer’s guidelines. - What regular maintenance does my generator need?

Regular maintenance includes checking oil and fuel levels, replacing air and fuel filters, inspecting the fuel system, and general cleaning. - How can I safely handle the fuel for my generator?

Store fuel in a certified container, away from heat sources. Use a funnel when refueling to avoid spills and never refuel a hot or running generator.

For the best performance and longevity of your generator, following a thorough break-in process is crucial. By adhering to the step-by-step guide provided, you’ll ensure your generator is set up to operate efficiently and reliably. Remember, investing a little time and effort now can save you from potential headaches and repairs in the future.

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment