How to Make a Rabbet Joint for Wood Timbers: Step-by-Step Guide

- November 15, 2024

- 0 comment

Creating a rabbet joint is one of the most fundamental woodworking techniques, and it’s been my go-to for countless projects. Whether you’re building a cabinet, a picture frame, or even a sturdy box, mastering the rabbet joint not only improves your woodworking precision but also elevates the durability of your creations.

Today, I’ll walk you through how I create rabbet joints and offer insights from my personal experience to help you achieve seamless results.

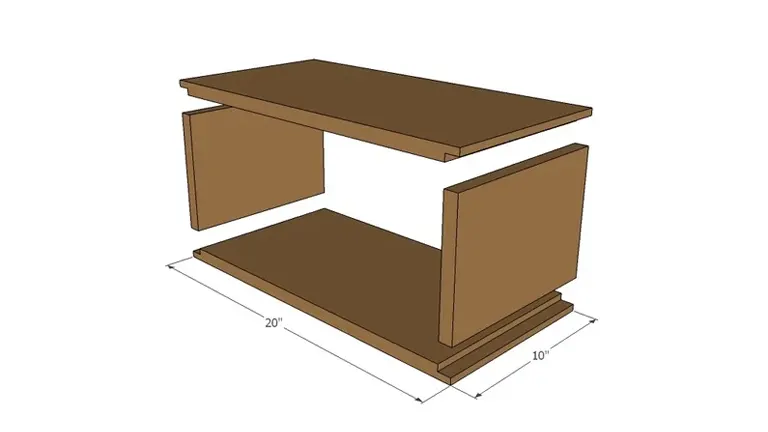

What is a Rabbet Joint?

In simple terms, a rabbet joint is a recess or groove cut into the edge or end of a wood board. This notch allows two pieces of wood to fit snugly together, forming a corner or edge joint. It’s particularly effective for creating a strong bond with minimal hardware, making it a favorite for traditional woodworking purists like me.

Tools and Materials Needed

To create a rabbet joint, you’ll need specific tools and materials. Here’s a checklist:

Essential Tools:

- Table saw or router

- Dado blade (for table saw) or rabbet bit (for router)

- Measuring tape or ruler

- Pencil or marking knife

- Clamps

- Chisel (optional, for cleaning up cuts)

Wood Selection:

- Choose a hardwood like oak, maple, or birch for durability.

- Ensure the timber is straight and free from knots or warps.

Six Ways Guide to Making a Precision Rabbet Joint

1. Plan and Measure

Planning and measuring are the foundation of a perfect rabbet joint. Before cutting, I carefully inspect the wood for knots or imperfections that might interfere with the joint’s stability. Once I’ve selected the right piece, I take a pencil and marking gauge to outline the rabbet.

- Depth and Width: A rabbet’s depth and width depend on your project. For a robust joint, I recommend making the depth one-third the thickness of the wood. For example, if you’re working with a ¾-inch board, aim for a rabbet depth of ¼ inch. This balance ensures strength without compromising the board’s integrity.

- Double-Check Measurements: I always measure twice—one wrong mark can ruin the cut. Use a square or straightedge to ensure your lines are perfectly perpendicular to the edge of the board. This step saves time and frustration later.

2. Set Up Your Tool

The tool setup is crucial for achieving precise and clean cuts. Depending on the tools at your disposal, follow these steps:

- Using a Table Saw with Dado Blades:

- Install a dado blade and adjust its height to match your rabbet’s depth. Most table saws have a height adjustment knob—use it carefully, measuring with a ruler for accuracy.

- Set the fence distance to align with your rabbet’s width. A test run on scrap wood will confirm your setup.

- Using a Router:

- Attach a rabbet bit to your router. The bit’s size should correspond to the desired width of the rabbet.

- Adjust the depth stop to prevent overcutting. Again, test your setup on scrap wood to ensure the cut is just right.

Taking the time to set up your tool properly eliminates mistakes and results in cleaner cuts.

3. Cut the Rabbet

Cutting the rabbet is where precision meets technique. I secure the wood using clamps or a featherboard to ensure it doesn’t move during cutting.

- For Table Saw Users:

- Feed the wood steadily along the fence, maintaining consistent pressure. A slow, steady pace prevents tear-out and ensures an even cut.

- If the rabbet is wider than the blade, make multiple passes, adjusting the fence slightly each time.

- For Router Users:

- Guide the router along the edge of the wood with firm, even pressure. Start with a shallow cut and gradually increase the depth. This minimizes the risk of chipping or burning the wood.

Inspect the rabbet after each pass to ensure the cut is smooth and even. Adjustments are easier mid-cut than after.

4. Fine-Tune the Cut

Once the rabbet is cut, the next step is cleaning up any imperfections. This process transforms a functional cut into a professional-grade joint.

- Inspect the Edges: Check for splinters, uneven surfaces, or rough edges. These can prevent the joint from fitting properly.

- Use a Chisel: I keep a sharp chisel handy for smoothing the corners and edges. A light tap with a mallet helps remove tiny imperfections without damaging the wood.

- Sanding: For finer adjustments, sandpaper works wonders. Wrap it around a small block for better control and work along the edges until they’re smooth.

This step is essential for achieving a snug, gap-free fit.

5. Test the Fit

Testing the fit is the moment of truth. Take the two pieces of wood and bring them together to check alignment.

- What to Look For: The pieces should fit seamlessly, with no visible gaps or overlaps. The joint should hold firmly but not require excessive force to assemble.

- Troubleshooting:If the fit is too tight, use sandpaper or a chisel to carefully remove material. For loose fits, applying glue or filler can compensate, but strive for a perfect mechanical fit first.

I never skip this step because it’s easier to fix alignment issues now than after assembly.

6. Assemble and Secure

Once the fit is perfect, it’s time to assemble the joint.

- Glue Application:Apply a thin, even layer of wood glue to the rabbet’s surface. Too much glue can create a mess, while too little won’t hold the joint securely.

- Clamp the Joint:

Use clamps to hold the pieces together while the glue dries. Ensure the joint is perfectly aligned before tightening the clamps. Misalignment at this stage can ruin the final product. - Reinforcement:

For extra strength, I sometimes add screws or nails, depending on the project. Pre-drill holes to prevent splitting, especially near the edges.

Let the glue cure for at least 24 hours before handling the joint further. Patience pays off with stronger, more durable results.

My Final Thoughts

Learning how to make a rabbet joint was a game-changer for my woodworking projects. It’s a skill that opens up a world of possibilities, from crafting fine furniture to sturdy utility boxes. My advice? Take your time and experiment with both dado blades and routers to see which method works best for you.

Whichever tool you choose, practice on scrap wood before diving into your main project. And remember, the key to a successful rabbet joint is precision and patience. As you hone this skill, you’ll not only gain confidence but also create stronger, more professional-looking woodwork.

FAQs

- What is a rabbet joint used for?

A rabbet joint is used to connect two wood pieces securely, ideal for frames, boxes, and cabinets. - How deep should a rabbet joint be?

A general rule is one-third the thickness of the wood for optimal strength and durability. - What tools are best for cutting a rabbet joint?

Table saws with dado blades and routers with rabbet bits are the most effective tools for precise cuts. - How do I ensure accurate cuts?

Measure carefully, mark with a gauge, and test the setup on scrap wood before making the final cuts. - What can I do if the joint doesn’t fit perfectly?

Sand or chisel tight spots for better alignment, or use glue and clamps to secure loose fits. - Can I reinforce a rabbet joint?

Yes, wood glue is the primary adhesive, but screws or nails can be added for extra strength.

We hope this guide has helped you master creating rabbet joints. Got tips or experiences to share? Drop them in the comments to inspire fellow woodworkers. Don’t forget to share this guide with others passionate about woodworking. Let’s build better together!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment