Understanding the Circular Saw: Essential Tips and Common Mistakes

- June 11, 2024

- 0 comment

Circular saws are a powerhouse tool in carpentry, combining intense power with pinpoint accuracy to elevate any DIY project. However, their formidable strength also introduces significant risks, particularly for novices. This guide dives deep into the essentials of circular saw usage, shedding light on how to harness this tool’s capabilities safely while steering clear of common pitfalls.

Choosing the Right Circular Saw

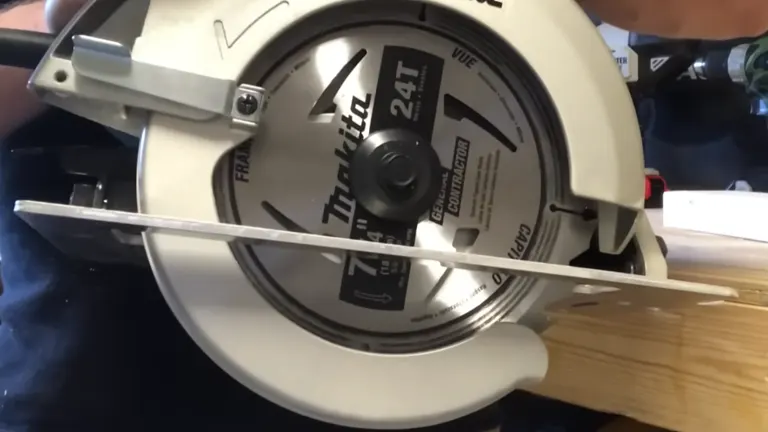

Before delving into the intricacies of circular saw usage, it’s important to choose the right tool. I recently acquired a Makita 7-1/4″ Circular Saw, a model renowned for its reliability and superior performance.

This corded saw stands out in the market for its longevity and value, priced at just over $100, or around $160 with a carrying case. It’s an investment that promises to pay off, potentially serving you well for over two decades with proper care.

Top Mistakes and How to Avoid Them

1. Misplacing Your Body Relative to the Cut Path

Using a circular saw requires strict attention to where you position your body relative to the saw’s cutting path. A critical safety measure is to avoid placing any part of your body directly along the trajectory of the cut, whether in front or behind the saw. Always maintain a position to the side of the saw’s path to minimize risk.

Moreover, it’s vital to keep your hands away from the cutting area to prevent any accidents. Rather than using your hands to stabilize the workpiece, employ clamps to securely hold the material in place. This approach not only ensures your hands remain at a safe distance but also aids in achieving more stable and precise cuts. Proper positioning and securing of the material are key to safe and effective circular saw use.

2. Blade Binding

Blade binding, a dangerous condition where the saw blade becomes overly pressured by the material it’s cutting, can lead to serious mishaps such as kickbacks. To mitigate this risk, it’s imperative to ensure that the material is adequately supported throughout the cutting process. This support prevents the material from sagging or pinching the blade, which is a common cause of binding.

In addition, maintaining the proper technique during cutting is crucial. Avoid any twisting motion of the saw, as this can increase the pressure on the blade and contribute to binding. It’s essential to keep the blade aligned within the kerf—the narrow slot made by the blade in the material. This alignment helps to reduce friction between the blade and the material, minimizing the chances of the blade binding and the saw kicking back towards the operator. These strategies are vital for safe operation, ensuring the blade moves smoothly through the material without unexpected resistance or dangerous movements.

3. Inadequate Support for the Cut

Ensuring that the material you are cutting has adequate support is critical for both safety and accuracy. Laying the workpiece directly on a flat surface without proper clearance underneath can result in unintended damage to both the material and the surface below, and can lead to imprecise cuts.

To avoid these issues, elevate the material using scrap wood or specialized supports. This setup allows the circular saw blade to pass through the material freely without any interference from the surface below, ensuring a cleaner and more controlled cut.

4. Incorrect Blade Depth

Adjusting the blade to an excessive depth is a common mistake that poses significant safety risks and hampers the saw’s performance. The ideal setting for the blade is to slightly extend beyond the thickness of the material being cut—no more than a quarter inch.

This setup limits the amount of blade exposed, minimizing the risk of kickback. It also enhances the saw’s efficiency, making it easier to handle and navigate through cuts. Keeping the blade depth appropriate ensures safer operation and better control over the cutting process.

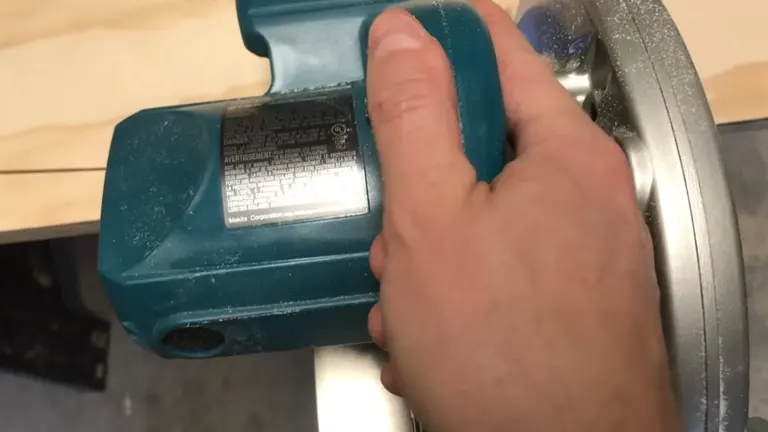

5. Adjusting the Saw During Operation

It’s crucial to avoid making adjustments to the blade depth or angle while the circular saw is running. This rule is vital for safety and precision. Making adjustments while the saw is active can lead to unintended movements or alterations, which can cause serious accidents or compromise the quality of your cut.

Always ensure the saw is completely turned off and has come to a stop before attempting any adjustments. This practice not only enhances safety but also ensures that your adjustments are accurate and effective, contributing to better overall performance and results from your cuts.

6. Removing the Blade Guard

The blade guard on a circular saw is an essential safety feature that should never be overlooked. Removing or disabling the blade guard exposes you directly to the blade, significantly increasing the risk of injury.

Always ensure that the blade guard is functional and properly positioned before beginning any cut. It’s designed to retract smoothly as you cut and snap back into place once the cut is completed, shielding you and others from the spinning blade. Keeping the blade guard intact and operational is not just a safety measure; it’s a necessary practice to ensure the safe and efficient operation of your circular saw.

7. Poor Handling and Storage

Proper handling and storage of your circular saw are vital for maintaining its longevity and safety. Never place the saw down while the blade is still spinning. Always wait for the blade to completely stop to prevent any unintended injuries or damage to the saw.

When storing your circular saw, make sure it is placed in a secure location where it won’t be accidentally activated. This precaution helps avoid unintended starts that could lead to safety incidents. Additionally, storing the saw in a dry, clean space prevents rust and keeps the saw in optimal condition, ready for the next use.

8. Starting with Blade Contact

Before you power on your circular saw, always make sure the blade is not in contact with the material you plan to cut. Starting the saw while the blade is touching the wood or other materials can cause it to jerk violently or bind, which not only jeopardizes your safety but can also damage both the blade and the material.

To ensure a smooth and safe operation, position the blade slightly above the surface before starting the saw. This small precaution helps facilitate a controlled and steady beginning to your cut.

9. Managing the Power Cord

Proper management of the power cord is crucial when using a circular saw. Ensure that the cord is always clear of the cutting path to avoid it getting tangled or inadvertently pulling the saw off its intended course.

During longer cuts, it’s especially important to be mindful of the cord’s placement. Actively manage the cord by positioning it away from the work area or holding it out of the way as you cut. This prevents the cord from snagging on the material or equipment, which could disrupt the saw’s operation and pose a safety hazard.

10. Trigger Discipline

Maintaining strict trigger discipline is essential when operating a circular saw, akin to handling a firearm. It’s important to keep your finger off the trigger until you are absolutely ready to start the cut. Once your cut is complete, immediately remove your finger from the trigger.

This practice helps prevent unintended starts, which can lead to accidents. Always be conscious of where your fingers are in relation to the trigger to ensure that your saw only operates when you intend it to, enhancing both safety and control over your cutting tasks.

Conclusion

This guide not only underscores the capabilities of a high-quality circular saw like the Makita but also emphasizes the importance of mindful operation to leverage this tool’s benefits safely. By understanding and addressing these common mistakes, DIYers and carpentry enthusiasts can use their circular saws with confidence and precision.

FAQs

- What type of blade should I use for different materials?

Choose your blade based on the material and the type of cut you need. For wood, use a blade with more teeth for a finer cut and fewer teeth for faster, rougher cuts. Specialized blades are available for materials like metal and masonry. - How do I know if my circular saw blade is dull?

A dull blade will require more force to push through material and may burn the wood or produce rough cuts. If you notice any of these signs, it’s time to sharpen or replace the blade. - Can I use a circular saw to cut metal?

Yes, but you’ll need a blade specifically designed for metal. Never use a wood-cutting blade for metal as it can be dangerous and will likely damage the blade. - What safety gear should I wear when using a circular saw?

Always wear safety glasses, ear protection, and a dust mask. Avoid loose clothing and jewelry, and consider wearing gloves and steel-toed boots for additional protection. - What does ‘kickback’ mean, and how can I prevent it?

Kickback occurs when the saw blade binds or gets pinched in the cut, causing the saw to jerk backward toward the user. To prevent kickback, ensure your material is well supported, and avoid pinching the blade. Keep the saw moving forward steadily without forcing it. - How can I make a perfectly straight cut with a circular saw?

Use a guide rail or a straight edge clamp along your marked line. This will keep your saw on track for a straight, clean cut. - What is the difference between a sidewinder and a worm drive circular saw?

Sidewinder saws, or direct drive saws, have the motor aligned with the blade, offering a compact and lightweight design. Worm drive saws use gears to increase torque and are generally heavier, providing more power and durability for heavy-duty tasks. - How do I change the blade on my circular saw?

First, disconnect the saw from power. Lock the blade using the blade lock mechanism, then loosen the bolt or nut that holds the blade in place using a wrench. Remove the old blade, install the new blade with the teeth facing the correct direction, then tighten the bolt or nut and re-engage the blade lock. - Why does my circular saw keep stopping during cuts?

This could be due to a few reasons: the saw might be overheating, the blade may be dull or damaged, or there might be an issue with your power source. Check these factors to resolve the problem. - How do I maintain my circular saw?

Keep your saw clean, lubricate moving parts as necessary, and regularly check for worn or damaged components. Sharpen or replace blades as needed, and ensure the cord and any batteries are in good condition. Store your saw in a dry, secure place to avoid rust and damage.

Got more tips or a personal saw story to share? Whether you’re a seasoned woodworker or a weekend warrior, your experiences can help enrich our community’s knowledge. Drop your thoughts and questions in the comments below—we’re eager to hear how you tackle projects and any unique insights you have on using circular saws. If you found this guide helpful, consider sharing it with fellow DIY enthusiasts to spread the wisdom! Happy cutting, and stay safe out there!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment