17 Wood Processing Equipment of a Completely New Level

- July 30, 2024

- 0 comment

The world of wood processing is rapidly evolving, with new technologies that push the limits of efficiency and design. This article introduces 17 groundbreaking machines that are shaping the future of forestry and wood processing industries. Each machine showcases innovative features that enhance productivity and sustainability. From high-powered shredders to precision sawmills, these tools are setting new standards in the field.

1. UNTHA PS1300 – $20,000 – $40,000

The UNTHA PS1300 is designed specifically for shredding wooden pallets, featuring a robust 24-horsepower motor that processes up to 30 pallets per hour. Its specialized system ensures efficient disposal by automatically feeding pallets into the cutting chamber and shredding them until the material passes through a specialized sieve.

The machine also includes a feature to magnetically remove metal parts such as nails and screws during the shredding process, making the resulting material suitable for recycling and reuse as fuel or natural mulch. This combination of power and precision technology makes the UNTHA PS1300 a valuable tool for businesses looking to manage wood waste effectively.

2. John Deere 1470G – $200,000 – $500,000

The John Deere 1470G is recognized as a flagship model among forestry harvesters due to its versatility and advanced engineering. Designed to perform multiple harvesting operations simultaneously, this machine excels in both selective and total felling environments. It features a robust, self-propelled frame that is optimized for tough off-road conditions, allowing it to navigate dense forests with ease.

The 1470G is also equipped with a large CH9 boom that enhances visibility from the cab, which is further supported by a cab rotating mechanism and a leveling system. Notably, it offers significant fuel efficiency, with savings of up to 10% compared to previous models, making it both an effective and economical choice for forestry operations.

3. Wravor Debarker WD 1400 – $50,000 – $100,000

The Wravor Debarker WD 1400 is a robust machine specifically designed for the efficient removal of bark from logs. It can handle logs ranging from 8 to 60 inches in diameter, ensuring that they are thoroughly cleaned and prepared for subsequent processing stages. This debarker is particularly noted for its precision, facilitated by an advanced optical log detection system that enhances its efficiency.

This system allows operators to adjust the thickness of the bark removal according to specific needs, ensuring optimal preparation of the logs for their next use, whether in construction, manufacturing, or another application. The combination of powerful processing capabilities and precise control makes the Wravor WD 1400 an essential tool for modern forestry operations.

4. Bell’s Super Log Splitter – $10,000 – $30,000

The Bell’s Super Log Splitter is a powerhouse designed for handling exceptionally large logs with its impressive 66-horsepower diesel engine. This industrial-grade splitter exerts a massive force of 76 tonnes, making it capable of splitting logs up to 48 inches in diameter.

A standout feature of this machine is its remote control operation, which enhances safety by allowing operators to maintain a safe distance while managing the wood splitting process. This functionality not only increases efficiency but also ensures operator safety, making the Bell’s Super Log Splitter an essential tool for heavy-duty logging operations.

5. Pezzolato TB 600 – $15,000 – $40,000

The Pezzolato TB 600 is an effective wood splitter specifically engineered for processing wood billets, which are commonly utilized as fuel in gas generators. This machine operates with a vertical splitting system that allows it to efficiently handle logs up to 24 inches in diameter.

It delivers a powerful force of 30 tonnes, ensuring quick and effective splitting. This capability makes the TB 600 ideal for industries that require consistent processing of wood billets for energy production, offering both speed and reliability in wood splitting operations.

6. Sherwood LS-600/200 – $8,000 – $20,000

The Sherwood LS-600/200 is a robust wood chipping machine designed to process a variety of wood residues into high-quality chips efficiently. This model features an 8-blade cutter that operates at a speed of 3,700 rpm, ensuring a consistent and fine chip size, ideal for various applications such as biomass fuel, mulch, or wood pulp.

A key design feature of the LS-600/200 is its advanced system that minimizes the entry of dust and dirt, which significantly prolongs the life of the hydraulic system and reduces maintenance needs. This thoughtful engineering ensures that the machine remains reliable and effective over time, making it a valuable asset for operations looking to optimize their wood residue processing.

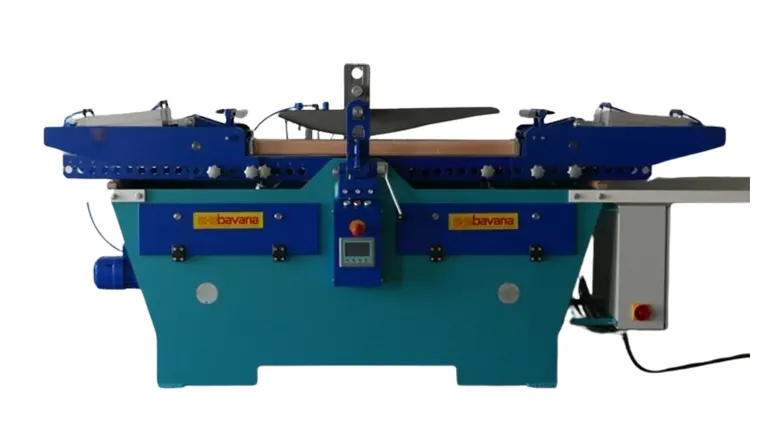

7. GHEBavaria Stuzama II – $30,000 – $70,000

The GHEBavaria Stuzama II is a state-of-the-art wood bending machine known for its high efficiency and capability to produce up to 5,000 curved pieces per shift. This machine is specifically designed to work with steam-treated wood, which softens the fibers to allow for effective compression and stretching.

This process is crucial for creating a variety of curved wooden items such as furniture components and wooden sleds. The Stuzama II’s advanced technology not only ensures precision in wood bending but also significantly enhances production capacity, making it an essential tool for manufacturers needing high-volume, complex wood shapes.

8. POSCH SmartCut 700 – $5,000 – $15,000

The POSCH SmartCut 700 represents a significant advancement in firewood processing technology. This innovative machine utilizes a gravity-fed system to automate the cutting process, allowing for efficient handling of logs up to 8 inches in diameter. It is capable of producing between 140 to 280 cubic feet of firewood per hour, demonstrating a high level of productivity.

The ergonomic design of the SmartCut 700 ensures that operation is both safe and comfortable for the user, further enhancing its effectiveness in meeting the demands of firewood production. This combination of automation, efficiency, and ergonomic design makes the POSCH SmartCut 700 an exemplary tool in the forestry equipment industry.

9. Greda POKER V – $50,000 – $100,000

The Greda POKER V is a CNC machine expertly designed for the intricate task of producing profiled wooden furniture parts. This machine stands out in the woodworking industry for its ability to perform multiple operations such as machining, milling, and polishing, all within a single cycle. Its integrated approach not only streamlines the production process but also significantly boosts productivity.

Moreover, the POKER V’s compact design maximizes space efficiency, making it an invaluable asset for furniture manufacturers who require precision and versatility in creating complex wooden components. This capability ensures that the POKER V can meet the high demands of modern furniture production, delivering excellent performance and reliability.

10. Komptech Chippo 8010C – $300,000 – $600,000

The Komptech Chippo 8010C is a mobile drum chipper renowned for its efficiency and ability to produce high-quality wood chips. Designed to handle logs up to 30 inches in diameter, this machine is equipped with a system that maximizes cutting accuracy, ensuring consistent chip size and quality.

Its innovative design also focuses on reducing operating costs, making it an economically viable option for large-scale wood processing operations. The Chippo 8010C’s mobile platform allows for easy relocation, making it versatile for various working environments where high mobility is crucial. This combination of performance, efficiency, and mobility makes it an indispensable tool in the forestry and wood recycling industries.

11. Gandini ForestCut 48 – $10,000 – $30,000

The Gandini ForestCut 48 from Gandini Mechanica is a highly efficient automated log splitter designed to streamline the production of firewood. This robust machine utilizes automated cycles, controlled by a joystick, to cut and split logs up to 16 inches in diameter.

This technology ensures that the process requires minimal operator effort while maintaining high productivity. The ForestCut 48’s design not only enhances operational efficiency but also reduces the physical strain on workers, making it an excellent solution for businesses looking to optimize their firewood production processes with a focus on both output and operator comfort.

12. Logosol B751 – $5,000 – $10,000

The Logosol B751 band sawmill is engineered for precision and efficiency, allowing for the quick and accurate cutting of logs up to 30 inches in diameter. This sawmill is distinguished by its user-friendly design, which includes fixed steps for depth cut adjustment, enabling consistent and precise cuts.

Additionally, it features a fan that keeps the saw head clean, minimizing debris build-up and enhancing the sawmill’s overall durability. This combination of features makes the B751 an ideal choice for both professional and hobbyist woodworkers who require reliable and precise wood cutting capabilities.

13. Vermeer AX19 Brush Chipper – $80,000 – $150,000

The Vermeer AX19 Brush Chipper is a versatile and powerful tool designed for efficient wood chipping, especially suitable for large logs. This machine integrates smoothly with a skid loader, which helps in feeding materials directly into the chipper, streamlining the wood processing workflow.

Once the logs are fed into the AX19, it rapidly produces fine wood chips at high speeds, enhancing productivity and reducing labor. The flexibility and efficiency of the AX19 make it ideal for operations looking to optimize their wood chipping processes while handling substantial log sizes effectively.

14. Drew Met WD-200/240/M – $20,000 – $50,000

The Drew Met WD-200/240/M is a multi-cutting machine designed for high-volume, industrial wood processing. Capable of handling wooden materials of varying thicknesses, this robust machine is equipped with a powerful pulling force that facilitates efficient cutting operations.

Additionally, it features an integrated mini chipper, which helps in processing wood debris, enhancing the overall productivity and cleanliness of the work environment. This combination of features makes the WD-200/240/M ideal for large-scale manufacturing settings where precision and efficiency are crucial.

15. Neuhauser K+ – $20,000 – $50,000

The Neuhauser K+ is an exceptionally versatile wood processing machine that combines several functions into one efficient unit. Capable of handling logs of various diameters, this machine excels at debarking, sawing, and chamfering, making it indispensable in settings where multiple wood processing tasks are frequently required.

Designed with precision and durability in mind, the K+ includes features that enhance both the accuracy of its operations and its longevity under consistent use. This multi-functional approach ensures that the Neuhauser K+ can meet a wide range of industrial wood processing needs while maintaining high standards of performance.

16. Brusa & Garboli TA30 – $30,000 – $60,000

The Brusa & Garboli TA30 is an advanced woodworking machine renowned for its ability to transform square wood into perfectly rounded pieces, making it highly valuable for the furniture industry. This machine excels in crafting spirals and complex shapes with high precision and efficiency, making it an ideal choice for manufacturers looking to produce intricate wooden designs.

The TA30’s capabilities ensure that each piece is crafted with exceptional detail, supporting the production of high-quality furniture components. This machine combines traditional woodworking techniques with modern technology to offer a versatile solution for today’s demanding woodworking tasks.

17. Bandit 1680 Beast – $100,000 – $250,000

The Bandit 1680 Beast from Bandit Industries truly stands up to its name, offering powerful and versatile shredding capabilities for a broad spectrum of wood waste materials. This universal wood shredder is engineered to efficiently tackle everything from branches and off-cuts to larger wood debris.

Its robust cutting power ensures high throughput, making it an optimal choice for industries focused on wood recycling and composting. With its ability to convert wood waste into smaller, manageable chips, the 1680 Beast is not only a tool for waste reduction but also for creating valuable compostable materials, thereby supporting eco-friendly practices.

Conclusion

These machines not only represent the pinnacle of current wood processing technology but also highlight the industry’s commitment to innovation, efficiency, and sustainability. As they continue to advance, these tools are redefining the standards of forestry and wood recycling, adapting to the evolving demands of both the market and environmental stewardship. With each development, they enhance operational efficiency and reduce environmental impact, paving the way for more sustainable practices in the industry. This relentless progress ensures that the forestry sector remains at the cutting edge of technological innovation, ready to meet future challenges with advanced solutions.

FAQs

- How do these advanced wood processing machines handle different wood densities and types?

These machines are equipped with adjustable settings and sensors that detect variations in wood density and composition. This allows for automatic adjustments in speed, pressure, and cutting techniques, ensuring optimal processing regardless of wood type. - What innovations in blade and cutting technology are included in these machines?

The latest machines feature carbide-tipped and diamond-coated blades that offer increased durability and precision. Many also incorporate laser-guided cutting and 3D modeling technology to enhance accuracy and minimize material waste. - Can the equipment be customized for specific wood processing tasks?

Yes, most of these machines come with modular components that can be swapped or adjusted based on specific processing needs, such as debarking, chipping, or milling. Manufacturers often provide various attachments and settings to accommodate different operations. - What are the energy consumption standards for these machines?

These machines are designed to be energy-efficient, adhering to international standards such as ISO 50001. Many use variable frequency drives (VFDs) to optimize power use and reduce energy consumption during less intensive operations. - How is software integration used to enhance machine performance?

Advanced wood processing machines often include integrated software that provides real-time analytics and control options. This software enables predictive maintenance alerts, efficiency tracking, and process optimization based on data analytics. - What safety features are standard on these high-tech machines?

Safety features include automated shut-offs, advanced sensor arrays that detect human presence, and mechanical guards that protect operators from high-speed components. Many systems also feature end-to-end encryption to secure operational data from unauthorized access. - Are there international certifications that these machines meet?

Yes, these machines typically meet various international certification standards, such as CE marking for European conformity, UL listing for safety in the United States, and ISO certifications for quality management and environmental handling. - What is the typical lifespan of these machines, and how is service life extended?

The typical lifespan depends on usage patterns but is generally enhanced through features like rust-resistant coatings, self-lubricating systems, and modular parts that are easy to replace. Manufacturers provide detailed service manuals and access to certified maintenance professionals to ensure longevity.

We hope you enjoyed exploring the cutting-edge capabilities of the 17 Wood Processing Equipment of a Completely New Level featured in our article. Your insights and experiences can enrich the discussion, so we invite you to share your thoughts and comments below. Have you used any of these machines, or do you see a particular technology that could transform your operations? Let’s continue the conversation and learn from each other’s experiences in the dynamic field of wood processing!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment