Forestry and Logging Equipment

- September 1, 2024

- 0 comment

Choosing the right logging equipment is one of the most important decisions in managing your forestry operations. The equipment you select will not only affect your productivity but also influence the safety and efficiency of your work. With the variety of machines available, from chainsaws to harvesters, it can be challenging to determine which tools best meet your specific needs.

Understanding your unique forestry requirements, including the size of your operation, the type of terrain you work on, and your budget, is key to making informed decisions. By carefully evaluating these factors and considering the latest advancements in logging technology, you can select equipment that will enhance your operation’s performance and ensure long-term success.

Understanding Logging Equipment

Overview of Logging Equipment

Logging equipment refers to the machines and tools used in the process of cutting, transporting, and processing timber. These machines are designed to handle the tough conditions found in forests, from dense underbrush to steep hillsides. The right equipment can greatly improve productivity while reducing the physical strain on workers.

Types of Equipment

There are several types of logging equipment, each designed for a specific role in the logging process:

- Chainsaws: Chainsaws are essential for felling trees and cutting logs into manageable sizes. They come in various sizes and power levels, making them suitable for different types of trees and tasks.

- Harvesters: Harvesters are advanced machines that can cut, delimb, and buck trees in one continuous operation. They are commonly used in large-scale logging operations due to their efficiency and ability to handle multiple tasks simultaneously.

- Forwarders: These machines are used to transport logs from the felling site to a collection area, minimizing damage to the forest floor. Forwarders are known for their ability to navigate rough terrain while carrying heavy loads.

- Skidders: Skidders are versatile machines that drag logs out of the forest to a landing area. They are particularly useful in areas where terrain and environmental conditions are challenging.

- Log Loaders: Log loaders are used to lift and load logs onto trucks or other transportation vehicles. They are available in various sizes, allowing you to choose one that fits your load capacity needs.

Factors to Consider When Choosing Logging Equipment

Type of Forestry Operation

The type of forestry operation you manage will heavily influence your choice of logging equipment. For instance, a small-scale operation focused on selective logging may only require basic tools like chainsaws and skidders. In contrast, large-scale operations may need a full suite of equipment, including harvesters and forwarders, to maximize efficiency.

Terrain and Environmental Conditions

The terrain and environmental conditions of your forestry site play a significant role in equipment selection. Steep, rocky, or swampy areas require machines that are specifically designed to handle difficult terrain. For example, tracked vehicles are often preferred in wet conditions, as they distribute weight more evenly and reduce soil compaction.

Budget and Cost Considerations

Budget is always a key consideration when purchasing logging equipment. While it might be tempting to go for the least expensive option, it’s important to consider the total cost of ownership, which includes maintenance, fuel, and repair costs. Investing in higher-quality, durable equipment may save money in the long run by reducing downtime and extending the life of your machinery.

Efficiency and Productivity Requirements

Efficiency and productivity are critical factors in logging operations. The right equipment should not only perform the required tasks but do so quickly and with minimal waste. Consider the specific needs of your operation, such as the volume of timber to be processed or the time frame for completing tasks, and choose equipment that can meet these demands.

Evaluating Equipment Features and Performance

Technical Specifications

When choosing logging equipment, it’s essential to pay attention to the technical specifications that determine how well a machine will perform in your specific forestry operation. Below is a table that highlights some key technical specifications to consider:

| Specification | Description | Importance |

|---|---|---|

| Engine Power (HP) | The horsepower of the machine’s engine. | Higher power allows for tougher tasks, but may consume more fuel. |

| Fuel Efficiency (mpg) | Measures how efficiently the machine uses fuel. | Higher efficiency reduces operating costs and environmental impact. |

| Load Capacity (lbs) | The maximum weight the machine can carry or haul. | Ensures the equipment can handle the expected workload. |

| Cutting Diameter (in) | The maximum diameter of trees the equipment can cut. | Important for ensuring the machine can process the trees in your forest. |

| Weight (lbs) | The overall weight of the machine. | Affects mobility, especially in soft or uneven terrain. |

| Track/Wheel Type | Indicates whether the machine is tracked or wheeled. | Tracks are better for rough terrain; wheels are better for speed. |

| Hydraulic Flow (gpm) | The flow rate of hydraulic fluid, affecting attachment performance. | Higher flow rates are needed for heavy-duty attachments. |

| Turning Radius (ft) | The smallest circular turn the machine can make. | Affects maneuverability in tight spaces. |

Durability and Maintenance

When selecting logging equipment, durability is a key consideration. Logging machines operate in harsh conditions, often dealing with tough terrains, heavy loads, and extreme weather. Therefore, choosing equipment that is built to last will ensure a longer lifespan and reduce downtime due to repairs.

- High-Quality Materials: Look for equipment made from durable materials such as high-grade steel and reinforced components. These materials are resistant to wear and tear, ensuring that your equipment can handle the rigors of logging operations.

- Protective Features: Equipment with features like reinforced undercarriages, protective guards, and weather-resistant seals can help extend the life of your machinery by preventing damage from environmental factors.

Maintenance

Proper maintenance is crucial to keeping your logging equipment in optimal condition. Regular upkeep not only extends the life of your machinery but also ensures safe and efficient operation. Here are some key maintenance practices:

- Regular Inspections: Conduct routine inspections of critical components such as hydraulic systems, engine parts, and tracks or tires. Identifying and addressing issues early can prevent costly breakdowns.

- Scheduled Servicing: Follow the manufacturer’s recommended service schedule, which typically includes oil changes, filter replacements, and lubrication of moving parts. Adhering to this schedule is vital for maintaining performance and efficiency.

- Cleaning: Regularly clean your equipment to remove dirt, debris, and tree sap, which can cause corrosion and hinder performance. Pay special attention to the air intake and cooling systems to prevent overheating.

- Replacement of Worn Parts: Keep an eye on parts that are subject to wear, such as chains, blades, and hydraulic hoses. Replace them promptly to avoid further damage to the equipment.

- Proper Storage: Store equipment in a dry, sheltered area when not in use to protect it from the elements. This will prevent rust and other weather-related damage.

By focusing on durability and adhering to a strict maintenance regimen, you can ensure that your logging equipment remains reliable and performs efficiently over the long term.

Latest Trends and Innovations in Logging Technology

Automated and Smart Technologies

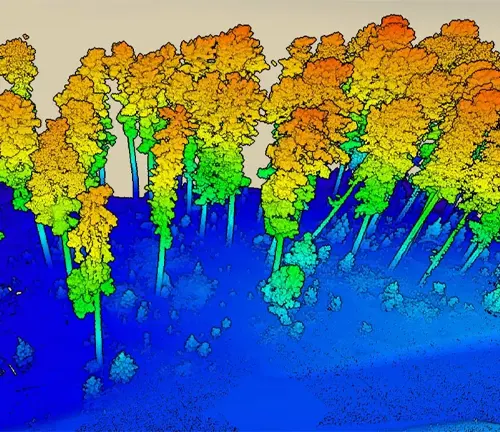

The logging industry is quickly adopting automated and smart technologies like LiDAR to improve efficiency and safety. Newer harvesters now come with features like GPS, sensors, and LiDAR, which allow for accurate tree cutting and careful placement

These advancements help reduce waste, boost productivity, and make the work safer by cutting down on the need for people to be directly involved in risky tasks. With automation, jobs that once needed manual labor can now be done faster and more precisely, making the entire process smoother and more efficient.

Environmental Considerations

Sustainability is becoming a major focus in the logging industry. As people become more aware of environmental issues, new technologies are being created to reduce the negative impact of logging on nature. Modern equipment often includes features that limit damage to the soil, save fuel, and lower emissions.

These environmentally friendly changes not only help protect the forest but also ensure that logging practices meet stricter environmental rules. By using these technologies, the logging industry is finding ways to stay productive while also caring for the environment.

Practical Tips for Making the Final Decision

Test Drives and Demonstrations

Before you commit to purchasing any logging equipment, it’s essential to get some hands-on experience with the machinery. Test driving the equipment or attending demonstrations is a highly recommended step in the decision-making process. By doing so, you can see how the machine performs in real-world conditions and get a feel for how easy it is to operate.

This experience will help you assess whether the equipment meets your specific needs in terms of power, comfort, and ease of use. Additionally, during these test drives or demonstrations, you can ask any questions that arise and address any concerns directly with the dealer or manufacturer. This is your chance to make sure the equipment is a good fit for your operation before making a significant investment.

Dealer Support and Service

The relationship you build with your equipment dealer is just as important as the equipment itself. A good dealer will offer more than just a machine; they will provide strong support and service throughout the life of the equipment.

When choosing a dealer, look for one who offers comprehensive warranties that cover potential issues and a maintenance plan to keep your equipment running smoothly. It’s also important to consider the availability of replacement parts and repair services. Having access to parts and services quickly can prevent long downtimes, which can be costly for your operation.

A reliable dealer can be a trusted partner, helping you maintain your equipment, troubleshoot problems, and ensure the long-term success of your forestry business. Establishing a good relationship with your dealer means you’ll have someone to turn to for advice and support whenever you need it.

Conclusion

Selecting the optimal logging equipment for your forestry needs is a critical decision that impacts the productivity, safety, and long-term success of your operations. By understanding the specific requirements of your forestry work, considering the type of terrain, and evaluating the latest technologies, you can make informed choices that enhance efficiency and reduce costs.

Remember to test equipment before purchasing and to build a strong relationship with a reliable dealer to ensure ongoing support and maintenance. With the right tools and knowledge, you can equip your forestry operation for success now and in the future.

Frequently Asked Questions

1. What is the most important factor when choosing logging equipment?

The most important factor is understanding your specific forestry needs, including the type of terrain, the size of your operation, and your budget.

2. How can I determine which logging equipment is right for my operation?

Evaluate your needs, test different machines, and consult with experts to find equipment that meets your performance and efficiency requirements.

3. Why is it important to consider the terrain when selecting logging equipment?

Different terrains require different types of equipment; for example, steep or rocky areas may need specialized machines to ensure safety and efficiency.

4. What are the benefits of using automated logging equipment?

Automated equipment improves efficiency, reduces waste, and enhances safety by minimizing manual intervention in dangerous tasks.

5. How does logging equipment affect the environment?

Modern logging equipment can reduce environmental impact by minimizing soil disturbance, reducing fuel consumption, and lowering emissions.

6. Why should I test logging equipment before purchasing?

Testing allows you to evaluate the machine’s performance, comfort, and ease of use in real-world conditions, ensuring it meets your needs.

7. What should I look for in a logging equipment dealer?

Look for a dealer who offers strong support, comprehensive warranties, a good maintenance plan, and readily available parts and services.

8. How often should logging equipment be maintained?

Follow the manufacturer’s recommended service schedule, which typically includes regular inspections, servicing, and cleaning.

9. What are the latest trends in logging technology?

The latest trends include the use of automated and smart technologies, such as GPS and sensors, and a focus on environmental sustainability.

10. How can I ensure my logging equipment lasts longer?

Choose durable, high-quality equipment, maintain it regularly, and store it properly when not in use to protect it from the elements.

We hope this guide on selecting optimal logging equipment has provided you with valuable insights into making the best choices for your forestry operations. Whether you’re managing a small woodlot or a large-scale logging operation, understanding the different types of equipment and their features can help you make informed decisions that enhance productivity and safety.

Charles Hayes

Forestry AuthorI'm Charles Hayes, I bring over 15 years of specialized expertise in landscaping and woodworking, blending artistic design with sustainable environmental stewardship. My career, fueled by a profound passion for the natural world, encompasses extensive education and hands-on experience in creating harmonious, eco-friendly outdoor spaces and responsibly managing forest resources. Recognized for my professional standing, I am committed to continuous learning and certification in cutting-edge practices. My expertise is not only reflected in my work but also in my contributions to community projects, educational workshops, and collaborations with industry leaders. As an authoritative voice in my field, I strive to share knowledge and promote environmentally conscious approaches, making me a trusted resource in landscaping and forestry.

Leave your comment