Aoben Biscuit Joiner Review

- March 27, 2024

- 0 comment

Dive into the Aoben Biscuit Joiner review, a power tool designed for creating strong, precise wood joints. Featuring an 8.5 Amp motor, a 4-inch carbide-tipped blade at 11,000 RPM, and adjustable cutting depths for standard biscuit sizes or custom depths, this joiner excels in versatility and performance. Weighing 7.6 lbs with dimensions of 17” x 14” x 5”, it’s crafted for ease of use and efficiency in woodworking projects, making it a valuable addition to your toolkit.

Technical Specs

- Motor: 8.5 Amps

- Blade: Diameter: 4 inches Material: Carbide-tipped Speed: 11,000 RPM

- Cutting Depth: Preset depths: 0, 10, and 20 (exact measurements likely refer to biscuit sizes) Manual mode for custom depths

- Groove Width: 5/32 inches

- Weight: 7.6 lbs

- Dimensions: 17” x 14” x 5”

Features of Aoben Biscuit Joiner

Precision Cutting

The Aoben Biscuit Joiner’s appeal is its ability to execute precision cuts with ease. Equipped with a tungsten carbide-tipped blade, this joiner ensures seamless and accurate wood joints, essential for high-quality cabinetry and woodworking projects. The cutter’s design and construction enable it to handle various materials, from hardwoods to composites, delivering clean and precise slots for biscuit insertion every time.

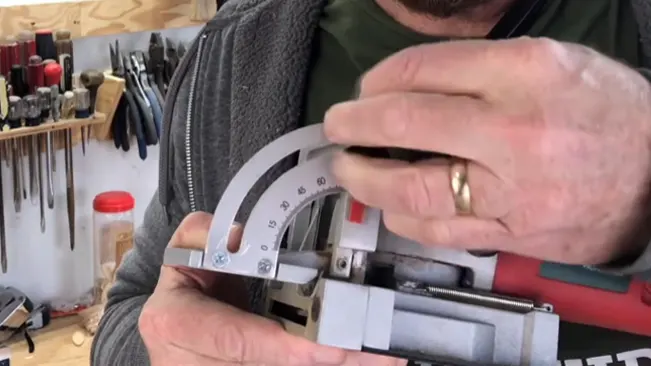

Adjustable Angles

Flexibility in joinery is paramount, and the Aoben Biscuit Joiner excels in this aspect with its adjustable angle feature. The tool’s tilt fence can be securely locked in positions ranging from 0 to 90 degrees, allowing for a wide array of joint configurations. This adaptability makes it possible to create everything from standard butt joints to intricate mitered corners, expanding the creative possibilities in woodworking projects.

Dust Collection System

Maintaining a clean work environment is crucial for both safety and precision in woodworking. The Aoben Biscuit Joiner addresses this need with its efficient dust collection system. The dust bag attaches easily with a simple push-on connection, and its suction function operates concurrently with the joiner’s use. This system effectively captures flying debris, keeping the work area clear and ensuring optimal visibility and cleanliness during operation.

How to Use Aoben Biscuit Joiner Step-by-Step Guide

1. Preparation

Safety First Always start by ensuring the biscuit joiner is unplugged to prevent accidental start-ups while making adjustments. This step is crucial for your safety.

Choose the Right Biscuit Size The Aoben Biscuit Joiner typically comes with three biscuit sizes: #0, #10, and #20. Select the size that best fits the width and strength requirements of your joint. For thinner materials, use smaller biscuits, and for thicker or heavier loads, opt for larger biscuits.

2. Adjusting the Fence

Determine the Joint Type First, identify the type of joint you need for your project, such as a corner joint, a miter joint, or a T-joint.

Fence Angle Adjustment Adjust the fence angle to match the joint type. The fence’s ability to tilt and lock between 0 to 90 degrees allows for versatile joint configurations. Ensure the fence is securely locked in place to maintain consistent slot positioning across workpieces.

3. Setting the Cutting Depth

Match Depth to Biscuit Size Select the cutting depth based on the biscuit size you’re using. The joiner features preset stops for the common sizes, enabling quick and accurate depth selection without manual measurement.

Check for Material Thickness Ensure the selected depth corresponds to the thickness of your workpieces to avoid cutting through the material or making too shallow slots.

4. Marking the Workpiece

Alignment Marks Use a pencil or marking tool to make clear, precise marks on the joining edges of your workpieces. These marks indicate where the center of each biscuit slot will be cut.

Precision is Key Double-check that the marks on both pieces align perfectly when the pieces are joined. Misalignment at this stage can lead to uneven or weak joints.

5. Cutting the Slots

Power Up Safely Once all adjustments are made, plug in the joiner. Align the tool’s cutting guide with the marks you made on the workpiece.

Steady Operation Firmly hold the workpiece with one hand (or secure it in a vice or clamp) and grip the joiner with the other. Press the joiner forward to engage the blade with the workpiece, cutting the slot at the marked position. Repeat for all marked positions.

6. Inserting Biscuits

Glue Application Apply a moderate amount of wood glue within each slot and on the biscuits. The glue should coat the sides of the slots and biscuits but not be so excessive that it fills the slot completely or spills out excessively when the biscuit is inserted.

Biscuit Insertion Slide the biscuits into the slots on one of the workpieces. The fit should be snug but not overly tight. The glue will swell the biscuits slightly, creating a tight joint.

7. Clamping

Join and Align Carefully align the two workpieces, ensuring the biscuits fit into the corresponding slots on the joining piece.

Secure the Joint Apply clamps across the joint to hold the pieces firmly together while the glue dries. The pressure should be even and just enough to close the joint without distorting the wood or squeezing out all the glue, which would weaken the joint.

Table Comparison

Summary

- Aoben Biscuit Joiner: A powerful and affordable option with a robust 8.5-amp motor, suitable for various woodworking applications. Its dust collection system and ergonomic design make it user-friendly, though the plastic components and quickly filling dust bag are drawbacks.

- Rexbeti Wood Biscuit Plate Joiner Kit: Known for its lightweight design and convenience right out of the box, this joiner is ideal for those seeking ease of use and portability. The safety-lock screw adds a unique touch, although it’s known to be noisy during operation.

- Festool Domino Joiner: While not a traditional biscuit joiner, the Festool Domino offers a high degree of accuracy and strength with its unique domino system. It’s an investment piece, priced higher than typical biscuit joiners but offers unmatched performance and durability.

Pros and Cons of Aoben Biscuit Joiner

Pros

- Precision Cutting: The Aoben Biscuit Joiner is known for its precision cutting capability, allowing for tight, accurate joints that enhance the structural integrity and appearance of woodworking projects.

- Adjustable Settings: With adjustable angle and depth settings, the tool can be customized for various project requirements, making it versatile for different types of joinery tasks.

- Dust Collection System: The built-in dust collection feature helps maintain a clean workspace by efficiently collecting wood shavings and dust, which also contributes to better health and safety standards.

- Ease of Use: Designed with the user in mind, the Aoben Biscuit Joiner is user-friendly, even for those new to woodworking, making it accessible to hobbyists and professionals alike.

- Durability: Constructed with high-quality materials, the tool is built to last, ensuring that it can withstand the rigors of frequent use in various woodworking projects.

- Cost-Effectiveness: Offering a good balance between quality and price, the Aoben Biscuit Joiner provides excellent value for money, making it an attractive option for those looking to invest in a reliable joinery tool without breaking the bank.

Cons

- Learning Curve: While generally user-friendly, beginners in woodworking might still face a learning curve in mastering precise biscuit placement and tool adjustments for optimal results.

- Blade Limitations: Depending on the model, the standard blade size may limit the range of biscuit sizes that can be used, potentially restricting the tool’s applicability to certain projects.

- Power Requirements: For those working in areas with limited access to power sources, the electric nature of the Aoben Biscuit Joiner might be a limitation, as it requires a power outlet for operation.

- Maintenance Needs: Regular maintenance is required to keep the tool in top working condition, including blade sharpening or replacement, which might be an additional cost and effort for some users.

- Size and Portability: Depending on the specific model, the tool might be bulkier than desired for those who need a highly portable option for on-site work or those with limited storage space.

- Specialized Use: As a specialized tool, the Aoben Biscuit Joiner might not be the most cost-effective option for those who only occasionally require biscuit joining capabilities in their projects.

Maintenance and Care of Aoben Biscuit Joiner

1. Regular Cleaning

- After Each Use: It’s crucial to clean your biscuit joiner after each use. Remove any dust and debris from the blade and cutting area using a soft brush or compressed air. This prevents buildup that can affect the tool’s performance.

- Deep Cleaning: Periodically, perform a more thorough cleaning. Unplug the tool, dismantle the removable parts, and carefully clean each component. Use a dry cloth for the body and a damp one for stubborn residues, ensuring no moisture enters the motor or electrical parts.

2. Blade Maintenance

- Inspection: Regularly inspect the blade for signs of wear, such as dullness or damage. A sharp blade is essential for clean, precise cuts.

- Cleaning: Clean the blade with a suitable solvent to remove any pitch or resin buildup, which can affect cutting efficiency.

- Sharpening/Replacement: If the blade is dull and cannot produce clean cuts, consider having it professionally sharpened or replace it if it’s damaged or excessively worn.

3. Lubrication

- Hinges and Moving Parts: Apply a light machine oil to any moving parts, such as the adjustment hinges, to keep them moving smoothly.

- Avoid Over-Lubrication: Be cautious not to over-lubricate, as excess oil can attract dust and debris, leading to a buildup that can impede the tool’s functionality.

4. Check for Wear and Tear

- Inspect Regularly: Regularly check all parts of the biscuit joiner for any signs of wear or damage, including the power cord, buttons, and housing.

- Address Issues Promptly: If you notice any problems, such as a frayed cord or a loose component, address them immediately to prevent further damage or potential safety hazards.

5. Storage

- Proper Storage: Store your Aoben Biscuit Joiner in a clean, dry place when not in use. If possible, keep it in its original case or a designated storage bag to protect it from dust and moisture.

- Avoid Stacking: Avoid placing heavy objects on top of the joiner, as this can damage the tool over time.

6. Handling and Use

- Gentle Use: While the Aoben Biscuit Joiner is built to be robust, it’s crucial to handle it gently and avoid dropping it, as this can cause internal damage or misalignment.

- Follow Instructions: Always use the tool according to the manufacturer’s instructions to ensure safe and effective operation.

Read More:

Conclusion

In conclusion, the Aoben Biscuit Joiner emerges as a significant tool in the realm of woodworking, blending functionality with user-friendliness to cater to both seasoned woodworkers and hobbyists alike. Its precision cutting capabilities, adjustable angles, and efficient dust collection system highlight its design ethos, focused on enhancing the quality and efficiency of woodworking projects. The simplicity of its operation, coupled with the tangible benefits it brings to joinery work, underscores its value in creating strong, aesthetically pleasing joints with ease.

FAQs

1. What is a biscuit joiner, and how does the Aoben Biscuit Joiner differ from others?

A biscuit joiner is a woodworking tool used to join two pieces of wood together with a biscuit—a small, oval-shaped piece of compressed wood. The Aoben Biscuit Joiner stands out for its precision cutting capabilities, adjustable angles, and efficient dust collection system, making it a reliable choice for both hobbyists and professionals.

2. Can the Aoben Biscuit Joiner be used by beginners?

Absolutely! The Aoben Biscuit Joiner is designed with user-friendliness in mind. It comes with clear instructions, making it accessible for beginners while still offering the precision and versatility that experienced woodworkers require.

3. What types of projects is the Aoben Biscuit Joiner best suited for?

The Aoben Biscuit Joiner is versatile and can be used for a wide range of woodworking projects, including but not limited to cabinet making, building furniture, creating picture frames, and any project that requires strong, seamless wood joints.

4. How do I maintain my Aoben Biscuit Joiner to ensure its longevity?

Regular maintenance includes cleaning the tool after each use, keeping the blade sharp, ensuring all moving parts are lubricated, and storing the joiner in a dry, dust-free environment. Additionally, it’s important to inspect the tool regularly for any signs of wear or damage.

5. Are replacement parts readily available for the Aoben Biscuit Joiner?

Yes, replacement parts for the Aoben Biscuit Joiner, such as blades and other components, are generally available from the manufacturer or authorized dealers. It’s always recommended to use original parts to maintain the tool’s performance and warranty.

Joel Cunningham

Forestry AuthorI'm Joel Cunningham, an expert in pruning and weed management with over a decade of experience. My skills are rooted in formal training and extensive practice, focusing on advanced pruning techniques and efficient weed control. I'm known for my quality work, precision, and deep understanding of plant health and soil dynamics. My contributions extend to educational initiatives where I share sustainable practices and advice, establishing myself as a reliable and authoritative figure in the gardening community.

Leave your comment