Chainsaw Kickback: Causes, Dangers, and Safety Tips

- January 5, 2024

- 1 comment

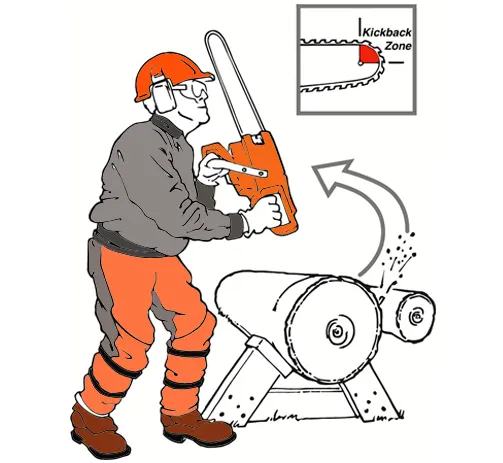

Chainsaw kickback is one of the most dangerous hazards users face. It occurs when the chainsaw’s guide bar suddenly jerks upward, often from the “kickback zone” at the bar’s tip. This unexpected motion can lead to severe chainsaw kickback injuries, making it a top concern for both beginners and seasoned professionals. To avoid chainsaw kickback, it’s essential to understand its causes, dangers, and implement effective chainsaw safety tips. In this guide, I’ll share practical advice from my personal experience, including proven methods for chainsaw kickback prevention and protection.

Understanding Chainsaw Kickback

Chainsaw kickback is a significant safety concern for everyone from professional loggers to casual woodcutters. It typically happens in two high-risk scenarios. The first, known as a “nose contact” kickback, occurs when the fast-moving chain at the tip of the guide bar also called the “kickback zone” hits a solid object. This could be a hidden nail, a rock, or a tough tree knot, all of which can trigger sudden and dangerous motion.

The second scenario, often referred to as “pinch” kickback, arises when the wood being cut unexpectedly clamps down on the chainsaw’s chain. This can happen during tree felling or cutting large logs, as internal tensions in the wood shift and close the cut. Understanding these chainsaw dangers is the first step toward effective chainsaw kickback prevention and protecting yourself during use.

Both “nose contact” and “pinch” kickback trigger a sudden, forceful reaction from the chainsaw’s guide bar. In mere seconds, the kickback bar can jerk upwards and backward, creating a highly dangerous situation. This abrupt motion is not only startling but can easily cause the operator to lose control of the chainsaw. Even seasoned users can struggle to maintain a firm grip during such an event, highlighting the importance of understanding chainsaw kickback prevention techniques. The speed and force involved make chainsaw kickback injuries a serious threat, reinforcing the need for proper safety measures and adherence to chainsaw safety tips.

Chainsaw kickback is an instantaneous and forceful reaction, leaving operators with little to no time to respond. This makes chainsaw kickback prevention a critical aspect of safe chainsaw operation. Proper handling techniques, utilizing built-in chainsaw safety features, and wearing protective gear like gloves, helmets, and eye protection are essential. Always be mindful of the kickback bar’s position relative to the workpiece to minimize the risk. By staying aware and following these chainsaw safety tips, you can significantly reduce the likelihood of dangerous kickback incidents.

Factors Increasing the Risk of Kickback

Understanding the factors that heighten the risk of chainsaw kickback is essential for safe operation. Both professional lumberjacks and casual users should prioritize addressing these common issues to avoid chainsaw kickback injuries.

- Improper Chainsaw Maintenance

Neglecting regular maintenance can significantly elevate the risk of kickback. Cleaning, oiling, and ensuring all parts are in good working order are critical chainsaw safety practices. - Dull or Improperly Sharpened Chains

A dull chain requires excessive force to cut, leading to unpredictable behavior. Incorrect sharpening can alter tooth angles, increasing the chance of kickback. - Loose Chain Tension or Parts

Proper chain tension is crucial for safe cutting. A loose chain can slip off the bar or snag in the wood, while loose components can destabilize the chainsaw, heightening the risk. - Damaged Chain Components

Bent, cracked, or broken chain parts compromise operational safety. Even minor damage can cause unexpected movements and increase the likelihood of kickback. - Incorrect Chain Depth Gauge Settings

Depth gauges control how much the teeth bite into the wood. Improper settings can make the saw overly aggressive or ineffective, both of which can lead to kickback incidents. - Large Guide Bar Noses

Larger noses expand the “kickback zone,” increasing the risk of the bar nose striking objects and causing kickback. Selecting the right guide bar size can minimize this hazard.

Understanding the Kickback Danger Zone

The top portion of a chainsaw’s guide bar tip, commonly called the “kickback bar,” contains a critical area known as the “kickback danger zone.” This zone requires heightened caution as it is the most likely point to trigger chainsaw kickback. Using this part of the bar for cutting should be avoided, as it significantly increases the risk of chainsaw kickback injuries. The danger intensifies when this zone contacts external objects, such as logs or branches, during sawing operations. Recognizing and avoiding the kickback danger zone is a key element of chainsaw kickback prevention and essential for safe operation.

To fully understand the chainsaw kickback danger zone, it’s essential to grasp what kickback truly entails. According to CSA Z62.3-11 (R2021) standards, kickback is defined as the sudden upward motion of the chainsaw’s guide bar. This phenomenon occurs in two main forms:

- Rotational Kickback

This type happens when the saw chain near the nose of the guide bar—within the kickback danger zone—contacts an object. The sudden impact causes the chainsaw to rotate upward and toward the operator, creating a highly hazardous situation. - Pinch Kickback

Pinch kickback occurs during cutting when the wood unexpectedly pinches the saw chain. This reaction can cause the chainsaw to jerk upward rapidly, increasing the risk of losing control and endangering the operator.

Both rotational and pinch kickbacks highlight the critical importance of avoiding the kickback danger zone during operation. By understanding these dynamics and adhering to chainsaw kickback prevention practices, operators can significantly reduce the risk of accidents while ensuring safe and effective use of this powerful tool.

Reducing the Risk of Chainsaw Kickback

- Understand Your Chainsaw

Familiarize yourself with the chainsaw’s mechanics and safety features. Review the manufacturer’s guidelines to prepare for safe operation. - Stay Focused

Always operate a chainsaw with full concentration. Avoid using it when fatigued or distracted, as quick reactions are crucial to avoid chainsaw kickback injuries. - Be Cautious When Limbing

Limbing a process prone to kickback requires extra vigilance. Ensure the nose of the kickback bar does not come into contact with objects that could trigger kickback. - Use Proper Cutting Methods

Cut with the lower part of the bar and avoid operations above shoulder height, where control is reduced, and the risk of kickback increases. - Avoid Bar Tip Contact

Never allow the tip of the bar, particularly within the kickback danger zone, to make contact with any surface. This is a critical step in chainsaw kickback prevention. - Test the Chain Brake Regularly

The chain brake is a vital safety feature designed to stop the chain during a kickback. Ensure it is functioning correctly before each use. - Choose Kickback-Reducing Chains

Select a chain engineered to reduce kickback. These chains are designed for safety and can significantly minimize the risk. - Opt for Narrow-Nose Bars

Narrow-nose bars reduce the kickback danger zone and are an excellent choice for enhanced chainsaw safety. - Wear Protective Equipment

Equip yourself with chainsaw chaps or pants, sturdy gloves, safety glasses or a face shield, a hard hat, hearing protection, and non-slip boots. - Dress Appropriately

Wear well-fitted clothing that allows easy movement but avoids loose fabric that could get caught in the chainsaw. - Maintain a Secure Grip

Always wrap your thumbs and fingers fully around the handles, ensuring a firm grip to maintain control and balance during operation. - Practice Regular Maintenance

Regularly sharpen the chain, adjust tension, and perform general upkeep as per the manufacturer’s instructions. A well-maintained chainsaw operates more safely and efficiently.

Guidance for Novice and Experienced Chainsaw Users: Navigating Kickback Risks

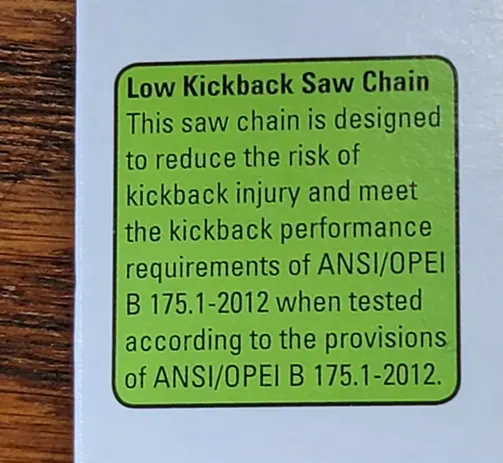

For Novice Users: Choosing the Right Chain

For beginners, selecting the right chain is one of the most important steps in reducing the risk of chainsaw kickback. Start with a low kickback chain specifically designed for novice users. Look for chains marked with a green label by the American National Standards Institute (ANSI), which indicates suitability for less experienced operators. Some older models, such as those from Oregon, may use a blue label to signify the same feature.

These chains are engineered to minimize the intensity and likelihood of kickback, offering added safety as you develop your chainsaw handling skills. Opting for a low kickback chain is an essential part of chainsaw kickback prevention, ensuring a safer learning experience for new users.

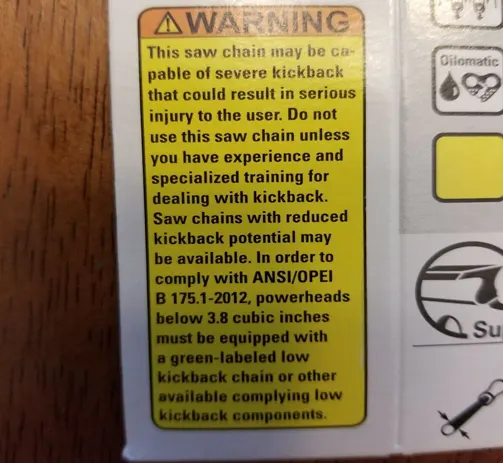

Safety Tips for Experienced Users: Handling Professional Chains

For seasoned chainsaw operators, professional chains marked with a yellow label offer enhanced efficiency and power for demanding tasks. Unlike low kickback chains, these are not designed to minimize kickback and require advanced skills and experience to handle safely. Their aggressive cutting capabilities make them suitable for professional use but also increase the risk of kickback, especially when working in the kickback danger zone.

If you’re considering a professional chain, ensure you have the necessary training and confidence in chainsaw kickback prevention techniques. Proper handling, along with regular maintenance and a firm grip, is critical when using these high-performance chains.

Conclusion

From my own experience, understanding chainsaw kickback and respecting the power of the kickback bar has been a game-changer for safe operation. Taking the time to learn proper techniques, using low kickback chains when starting out, and always staying aware of the kickback danger zone can make a huge difference. Don’t skip on wearing protective gear it’s your last line of defense against unexpected accidents.

The biggest lesson I’ve learned? Safety isn’t optional it’s essential. By staying alert and sticking to these chainsaw safety tips, you’ll not only reduce the risk of kickback but also build confidence every time you power up your chainsaw. Trust me, taking these precautions is well worth the effort for a safer, smoother experience.

Related Articles:

- Types of Chainsaw Chains and How to Choose

- How Tight Should A Chainsaw Chain Be

- Best Chainsaw Mill Attachments

- Best ATV Chainsaw Holder

- Common Reasons Your Chainsaw Is Smoking

- Best Chainsaw for the Money: Top Picks for Every User

- Top 5 Causes of a Loose or Detached Chainsaw Chain: How to Identify and Fix

- Chainsaw Safety Guide Tips

FAQs

- What is a kickback bar on a chainsaw, and how does it relate to safety?

A kickback bar refers to the guide bar of a chainsaw, particularly highlighting its role in kickback incidents. Understanding its dynamics and risks is crucial for safe chainsaw operation. - Can kickback happen even with a low kickback chain?

Yes, while low kickback chains reduce the risk, they do not eliminate it entirely. Kickback can still occur if the chainsaw is used improperly or if the kickback bar’s tip strikes an object. - Is there a particular technique to hold the chainsaw to prevent kickback?

Yes, always hold the chainsaw firmly with both hands, keeping your thumbs and fingers wrapped around the handles. This grip aids in controlling the saw during a potential kickback. - Why is the size of the guide bar’s nose important in kickback prevention? The larger the nose of the guide bar, the greater the area of the kickback danger zone. Using a bar with a smaller nose reduces the likelihood of kickback.

- How often should I check my chainsaw for features that prevent kickback?

Before each use, inspect your chainsaw for safety features like the chain brake and ensure they are functioning properly. Regular maintenance checks are also essential. - Can professional chainsaw users ignore kickback safety measures?

No. Regardless of experience, all chainsaw users should adhere to kickback safety measures. Professionals often use more powerful saws, which can increase kickback risks. - Are electric chainsaws less prone to kickback than gas-powered ones?

Electric chainsaws can still experience kickback, but their generally smaller size and lower power can reduce the severity compared to gas-powered models. - Does wearing protective gear really help in a kickback scenario?

Absolutely. Protective gear like chainsaw chaps, gloves, and helmets can provide crucial protection in the event of kickback, potentially preventing serious injuries. - What is the ‘kickback danger zone,’ and how can I identify it?

The kickback danger zone is located at the top quarter of the chainsaw bar’s nose. Avoid using this area for cutting, as it’s most prone to causing kickback. - How can a beginner practice safe chainsaw use to avoid kickback?

Beginners should start with a low kickback chain and bar, read the chainsaw’s operating manual thoroughly, practice under supervision if possible, and always stay alert and focused while using the saw.

Join the discussion below by sharing your experiences, tips, or reviews. Your contributions help others make informed decisions and navigate their chainsaw choices with confidence. Let’s build a community of shared knowledge for all wood-cutting enthusiasts!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

181se or 394xp 266xpw 288xp I think all good models forsure 288 case 181 jug 52mm piston primary and secondary transfers cleaned up for faster fiel and air

Kenneth

January 7, 2024 9:31 am