Granberg Chainsaw Mill Review

- January 23, 2024

- 0 comment

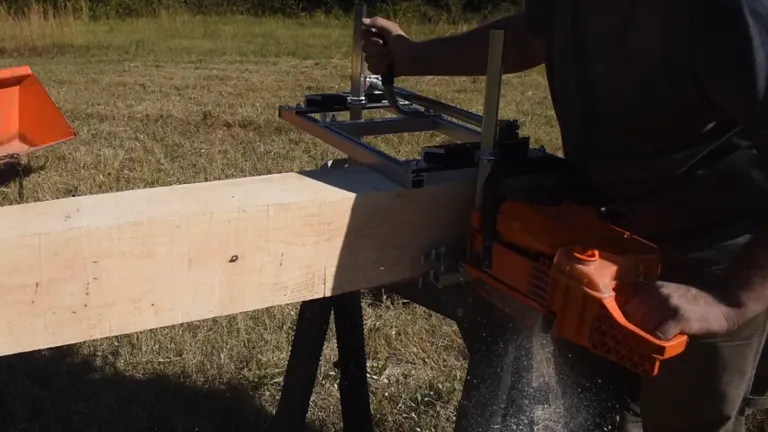

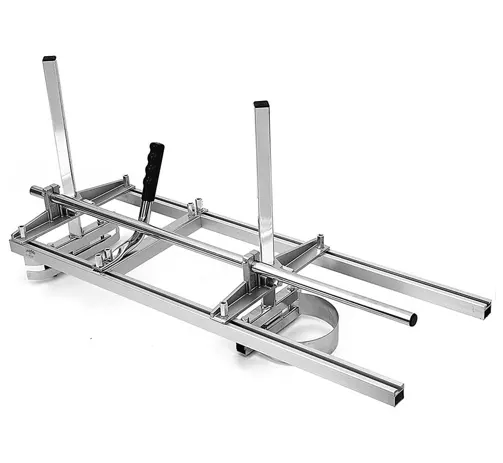

After spending considerable time with the Granberg Alaskan Chainsaw Mill MKIV, I am ready to share my hands-on experience. This tool is not just an accessory; it’s a robust, portable sawmill capable of transforming raw logs into usable lumber on-site. Below is a detailed review based on my personal use of the product.

Granberg Chainsaw Mill Specifications

- Item Weight: 18.1 pounds

- Product Dimensions: 37 x 14 x 4 inches

- Item Model Number: GRANBERG – G778-36

- Style: Mill

- Material: Metal (Aircraft Aluminum Extrusion & Zinc Plated Steel)

- Power Source: Hand Powered

Assembly and Setup

Setting up the Granberg Alaskan Chainsaw Mill MKIV is straightforward, thanks to the comprehensive instruction manual and assembly hardware included in the package. Clamping the mill onto my chainsaw bar was hassle-free, requiring no drilling, which was a relief. The only minor hiccup I encountered was adjusting the back bar, which needed a bit of force, but I suspect it might become smoother with more use or perhaps I’m missing a trick here.

If you are having trouble assembling the Granberg Chainsaw Mill, you can check it out here!

Build Quality and Design

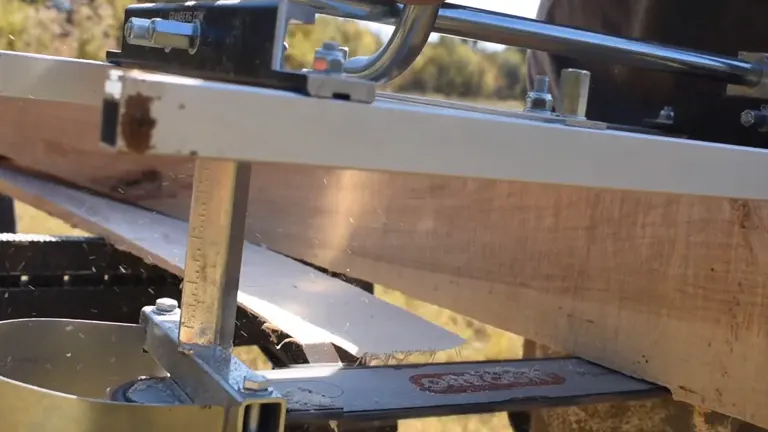

The build quality of the Granberg Mill is impeccable. It’s crafted from high-quality U.S.-made aerospace aluminum and zinc-plated steel, ensuring durability and a long lifespan. The newly designed CNC-Machined billet end brackets are a significant upgrade over the previous version. They are not only more accurate and easier to adjust but also reduce vibration and are nearly unbreakable.

Performance

In action, the Granberg Mill is a powerhouse. I used it with an Echo CS590 with a 24-inch bar, and it handled the job effortlessly, providing me with about 18 and three-quarter inches of cutting width. The mill can cut planks and beams up to 32” wide and 1/2” to 13” deep, which is more than sufficient for most DIY projects and professional tasks. The precision of the cuts impressed me the most. Each plank came out truly straight and even, every time.

Safety and Comfort

Safety features are well-thought-out, like the safety guard to prevent accidental cuts. The push handle and the overall design of the mill make it comfortable to use, even for extended periods. However, it’s crucial to plan your cuts and work methodically, as with any powerful tool.

Portability

One of the most significant advantages of the Granberg Mill is its portability. Being able to mill lumber right where the tree falls is a game-changer, especially for outdoor and remote projects. Despite its sturdy construction, it’s surprisingly lightweight and portable.

Granberg Chainsaw Mill Pros and Cons

Pros

- The assembly process is a no-brainer, thanks to the clear instruction manual and included hardware. It’s like putting together a piece of IKEA furniture but without the leftover screws!

- Clamping the mill onto the chainsaw bar was as easy as pie – no need for drilling or complicated modifications.

- Crafted with U.S.-made aerospace aluminum and zinc-plated steel, this mill feels like it could survive a tank battle. The new CNC-Machined billet end brackets are the cherry on top – sturdy and almost indestructible.

- The precision is spot-on. Each plank is as straight and even as a ballet dancer’s posture. The adjustable depth and width cater to various lumber sizes, making it versatile.

- The safety guard is a thoughtful touch, keeping my legs safe during operation. The push handle design also makes the milling process comfortable, reducing fatigue over prolonged use.

- The ability to mill right where the tree falls is a game-changer, especially for off-grid projects. Its lightweight nature doesn’t compromise its sturdiness, making it a trusty companion in the wild.

Cons

- The back bar needed a bit more muscle than expected to adjust. It’s not a deal-breaker, but it made me wish I had skipped arm day at the gym a few times less.

- While the setup is straightforward, mastering the milling process takes a bit of practice. Planning your cuts and understanding the log’s nature is crucial to avoid any ‘oops’ moments.

- Let’s be honest, milling lumber is not a walk in the park. It requires physical effort and stamina, especially for larger projects. It’s a good workout, but make sure to pace yourself and take breaks.

- The mill’s performance heavily relies on the chainsaw used. A robust and powerful chainsaw is a must to harness the full potential of this mill.

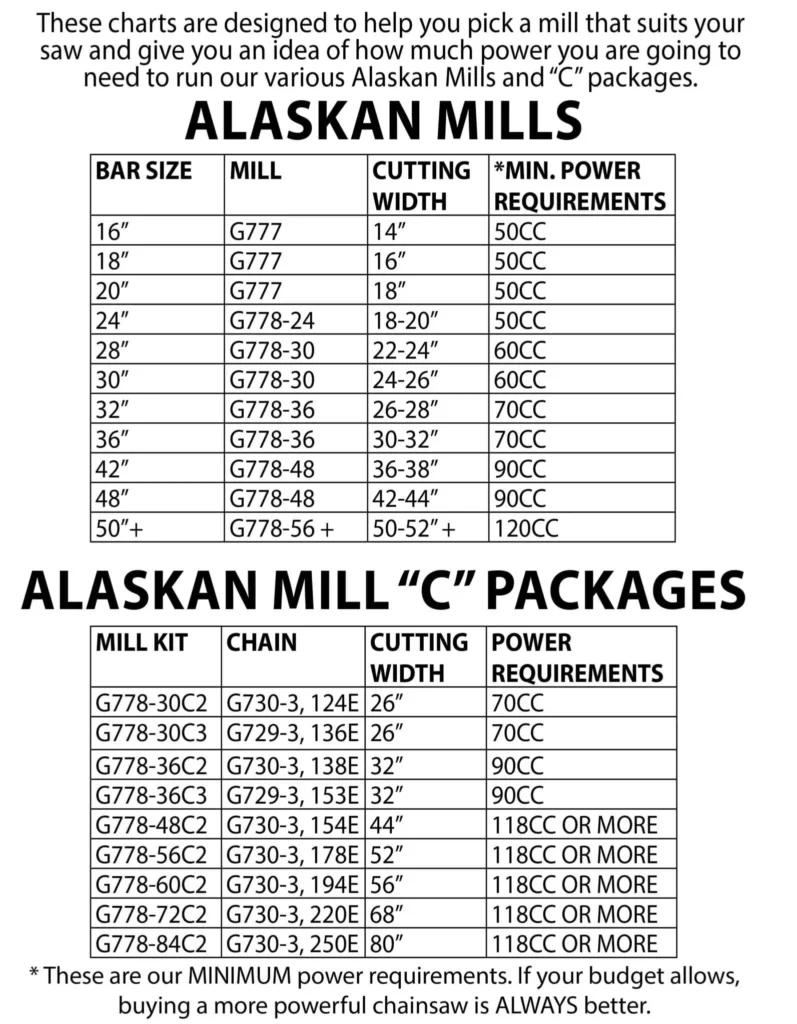

Chainsaw Mill Guide

Chainsaw Mill is an incredibly effective method to transform logs into lumber or other woodworking materials on-site. If you’re venturing into this method for the first time, here are some structured steps and tips to guide you through the process:

- Selecting the Right Chainsaw: Begin by ensuring that your chainsaw is powerful enough for the task at hand. For milling a log about 30 inches in diameter, a chainsaw with 70-90 CC is generally sufficient. It’s crucial to have a chainsaw robust enough to handle the job to ensure a smooth cutting process and to prevent undue stress on your equipment.

- Choosing the Right Chain: Opt for a ripping chain, which is specifically designed for milling purposes. These chains are known for their ability to cut smoother and stay sharper for longer durations compared to standard chains, making them indispensable for a clean and efficient milling process.

- First Cut System: Implement a first cut system such as EZ rails or slabbing rail brackets attached to 2x4s. This setup aids in achieving a level and smooth initial cut, which is vital for the overall quality of the milling. While alternatives like an aluminum ladder or a straight 2×8 can be used, they might not offer the same level of precision or convenience.

- Inspecting the Log: Before beginning the milling process, inspect the log for any dirt, stones, or other forms of contamination in the bark. Such contaminants can dull your chain rapidly, so it’s advisable to clean or remove the bark if necessary, especially if the log has been lying in a potentially dirty environment. For certain types of wood like redwood or Sequoia, whose bark is particularly fibrous, removing the bark can be a beneficial step to avoid quick dulling of the chain.

- Preparing the Mill: Make sure the mill is appropriately sized for the log you’re working with. If the log’s width exceeds the capacity of the mill, you may need to trim the log to fit. Mounting the Alaskan sawmill onto the chainsaw bar is a critical step—ensure it’s centered and the clamping brackets are securely tightened to prevent any movement during the cutting process.

- Making the First Cut: Properly positioning the mill at the start of the cut is crucial for stability and precision. Begin by placing the skids against the diameter of the log and then carefully rotate the saw into the log, maintaining a level position. This approach helps in establishing a stable and controlled initial cut.

- Safety First: Prioritizing safety cannot be overstated. Always wear appropriate safety gear, including chaps, steel-toe boots, gloves, ear protection, and eye protection. Additionally, use wooden wedges to prevent the log from pinching the saw. Insert the wedges gently to hold the slab in place without affecting the accuracy of the cut.

- Maintenance: Regular maintenance of your chainsaw and mill is essential. Keep the chain sharpened and check the mill’s components regularly to ensure everything is tight and properly aligned. Post-use cleaning of your equipment also contributes to its longevity and ensures it’s ready for your next milling session.

Embarking on Alaskan Chainsaw Milling can be a highly rewarding experience, offering the capability to process lumber directly at the cutting site. However, it demands meticulous preparation, attention to detail, and a strict adherence to safety procedures. With these tips in mind, you’re ready to start milling with confidence and precision.

Comparison Table: Granberg Alaskan Chainsaw Mill MKIV vs. Carmyra Portable Chainsaw Mill

The Granberg Alaskan Chainsaw Mill MKIV stands out for its superior construction and precision. It’s designed for professionals and those requiring a high degree of durability and versatility in their milling tasks. The ease of use, coupled with its lightweight yet robust design, makes it an ideal choice for serious woodworking projects.

On the other hand, the Carmyra Portable Chainsaw Mill is a more budget-friendly option. While it offers decent quality and portability, it’s more suited for hobbyists or those with occasional milling needs. Its build is sturdy, but adjustments might require more effort compared to the Granberg.

In conclusion, your choice between the two should be guided by the intensity of your milling tasks, your budget, and the level of precision you require. The Granberg is a substantial investment for serious, frequent milling work, while the Carmyra offers a practical solution for less demanding tasks.

Buyer’s Chart

Final Thoughts

Overall, the Granberg Alaskan Chainsaw Mill MKIV is a top-tier tool that lives up to its promises. Whether you’re a professional arborist, a weekend hobbyist, or somewhere in between, this mill is a fantastic investment. It simplifies the milling process, cuts with precision, and is built to last. The after-sales support and advice from Granberg, coupled with the wealth of instructional videos, make it a product that’s not just bought but also backed by the manufacturer. It’s a solid, USA-made tool that I’d recommend to anyone in the market for a reliable and efficient chainsaw mill.

FAQs

- Can the Granberg Alaskan Chainsaw Mill MKIV cut through hardwoods like oak or maple?

Absolutely! The mill is designed to handle a variety of wood types, including hardwoods. Just ensure your chainsaw is powerful enough (minimum 70cc) and equipped with a sharp, suitable chain for the best results. - How portable is the Granberg Mill? Can one person carry it to a remote site?

Yes, one person can carry it. The mill itself weighs 18.1 pounds and is designed for portability. Its lightweight yet sturdy construction makes it ideal for remote sites, allowing you to mill lumber right where the tree falls. - I’m new to milling. How steep is the learning curve for the Granberg Alaskan Chainsaw Mill MKIV?

The learning curve is relatively moderate. While the setup is straightforward, getting used to milling and mastering the technique may take a little time. Granberg provides instructional videos, and with a bit of practice, you’ll quickly become proficient. - Is there a maximum length of log I can mill with the Granberg Alaskan Chainsaw Mill MKIV?

The length of log you can mill is not limited by the mill but by the reach of your chainsaw bar and the physical space around the log. The mill can handle a maximum width of 42 inches, allowing for a wide range of log sizes. - Can the milling depth be adjusted, and if so, how?

Yes, the milling depth can be adjusted from 1/2 inch to 13 inches. Adjustments are made by loosening the bolts and setting the mill to the desired depth using the clearly marked measurements on the mill frame. - Does the Granberg Mill require regular maintenance?

Like any tool, regular maintenance is key to longevity. Keep the mill clean, ensure bolts are tight, and periodically check for any wear. Proper maintenance ensures consistent performance and extends the life of the mill. - What safety gear should I wear while using the Granberg Alaskan Chainsaw Mill MKIV?

Safety should be your top priority. Always wear protective gear, including eye protection, ear protection, chainsaw chaps, gloves, and a helmet. The mill includes a safety guard, but personal protective equipment is crucial. - Can the mill be used by left-handed operators as comfortably as right-handed ones?

Yes, the mill’s design accommodates both left and right-handed operators. The important factor is the setup of your chainsaw and your comfort with its operation. - How does the weather affect milling with the Granberg Mill? Can I mill in the rain or snow?

While the mill itself can withstand various weather conditions due to its durable build, milling in wet conditions can be challenging and potentially dangerous. It’s best to mill in dry conditions for safety and to ensure the quality of your lumber. - Is the Granberg Alaskan Chainsaw Mill MKIV environmentally friendly?

The mill promotes sustainable lumbering by enabling users to mill trees where they fall, reducing the need for transportation. This method minimizes the carbon footprint associated with lumber processing and transportation.

Join the discussion below by sharing your experiences, tips, or reviews. Your contributions help others make informed decisions and navigate their chainsaw choices with confidence. Let’s build a community of shared knowledge for all wood-cutting enthusiasts!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment