How To Use A Chainsaw Depth Gauge

- February 2, 2024

- 1 comment

Operating a chainsaw effectively and safely demands precise maintenance, especially when it comes to sharpening the chain. After sharpening the teeth, it’s crucial to adjust the depth gauge, ensuring your chainsaw performs optimally. This guide will take you through the steps of setting the depth gauge, a key component in regulating how much wood is cut with each tooth of the chain.

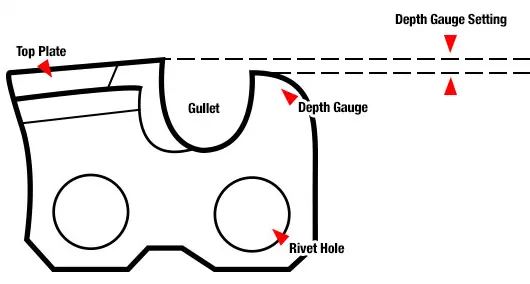

Understanding the Role of the Depth Gauge

Before diving into the adjustment process, it’s essential to comprehend the depth gauge’s role. The depth gauge is the small metal protrusion in front of each tooth on the chainsaw chain. Its height determines the thickness of the wood chip taken by the tooth. As you sharpen the teeth, making them shorter, the relative height of the depth gauge increases, which can reduce the cutting efficiency of the chain.

Step-by-Step Guide to Adjusting the Depth Gauge

Step 1: Inspect the Teeth and Depth Gauge

After sharpening the chain’s teeth, observe the profile of the teeth and the depth gauge. You’ll notice the teeth’s cutting edge slopes downward. As the teeth are filed and become shorter, the depth gauge may protrude excessively, requiring adjustment.

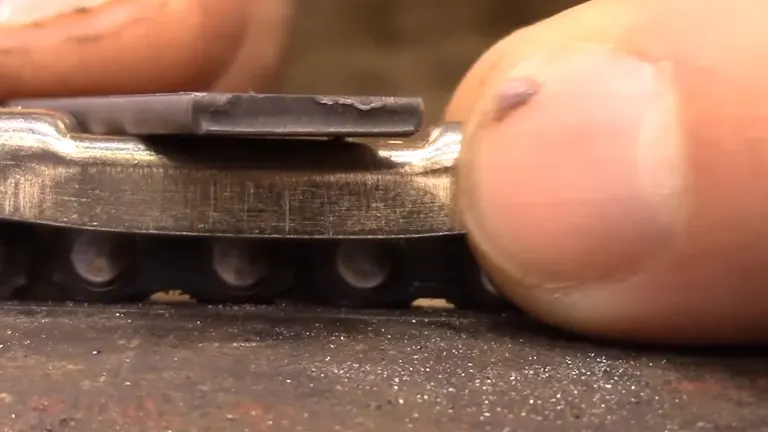

Step 2: Place the Depth Gauge Tool

Use a depth gauge tool for this adjustment. Position it over a chain tooth, ensuring it sits snugly against the tooth and the depth gauge. The tool will help you maintain the correct height for the depth gauge relative to the tooth.

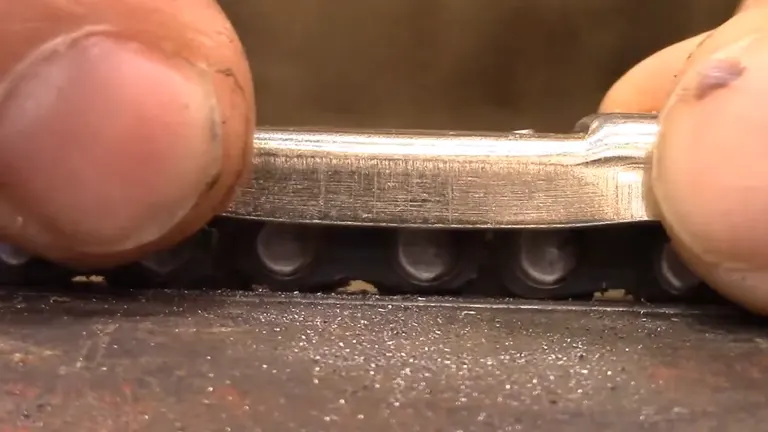

Step 3: File the Depth Gauge

With the depth gauge tool in place, file across the top of the depth gauge. Do this gently and with precision. You should feel the file making contact with the metal. Continue filing until the depth gauge aligns perfectly with the tool, and it no longer protrudes above it.

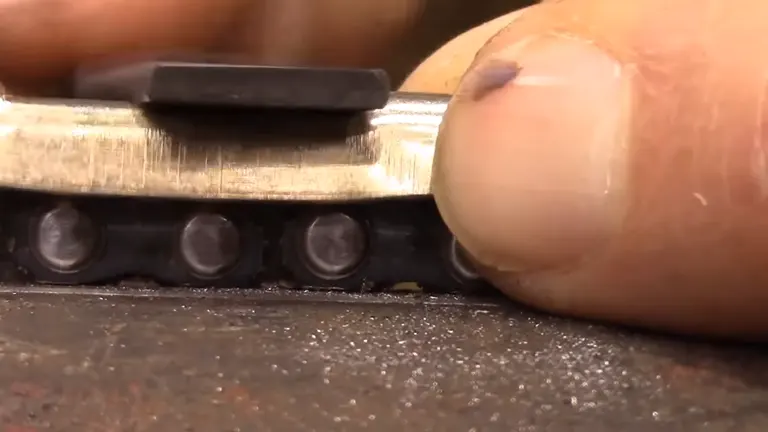

Step 4: Proceed Tooth by Tooth

Move to the next tooth and repeat the process. It’s vital to treat each tooth individually to maintain a uniform cutting surface across the entire chain.

Step 5: Efficiency Tip

Once you get the hang of it, you’ll find that you can adjust an entire chain within a few minutes. It’s a quick, hands-on process that can be more convenient than resetting and using a grinder for the same purpose.

Maintenance Advice: Holistic Chainsaw Upkeep

Maintaining your chainsaw extends beyond adjusting the depth gauge. Regular upkeep ensures longevity, safety, and optimal performance. Key maintenance tasks include:

- Regularly clean the chain to remove debris and sap. Ensure the chain is well-lubricated to reduce friction and prevent premature wear.

- A clean air filter ensures efficient engine operation. Clean or replace it periodically, especially when operating in dusty conditions.

- Check the spark plug for carbon build-up or damage. A poorly functioning spark plug can lead to starting difficulties and inefficient engine performance.

- Regularly inspect the chainsaw for loose, damaged, or worn parts, including the chain, bar, and sprockets. Replace parts as needed to maintain safety and performance.

Troubleshooting Tips: Depth Gauge Adjustment

Adjusting the depth gauge can sometimes be tricky. Here are common issues and their solutions:

- If the saw cuts unevenly, it might be due to uneven depth gauge settings. Ensure each gauge is filed down to the same level.

- If the saw isn’t cutting efficiently after adjustment, the depth gauges might be set too low, causing the chain to bite too deeply and bog down. Recheck and readjust the gauges.

- This could be a sign of depth gauges set too high, making the chain skim over the wood. Lower the gauges slightly for a proper bite.

Tool Recommendations: Depth Gauge Tools and Files

When it comes to maintaining your chainsaw, especially for tasks like setting the depth gauge, using high-quality tools can significantly affect the ease of the job and the quality of your results. Here are some recommendations for depth gauge tools and files:

Depth Gauge Tools

Stihl Depth Gauge

Known for their high-quality chainsaw accessories, Stihl offers depth gauge tools that are precise and user-friendly. Their tools are durable and designed to give you a consistent and accurate gauge setting.

Husqvarna Depth Gauge

Another leading brand in the chainsaw market, Husqvarna’s depth gauge tools are known for their robustness and precision. They are a great choice for both professionals and homeowners.

Oregon

Specializing in chainsaw accessories, Oregon provides depth gauge tools that are widely praised for their accuracy and ease of use. They are a cost-effective option without compromising on quality.

Flat Files

Pferd Flat File

Pferd files are synonymous with quality. They offer flat files that are specifically designed for chainsaw maintenance, ensuring the right hardness and sharpness for efficient and smooth filing.

Nicholson Flat File

A reputable brand with a long history, Nicholson’s flat files are known for their durability and excellent cutting performance. They are suitable for various maintenance tasks, including depth gauge adjustments.

By choosing tools from these reputable brands, you can ensure that your chainsaw maintenance is effective, precise, and leads to a longer life for your equipment. Remember, investing in good quality tools not only makes the maintenance task easier but also ensures safety and the optimal performance of your chainsaw.

Conclusion

Properly maintaining the depth gauge of your chainsaw chain is as crucial as sharpening the teeth. It ensures that your chainsaw cuts efficiently and safely. Remember, a correctly set depth gauge significantly enhances the cutting performance, making your woodcutting tasks smoother and quicker. While you can use a grinder for this task, manually adjusting the depth gauge with a file offers simplicity and speed, making it a preferred method for many.

Now that you’re equipped with the knowledge on how to adjust the depth gauge on your chainsaw, you’re ready to ensure your chainsaw performs at its best, providing clean and efficient cuts every time. Happy and safe cutting!

Related Articles:

- Best STIHL Top Handle Chainsaws

- Can You Use a Chainsaw in the Rain?

- How to Clean a Stihl Chainsaw Carburetor

- How to Mix Oil & Gas for 2 Stroke Engines

- Can You Put a Longer Bar on a Chainsaw?

- Why My Chainsaw Won’t Start

FAQs

- Why is it important to adjust the depth gauge on a chainsaw?

Adjusting the depth gauge is crucial because it controls the amount of wood each tooth cuts. If the depth gauge is too high, the chainsaw will cut inefficiently, making it slow and requiring more effort. If it’s too low, the chainsaw can cut too aggressively, making it dangerous and potentially damaging the chainsaw or the wood. - How often should I check and adjust the depth gauge on my chainsaw? It’s recommended to check the depth gauge every time you sharpen the chain. Regular maintenance ensures consistent performance and extends the life of your chainsaw.

- Can I use any flat file for adjusting the depth gauge, or does it need to be a specific type?

While many flat files might seem suitable, it’s best to use a file specifically designed for chainsaw maintenance. These files are crafted to match the hardness of the chainsaw’s components and provide the precision needed for effective maintenance. - What are the risks of not maintaining the depth gauge properly? Improper maintenance of the depth gauge can lead to several issues, including uneven cuts, increased wear and tear on the chainsaw, and a higher risk of kickback, which is a sudden upward motion of the chainsaw that can be dangerous.

- Is it better to use a manual tool or a grinder for depth gauge adjustment?

Both methods can be effective. Manual tools offer more control and are often preferred for their simplicity and precision. Grinders can be faster but require careful setup to ensure the depth gauge is not ground down too much. - How do I know if the depth gauge is set at the correct height?

The correct height is often specified in the chainsaw’s user manual and can be measured using a depth gauge tool. The tool helps ensure that the height is consistent across all teeth, providing even and effective cutting. - Can I file the depth gauge too much, and what happens if I do?

Yes, filing the depth gauge too much can make the chainsaw cut too deeply into the wood, making it prone to getting stuck and increasing the risk of kickback. It’s important to file only until the depth gauge is level with the guide on the depth gauge tool.

Join the discussion below by sharing your experiences, tips, or reviews. Your contributions help others make informed decisions and navigate their chainsaw choices with confidence. Let’s build a community of shared knowledge for all wood-cutting enthusiasts!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

The information is very important for us the Forester to improve our productivity when using a well maintained chain saw

Elson Tumusiime

February 5, 2024 9:11 am