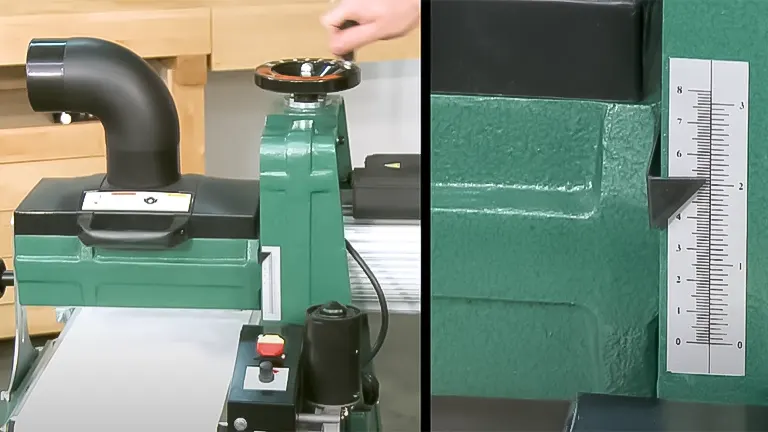

Grizzly G0716 – 10″ 1 HP Drum Sander Review

- February 27, 2024

- 0 comment

When I first embarked on my woodworking journey, I quickly realized the importance of having the right tools to achieve the perfect finish on my projects. Among the myriad of choices, the Grizzly G0716 – 10″ 1 HP Drum Sander stood out as a potentially game-changing addition to my workshop. Now, after extensive use, I’m ready to share my comprehensive review from a hands-on, user perspective.

Specifications

- Manufacturer: Grizzly

- Item Weight: 220 pounds

- Product Dimensions: 25 x 31 x 25 inches

- Style: Grizzly

- Power Source: Corded Electric

- Voltage: 110 Volts

- Amperage Capacity: 10.5 Amps

- Grit Description: Fine

- Motor: 1 HP, 110V, single-phase, 10A

- Conveyor Belt Drive Motor: 1/10 HP

- Drum Speed: 2300 FPM

- Drum Size: 5-1/8″ x 10″

Understanding The Overview Grizzly G0716

The Grizzly G0716 stands out as a robust drum sander that, despite its compact form, packs a considerable punch. Specifically engineered to cater to the needs of dedicated hobbyists and smaller professional workshops, this machine features a sanding width of 10 inches.

It is driven by a 1 HP motor, a testament to its ability to handle an extensive array of sanding operations with ease. What sets the G0716 apart is its versatility, showcased through its variable feed rate and the ability to adjust the drum height. These features ensure users can achieve unparalleled precision in the finishing of their projects, tailoring the outcome to the exact requirements of the workpiece.

Key Features:

- Quick-disconnect smooth-sweep 90° 4″ Dust Port: This feature facilitates efficient dust extraction, minimizing cleanup and maintaining a healthier work environment. The quick-disconnect mechanism allows for fast and easy attachment or removal of a dust collection system, while the smooth-sweep design ensures optimal airflow, reducing clogs and improving dust collection efficiency.

- Variable-speed Conveyor: The inclusion of a variable-speed conveyor offers the user precise control over the feed rate of the material. This adaptability is crucial for achieving the desired finish on various types of wood, allowing for adjustments to be made based on the wood’s hardness or the amount of material to be removed.

- Wheels and Handles for Mobility: Mobility is greatly enhanced with built-in wheels and handles, making it easy to move the machine around the workshop or to different job sites. This feature is especially beneficial for small workshops where space is at a premium or for professionals who need to transport their equipment.

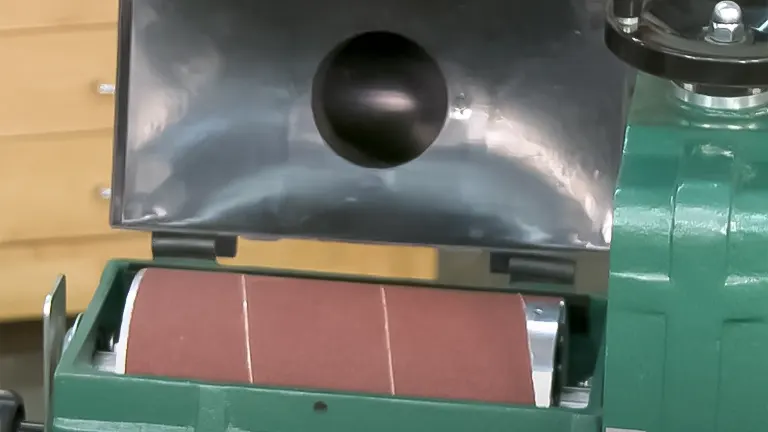

- Spring-loaded Belt Tension/Sandpaper: This mechanism simplifies the process of changing the sandpaper and ensures consistent belt tension. Proper tension is vital for effective sanding and prolongs the life of the sandpaper, resulting in a smoother finish and reduced maintenance costs.

- Rubber Conveyor: A rubber conveyor belt provides a stable and non-slip surface for the workpiece, enhancing safety and precision during the sanding process. This feature also reduces the risk of marking the wood, ensuring a flawless finish.

- Direct Drive Main Motor; Gear Drive Feed Motor: The direct drive main motor offers efficient power transfer for the sanding drum, ensuring consistent performance and durability. Meanwhile, the gear drive feed motor provides reliable and precise control over the conveyor’s speed, allowing for smooth and even sanding across different materials.

Grizzly G0716 Power and Efficiency

The Grizzly G0716’s 1 HP motor is a powerhouse, designed to effortlessly sand through both softwoods and hardwoods alike. Whether I’m working with the more pliable maple or tackling the resilience of oak and walnut, this machine’s performance remains unwavering.

The motor’s ability to maintain a constant speed is a game-changer, ensuring that even the toughest grains don’t cause it to bog down. This consistent power output not only enhances efficiency but also guarantees smooth operation across a variety of wood types, making it an indispensable tool in my workshop.

Grizzly G0716 Surface Finish Quality

The standout feature of the Grizzly G0716 is undoubtedly its ability to produce exceptionally high-quality finishes. By selecting the appropriate grit, I’ve consistently achieved surfaces so smooth they barely necessitate any hand sanding, if at all.

This capability is a major advantage, significantly reducing the time and effort traditionally required for finishing. It’s this level of finish that elevates the G0716, making it an essential piece of equipment for anyone seeking professional-grade results in their woodworking projects.

Grizzly G0716 Dust Collection

Effective dust management is vital for maintaining a clean and safe workshop environment, and the G0716 excels in this area when paired with a quality dust collector.

While it’s understood that no dust collection system can be entirely foolproof, the right combination with this drum sander ensures that sawdust and particles are efficiently captured and removed.

This effectiveness in dust control not only helps in keeping the workspace tidy but also significantly improves air quality, making for a healthier and more pleasant working environment.

Comparisons and Considerations

When comparing the Grizzly G0716 to its competitors, such as the JET JWDS-1020, it’s crucial to consider factors like price, size, and specific features tailored to your needs.

The G0716 falls in a sweet spot for those who require a balance between affordability and performance. While it might lack the width capacity of the JET JWDS-1020, its footprint and efficiency make it ideal for enthusiasts and small shop owners alike.

Table of Comparison vs. Competitor

Below is a comparison table that outlines the key features and specifications of the Grizzly G0716 Drum Sander and the JET JWDS-1020 Drum Sander. This table aims to provide a clear overview to help differentiate between these two popular models.

| Features | Grizzly G0716 Drum Sander | JET JWDS-1020 Drum Sander |

|---|---|---|

| Motor Power | 1 HP | 1 HP |

| Sanding Width | 10 inches | 10 inches |

| Power Source | Corded Electric | Corded Electric |

| Voltage | 110 Volts | 115 Volts |

| Amperage Capacity | 10.5 Amps | 15 Amps |

| Dust Port Size | 4 inches (Quick-disconnect, 90°) | 4 inches |

| Variable-Speed Conveyor | Yes | Yes |

| Conveyor Speed | 1-10 HP | 1-10 HP feet per minute |

| Mobility | Wheels and handles for mobility | Same as Wheels and handles for mobility |

| Tension/Sandpaper Mechanism | Spring-loaded belt tension | Sandsmart control for feed rate |

| Conveyor Material | Rubber | Rubber |

| Drive System | Direct drive main motor; gear drive feed motor | Direct drive |

| Additional Features | Compact design for small workshops | Infinitely variable control of conveyor speed; enhanced precision |

Procedures for Managing Safety and Maintaining Equipment

- Regular Inspection: Regularly inspect the drum sander for any signs of wear or damage, especially on the sanding drum, conveyor belt, and electrical cords. Address any issues promptly to prevent accidents or further damage to the machine.

- Dust Collection Maintenance: Ensure the dust collection system is properly connected and functioning before each use. Regularly clean out the dust collection bag or system to maintain effective dust removal and air quality in the workspace.

- Belt Tension and Alignment: Check the sanding belt tension and alignment periodically. Adjust according to the manufacturer’s instructions to prevent slipping or uneven wear, which can affect the quality of the sanding finish and lead to premature belt failure.

- Conveyor Belt Adjustment: Monitor and adjust the conveyor belt as needed for proper tension and tracking. A misaligned conveyor belt can cause uneven sanding and may damage the workpiece or the machine itself.

- Sanding Drum Maintenance: Clean the sanding drum regularly to remove any accumulated debris or resin that could affect sanding performance. Ensure the drum is free from damage or excessive wear.

- Lubrication: Lubricate moving parts as recommended in the user manual. Proper lubrication reduces wear and tear on components, ensuring smoother operation and extending the life of the machine.

- Electrical Safety: Always unplug the drum sander before performing any maintenance, cleaning, or when changing the sanding belts. This prevents accidental start-up, which could lead to injury.

- Use Appropriate Safety Gear

Wear appropriate personal protective equipment (PPE) such as safety glasses, dust masks, and hearing protection when operating the drum sander. This protects against flying debris, dust inhalation, and noise-induced hearing loss. - Workpiece Handling: Securely fasten the workpiece before sanding. Avoid forcing the workpiece into the sander; let the machine do the work at a pace it can handle to prevent overloading the motor or damaging the workpiece.

- Emergency Preparedness: Familiarize yourself with the machine’s emergency stop function and keep a first aid kit readily available in the workshop. Being prepared for accidents can significantly reduce the severity of injuries.

Pros and Cons

Pros

- Powerful Performance: Consistently handles various wood types without losing speed.

- Superior Finish: Achieves professional-grade smoothness, reducing additional finishing work.

- Compact Design: Ideal for smaller workshops without sacrificing performance.

Cons

- Learning Curve: Adjusting to the optimal feed rate and drum height might take some trial and error for beginners.

- Noise Level: Like most shop equipment, it can be loud, necessitating ear protection during operation.

Who Should Consider the Grizzly G0716

This drum sander is best suited for serious hobbyists or small professional workshops where space is at a premium but quality cannot be compromised. It’s an excellent choice for anyone looking to upgrade from hand sanding or smaller, less capable machines without breaking the bank.

Final Thoughts

The Grizzly G0716 – 10″ 1 HP Drum Sander has proven to be an invaluable asset in my workshop. Its combination of power, efficiency, and finish quality has elevated my projects to a new level. While it might not be the perfect fit for every woodworker, for those in similar situations to mine, it offers a compelling blend of features and performance that’s hard to beat. My personal experience has shown that with this drum sander, achieving that flawless finish is not just possible, but expected.

Frequently Asked Questions

- What is the maximum sanding width of the Grizzly G0716 Drum Sander?

The Grizzly G0716 Drum Sander has a maximum sanding width of 10 inches, making it suitable for a wide range of small to medium-sized projects. - Can the G0716 handle both softwoods and hardwoods?

Yes, the Grizzly G0716 is equipped with a 1 HP motor that provides sufficient power to sand both softwoods and hardwoods effectively. Its consistent motor speed helps prevent bog-downs, even with tougher wood grains. - What type of power source is required for the Grizzly G0716?

The G0716 requires a corded electric power source and operates on 110 volts, making it compatible with standard household electrical outlets in the United States. - Does the G0716 come with variable-speed control for the conveyor belt?

Yes, it features a variable-speed conveyor that allows users to adjust the feed rate of the material for optimal sanding results and finish quality. - How effective is the dust collection system on the Grizzly G0716?

The G0716 comes with a quick-disconnect smooth-sweep 90° 4″ dust port that, when connected to a high-quality dust collector, effectively manages dust and keeps the workspace clean. While no system is 100% efficient, proper setup can significantly reduce dust. - Is the Grizzly G0716 easy to move around the workshop?

Yes, the G0716 includes wheels and handles for mobility, allowing for easy movement around the workshop or to different job sites, which is particularly beneficial for small workshops or mobile professionals. - How does the sandpaper tensioning mechanism work?

The machine features a spring-loaded belt tension mechanism that simplifies the process of changing sandpaper and ensures consistent belt tension for effective sanding and prolonged sandpaper life. - What grit sandpaper should be used with the G0716 for the best finish?

The appropriate sandpaper grit depends on the specific project and desired finish quality. However, the G0716 can accommodate a range of grits, allowing for fine finishes with minimal to no hand sanding afterward. - Can the drum height be adjusted for different thicknesses of wood?

Yes, the drum height on the Grizzly G0716 is adjustable, enabling users to precisely control the thickness and finish of the workpiece, accommodating various sizes and types of wood. - What should I do if the conveyor belt starts slipping or not feeding properly?

If the conveyor belt on the G0716 starts slipping or not feeding properly, it may be necessary to adjust the belt tension or alignment. Consult the user manual for detailed instructions on how to make these adjustments safely and effectively.

We’re eager to hear from you! Share your personal experiences and insights about the Grizzly G0716 – 10″ 1 HP Drum Sander in the comments section below. Whether you’ve tackled a challenging project or found unique ways to maximize its performance, your feedback could greatly assist fellow woodworkers and hobbyists in making well-informed decisions. Let’s build a community of knowledge and support around this versatile tool!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment