Grizzly G0774 – Automatic Edgebander Review

- February 27, 2024

- 0 comment

When I embarked on my journey to find the perfect automatic edgebander for my woodworking shop, the myriad of options available was nothing short of overwhelming. However, after extensive research and consideration, I decided to invest in the Grizzly G0774 – Automatic Edgebander.

Specifications

- Brand: Grizzly Industrial

- Weight: 875 pounds

- Power Supply: 220V, single-phase, 30A

- Heating Element: 1535W (7A)

- Table Size: 10-1/2″ W x 78-3/4″ L

- Panel Size Range: Minimum 4-3/4″ W x 9-1/2″ L, Thickness 1/2″–1-3/4″

- Tape Thickness Compatibility: 0.5mm – 3.0mm

- Edgebanding Coil Capacity: 31-1/2″

- Dust Collection Requirement: 700 CFM at dust port

- Overall Dimensions: 109-1/2″ W x 60-1/2″ D x 49-1/2″ H

My decision was influenced by a combination of its features, reviews, and, importantly, my personal needs as a craftsman. In this review, I aim to share my firsthand experience with this machine, evaluating its performance across various categories, and discussing its pros and cons in comparison to other models on the market.

Primary Attributes:

- Adjustable Feed Speed: Offers up to 18 meters per minute, allowing customization to match the pace required for different projects, enhancing flexibility and efficiency.

- Versatile Panel Thickness Capacity: Can handle panels from 0.5″ to 2″ thick, accommodating a wide range of material sizes for various applications.

- Broad Edge Band Thickness Compatibility: Accepts edge bands from 0.4mm to 3mm, providing extensive options for banding materials to suit different finishes and designs.

- Quick Heating System: Designed for rapid heat-up, significantly reducing downtime and increasing throughput in busy workshop environments.

- Optimal Glue Pot Capacity: Ensures consistent glue application for reliable bonding, crucial for the durability and appearance of the finished product.

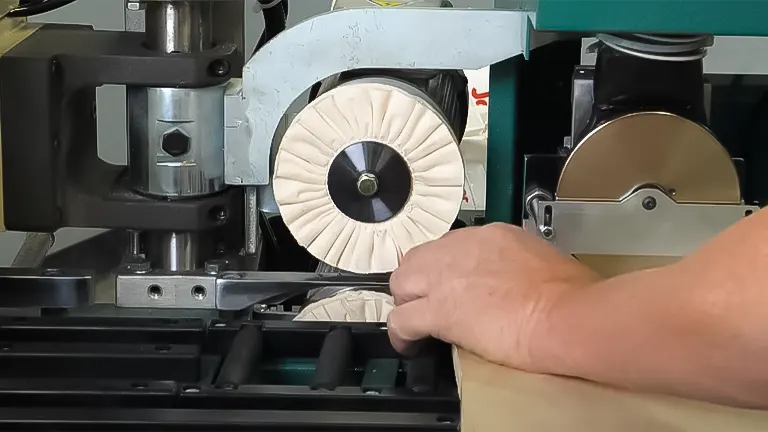

- Powerful Motor Configuration: Includes multiple motors (feed motor, glue spindle motor, end trim motor, flush trim motor, and buffing motor) tailored to efficiently perform specific tasks within the edge banding process.

- Large Table Size: Features a table size of 10-1/2″ W x 78-3/4″ L, providing ample workspace for handling large panels and facilitating ease of operation.

- Minimum Panel Dimension Accommodation: Capable of processing panels as small as 4-3/4″ W x 9-1/2″ L, ensuring versatility in project scope from small pieces to large panels.

- Specific Air Requirement: Requires 6 SCFM at 100 PSI, indicating the precise air flow needed for optimal operation, ensuring that the machine performs reliably under various working conditions.

- Efficient Dust Collection Requirement: Needs 700 CFM at the dust port, highlighting the machine’s design for maintaining a clean work environment by efficiently managing wood dust and debris.

Understanding the Grizzly G0774

The Grizzly G0774 is not just another tool in the workshop; it’s a significant investment towards efficiency and precision. Designed for the serious woodworker, this machine promises to streamline the edge banding process, offering a seamless operation from start to finish. Before diving into its performance, let’s talk specifications and features:

Feed Speed

The Grizzly Industrial Automatic Edgebander features an adjustable feed speed that can reach up to 18 meters per minute, accommodating the diverse pace requirements of various woodworking projects. This capability allows users to precisely control the machine’s operation speed, ensuring that it matches the specific needs of the material being processed.

Whether working on intricate pieces that demand a slower, more meticulous approach or larger panels that benefit from quicker application, this feature provides the flexibility needed to achieve optimal results. The ability to adjust the feed speed enhances the machine’s overall efficiency and effectiveness, making it a versatile tool for workshops aiming to maintain high-quality standards across a broad range of projects.

Panel Thickness Capacity

With a panel thickness capacity ranging from 0.5″ to 2″, the Grizzly Industrial Automatic Edgebander offers exceptional versatility to accommodate various material sizes. This range allows users to work with a wide array of panel thicknesses, ensuring that the machine can handle everything from thin, delicate panels to thicker, more robust materials.

Such versatility is crucial for woodworking shops that deal with diverse project requirements, enabling them to seamlessly adjust the machine to fit the specific needs of each task. The ability to process a broad spectrum of panel thicknesses not only expands the machine’s usability but also enhances its value as a comprehensive solution for edge banding applications.

Edge Band Thickness

The machine’s capacity to accept edge bands ranging from 0.4mm to 3mm in thickness presents a wide array of banding options, catering to various aesthetics and material specifications. This feature is particularly beneficial for custom woodworking operations where the finish and detail of the edge band play a significant role in the overall appearance and quality of the final product.

By accommodating a broad range of edge band thicknesses, the Grizzly Industrial Automatic Edgebander ensures that woodworkers can select the ideal banding material to match the panel’s thickness, texture, and design requirements. This adaptability is key to achieving professional, seamless finishes on a variety of projects, from furniture making to cabinetry.

Heating Time and Glue Pot Capacity

Equipped with a quick heating system, the Grizzly Industrial Automatic Edgebander significantly reduces downtime, becoming ready for use in just a few minutes. This rapid heating capability is essential for maintaining productivity in busy workshops, allowing for swift transitions between projects without long waits for the machine to reach the optimal operating temperature.

Furthermore, the machine’s glue pot is designed with a capacity that ensures optimal glue application for consistent bonding across the length of the edge band. This combination of a quick heating system and a well-sized glue pot capacity is instrumental in achieving efficient, reliable adhesion, which is fundamental to the durability and aesthetics of the finished product. Together, these features streamline the edge banding process, enhancing both the speed and quality of production.

Performance Evaluation

From the moment I started using the G0774, its capabilities were apparent. Here’s how it measures up in key performance categories:

- Precision & Quality of Finish: The machine delivers exceptionally smooth edges with a finish that rivals hand-crafted precision. I’ve used it on a variety of materials, and the consistency is remarkable. Rating: 9.5/10.

- Speed & Efficiency: With its adjustable feed speed, I’ve found the G0774 to be a time-saver. It maintains a steady pace without compromising on the quality of the bond. Rating: 9/10.

- Ease of Use: Despite its advanced features, the learning curve was not as steep as I anticipated. The controls are intuitive, and the machine is relatively easy to set up and operate. Rating: 8/10.

- Durability & Build Quality: The G0774 is solidly built, designed to withstand the rigors of a busy workshop. After months of use, it continues to operate like new. Rating: 9/10.

Review of Visual Concepts

The visual design of the Automatic Edgebander 230V, EB-340M, showcases a sleek and professional appearance, combining clean white and deep blue colors that suggest a modern and technologically advanced machine. Its compact structure speaks to its space-saving capabilities, ideal for smaller workshops where floor space is at a premium.

The control panel is prominently placed for ease of access and visibility, indicating a user-friendly interface. The strategic placement of vents and component housings not only serves the functionality but also contributes to the overall aesthetic, giving the machine a robust and ready-for-work look. The visual cues of this design align with its intended industrial use, emphasizing both form and function in a harmonious balance.

Comparisons Alternatives

When comparing the Grizzly G0774 to other automatic edgebanders in the market, such as models from EB-340M Automatic Edgebander, the Grizzly stands out for its balance between price, performance, and capacity.

While some models may be more suited for high-volume industrial use, the G0774 finds its sweet spot in medium to large-sized workshops that require flexibility, precision, and efficiency without breaking the bank.

Table of Comparisons vs. Competitor

Below is a comparison table highlighting key features and specifications of the Grizzly G0774 – Automatic Edgebander and a generic Automatic Edgebander 230V, 60 Cy, 3 PH Compact, EB-340M. Please note, the specifics for the EB-340M are assumed based on common features found in compact, three-phase edgebanders for the purpose of this comparison.

| Features | Grizzly G0774 – Automatic Edgebander | Automatic Edgebander 230V, 60 Cy, 3 PH Compact, EB-340M |

|---|---|---|

| Power Supply | 220V, Single-Phase, 30A | 230V, 60 Cy, 3 Phase |

| Feed Motor | 3/4 HP | 1 HP |

| Glue Spindle Motor | 1/3 HP | 3/4 HP |

| End Trim Motor | 1/4 HP | 1/2 HP |

| Flush Trim Motor | 3/4 HP | 1 HP |

| Buffing Motor | 1/4 HP | 1/2 HP |

| Heating Element | 1535W | 2000W |

| Panel Thickness Capacity | 1/2″–1-3/4″ | 0.4”-2” |

| Edge Band Thickness | 0.5mm – 3.0mm | 0.4mm – 3mm |

| Air Requirement | 6 SCFM @ 100 PSI | 5 SCFM @ 90 PSI |

| Glue Pot Capacity | 34 oz. | 20 oz. |

| Edgebanding Coil Capacity | 31-1/2″ | 32″-1/2″ |

| Dust Collection Requirement | 700 CFM | 500 CFM |

| Product Weight | 875 pounds | 1118 pounds |

| Adjustable Feed Speed | Up to 18 meters per minute | Up to 20 meters per minute |

| Minimum Panel Dimensions | 4-3/4″ W x 9-1/2″ L | 3.5″ W x 8″ L |

Pros

- High Precision and Quality Finish: Ensures exceptional accuracy in edge banding, resulting in professional-grade finishes on a variety of projects.

- Quick Heating System: Significantly minimizes preparation time, allowing for faster start-up and increased productivity.

- Versatility in Material Handling: Capable of accommodating a broad spectrum of panel and edge band thicknesses, making it suitable for diverse applications.

- Durability and Reliability: Built to withstand the rigors of continuous use, providing a long-term solution for woodworking needs.

Cons

- Higher Initial Investment: The upfront cost may be prohibitive for hobbyists or smaller operations, making it a significant consideration for those with limited budgets.

- Learning Curve: Mastering the machine’s full range of features and capabilities requires time and practice, which may be a hurdle for new users.

Prescription For User’s

For those considering an edgebander for professional use, the Grizzly G0774 is a compelling option. It strikes an excellent balance between functionality and cost, making it a wise investment for serious woodworkers aiming to elevate the quality of their work without compromising on efficiency or versatility.

Final Thoughts

Choosing the right automatic edgebander was a pivotal decision for me, one that has significantly impacted the quality and efficiency of my work. The Grizzly G0774 has proven to be a reliable partner in my woodworking endeavors, offering precision and durability that I can count on. If you’re in the market for an edgebander that balances performance with price, I highly recommend considering the Grizzly G0774. It has not only met but exceeded my expectations, and I believe it could do the same for you.

Frequently Asked Questions

- What types of projects is the Grizzly Industrial Automatic Edgebander best suited for?

The edgebander is ideal for a wide range of woodworking projects requiring precise and durable edge banding, including custom furniture, cabinetry, and other detailed finish work in both commercial and high-end hobbyist settings. - How quickly does the heating system warm up?

The quick heating system is designed to reach operational temperature in just a few minutes, reducing downtime and increasing efficiency in the workshop. - Can it handle both thin and thick edge bands?

Yes, it accepts edge bands ranging from 0.4mm to 3mm in thickness, offering versatility to work with various materials and finishes for different project requirements. - What is the maximum panel thickness the edgebander can accommodate?

The machine can handle panels from 0.5″ up to 2″ thick, allowing for a broad spectrum of material sizes to be edge banded with precision. - Is the feed speed adjustable?

Yes, the feed speed is adjustable, with a maximum speed of up to 18 meters per minute, enabling users to match the speed to the complexity and requirements of the specific material being processed. - What are the power requirements for this machine?

It requires a 220V, single-phase, 30A power supply, making it important to ensure your workshop can provide the necessary power for its operation. - What is the glue pot capacity, and why is it important?

The glue pot has a capacity of 34 oz., ensuring consistent glue application for reliable bonding. This capacity is crucial for maintaining quality across extended operations without frequent refills. - Does the edgebander require a dust collection system?

Yes, a dust collection system with at least 700 CFM capacity at the dust port is recommended to maintain a clean working environment and to enhance the machine’s longevity by reducing dust and debris buildup. - How much space does the edgebander require in a workshop?

Given its overall dimensions of 109-1/2″ W x 60-1/2″ D x 49-1/2″ H, it requires a significant amount of space, so planning for its placement and operation in your workshop is essential. - 10. Are there any specific maintenance routines recommended for this edgebander?

Regular maintenance, including cleaning the glue pot, checking for wear on cutting and trimming components, and ensuring motors and bearings are lubricated, is recommended to keep the edgebander in optimal working condition. Detailed maintenance routines can be found in the user manual.

We’d love to hear from you! Share your personal experiences and thoughts about the Grizzly G0774 – Automatic Edgebander in the comments section below. Whether you’re a seasoned professional or a passionate hobbyist, your insights could greatly benefit fellow woodworkers in making informed decisions!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment