Grizzly Industrial 3 HP Shaper Review

- December 12, 2023

- 0 comment

For woodworkers who hold precision and quality as their guiding principles, acquiring the right tools is akin to unearthing buried treasures. Each acquisition brings a unique set of capabilities and unlocks the potential for creating unparalleled masterpieces. One such treasure that has found a coveted spot in my workshop is the Grizzly Industrial G1026-3 HP Shaper.

Within this review, I delve into the heart of this woodworking powerhouse, offering a glimpse into its intricate design and robust functionality from the perspective of a seasoned user. We’ll embark on a journey that reveals why the G1026 stands out from its competitors, exploring its salient features and capabilities, and ultimately demonstrating its potential to elevate your woodworking endeavors to new heights.

Technical Specifications

- Manufacturer: Grizzly

- Blade Material: High-Speed Steel

- Material: Alloy Steel

- Surface Recommendation: Door

- Power Source: 3-horsepower

- Horsepower: 3

- Included Components: Stand

- Product Dimensions: 30.5″L x 30″W x 39.5″H

- Style: Grizzly

- Voltage: 220 Volts

- Item Weight: 394 Pounds

- Speed: 10,000 RPM

Getting Acquainted and Seamless Setup Experience

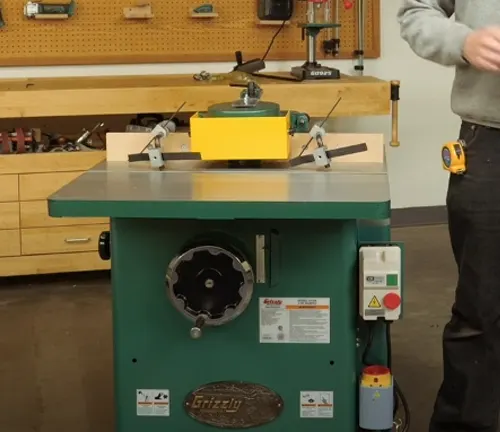

As I eagerly unpacked the Grizzly G1026, its robust build instantly commanded attention. The machine’s construction exuded a sense of durability that suggested it was engineered to withstand the rigors of diverse woodworking projects, from intricate detailing to larger-scale endeavors.

The solidity of its frame and components hinted at a tool designed for longevity, promising to be a steadfast companion in the workshop. This initial visual inspection instilled confidence in the shaper’s potential to handle a spectrum of tasks with resilience and precision. Navigating through the initial setup of the Grizzly G1026 was a pleasantly straightforward experience. The packaging included clear and concise instructions, simplifying the assembly process for even those less accustomed to intricate machinery.

Each component was thoughtfully labeled, further easing the installation and configuration process. This attention to detail in packaging and instructions not only accelerated the setup time but also showcased the manufacturer’s commitment to user-friendly design. The simplicity of the initial installation process was a noteworthy aspect for users like me who value a hassle-free introduction to a new tool, ensuring a positive start to the woodworking journey with the Grizzly G1026.

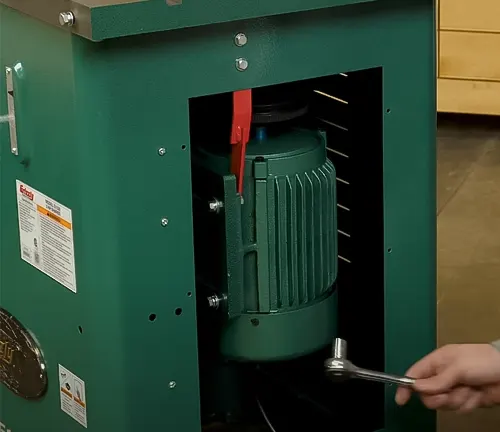

Power and Performance

The true marvel of the G1026 lies in its 3 HP motor, a powerhouse that transforms shaping tasks into a seamless experience. I put this machine through its paces with various woods, including challenging hardwoods and thick stock, and it performed admirably without any signs of bogging down.

The variable speed control emerged as a standout feature, allowing me to tailor the speed to the specific bit and material, ensuring optimal outcomes for each project. The reliability of this shaper in handling demanding tasks makes it a standout choice for woodworkers seeking both power and efficiency.

Accuracy and Control

One of the hallmarks of the G1026 is its commitment to precision and control. The fence adjustment is intuitive and locks securely in place, providing the accuracy needed for intricate shaping work. The miter gauge, a critical component for angular cuts, proved to be not only precise but also easily repeatable.

The expansive table offered substantial support for workpieces of varying sizes, contributing to the overall stability of the machine. Safety is paramount, and the adjustable guard provided an additional layer of protection, allowing me to focus on my craft with confidence. The G1026 impresses not only with its raw power but also with the thoughtful design elements that enhance the woodworker’s experience in terms of accuracy and control.

Visual Aspects

The Grizzly Industrial G1026-3 HP Shaper not only excels in functionality but also boasts a visually appealing design that reflects its commitment to craftsmanship. The machine’s sturdy frame, constructed from high-quality materials, exudes durability and reliability. The cast-iron table, with its smooth surface and precision-machined details, adds a touch of elegance to the overall aesthetic.

The thoughtful placement of controls and indicators enhances user accessibility, making adjustments seamless during operation. The blend of industrial ruggedness and a well-thought-out design gives the G1026 a distinctive visual appeal that aligns with its reputation as a top-tier woodworking tool. In any workshop setting, this shaper stands out as a testament to the marriage of form and function, adding a touch of sophistication to the practicality it brings to woodworking projects.

Proper Safety Precautions Guidelines

- Read the Manual Thoroughly: Begin by thoroughly reading and understanding the user manual provided by Grizzly Industrial. Familiarize yourself with the machine’s specifications, safety features, and operational guidelines.

- Wear Personal Protective Equipment (PPE): Always wear appropriate personal protective equipment, including safety glasses, hearing protection, and dust masks, to safeguard against potential hazards during operation.

- Secure Workpieces Properly: Ensure that workpieces are securely fastened to the table using appropriate clamps or fixtures. This prevents unexpected movements and enhances overall stability during shaping tasks.

- Adjust and Secure the Fence: Prior to operation, carefully adjust and securely lock the fence in place. A stable and well-positioned fence contributes to accurate and safe shaping.

- Use Push Sticks and Featherboards: Utilize push sticks and featherboards when working with smaller pieces or narrow stock. These accessories help maintain a safe distance between your hands and the cutting tool.

- Keep Workspace Well-Lit and Clean: Maintain a well-lit and clutter-free workspace to enhance visibility and reduce the risk of accidents. Regularly clean the machine and surrounding area to minimize dust buildup.

- Avoid Loose Clothing and Jewelry: Dress appropriately for the task, avoiding loose clothing and removing any jewelry that could get caught in moving parts. This reduces the risk of entanglement.

- Disconnect Power When Making Adjustments: Always disconnect the power source before making any adjustments or changing accessories. This prevents accidental startups during maintenance tasks.

- Do Not Override Safety Features: The G1026 is equipped with safety features designed to protect users. Do not override or bypass these features, as they play a crucial role in preventing accidents.

- Know Emergency Procedures: Familiarize yourself with emergency shutdown procedures and the location of the emergency stop button. Be prepared to respond quickly in case of any unexpected situations.

Comparable Considerations

When considering other shapers on the market, the Grizzly G1026 stands out in terms of both power and affordability. Its 3 HP motor surpasses many competitors in its class, providing a significant advantage for users tackling heavy-duty projects. The sturdy construction and precision engineering also make it a standout choice compared to similarly priced models.

Table of Comparisons and Competitive:

| Feature | Grizzly Industrial G1026-3 HP Shaper | Shop Fox W1674-2 HP Shaper |

|---|---|---|

| Motor Power | 3 HP | 2 HP |

| Spindle Speed Range | 7,000 – 10,000 RPM | 7,000 – 10,000 RPM |

| Maximum Cutter Height | 2-1/2 inches | 2 inches |

| Maximum Cutter Diameter | 5-1/2 inches | 4 inches |

| Spindle Diameters | 1/2, 3/4, 1 inch | 1/2, 3/4, 1 inch |

| Spindle Lengths | 2-3/4, 3, 3-1/2 inches | 2-3/4, 3, 3-1/2 inches |

| Spindle Capacity Under Nut | 2, 2-1/4, 2-1/2 inches | 2 inches |

| Spindle Travel | 3 inches | 2 inches |

| Table Size | 28-1/4 x 30-1/2 inches | 22 x 18 inches |

| Adjustable Spindle Speed | Yes | Yes |

| Cast-Iron Table | Yes | Yes |

| Weight | Approx. 392 lbs. | Approx. 286 lbs. |

Competitive Analysis

In the realm of woodworking shapers, the Grizzly Industrial G1026-3 HP and the Shop Fox W1674-2 HP emerge as formidable contenders with distinct features catering to different user needs. The Grizzly G1026 boasts a more powerful 3 HP motor compared to the Shop Fox’s 2 HP, offering a potential advantage in handling heavier loads and more challenging materials. Both models share a similar spindle speed range, providing flexibility for various woodworking tasks.

The G1026’s larger maximum cutter diameter and spindle capacity under the nut may be advantageous for users seeking versatility in their projects. On the other hand, the Shop Fox W1674 is a more compact option, weighing significantly less, making it potentially more suitable for users with limited space or those who prioritize portability. Ultimately, the choice between these two shapers depends on individual preferences, project requirements, and workshop constraints.

Pros and Cons

Pros

- Powerful Motor: The 3 HP motor ensures consistent and reliable performance.

- Variable Speed Control: Adaptability for different woodworking tasks.

- Sturdy Construction: The robust build guarantees durability and stability.

- Ample Table Size: The spacious cast-iron table provides excellent support for workpieces.

Cons

- Weight and Size: Due to its power and solid construction, the G1026 is on the heavier side, making it less portable.

- Learning Curve: Beginners might find the machine’s features and settings a bit overwhelming initially.

Decision Making Variables

For woodworkers prioritizing power, precision, and durability, the Grizzly Industrial G1026-3 HP Shaper is an excellent choice. The variable speed control and substantial table size make it versatile for a wide range of projects. However, if portability is a key consideration, users may need to explore more compact options.

Recommendation

After thorough testing and consideration, I confidently recommend the Grizzly Industrial G1026-3 HP Shaper as the best overall choice for serious woodworkers. Its impressive motor, variable speed control, and sturdy construction set it apart in the market. For those looking to invest in a reliable and powerful woodworking tool, the G1026 is a solid bet.

Final Thoughts

In the realm of woodworking, where precision and power are paramount, the Grizzly Industrial G1026-3 HP Shaper seamlessly combines both attributes, solidifying its status as an exceptional choice for both enthusiasts and seasoned professionals. As someone who places a premium on quality craftsmanship, I can unequivocally affirm that this shaper has not only met but exceeded my expectations, securing its position as a cornerstone within my workshop. Its robust performance, marked by a powerful 3 HP motor, aligns perfectly with the demands of intricate woodworking projects, making it an indispensable tool for anyone who values precision and power in their craft.

Frequently Asked Questions

- What makes the Grizzly Industrial G1026-3 HP Shaper stand out in terms of performance?

The G1026 distinguishes itself with a robust 3 HP motor, providing exceptional power and efficiency for a wide range of woodworking tasks. - Is the spindle speed adjustable on the G1026?

Yes, the G1026 features variable speed control, allowing users to adjust the spindle speed between 7,000 and 10,000 RPM for optimal results based on the task at hand. - How does the G1026 ensure precision in shaping work?

The shaper offers a high level of accuracy with an easily adjustable fence, a precise and repeatable miter gauge, and a spacious cast-iron table for stable support. - What safety features does the G1026 incorporate?

The G1026 prioritizes safety with a fully-adjustable guard to protect users during operation, ensuring a secure working environment. - Can the G1026 handle hardwoods and thick stock effectively?

Absolutely, the 3 HP motor of the G1026 is designed to handle challenging materials, providing consistent performance even with hardwoods and thick stock. - Is the G1026 suitable for beginners, or does it have a steep learning curve?

While it offers advanced features, the G1026 is designed with user-friendliness in mind. Beginners may find it approachable, and the clear instructions aid in the initial learning process. - What are the spindle diameters available on the G1026?

The G1026 comes with three spindle diameters: 1/2, 3/4, and 1 inch, offering versatility for various shaping applications. - Can the G1026 be used for creating intricate profiles and moldings?

Yes, the G1026 is well-suited for creating intricate profiles and moldings, thanks to its powerful motor and precise controls. - Is the G1026 compatible with mobile bases for easier mobility in the workshop?

The G1026 is not compatible with the D2260A Mini Mobile Base, but it can be paired with the T28000 Bear Crawl Heavy-Duty Mobile Base for increased mobility. - What certifications does the G1026 hold?

The G1026 is certified to meet CSA (Canadian Standards Association) and UL (Underwriters Laboratories) standards, ensuring adherence to safety and quality regulations.

We value your input! Feel free to share your firsthand experiences and insights regarding the Grizzly Industrial G1026-3 HP Shaper in the comments section. Your unique perspective can contribute to a wealth of information, assisting fellow woodworkers in making well-informed decisions for their craft. Let’s build a community of shared knowledge and expertise!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment