How To Speed Up Your Log Splitter

- February 19, 2024

- 0 comment

Improving the efficiency of a log splitter, especially an older model with longer cycle times, can significantly enhance its performance. The primary goal in speeding up a log splitter is to reduce the cycle time – the period it takes for the splitting ram to extend, split the log, and retract. This review details a practical, DIY approach to achieving faster cycle times by modifying the log splitter to stop the ram’s retraction at a predetermined point, thus saving time both in the forward and retraction strokes.

List of How To Speed Up Your Log Splitter:

- Cycle Time Reduction

- Power (Tons)

- Log Size Capacity

- Modification Steps

- Demonstration and Usage

- Additional Tips

Common Problem For Log Splitter

A common challenge faced by operators of aging log splitters is the excessive cycle time required for the machine’s ram to execute its complete operational cycle, encompassing both the extension towards and retraction from the log. This inefficiency predominantly stems from the use of smaller hydraulic pumps in these older models, components that were not engineered with rapid movement in mind.

As a result, the machinery operates at a pace that is markedly slower than desired, impacting productivity and efficiency during the log splitting process. This inherent design limitation poses a significant drawback for users seeking to optimize their workflow and reduce the time spent on each log splitting task.

The Solution For Log Splitter

The solution involves a clever modification to the log splitter to reduce the ram’s travel distance, specifically its retraction length. By stopping the ram at around 16 inches or at a suitable point before it fully retracts, the cycle time is significantly reduced. Here’s a step-by-step breakdown of the modification process:

1. Cycle Time Reduction

One of the first aspects I focused on was reducing cycle time—the time it takes for the splitter’s ram to extend, split the log, and retract. I found that models with a cycle time of around 10-15 seconds offered a sweet spot, balancing speed and safety. Reducing this time was key to enhancing efficiency, especially when dealing with larger volumes of wood.

2. Power (Tons)

Power is another critical factor. While a 10-ton splitter worked wonders for smaller, softer logs, I discovered it struggled with the knottier, harder wood. Upgrading to a 25-ton model transformed my experience, allowing me to tackle a wider range of log types with ease.

3. Log Size Capacity

Initially, I underestimated the importance of the splitter’s maximum log size capacity. However, I quickly realized that having to manually trim logs to fit the machine’s limits was a significant time drain. Choosing a splitter that could accommodate larger logs (both in length and diameter) minimized prep time and boosted overall efficiency.

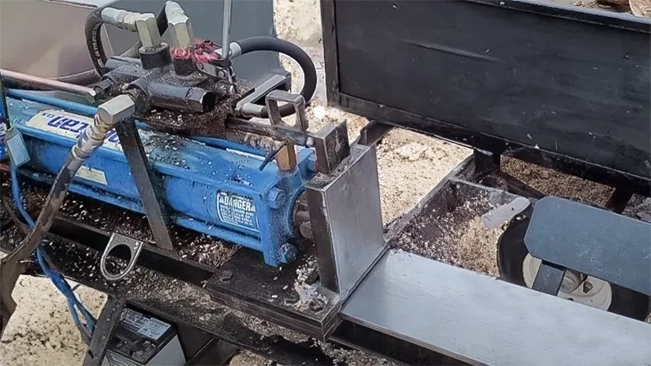

4. Modification Steps

- A block is welded onto the splitter at a point where the ram should stop.

- An old copper piping, previously used for an airline around the shop, is attached to the block with a fitting. This serves as a guide or stopper.

- A piece of tubing that fits over the copper piping is used to slide on it, creating a movable stop.

- To trigger the stop, a piece of square tubing is cut and welded to the frame at an appropriate height. A bolt with a welded nut is used to create an adjustable T-handle, allowing the stop position to be locked in place.

5. Demonstration and Usage

- The modification allows for adjustment of the stop point based on the size of the log, providing flexibility.

- This adjustment significantly saves time as the ram no longer needs to retract fully, reducing both the forward and backward cycle times.

- A demonstration shows how easily the splitter can be adjusted to stop at the desired point, showcasing the effectiveness of this simple yet innovative modification.

Pros and Cons Based on Experience

- Electric Splitters: They’re quiet, environmentally friendly, and perfect for light-duty tasks. However, their performance can falter with tougher jobs, and their reliance on a power source limits mobility.

- Gas-Powered Splitters: These beasts can handle almost anything you throw at them, with superior power and mobility. The downside? They’re louder, emit fumes, and require more maintenance.

- Manual Splitters: Ideal for those seeking a workout or with minimal splitting needs. They’re the most affordable and portable option but require considerable physical effort and time.

Additional Tips

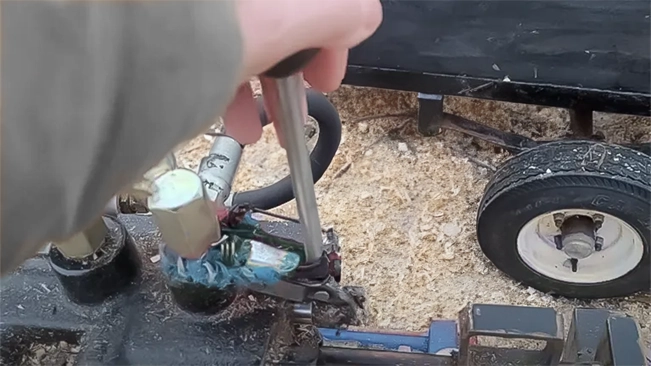

- It’s suggested to weld a tube underneath the apparatus to control the guide rod from bouncing around during operation, ensuring stability and efficiency.

- Ensuring the guide rod is long enough to not slip out of the controlling tube is critical for the modification’s success.

Decision Making Variables For User’s

When considering how to expedite the operation of a log splitter, users must evaluate a variety of decision-making variables. These include assessing the current cycle time and identifying the maximum log size typically split, to determine the optimal point for the ram to stop. The power source and capacity of the hydraulic system must be taken into account to ensure that any modifications do not exceed the system’s capabilities.

The type of wood being split is also crucial, as harder woods may require a full cycle for effective splitting. Additionally, users should consider their mechanical skill level and the tools available for making modifications, as well as the potential impact on the machine’s warranty and overall longevity. Safety is paramount; thus, any changes should not undermine the splitter’s built-in safety features. Lastly, users should factor in the cost-effectiveness of modifications versus investing in a newer, faster model.

Final Conclusion

Speeding up your log splitter involves a blend of choosing the right equipment and understanding how to optimize its performance. Through my journey, I’ve learned that while there’s no one-size-fits-all solution, focusing on key factors like cycle time, power, and log size capacity can significantly enhance efficiency. Whether you’re a casual user or someone with extensive needs, the right log splitter can transform this task from a time-consuming chore into a quick, even enjoyable, part of your routine.

Frequently Asked Questions

- What causes slow cycle times in older log splitters?

Slow cycle times in older log splitters are often due to the smaller hydraulic pumps that these machines are equipped with, which were not designed for high-speed operation. This results in longer durations for the ram to complete its forward and backward movements. - Can I modify my log splitter to improve its speed?

Yes, you can modify your log splitter to improve its speed. One effective modification is to create a mechanism that stops the ram’s retraction at a predetermined point, reducing the distance and time it takes for the ram to cycle. - What materials do I need for speeding up my log splitter?

To speed up your log splitter, you might need materials such as a block of metal for welding onto the splitter as a stop point, copper piping or similar materials for creating a guide or stopper, and tubing to fit over the guide. Additionally, tools for welding and cutting metal will be necessary. - How does reducing the retraction distance of the ram save time?

Reducing the retraction distance of the ram saves time by decreasing the overall cycle time. Since the ram does not have to travel back to its original starting point, both the forward and backward movements are shortened, leading to quicker operation cycles. - Is it necessary to have welding skills to make these modifications?

While having welding skills is beneficial for making these modifications, some adjustments might be made without welding by using alternative fastening methods. However, welding provides a more durable and permanent solution. - Will modifying my log splitter void its warranty?

Modifying your log splitter could void its warranty. It’s important to check your warranty terms before proceeding with any modifications. Consider consulting with the manufacturer or a professional if unsure. - How do I determine the optimal stopping point for the ram?

The optimal stopping point for the ram depends on the average size of the logs you are splitting. You should set the stop point to accommodate the maximum size you typically split, ensuring the ram stops just beyond that point to maximize efficiency. - Can these modifications lead to wear and tear on the log splitter?

Any modification has the potential to affect the wear and tear on your log splitter, especially if it alters the machine’s operation significantly. Ensuring that modifications are done correctly and maintaining the splitter well can help mitigate these effects. - What safety precautions should I take when modifying my log splitter?

Always disconnect the power supply before starting any modifications to prevent accidental operation. Wear appropriate protective gear, such as gloves and eye protection, when welding or cutting. Ensure all modifications do not compromise the machine’s stability or safety features. - Can I revert the modifications if needed?

Depending on the modification, some changes may be reversible, especially if additional components are bolted on rather than welded. However, modifications involving significant alterations to the machine’s structure or operation may not be easily reversible without professional help.

We’re eager to hear from you! Share your personal experiences and tips on how you’ve managed to speed up your log splitter. Whether it’s through modifications, adjustments, or innovative techniques, your insights could greatly benefit fellow enthusiasts looking to enhance their log splitter’s efficiency. Drop your stories and advice in the comments section below. Your contribution could be the key to helping others achieve quicker, more efficient log splitting!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment