Makita XDT11Z 18V Impact Driver Review

- April 17, 2024

- 0 comment

Today, we’re diving into the Makita XDT11Z 18V 1/4-inch brushed impact driver. This tool brings together functionality and durability in a compact form, making it a must-have for both professional and DIY projects. Let’s take a closer look at what makes this impact driver stand out.

Specifications of Makita XDT11Z 18V Impact Driver Review

- Hex Shank: 1/4″

- No Load Speed (variable speed): 0 – 2,900 RPM

- Impacts Per Minute (variable speed): 0 – 3,500 IPM

- Maximum Torque: 1,460 in.lbs. / 165 N•m

- Speed Power Selection: 1

- Battery Type: 18V LXT® Lithium-Ion

- Overall Length: 5-3/8″

- Net Weight (with battery): 3.3 lbs.

- Power Type: Cordless

- Form Factor (LXT): 18V LXT®

- Motor Type: Brushed

- Shipping Weight: 2.52 lbs.

Tool Overview

Starting from the base, the XDT11Z features a slot for 18V Makita batteries and a handy belt clip attachment hole for easy portability. The ergonomic design includes a hand grip with a rubbery texture that provides a secure and comfortable hold during use.

Moving upwards, we find the forward/reverse locking switch along with a variable speed trigger that enhances the tool’s usability. The LED light near the trigger isn’t the brightest but does an adequate job illuminating the work area, which is a nice touch for working in dim environments.

Bit Insertion and Build Quality

The quick insert 1/4 inch bit chuck is a standout feature, allowing for easy and swift bit changes which enhance workflow efficiency. The overall build quality of the XDT11Z feels superior, especially when compared to other models like the Ryobi P238 brushless impact driver. The Makita’s solid feel in hand indicates robust construction, likely to withstand rigorous use.

Performance and Operation

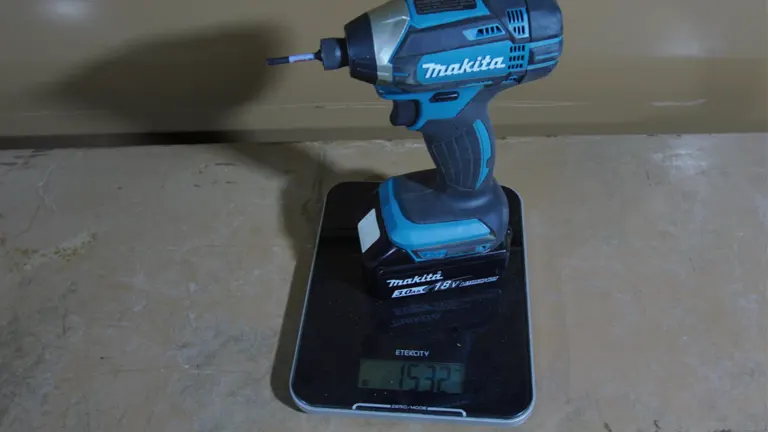

Weighing approximately 1,532 grams with a 3 amp-hour battery, this tool is impressively compact yet powerful. It supports up to 3,500 impacts per minute (IPM) and achieves 0-2,900 rotations per minute (RPM), delivering up to 1,460 in.lbs. of torque. Although compact, it outmatches many larger and more cumbersome tools in performance.

My Experience

During operation, the XDT11Z feels quick and responsive. However, the variable speed trigger does lack some finesse, with speeds accelerating a bit too quickly for delicate screw driving. This can make precision work tricky without pre-drilled holes, as there isn’t a significant variation in speed control.

Despite this, the impact driver performs admirably with basic fastening tasks and can handle drilling duties with hex bits. It’s particularly effective in driving screws rapidly, although it could benefit from additional speed settings for enhanced control.

Practical Applications

This impact driver shines in general construction, furniture assembly, and other projects where fast and reliable screw driving is necessary. While it may not be the best choice for tasks requiring extremely delicate screw placements due to its speed intensity, it excels in environments where speed and efficiency are valued.

Price Point

At $83.30, the Makita XDT11Z offers excellent value. It combines a robust build and satisfactory performance at a price point that is hard to beat, especially within the 18V tool category. It’s a solid choice for those already invested in the Makita battery ecosystem.

Pros and Cons of Makita XDT11Z 18V Impact Driver

Pros

- Makita is renowned for its robust construction, and the XDT11Z is no exception. It boasts a durable design with a heavy use of rubber and metal, providing a reassuring feel during use.

- The hand grip is rubberized, offering a comfortable and firm hold, which is crucial during extended use periods.

- Although not the smallest in the market, its size is quite practical, especially considering the balance it offers with the 18V system it employs.

- It uses the universal 18V battery, which is compatible with many tools, making it a versatile choice for those already invested in the Makita ecosystem.

- The quick insert chuck is user-friendly, allowing bits to be changed swiftly and effortlessly without needing to manipulate a release ring, enhancing productivity.

- The built-in cooling system is designed to prevent overheating, ensuring the tool performs optimally even under heavy use.

Cons

- One significant drawback is the lack of finer control over speed settings. The impact driver tends to start too quickly, which can be a disadvantage when working with delicate screws or materials.

- In an era where brushless motors are becoming standard due to their efficiency and longevity, the brushed motor of the XDT11Z feels a bit outdated.

- Unlike some of its competitors, this model lacks a speed selection switch. This feature can be very useful for matching the speed to the task at hand, and its absence is felt particularly when a job requires precision.

- While it includes an LED light, it’s not the brightest, which might not be sufficient in poorly lit environments.

Maintenance of Makita XDT11Z

As someone who frequently uses the Makita XDT11Z impact driver, I’ve learned a few maintenance routines that are essential to keep this tool running smoothly. Here’s how I approach the upkeep:

- Cleaning After Use: After wrapping up my work, I always take a moment to clean off the impact driver. A soft brush or a blast of compressed air gets rid of any sawdust or debris, especially around the vents where it can block airflow.

- Battery Maintenance: I pay special attention to the battery contacts. Dirt or corrosion can cause power issues, so I wipe them down regularly with a dry cloth to maintain a solid connection.

- Lubrication Is Key: Every once in a while, I apply a drop of light machine oil to the chuck and other moving parts. It’s crucial not to go overboard; just enough to keep things moving without attracting extra grime.

- Inspecting the Bits: Dull or worn bits make the driver work harder, which isn’t good for the motor. I check my bits frequently and replace them if they’re not cutting it anymore.

- Proper Battery Usage: I store my batteries in a cool, dry place and try to keep them from getting too low before recharging. This helps prolong their life.

- Safe Storage: When I’m not using the driver, I store it in a protective case or on a shelf out of harm’s way. It’s an easy step that helps avoid any accidental damage.

- Listening for Signs: I’m always on the alert for any odd sounds or excessive heating when using the tool. These could indicate something’s wrong internally, and catching them early can save a lot of hassle.

- Routine Check-Ups: Every now and then, especially if the tool’s been through a lot, I’ll take it in for a professional service. They check everything inside out and make sure it’s in top shape.

Staying on top of these maintenance tasks not only extends the life of my Makita impact driver but also ensures it’s ready and reliable for every job I need it for.

Comparative Analysis: Makita XDT11Z vs. Ryobi P238

| Feature | Makita XDT11Z | Ryobi P238 |

|---|---|---|

| Motor Type | Brushed | Brushless |

| Speed Control | No variable speed options; starts fast | Three speed settings for better control |

| Weight (with battery) | 1532 grams | Not specified; generally comparable |

| Battery System | 18V LXT | 18V One+ |

| Build Quality | High-quality materials; solid feel | Solid build with more plastic components |

| Ergonomics | Comfortable, rubberized grip | Ergonomic design with good hand fit |

| LED Light | Basic; not very bright | Powerful and better positioned |

| Bit Insertion | Quick bit chuck without release ring | Quick bit chuck with easy handling |

| Additional Features | Basic | Magnetic tray, belt clip, enhanced LED |

| Best For | Durable, straightforward tasks | Tasks requiring precision and flexibility |

| Price Range | $95.99 | $120.00 |

Summary: The Makita XDT11Z and Ryobi P238 impact drivers both offer robust performance with key differences that cater to varying user needs. The Makita, with its brushed motor and lack of variable speed settings, provides a straightforward, durable option, ideal for users who prefer a simple, reliable tool and are already invested in the Makita battery system.

In contrast, the Ryobi P238 features a more efficient brushless motor and boasts three speed settings, offering enhanced control and flexibility for precision tasks. Additionally, the Ryobi includes extra features like a stronger LED light and a magnetic tray, making it a potentially better value for those who need a versatile tool. Both models are similarly priced, but the Ryobi may offer slightly more for your money due to its advanced functionalities and motor technology.

Conclusion

The Makita XDT11Z 18V Impact Driver stands out for its compact design, solid construction, and effective performance. While it lacks some advanced features like multiple speed settings, its price-to-performance ratio makes it an attractive option for anyone looking for a reliable impact driver. Whether you’re tightening bolts or assembling furniture, this tool is designed to handle a variety of tasks efficiently.

FAQs

- Can the Makita XDT11Z impact driver be used for automotive work such as changing tires or working on engines?

While the Makita XDT11Z is primarily designed for driving screws and fasteners in woodworking and construction, it can be used for light automotive tasks. However, for high-torque requirements like changing car tires, a dedicated impact wrench is recommended. - Is it possible to use the Makita XDT11Z in wet conditions?

The Makita XDT11Z is not waterproof or specifically designed for use in wet conditions. Exposure to moisture can damage the electronic components. If it must be used in damp environments, precautions should be taken to minimize water exposure. - How does the LED light feature impact battery life when used frequently?

The LED light on the Makita XDT11Z has minimal impact on battery life. It is designed to be energy-efficient, providing adequate light without significantly draining the battery. - Can the Makita XDT11Z be used with accessories intended for impact wrenches?

Accessories specifically designed for impact wrenches, such as sockets, typically require a different chuck interface and may not be compatible with the 1/4 inch hex chuck of the Makita XDT11Z. Always ensure accessories are suitable for the tool’s specifications. - What are the electromagnetic interference characteristics of the Makita XDT11Z? Does it affect other electronic devices?

The Makita XDT11Z is designed to comply with standard electromagnetic compatibility regulations and typically does not interfere with other electronic devices. However, use near sensitive electronic equipment should be monitored for any potential interference. - Is there a recommended technique for using the variable speed trigger to maximize precision in sensitive materials?

To maximize control when working with sensitive materials, start the trigger slowly and increase the speed gradually. This allows for better control of the fastener and reduces the risk of damage to the material. - How does the vibration level of the Makita XDT11Z compare to other impact drivers in the market?

The Makita XDT11Z is engineered to minimize vibration through its ergonomic design and internal components. However, compared to newer models with brushless motors and advanced vibration control, it may exhibit slightly higher vibration levels.

We hope you found this deep dive into the Makita XDT11Z impact driver helpful! Whether you’re a seasoned pro or just starting out, we’d love to hear from you. Have you used this tool on a project? Maybe you’ve got some tips, or perhaps there’s something we missed? Drop us a comment below and share your thoughts and experiences. Your input helps us all learn and grow. Don’t forget to share this article with your fellow tool enthusiasts!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment