Powermax45 XP Plasma Cutter Review

- April 5, 2024

- 0 comment

Creating an in-depth review of the Hypertherm Powermax45 XP Hand System involves evaluating several aspects such as its design, performance, versatility, ease of use, and overall value. This plasma cutting system is designed for both industrial and hobbyist use, striking a balance between performance and portability.

We’ve got your welding covered! Find comfy, Best welding gloves, Best welding carts, Best welding jackets, plus top picks for Best TIG Welder, Best MIG Welder & Best ARC Welders – all without breaking the bank!

Specifications

- Product Type: Plasma Cutting System

- Maximum Cut Capacity: 5/8″ (16 mm) for clean cuts; 1 1/8″ (29 mm) for severance cuts

- Power Supply: Advanced inverter technology with auto-voltage (110V – 240V) adaptation

- Output Current: 10A – 45A

- Duty Cycle: 50% at 45A, 200-240V

- Dimensions: Approximately 17.4″ x 6.8″ x 13.7″ (442 mm x 173 mm x 348 mm)

- Weight: 37 lbs (16.8 kg) (without torch)

- Safety Features: Safety trigger, thermal overload protection

- Energy Efficiency: Enhanced with inverter technology

Design and Build Quality

The Hypertherm Powermax45 XP Hand System distinguishes itself through its superior build quality, showcasing a blend of ruggedness and technological sophistication that’s tailored for the rigors of industrial work. Its sturdy metal exterior and carefully sealed components are designed to withstand the harsh conditions often encountered in professional metal cutting environments, ensuring that it remains reliable over years of service.

The compactness of the unit does not compromise its power, offering users an optimal balance between performance and ease of transport. Furthermore, the hand torch, a critical interface between the machine and its operator, is meticulously crafted with ergonomics in mind. This design philosophy ensures that operators can achieve precise cuts with minimal effort, reducing the risk of strain over long periods of operation, thereby enhancing productivity and safety.

Smart Sense™ Technology

The Hypertherm Powermax45 XP Hand System Smart Sense™ Technology intelligently regulates the gas pressure to match the specific requirements of the torch and the material being cut, guaranteeing peak performance and superior cut quality. This innovative feature not only maximizes the efficiency of each cut but also significantly extends the lifespan of consumables, offering both economic and operational advantages.

Ergonomic Hand Torch

The ergonomic hand torch of the Hypertherm Powermax45 XP is meticulously engineered to prioritize operator comfort and control, incorporating a grip that aligns with the natural contours of the hand. This thoughtful design minimizes user fatigue and enhances precision during prolonged cutting tasks, making it an indispensable tool for professionals seeking both efficiency and comfort in their cutting operations.

Wide Range of Consumables

Equipped with a diverse array of consumables, each tailored for specific cutting tasks, significantly broadening the system’s application across a multitude of projects and materials. This flexibility is complemented by the user-friendly design of the consumables, which can be quickly and easily replaced, minimizing downtime and sustaining optimal productivity levels for users in demanding industrial environments.

Performance and Capabilities

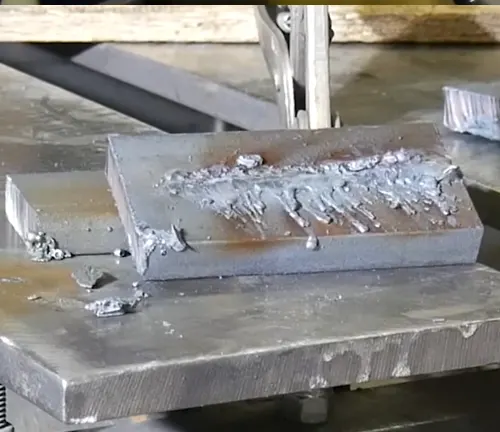

Equipped with advanced inverter technology, the Powermax45 XP delivers impressive cutting and gouging capabilities. It can cleanly cut through metals up to 5/8″ (16 mm) thick, with severance capability up to 1 1/8″ (29 mm), showcasing its versatility across various materials and applications. The system’s high-duty cycle ensures it can handle the demands of both heavy industrial jobs and lighter, fine-detail work.

The Hypertherm Powermax45 XP Hand System also features Smart Sense™ technology, which automatically adjusts the gas pressure according to the cutting mode and torch length, optimizing performance. This feature not only enhances the cut quality but also extends consumable life, providing cost savings over time.

Versatility

One of the Hypertherm Powermax45 XP’s strengths is its versatility. It’s equipped with multiple cutting modes and consumables that can be easily swapped to match different cutting requirements, from fine-feature cuts to maximized productivity for faster cutting speeds. The system is also capable of precision gouging, offering a valuable tool for welding preparation and repairs.

Ease of Use

Hypertherm has designed the Powermax45 XP to be user-friendly. Its intuitive interface allows for quick setup and operation, even for users with limited plasma cutting experience. The drag-cutting technology enables users to achieve precise cuts without the need for a pilot arc, reducing the learning curve.

Pros and Cons

Pros

- Suitable for a wide range of cutting tasks.

- Clean cuts with minimal finishing required.

- Optimizes gas pressure for performance and consumable life.

- Designed for comfort and easy operation.

- Compact and lightweight for ease of transport.

- Uses advanced inverter technology for efficient operation.

- Built to withstand rigorous use.

Cons

- Represents a significant initial investment.

- Features and settings may initially overwhelm beginners.

- Needs access to a suitable power source.

- Regular replacement of consumables adds to ongoing costs.

- May be cumbersome for some users or applications.

Safety and Maintenance

Safety

- Wear Proper PPE Always wear protective gear, including eye protection, gloves, and fire-resistant clothing, to shield against sparks, metal fragments, and UV radiation.

- Check for a Safe Environment Ensure the working area is free of flammable materials and that there’s adequate ventilation to dispel fumes and smoke.

- Use Correct Settings and Consumables Match the cutting settings and consumables to the material and thickness to prevent excessive sparks or damage to the tool.

- Maintain a Proper Distance Keep the torch at the recommended distance from the workpiece to prevent accidents and ensure clean cuts.

- Follow Lockout/Tagout Procedures Ensure the machine is properly turned off and disconnected from the power supply when not in use or during maintenance.

Maintenance

- Regularly Check and Replace Consumables Inspect consumables regularly for wear and replace them as needed to maintain cut quality and machine performance.

- Clean the Machine Keep the machine clean from dust and debris, especially around the ventilation areas, to prevent overheating and ensure proper airflow.

- Inspect Electrical Cords and Connections Regularly check for any signs of wear or damage to the power cords and connectors to prevent electrical hazards.

- Update Software If applicable, keep the machine’s software up to date to ensure optimal performance and access to new features.

- Scheduled Inspections Conduct regular inspections of the torch, lead cables, and machine components for signs of wear or damage, replacing parts as necessary.

About This Item

- High Performance Cutting The Hypertherm Powermax45 XP delivers clean cuts through metals up to 5/8″ thick and offers severance cuts up to 1 1/8″, supporting a wide range of cutting applications with precision and efficiency.

- Smart Sense™ Technology Features advanced Smart Sense™ technology that automatically adjusts gas pressure for optimal performance, enhancing cut quality and extending consumable life.

- User-Friendly Design Designed for ease of use with an intuitive interface and ergonomic hand torch, making it suitable for users of all experience levels, from beginners to seasoned professionals.

- Portability and Durability Combines a compact, lightweight design with robust construction, making it easy to transport for on-site jobs while being durable enough to withstand the rigors of heavy industrial use.

Comparison Table

| Feature | Hypertherm Powermax45 XP | Miller Electric Spectrum 625 X-TREME |

|---|---|---|

| Maximum Cut Capacity | 5/8″ (16 mm) clean cut, 1 1/8″ (29 mm) severance | 5/8″ (16 mm) clean cut, 7/8″ (22 mm) severance |

| Technology | Smart Sense™ for automatic gas adjustment | Auto-Refire™ Technology for cutting expanded metals |

| User Interface | Intuitive with advanced controls | LCD display with Auto-Line technology and MVP adapters |

| Portability | Compact and lightweight (37 lbs without torch) | Extremely portable with a protective case (21 lbs) |

| Ergonomics | Ergonomic hand torch design | XT40 torch with ergonomic design and flexible cable |

| Energy Efficiency | High with advanced inverter technology | High efficiency with inverter design |

| Durability | Built for heavy industrial use | Durable with a protective case for extreme conditions |

| Maintenance & Safety Features | Easy-to-replace consumables, safety triggers | Protective case, Wind Tunnel Technology to prevent abrasive dust from damaging internal components |

| Versatility | Wide range of consumables for different tasks | Can cut through various materials and thicknesses with precision |

| Support and Warranty | Comprehensive warranty and support network | 3-year warranty with access to Miller’s extensive support network |

Miller Electric Spectrum 625 X-TREME Specifications

- Product Type: Portable Plasma Cutting System

- Maximum Cut Capacity: 5/8″ (16 mm) clean cut; 7/8″ (22 mm) severance cut

- Input Voltage: 110/115/120V and 220/230/240V with MVP (Multi-Voltage Plug)

- Output Current: 15A to 40A

- Duty Cycle: 50% at 40A (240V), 20% at 40A (120V)

- Dimensions: 13.25″ x 5.5″ x 9″ (337 x 140 x 229 mm)

- Weight: 21 lbs (9.5 kg) with torch

- Torch Type: XT40 hand-held torch with a 12-ft. (3.7 m) cable

Review of Visual Aspects

The Hypertherm Powermax45 XP Hand System boasts a compact and robust design that reflects its industrial-grade capabilities while maintaining a user-friendly interface. Its ergonomic hand torch is designed for precision and comfort, enabling prolonged use without fatigue, a testament to thoughtful engineering.

The visual cues on the machine, including clear labeling and intuitive controls, enhance ease of use, making it accessible to both experienced professionals and newcomers to plasma cutting. The system’s aesthetics, characterized by Hypertherm’s signature color scheme and rugged construction, not only appeal to the eye but also promise durability and reliability, encapsulating the essence of practical design in the demanding environments it’s built for.

Value and Support

While the Hypertherm Powermax45 XP is an investment, its durability, performance, and versatility offer significant value over time. Hypertherm’s comprehensive warranty and customer support network provide additional value, ensuring that users can maximize their investment through prompt service and support.

Conclusion

The Hypertherm Powermax45 XP Hand System is a highly capable, versatile, and user-friendly plasma cutting tool that suits a wide range of applications, from industrial fabrication to creative metalworking projects. Its combination of performance, ease of use, and support makes it a valuable addition to any workshop or job site, offering the reliability and quality expected from Hypertherm products. Whether for heavy-duty cutting tasks or precise detailing, the Powermax45 XP stands out as a top choice for professionals and hobbyists alike.

Frequently Asked Questions

- What materials can the Powermax45 XP cut?

It can cut steel, stainless steel, aluminum, brass, and copper. - How thick can the Powermax45 XP cut?

It offers a 5/8″ clean cut and 1 1/8″ severance cut capability. - Does it come with a warranty?

Yes, it includes a comprehensive warranty. Specific terms can vary, so check with Hypertherm or your distributor. - Can the Powermax45 XP be used for gouging?

Yes, it is equipped with gouging capabilities for metal removal and weld preparation. - Is it portable?

Yes, it’s designed for portability, weighing 37 lbs without the torch. - What power supply is needed for the Powermax45 XP?

It operates on an auto-voltage system (110V – 240V), adapting to any standard power supply. - What is Smart Sense™ technology?

Smart Sense™ automatically adjusts the gas pressure according to the cutting mode and torch length, optimizing performance. - How can I maintain the consumables?

Regular inspection and replacement when worn are recommended. The system alerts you when efficiency drops due to consumable wear. - Can the Powermax45 XP be used with a CNC table?

Yes, it’s fully capable of CNC integration for automated cutting processes. - Where can I purchase consumables?

Consumables are available through Hypertherm’s network of distributors and online retailers.

We’re eager to hear from you! Share your personal experiences and insights on the Hypertherm Powermax45 XP Hand System in the comments section below. Whether it’s about your cutting projects, the system’s performance, or any tips you’ve discovered, your feedback can guide fellow fabricators and hobbyists in making informed decisions. Let’s create a valuable resource together!

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment