Types of Chainsaw Chains and How to Choose

- January 4, 2024

- 6 comment

Choosing the right chainsaw chain is essential for safety, efficiency, and performance. Chains come in different types full chisel, semi-chisel, and skip chains each suited for specific cutting tasks. Full chisel chains cut fast but dull quickly, semi-chisel chains stay sharp longer and offer better control, while skip chains reduce drag for large cuts. If you’re unsure which to use, selecting the right chain depends on your saw, wood type, and cutting conditions. This guide will help you understand chainsaw chain types and how to choose the best one for your needs.

Understanding the Chainsaw Chain

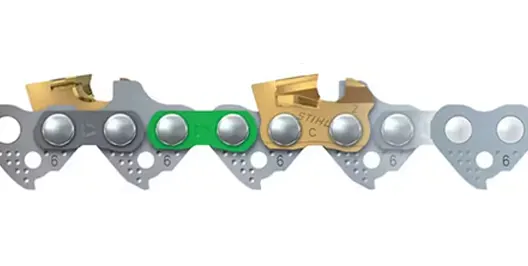

To choose the best chainsaw chain, you first need to understand its components and how they affect cutting performance. A chainsaw chain is more than a simple metal loop it’s a system designed for efficient cutting, durability, and safety.

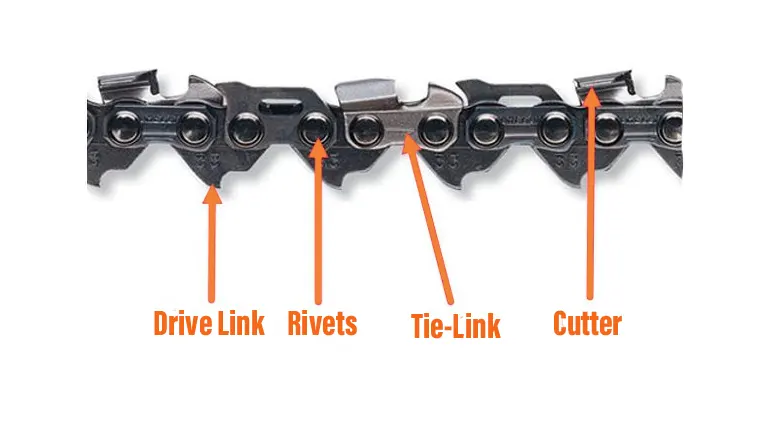

Components of a Chainsaw Chain

- Cutters – The sharp teeth that determine cutting speed and efficiency.

- Drive Links – Fit into the guide bar to ensure smooth movement.

- Tie Links – Hold everything together for chain stability.

- Rivets – Allow the chain to flex and rotate properly.

Essential Specifications for Chain Selection

Pitch

Pitch is the distance between three consecutive rivets divided by two. It affects how the chain fits your saw’s sprocket and bar. Common sizes include 1/4″, .325″, 3/8″, and .404″, with larger pitches for heavy-duty tasks.

Drive Links

Drive links are the small metal tabs that fit into the chainsaw bar’s groove. The number of drive links must match your saw’s guide bar exactly to ensure a proper fit.

Gauge

Gauge refers to the thickness of the drive links where they sit in the guide bar. Common sizes are .043″, .050″, .058″, and .063″.

Bar Length

While not a chain component, your chainsaw bar length dictates the correct chain size. The chain must be designed for the exact length of your guide bar.

Understanding Chainsaw Chain Types: From Cutting Teeth to Specialty Chains

Types of Cutting Teeth

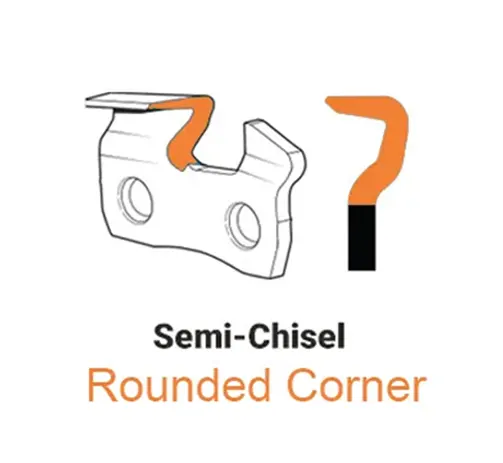

Semi-chisel cutters are ideal for homeowners, offering longer sharpness, easier sharpening, and reduced kickback for safer cutting. While they cut slower than full-chisel cutters, they are more durable and handle dirty or frozen wood better, making them a versatile and low-maintenance choice for general chainsaw use.

Full chisel chainsaw chains are ideal for commercial users and experienced operators due to their sharp, square-cornered cutters that bite deep into wood for fast, aggressive cuts. These chains excel in high-speed cutting tasks, making them perfect for heavy-duty jobs. However, they come with trade-offs, including a higher risk of kickback, quicker dulling especially in dirty conditions and a more demanding sharpening process.

Specialty Chains

Low Profile (Low Pro) Chains

Low-profile chains are designed for electric chainsaws and low-horsepower models, featuring shorter cutters that make shallower cuts. These chains are lighter, safer, and easier to control, making them ideal for beginners, casual users, and light-duty cutting tasks.

Narrow Kerf Chains

The primary benefit of narrow kerf chains is their ability to remove less wood, which in turn decreases friction and enhances the cutting speed. This feature is particularly beneficial for chainsaws with lower power, where maximizing efficiency is crucial.

Low-Kickback Chains

Specifically designed for enhanced safety, Low-kickback chains feature additional metal that smooths the transition around the bar’s nose. This design greatly reduces the risk of kickback, making these chains well-suited for general yard work. However, they do have limitations, such as restricting certain cutting techniques like bore or plunge cuts.

Ripping Chains

Primarily used for milling or cutting along the grain of a log, ripping chains are characterized by cutters set at a lower angle. This design allows them to produce finer and less aggressive cuts, making them ideal for specific types of wood cutting, particularly when precision is necessary.

Understanding Different Chainsaw Chain Configurations

- Semi Skip Chains: The semi skip chain offers a middle ground between standard and full skip configurations. In a semi skip chain, the arrangement of the teeth is a mix of the patterns found in standard and full skip chains. This design provides a balance of flexibility in cutting, making it a versatile choice for various applications. However, it’s important to note that semi skip chains are less popular compared to standard and full skip chains. Their specific use-case scenario often falls into a niche category, where the user requires a chain that strikes a balance between smooth cutting and reduced drag, without the specific advantages or drawbacks of the standard or full skip configurations.

- Full Skip Chains: Full skip chains are designed with a cutter placed every third drive length. This unique arrangement significantly reduces the chain’s drag, making these chains ideal for use with larger bars and saws typically found in more demanding, professional environments. The reduced number of cutting teeth means there’s less likelihood of the chain clogging during heavy-duty cutting. However, this advantage comes with certain drawbacks, such as an increased risk of kickback and a tendency for higher vibration during use. These factors make full skip chains more suited to experienced users who require chains for large-scale or intense cutting tasks.

- Standard Chains: Standard chains are characterized by having a cutting tooth on every other link. This configuration is particularly noted for providing smooth cutting and a high degree of versatility, which is essential for various cutting tasks. Standard chains are suitable for use with chainsaw bars up to 24 inches in length. This type of chain is often preferred for its balance between cutting efficiency and safety, making it a popular choice for both professional and casual users.

Each of these chain types serves a specific purpose and is optimized for different cutting conditions and chainsaw types. When selecting a chainsaw chain, it’s crucial to consider the nature of the work, the type of saw being used, and the user’s experience level to ensure optimal performance and safety.

Can a chainsaw chain be put on backwards?

A chainsaw chain can indeed be installed backwards, a common mistake if one is not cautious during assembly. Chainsaw chains have a designated direction for proper operation, and overlooking this detail can result in the chain being mounted in reverse, leading to ineffective cutting and potential safety hazards. It’s crucial to ensure the chain’s orientation aligns correctly with the manufacturer’s specifications to guarantee efficient and safe operation.

Conclusion

Understanding the nuances of chainsaw chains is essential for selecting the right chain for your task. Whether you’re a homeowner doing yard work or a professional in lumber, the right chain not only ensures efficiency but also maintains safety. Remember, the chain you choose should align with your saw’s specifications and the nature of the task at hand. With this guide, you’re now equipped to make an informed decision in selecting the most suitable chainsaw chain for your needs.

Related Articles:

- How Tight Should A Chainsaw Chain Be

- Best ATV Chainsaw Holder

- Best Chainsaw Mill Attachments

- Common Reasons Your Chainsaw Is Smoking

- Best Chainsaw for the Money: Top Picks for Every User

- Top 5 Causes of a Loose or Detached Chainsaw Chain: How to Identify and Fix

- Chainsaw Safety Guide Tips

FAQs

- What’s the difference between semi-chisel and full chisel chains?

Semi-chisel chains have a rounded cutting edge and are more durable and less prone to dulling quickly, making them ideal for cutting in dirty or gritty conditions. Full chisel chains, with their sharper, square-cornered teeth, cut faster but dull more quickly and are best used in clean wood. - Can I use a full skip chain on a small chainsaw?

Full skip chains are generally recommended for larger chainsaws and longer bars (over 24 inches) because they are designed for bulk cutting and can handle the increased power. Using a full skip chain on a small chainsaw is not advisable as it can reduce cutting efficiency and increase the risk of kickback. - How do I know when to replace my chainsaw chain?

A chainsaw chain needs replacing when it becomes dull and doesn’t cut efficiently even after sharpening, if the teeth are significantly worn down, or if there’s visible damage like broken or bent links. - What does the term ‘pitch’ in chainsaw chains mean?

Pitch refers to the size of the chain and is measured by the distance between any three consecutive rivets divided by two. It’s an important specification as it determines the fit of the chain on the chainsaw’s bar and sprocket. - Is it safe for a beginner to use a chainsaw with a full chisel chain?

While it’s not inherently unsafe, full chisel chains are more aggressive and prone to kickback. Beginners are typically recommended to start with a less aggressive chain, like a semi-chisel, to gain experience while minimizing risk. - What are the advantages of using a narrow kerf chain?

Narrow kerf chains are thinner and remove less wood, reducing the power needed to make a cut. This makes them ideal for smaller, less powerful saws, improving cutting efficiency and reducing the strain on the saw. - Can I interchange chains between different brands of chainsaws?

Chains can be interchanged between different chainsaw brands, provided they match in pitch, gauge, and drive link count. However, it’s crucial to consult the chainsaw’s manual to ensure compatibility. - Why do some chains have a ‘low-kickback’ feature?

Low-kickback features, often found in chains designed for consumer use, include specific design elements like guard links that reduce the risk and severity of kickback, making the chainsaw safer for less experienced users. - How often should I sharpen my chainsaw chain?

The frequency of sharpening depends on usage, but generally, a chain should be sharpened after every few hours of cutting time, or whenever the saw starts to produce sawdust instead of chips, or requires more pressure to cut. - What is a ripping chain, and when should I use it?

A ripping chain is designed for cutting parallel to the wood grain, such as in milling operations. It features a special tooth angle for smoother cuts in this specific direction and is not typically used for general chainsaw work.

Join the discussion below by sharing your experiences, tips, or reviews. Your contributions help others make informed decisions and navigate their chainsaw choices with confidence. Let’s build a community of shared knowledge for all wood-cutting enthusiasts!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

6 comments

Thank you for adding to my education / understanding. I've been cutting with a chainsaw for over 55 years. And I'm about to buy my first "Real Professional" chainsaw. I think it's time to learn more of the reasons WHY things are designed the way they are.

Frank Woechan

January 9, 2024 4:53 pmI heard there are different chains fir green wood and dry wood. What are they

Wanda

January 7, 2024 7:07 pmGood job

Jerry

January 5, 2024 9:03 pmLooking for a great 16"chain to cut tree stump pine tree

Earl L Blannon

January 5, 2024 4:46 pmVery informative learned quite a bit

Thank you for the information on the types of chains. Quick question, is there some flexibility in the number of drive links? Husqvarna has a chain for my saw that shows 80 drive links for 20" bar, but Oregon has a chain with 78 links, same pitch and gauge, for a 20" bar. Thank you

John Baptist

January 19, 2024 9:37 am