Hot Max WC100 Welding Cart Review

- March 21, 2024

- 0 comment

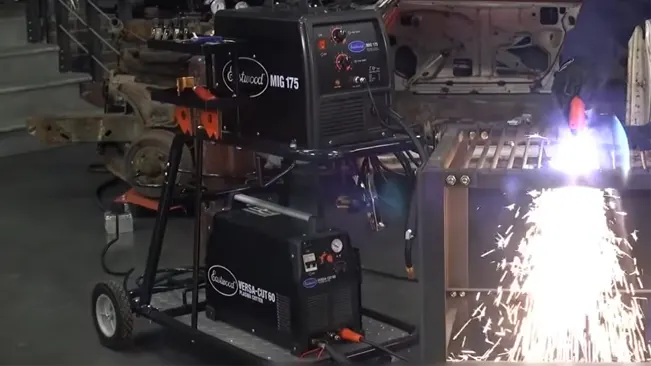

The Hot Max WC100 Welding Cart, it’s important to consider several key aspects that are critical to both professionals and hobbyists in the welding and plasma cutting fields.In this Hot Max WC100 welding cart review aims to offer convenience, durability, and efficiency to its users, addressing the common needs and challenges faced in welding and plasma cutting environments. Here’s an in-depth review from an expert perspective.

We’ve got your welding covered! Find comfy, Best welding gloves, Best welding carts, plus top picks for Best TIG Welder, Best MIG Welder & Best ARC Welders – all without breaking the bank!

Hot Max WC100 Cart Specifications

- Brand: Hot Max

- Model: WC100

- Material: Durable Steel Construction

- Handle: Ergonomic Design for Easy Maneuverability

- Rear Wheels: Solid Rubber, Large Diameter for Stability and Smooth Movement

- Front Wheels: Swivel Caster Wheels for Enhanced Steering and Mobility

- Safety Features: Adjustable Safety Chain for Securing Equipment

Hot Max WC100 Welding Cart Build Quality and Design

The Hot Max WC100 is constructed with a heavy-duty steel frame, designed to withstand the rigors of daily use in a professional workshop as well as the occasional demands of a home garage.

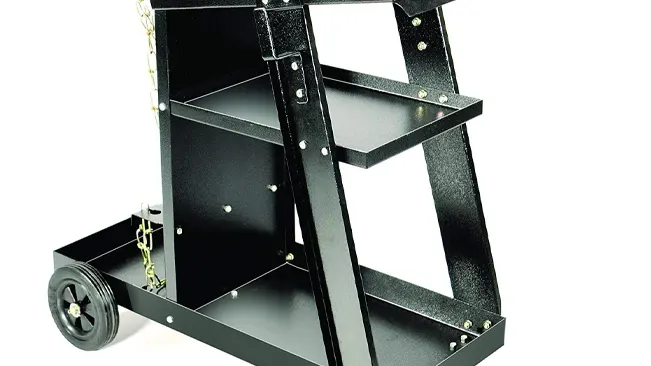

The robust build quality ensures that the cart can carry significant weight, which is crucial for accommodating heavy welding machines and plasma cutters along with their accessories. The design includes a tilted top shelf for easier access and control of the welding or cutting equipment, and lower shelves to store essential supplies such as gas tanks, tools, and protective gear.

Storage and Organization

One of the standout features of the WC100 is its thoughtful storage solutions. The cart includes a gas bottle storage area that is both secure and easily accessible, reducing the risk of accidents while ensuring that welding gases are at hand.

Additionally, the cart features hooks and storage racks for holding cables, hoses, and other accessories, keeping them organized and readily available. This level of organization not only improves efficiency but also extends the lifespan of equipment by preventing unnecessary wear and tear.

Handle Design

The handle of the Hot Max WC100 is ergonomically designed to ensure ease of maneuverability and comfort during use.

This feature is crucial for professionals and hobbyists who frequently move their welding or plasma cutting equipment across various locations in a workshop or job site. The handle’s design minimizes strain on the user’s hands and back, promoting longer periods of use without fatigue.

Rubber Rear Wheels

Equipped with durable rubber rear wheels, the Hot Max WC100 offers stability and smooth movement over different types of surfaces, from smooth workshop floors to more uneven and rugged terrains found in some job sites.

The choice of rubber as a material for the rear wheels is significant for reducing vibrations and noise during transportation, thereby protecting the equipment mounted on the cart from potential damage caused by excessive shaking.

Front Caster Wheels

The inclusion of front caster wheels enhances the cart’s maneuverability, allowing for easy steering and positioning of the cart in tight spaces.

These wheels can pivot in any direction, enabling the user to navigate around obstacles with minimal effort. The caster wheels are designed to support the weight of heavy welding and plasma cutting equipment without compromising on mobility, making the Hot Max WC100 a versatile solution for various working environments.

Safety Chain

Safety is paramount when transporting heavy and potentially hazardous equipment such as welders and plasma cutters. The Hot Max WC100 incorporates a safety chain feature to secure the equipment onto the cart firmly.

This precaution prevents the machinery from shifting or falling off the cart during movement, reducing the risk of injury to the user and damage to the equipment. The safety chain is easily adjustable to accommodate different sizes and shapes of machines, ensuring a snug and secure fit.

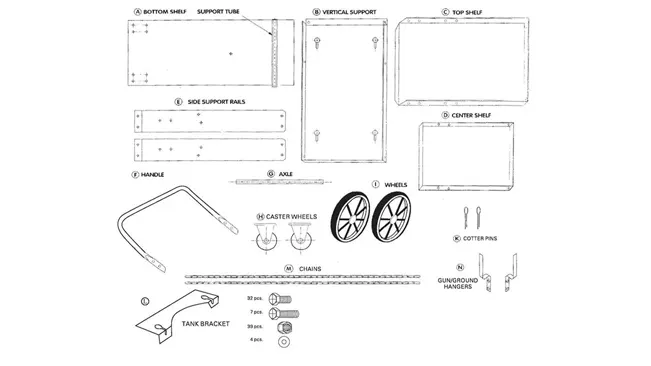

Ease of Assembly and Use

The assembly process for the Hot Max WC100 is straightforward, with clear instructions that make it manageable even for those who may not be particularly handy.

Once assembled, the cart’s user-friendly design becomes evident, with all features and storage options designed to be easily accessible. The simplicity of use allows welders and cutters to focus more on their work and less on managing their workspace.

Value for Money

Considering its durable construction, thoughtful design, and the level of organization it offers, the Hot Max WC100 provides excellent value for money. It’s a worthwhile investment for both professional and amateur welders and plasma cutters looking for a reliable, efficient way to manage their equipment and workspace.

Pros and Cons

Pros

- Constructed from high-quality steel with a powder-coated finish, the Hot Max WC100 is built to last. It’s designed to withstand the rigors of a workshop environment, resisting rust and corrosion.

- With two shelves for equipment and supplies, plus a built-in cylinder rack, it offers ample storage solutions. This versatility makes it suitable for a variety of welding and plasma cutting setups.

- Equipped with two fixed and two swivel casters, the cart is easy to move around, even in tight workshop spaces. This enhances workflow efficiency by allowing users to position their equipment exactly where needed.

- The tilted top shelf improves visibility and access to the machine’s control panel, which is a thoughtful feature that can reduce user fatigue and increase productivity.

- The inclusion of a cylinder rack not only organizes the workspace but also safely secures gas cylinders, reducing the risk of tipping and accidents.

Cons

- Some assembly is needed upon delivery, which might be a drawback for those who prefer ready-to-use products. However, the assembly process is generally straightforward.

- While it can support up to approximately 100 pounds, this might not be sufficient for some of the larger, industrial-grade machines. Users should verify their equipment’s weight before purchasing.

- The one-size-fits-all approach means it may not accommodate very large or uniquely shaped machines or tools perfectly. It’s essential to compare equipment dimensions with the cart’s shelf sizes.

- For those looking to maximize the cart’s utility, additional hooks for cable management or magnetic tool holders must be purchased separately, adding to the overall cost.

Maintenance for Hot Max WC100 Welding/Plasma Cutter Cart

- Regular Cleaning Wipe down the cart with a clean, damp cloth to remove dust, dirt, and metal filings regularly. Avoid using harsh chemicals that could damage the paint or metal.

- Rust Prevention Check for any signs of rust or corrosion, especially if the cart is kept in a humid environment. Use a rust inhibitor or lightly sand and apply a touch-up paint to any affected areas to prevent further corrosion.

- Wheel Inspection Regularly inspect the wheels for wear and tear. Ensure they spin freely and do not wobble. Tighten any loose bolts and replace the wheels if they are damaged or excessively worn.

- Lubricate Moving Parts Apply a light lubricant to the swivel casters and any other moving parts periodically to ensure smooth operation.

- Tighten Bolts and Screws Over time, bolts and screws may loosen due to vibration and movement. Periodically check and tighten all fasteners to ensure the cart remains stable and secure.

- Check Welds Inspect the welds for any signs of cracking or fatigue. If any damage is found, have the cart repaired by a professional welder to ensure structural integrity.

- Storage Considerations When not in use, store the cart in a dry, covered area to protect it from the elements and reduce the risk of rust and corrosion.

- Load Capacity Always adhere to the recommended load capacity to avoid overburdening the cart, which can lead to structural damage or failure.

- Organize Tools and Supplies Use the shelves and racks efficiently to prevent clutter. This not only keeps your workspace organized but also reduces the risk of damaging the cart or your equipment.

- Periodic Review Every few months, conduct a comprehensive review of the cart, including checking its overall condition, cleaning it thoroughly, and performing any necessary maintenance tasks. This proactive approach can help identify potential issues before they become serious problems.

About this Item

- Durable Construction Crafted from high-quality steel with a powder-coated finish, the Hot Max WC100 is built to withstand the demands of any workshop environment, offering durability against rust and corrosion.

- Versatile Storage Solutions Equipped with two storage shelves and a built-in cylinder rack, this cart provides ample space for your welding machine or plasma cutter, accessories, and gas cylinders, ensuring everything you need is within reach.

- Enhanced Maneuverability Featuring two fixed and two swivel casters, the cart allows for easy movement around the workshop or job site, enabling you to position your equipment precisely where needed without strain.

- User-Friendly Design The cart’s thoughtful design includes a tilted top shelf for easier access to your machine’s controls, improving visibility and reducing the need to bend over, which enhances user comfort during operation.

- Safety Features The integrated cylinder rack securely holds gas cylinders up to 7-1/2 inches in diameter, minimizing the risk of tipping and ensuring a safe and organized working environment.

Technical Details Table

| Detail | Description |

|---|---|

| Manufacturer | Hot Max |

| Part Number | WC100 |

| Item Weight | 34.2 pounds |

| Package Dimensions | 30 x 15.5 x 5.75 inches |

| Country of Origin | China |

| Item model number | WC100 |

| Is Discontinued By Manufacturer | No |

| Style | Welding/Plasma Cutting Cart |

| Installation Method | Welding Equipment Transportation |

| Item Package Quantity | 1 |

| Batteries Included? | No |

| Batteries Required? | No |

| Warranty Description | 1 Year Limited |

Final Thoughts

The Hot Max WC100 Welding/Plasma Cutter Cart is a highly recommended accessory for anyone in the welding or plasma cutting field. Its durability, mobility, and storage capabilities significantly enhance the user’s workflow and productivity. While there are many carts available on the market, the WC100’s balance of quality, functionality, and price make it a standout choice for professionals and hobbyists alike. Whether you’re operating in a large industrial workshop or a small garage, the Hot Max WC100 can meet and exceed your expectations, making it an excellent addition to your equipment lineup.

FAQs

- What are the dimensions of the Hot Max WC100 Welding Plasma Cutter Cart?

The cart measures approximately 33 inches in length, 28 inches in height, and 12 inches in width, designed to accommodate most standard welding machines and plasma cutters. This size allows for easy integration into various workshop spaces without taking up excessive room. - Can the Hot Max WC100 hold any brand or size of welding machine and plasma cutter?

While it’s designed to be versatile, there may be limitations with extremely large or uniquely shaped machines. It’s best to compare the dimensions of your equipment with the cart’s shelf sizes to ensure a good fit. - How much weight can the Hot Max WC100 cart support?

The cart is built to support up to approximately 100 pounds, allowing it to handle a wide range of welding machines and plasma cutters along with essential accessories. - Is assembly required for the Hot Max WC100, and if so, how complicated is it?

Some assembly is required upon delivery. However, the process is straightforward, with clear instructions provided. Most users can assemble the cart with basic tools in under an hour. - What materials is the Hot Max WC100 made from, and how does this affect its durability?

Constructed from high-quality steel with a powder-coated finish, the WC100 is designed for durability and resistance to rust and corrosion, ensuring longevity even in harsh workshop conditions. - Does the Hot Max WC100 come with any warranty?

The cart typically comes with a one-year manufacturer’s warranty covering defects in materials and workmanship, providing peace of mind to users. - How easy is it to maneuver the Hot Max WC100 around a workshop?

Thanks to its robust wheels, two of which are swivel casters, the WC100 can be easily moved across various surfaces. Its design prioritizes mobility, even when fully loaded. - Are there any accessories or additional parts available for the Hot Max WC100 to enhance its functionality?

While the WC100 comes ready to use, users can add hooks for cable management or magnetic tool holders to increase its utility. These accessories need to be purchased separately. - How does the built-in cylinder rack enhance the safety and efficiency of welding operations?

The cylinder rack securely holds gas cylinders, minimizing the risk of tipping and facilitating easy access. This feature helps maintain a clutter-free and safe working environment, crucial for effective welding operations. - Where can I purchase the Hot Max WC100 and are there any recommended retailers?

The Hot Max WC100 is available through various online retailers, including the manufacturer’s website, as well as at brick-and-mortar stores specializing in welding supplies. For the best deals and customer service, purchasing from authorized dealers is recommended.

We’re eager to hear from you! If you’ve used the Hot Max WC100 Welding/Plasma Cutter Cart, please share your personal experiences and insights in the comments section below. Whether it’s about its durability, functionality, or any unique ways you’ve utilized it, your feedback is invaluable. Your firsthand account could greatly assist fellow welders and craftsmen in making informed decisions about this tool. Let’s help each other build better workspaces by sharing our knowledge and experiences!

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment