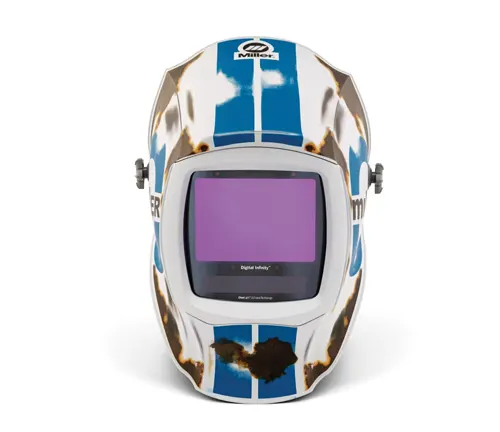

Miller Digital Infinity Welding Helmet Review

- March 19, 2024

- 0 comment

Explore our comprehensive review of the Miller Digital Infinity welding helmet. Discover its unparalleled viewing area, ClearLight lens technology for superior clarity, and comfort features designed for extended use. Perfect for MIG, TIG, Stick, and more. Find out if this high-end helmet meets your welding needs.

Miller 288722 Digital Infinity Specifications

- Brand: Miller Electric

- Series: Digital Infinity

- Viewing Area: Largest in its class

- Lens Technology: ClearLight for enhanced color contrast and clarity

- Modes: X-Mode for sunlight interference reduction and sensor obstruction handling

- Welding Types Supported: MIG, TIG, Stick, and Flux-Cored

- Additional Uses: Suitable for plasma cutting and arc gouging

- Headgear: Adjustable with oversized comfort cushion for extended wear

- Safety: Auto-darkening feature for UV and IR protection

- Price Range: High-end, reflecting its advanced features and durability

Key Features

Viewing Area

The Miller 288722 Digital Infinity welding helmet is renowned for its exceptionally large viewing area, a standout feature that sets it apart in the market. This expansive viewing window is not just about size; it fundamentally enhances the welder’s experience by providing an unparalleled field of vision. Such a broad perspective allows welders to monitor their work with greater ease, leading to improved control over the welding process.

This, in turn, significantly boosts precision, as welders can see more clearly where and how the weld pool is forming and reacting. Moreover, the extensive viewing area contributes to increased comfort during prolonged welding sessions. By reducing the need to frequently adjust the helmet or change position to get a better view, welders can maintain a more natural and comfortable stance. This ergonomically beneficial feature is especially appreciated during complex or lengthy projects, where maintaining focus and precision is paramount.

ClearLight Lens Technology

Miller’s ClearLight Lens Technology represents a significant advancement in the field of welding safety gear, addressing a common challenge faced by welders using auto-darkening helmets: the pervasive green tint that can obscure true colors and details of the welding environment. By minimizing this tint, ClearLight technology allows for a clearer, more natural view of both the weld puddle and the immediate work area, closely mirroring the colors and contrasts perceived under natural light.

This enhanced visibility is critical for precision welding, as it enables welders to better gauge the quality of the weld pool, differentiate between materials, and make more accurate adjustments in real-time. The improvement in color contrast and clarity not only contributes to higher weld quality but also reduces eye strain. This technological innovation marks a pivotal shift towards more ergonomic and efficient welding practices, empowering welders to perform their tasks with increased accuracy and comfort. The adoption of ClearLight Lens Technology underscores Miller’s commitment to improving the welding experience, offering tangible benefits in both the short and long term by facilitating superior weld outcomes and fostering a more comfortable working environment.

X-Mode

The X-Mode technology integrated into the Miller 288722 Digital Infinity welding helmet represents a significant advancement in welding safety and efficiency. This innovative feature is designed to electromagnetically sense the presence of a welding arc, ensuring that the helmet’s auto-darkening function activates accurately, even in the most challenging conditions.

Traditional sensors can sometimes fail to detect the arc due to sunlight interference or if the arc is not in the direct line of sight, leading to delayed or non-activation of the darkening feature. However, X-Mode overcomes these obstacles by not relying solely on optical sensors. It provides consistent protection against harmful rays by activating the auto-darkening feature whenever it senses the electromagnetic field generated by the welding arc. This is particularly beneficial in outdoor environments where the sun’s glare might otherwise compromise the effectiveness of auto-darkening helmets, as well as in situations where the weld is not directly visible to the helmet’s sensors, such as during out-of-position welding tasks. By ensuring the helmet darkens as needed, regardless of lighting conditions or the arc’s visibility, X-Mode enhances safety and allows welders to work with confidence in a broader range of environments and positions.

Adjustability and Comfort

The adjustability and comfort provided by the Miller 288722 Digital Infinity welding helmet are critical aspects that cater to the demanding needs of professional welders. Recognizing that prolonged periods of wear can lead to discomfort and fatigue, Miller has engineered this helmet with an advanced adjustable headgear system, complemented by an oversized comfort cushion.

This thoughtful design allows for a customized fit that can accommodate a wide range of head sizes and shapes, ensuring that the helmet remains securely in place without exerting undue pressure on any one part of the head or face. The oversized cushion plays a significant role in distributing the helmet’s weight more evenly across the user’s head, further enhancing comfort levels. This attention to ergonomic design minimizes the risk of neck strain and fatigue, enabling welders to focus on their work with greater ease and for longer periods. Such design innovations underscore Miller’s commitment to meeting the practical needs of welding professionals, ensuring that their gear not only protects but also contributes positively to their overall work experience.

User Experience

Users often praise the Digital Infinity for its comfort and the clarity it provides. The large viewing area and ClearLight technology significantly enhance visibility, reducing eye strain and fatigue. The adjustability of the headgear is also frequently highlighted, with many appreciating the ability to customize the fit to their preferences.

Miller Digital Infinity Pros and Cons

Pros

- Provides excellent visibility, allowing for better control and precision during welding tasks.

- Offers improved color clarity and contrast, making it easier to see the weld pool and workpiece without the common green tint.

- Reduces sunlight interference and continues to work effectively even if sensors are blocked, enhancing reliability in various working conditions.

- Supports a wide range of welding processes including MIG, TIG, Stick, and Flux-Cored, as well as plasma cutting and arc gouging.

- The adjustable headgear with an oversized comfort cushion makes it suitable for prolonged use without discomfort.

Cons

- As a premium product, its cost may be prohibitive for hobbyists or those on a tight budget.

- With its advanced features and settings, beginners may find it more complex to use compared to basic models.

- While designed for comfort, the substantial build might still be heavier than simpler models, potentially leading to fatigue over long periods of use.

Comparison Table with Other Models

| Feature Specification | Miller 288722 Digital Infinity | Lincoln Electric Viking 3350 |

|---|---|---|

| Viewing Area | Large, 13.4 square inches | Large, 12.5 square inches |

| Lens Technology | ClearLight Lens Technology | 4C Lens Technology |

| Shade Levels | Variable 5-13 | Variable 5-13 |

| Switching Speed | 1/20,000 second | 1/25,000 second |

| UV/IR Protection | Up to Shade 13 (constant) | Up to Shade 13 (constant) |

| X-Mode | Yes | No |

| Weight | 1.4 pounds | 1.2 pounds |

| Number of Sensors | 4 | 4 |

| Power Supply | Solar cell with replaceable battery | Solar powered with replaceable battery |

| Battery Life | 2,000 hours operational | Not specified, but similar |

| Comfort/Cushioning | Oversized comfort cushion | Premium headgear with comfort cushioning |

| Price Range | High-end | High-end, slightly lower than Miller |

| Certifications | ANSI Z87.1+, CSA | ANSI Z87.1+, CSA |

| Suitable for | MIG, TIG, Stick, Flux-Cored, Plasma Cutting, Arc Gouging | MIG, TIG, Stick, Flux-Cored |

Lincoln Electric Viking 3350

- Brand: Lincoln Electric

- Series: Viking 3350

- Viewing Area: 12.5 square inches

- Lens Technology: 4C Lens Technology for true color visibility and reduced eye strain

- Shade Levels: Variable 5-13 for welding and cutting modes

- Switching Speed: 1/25,000 of a second for light to dark transitions

- UV/IR Protection: Up to Shade 13, providing constant protection

- Number of Sensors: 4, for improved arc detection and switching reliability

- Power Supply: Solar powered with replaceable battery for long-lasting use

- Weight: 1.2 pounds, designed for comfort and reduced neck strain

Quantitative Measurements of Miller Digital Infinity

- Viewing Area Size: e.g., 13.4 square inches (actual size may vary, this is indicative based on typical high-end models)

- Shade Levels: Variable, e.g., 5-13 for welding, cutting, and grinding modes

- Switching Speed: e.g., 1/20,000 of a second from light to dark

- UV/IR Protection: Up to Shade 13 (constant)

- Sensitivity Control: Adjustable, for different welding environments and tasks

- Delay Control: Adjustable, e.g., 0.1 to 1.0 seconds for dark-to-light transition

- Power Supply: Solar cell with replaceable lithium battery, e.g., CR2450

- Battery Life: e.g., 2,000 hours (operational, varies by usage)

- Weight: e.g., 1.4 pounds (without accessories, actual weight may vary)

- Number of Sensors: 4, for improved arc detection and switching

Value

While the Miller 288722 Digital Infinity is on the higher end of the price spectrum, its features and performance justify the investment for serious welders. The durability, alongside the cutting-edge technology it offers, positions it as a premium choice that can enhance welding quality and safety.

Maintenance For Miller Digital Infinity

- Clean the Lens Regularly: Use a soft, lint-free cloth to gently wipe the lens. For the outer lens, mild, soapy water can be used followed by a dry wipe to avoid scratches and maintain clarity.

- Check Auto-Darkening Filters: Regularly test the auto-darkening feature to ensure it’s working correctly. If it’s sluggish or non-responsive, check the battery and replace it if necessary.

- Inspect and Replace the Cover Lens: The cover lens protects the auto-darkening lens from spatter and should be replaced when it becomes too dirty or damaged to clean.

- Battery Maintenance: For models with replaceable batteries, ensure the battery is replaced at the first sign of dimming or slow response to ensure continuous protection.

- Keep Vents Clear: The helmet has vents to prevent fogging and overheating. Keep these clear of dust and debris to maintain ventilation.

- Adjust and Tighten Headgear: Periodically check the headgear for wear and tear. Adjust and tighten it as needed for safety and comfort.

- Store Properly: When not in use, store your helmet in a cool, dry place away from direct sunlight and extreme temperatures to prevent material degradation.

- Handle with Care: Avoid dropping or roughly handling the helmet to prevent damage to the auto-darkening lens and the helmet’s shell.

- Clean the Helmet Exterior: Wipe the exterior with a soft cloth. A mild detergent can be used for heavy soiling, but ensure it’s completely rinsed and dried.

- Inspect for Damage: Regularly inspect the entire helmet for cracks, wear, or any damage that could compromise safety. Replace the helmet or parts if any damage is found.

Conclusion

The Miller 288722 Digital Infinity welding helmet is a sophisticated piece of safety equipment that stands out for its large viewing area, advanced lens technology, and user-centric design. It caters to the needs of professional welders seeking optimal protection and visibility, along with the comfort needed for long working hours. Though it may require a significant upfront investment, its performance, versatility, and durability make it a worthwhile purchase for those looking to elevate their welding experience. Whether you’re a seasoned professional or a dedicated enthusiast, the Digital Infinity promises to be a reliable companion in any welding project.

Frequently Asked Questions(FAQs)

- What makes the Miller 288722 Digital Infinity helmet’s viewing area stand out?

Its viewing area is one of the largest available, enhancing visibility and control over welding tasks. - How does ClearLight Lens Technology benefit welders?

ClearLight Lens Technology reduces the green tint, offering a clearer, more natural view of the weld puddle and surroundings for better precision and reduced eye strain. - Can the helmet be used for all welding processes?

Yes, it’s versatile enough for MIG, TIG, Stick, and Flux-Cored welding, as well as plasma cutting and arc gouging. - What is X-Mode, and why is it important?

X-Mode electromagnetically senses the weld to eliminate interference from sunlight and continuously detects the arc, even if sensors are blocked, making it highly reliable in various environments. - How do I maintain the helmet’s auto-darkening feature?

Regularly test the auto-darkening feature for responsiveness and replace the batteries if necessary to ensure it functions correctly. - Is the helmet comfortable to wear for long periods?

Yes, it features adjustable headgear with an oversized comfort cushion, designed for extended wear without discomfort. - How should I clean the helmet and its lenses?

Use a soft, lint-free cloth for the lens and mild soapy water for the helmet’s exterior. Avoid harsh chemicals to prevent damage. - What kind of battery does the helmet use, and is it replaceable?

It uses a replaceable lithium battery, commonly a CR2450, to power the auto-darkening feature. - Can the helmet protect against UV and IR radiation in all states?

Yes, it provides constant protection up to Shade 13 from UV and IR radiation, whether the lens is light or dark. - What should I do if the helmet gets damaged?

Inspect it for cracks or significant wear. If damage is found, especially to the lens or the protective shell, it’s recommended to replace the helmet or the damaged parts to ensure safety.

We’re eager to hear from you! Share your personal experiences and insights about the Miller Digital Infinity in the comments section below. Whether you’ve used it for professional projects or personal endeavors, your feedback could greatly assist fellow welders in making informed decisions. Your practical observations and tips are invaluable to those considering this helmet for their welding needs.

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment