Best 110v MIG Welders

- January 24, 2024

- 0 comment

As an avid welding aficionado who has delved deep into the world of various welding methods and equipment, my experience has led me to a profound realization: uncovering the ideal MIG welder, particularly one that operates efficiently on a 110V system, is much like a quest for a rare treasure. The quest goes beyond mere technical specifications; it delves into the realms of user experience, operational simplicity, and the quality of results achieved.

In this comprehensive guide, I aim to dissect and discuss an array of 110V MIG welders, meticulously evaluating them based on crucial criteria that influence decision-making. These criteria include their performance capabilities, user-friendliness, and their adaptability to diverse welding tasks. This detailed analysis is designed to assist you in identifying the MIG welder that seamlessly aligns with your specific welding requirements.

List of Best 110v MIG Welders:

- Hobart Handler 140

- Forney 140 Easy Weld FC-i

- Hobart Handler 210 MVP

- Lotos MIG140

- Forney Easy Weld 140 MP

- PowerMIG 210 MP

- Miller Multimatic 215

MIG welders that run on 110 volts are compact, easily transportable devices that you can conveniently power using standard household electrical outlets. Despite their primary design for lighter, home-based tasks, the top-tier 110V MIG welders boast remarkable versatility.

Take car restoration, for instance. A 110V MIG welder can adeptly handle the repair of robust suspension components by employing multiple passes at its highest power setting. Conversely, it can also execute precise spot-welds on delicate body panels with a lower power setting, showcasing its adaptability.

However, it’s important to note that even among the best MIG welders available in the market, there’s a spectrum of price points, quality levels, and functionalities. What might be the optimal choice for some may not necessarily meet your unique needs. Therefore, in this review, I present seven distinct recommendations, each catering to different requirements and preferences in the realm of MIG welding.

7 Best 110V MIG Welders

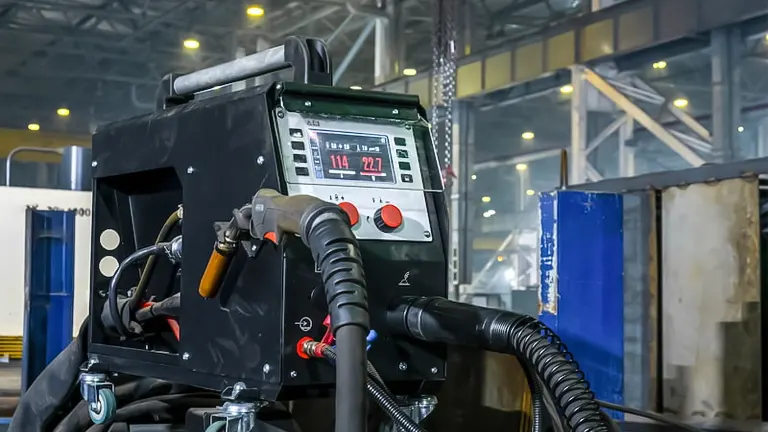

1. Hobart Handler 140 – Premier Choice for 110V MIG Welding

Specifications

- Process Type: MIG and flux core

- Input Voltage: 110V/115V/120V

- Output Amperage: 25 – 140A

- Duty Cycle: 20% at 90A/18.5V

- Weldable Material Thickness: 24 gauge to 1/4 inch

- MIG Cable Length: 10 feet

- Ground Cable Length: 10 feet

- Weight: 57 pounds

- Dimensions: 12.375 inches (height) x 10.625 inches (width) x 19.5 inches (depth)

The Hobart Handler 140 MIG welder emerges as an ideal choice for those seeking a reliable and straightforward welding tool for home use. Crafted in the USA, model #500559 is particularly favored by home hobbyists, classic car restorers, and metalworking artists for its robust construction and efficient performance.

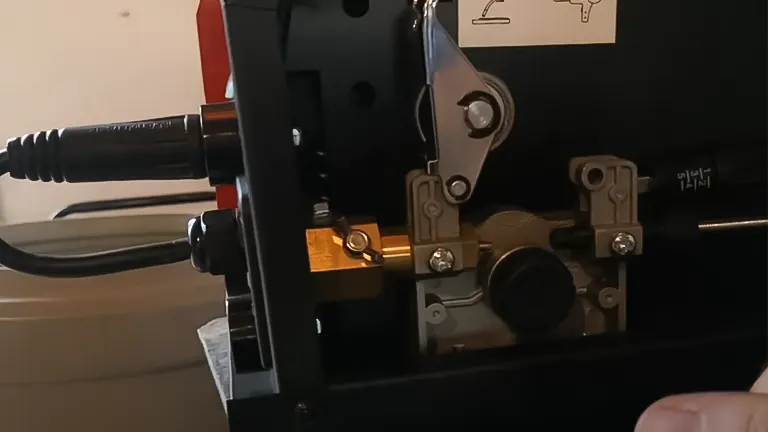

This 110V welder combines a classic transformer-type power source with a wire feed drive system, delivering a consistently smooth and hassle-free MIG welding experience. In my personal usage, the Hobart 140 has demonstrated both longevity and durability, qualities that make it a potential family heirloom for generations of DIY enthusiasts.

In terms of power, the Hobart 140 boasts a top output of 140 amps, ample for welding 3/16-inch mild steel in one pass and 1/4-inch steel in multiple passes, making it more than sufficient for most home automotive repairs. The welder’s 5-position voltage control, adjustable down to 25 amps, is a boon for working on thin auto body panels as light as 24 gauge.

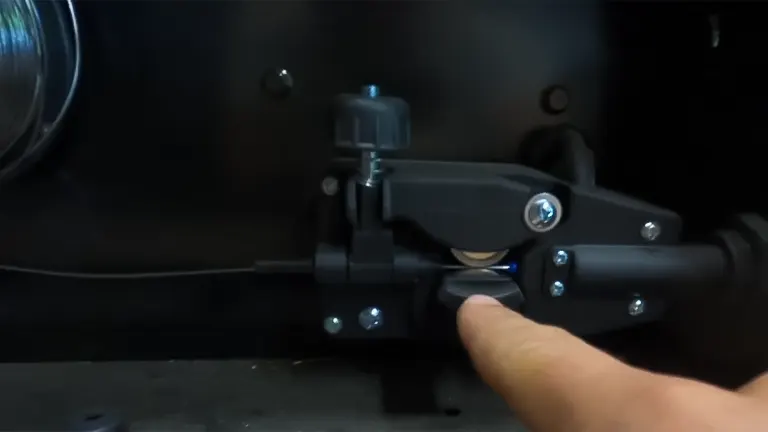

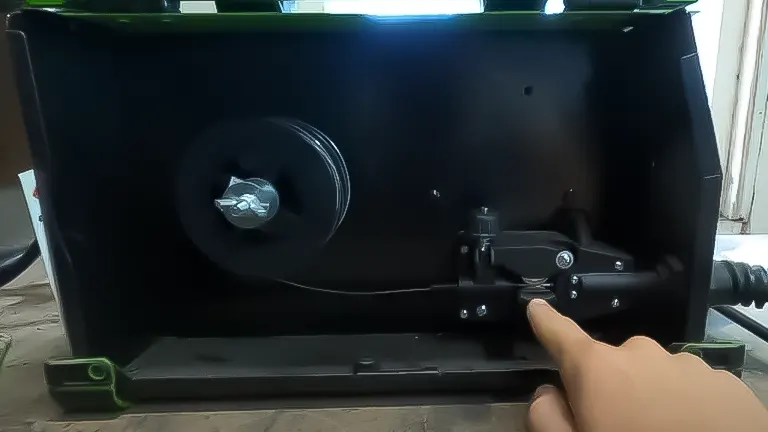

Another standout feature is its wire feed speed control, offering infinite adjustability between 40 and 700 inches per minute (IPM) for precise arc tuning. Despite its lack of a spool gun, I’ve successfully used the Hobart 140 to MIG weld 1/8-inch aluminum, a testament to its superior wire drive system that handles both aluminum and more common solid and flux-core wires with ease. The quick change drive roll and calibrated tension control further ensure that its single-roller drive wire feed system remains one of the best in its class, contributing to a reliable and satisfying welding experience.

Pros

- Reliable Wire Feed Drive: Ensures consistent performance and smooth operation.

- Ease of Use: User-friendly, making it suitable for beginners and professionals alike.

- Durable Construction: Built to last, providing longevity and reliability.

- Affordable: Offers good value for its price, making it accessible to a wider range of users.

- Solid Warranty: Comes with a reassuring warranty, adding to its value and reliability.

Cons

- Lacks Spool Gun Option: Limits its versatility, especially for welding aluminum.

- Small Work Clamp: The clamp provided is somewhat undersized, which may affect stability and efficiency.

- No Bonding Cable: The absence of a bonding cable can be a drawback for certain welding tasks.

2. Forney 140 Easy Weld FC-i – Top Choice for Portable 110V Flux Core Welding

Specifications

- Process Type: Flux Core Welder

- Input Voltage: 110V/115V/120V

- Output Amperage: 32 – 140A

- Duty Cycle: 30% at 90A

- Weldable Material Thickness: 22 gauge to 1/4 inch

- MIG Cable Length: 8 feet

- Ground Cable Length: 8 feet

- Weight: 19 pounds

- Dimensions: 12 inches (height) x 8.125 inches (width) x 16.75 inches (depth)

The Forney 140 FC-i MIG Welder (model #261) is a standout in the 110V MIG welder market, especially for its exceptional portability. Weighing a mere 19 pounds, this compact welder is incredibly easy to transport, fitting effortlessly into any vehicle. This makes it a perfect choice for those who need to move between project locations or require a reliable welder for unexpected repairs.

However, it’s important to note that as a flux core (gasless) welder, it comes with the trade-offs of dealing with slag, increased smoke, and spatter compared to traditional MIG welders. Its inability to connect shielding gas and use solid welding wire limits users to flux core welding, which impacts the cleanliness of the welds and precludes aluminum welding tasks.

Despite its compact size, the Forney 140 FC-i doesn’t skimp on power, boasting an efficient inverter power source. It supports both 4-inch and 8-inch wire spools, allowing for versatility between lightweight portability and larger project capacity. On a 20A circuit, it achieves up to 140 amps, capable of welding mild steel up to 1/4-inch thick. With infinite adjustability in both voltage and wire speed, it offers precise control for welding thin sheet metal down to 22 gauge.

Forney backs this welder with a 30-day warranty against material or workmanship defects and a 1-year warranty on internal electrical components, though transportation costs for repair fall on the customer. With over 150 service facilities in the US, warranty service is accessible provided the purchase is registered. During my review, I inquired about the wire feed speed (WFS), which is not specified in the literature. Forney confirmed that the 140 FC-i operates at a WFS of 47 to 173 inches per minute (IPM), regardless of load and voltage setting, an essential detail for users to consider when assessing its suitability for their welding needs.

Pros

- Portability and Storage: Lightweight and compact, making it easy to carry and store.

- No Gas Cylinder Needed: Operates without the need for a gas cylinder, simplifying the setup.

- Versatility in Location: Can be used anywhere with a 110V power source.

- Generator Compatibility: Approved for use with a 4000-watt generator, enhancing its portability.

Cons

- Messy Flux Core Welds: Flux core welding can be more spatter-prone and messy compared to other methods.

- Limited Warranty Period: Offers a relatively short warranty period.

- Challenging Warranty Service: Warranty claims may involve complex and expensive processes.

3. Hobart Handler 210 MVP – Top-Rated 110V MIG Welder for Overall Value

Specifications

- Process Type: MIG, Flux Core

- Input Voltage: 115V/230V

- Output Amperage: At 115V: 25 – 140A & At 230V: 25 – 210A

- Duty Cycle: At 115V: 20% at 90A (19V)

- Weldable Material Thickness: 24 gauge to 3/8 inch

- MIG Cable Length: 10 feet

- Ground Cable Length: 10 feet

- Weight: 79 pounds

- Dimensions: 12-3/8 inches (height) x 10-5/8 inches (width) x 19-1/2 inches (depth)

The Hobart 210 MVP (model #500553) stands out in the MIG welder market, especially for those looking beyond the basic 140-amp models. While it might be a bit pricier, its features and capabilities justify the investment, making it a top contender for both beginners and experienced users. The welder’s standout feature is its robust 210-amp welding capability, combined with a dual-voltage flexibility, all packaged into a compact size similar to Hobart’s 140-amp models.

As a reviewer exploring its features, I found the Hobart 210 MVP incredibly convenient, especially with its ability to seamlessly switch from 115V to 230V. This ease of transition is credited to Hobart’s innovative Multi-Voltage Plug (MVP) system, which allows changing the plug without any tools and without the hassle of an extra power cord.

On a standard 110V (20-amp) household outlet, the Hobart 210 MVP delivers up to 140 amps of MIG welding power, which jumps to 210 amps when switched to 230V. This power is more than sufficient for welding materials up to 3/8-inch mild steel. During my testing, I was particularly impressed with the welder’s versatility. It features seven voltage settings and an infinitely adjustable wire feed speed (WFS), providing exceptional control over the welding arc. This precision is crucial when working with delicate materials like 24-gauge sheet metal. For those interested in aluminum welding up to 1/4-inch, the welder offers the option to connect the SpoolRunner 100 spool gun, enhancing its efficiency and ease of use for handling various materials.

MVP Plug Types:

- 115V/15A − NEMA Type 5-15P (included)

- 230V/50A − NEMA Type 6-50P (included)

- 115V/20A − NEMA Type 5-20P (available)

The Hobart 210 MVP presents itself as a versatile, powerful, and user-friendly welder, ideal for a wide range of welding tasks at home or in a professional setting.

Pros

- Robust Build Quality: Designed for durability and heavy-duty use.

- Dual Voltage Capability: Operates on both 115V and 230V power sources.

- Spool Gun Ready: Facilitates easy welding of aluminum with spool gun compatibility.

- Compact Design: Convenient size for easy handling and storage.

- Reliable Wire Drive System: Ensures consistent wire feed for smooth welding.

Cons

- Weight: Relatively heavy, which might affect its portability.

- Fixed Voltage Control: Lacks flexibility in voltage adjustments due to preset control levels.

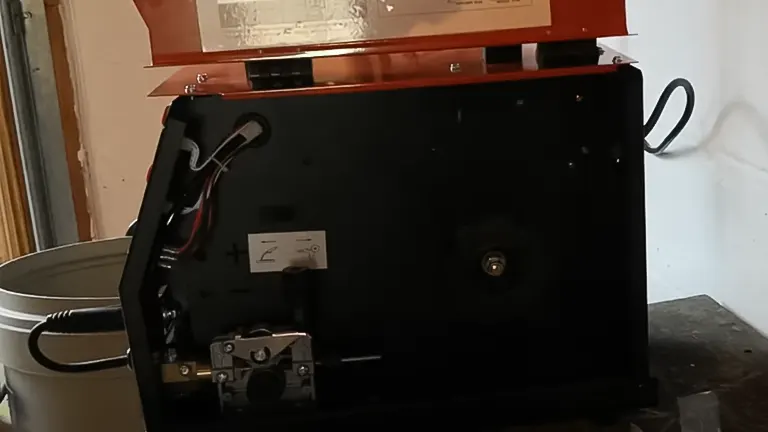

4. Lotos MIG140 – Leading Affordable 110V MIG Welder

Specifications

- Process Type: MIG, Flux Core

- Input Voltage: 110V/115V/120V

- Output Amperage: 25 – 140A

- Duty Cycle: 20% at 90A/18V

- Weldable Material Thickness: 24 gauge to 3/16 inch

- MIG Cable Length: 10 feet

- Work Cable Length: 8 feet

- Weight: 54 pounds

- Dimensions: 12 inches (height) x 8.125 inches (width) x 16.75 inches (depth)

The Lotos MIG140, a notably revamped 110v MIG welder, stands out for its advanced features at an affordable price point. As a reviewer exploring its capabilities, I was impressed by its readiness for a spool gun, an addition that makes it capable of welding 1/8-inch aluminum at a cost significantly lower than many high-end welders.

A key enhancement in the Lotos MIG140 is the inclusion of digital readout displays, which provide infinitely adjustable voltage and wire feed speed controls. This feature allows for the precise replication of preferred welding settings. Additionally, the welder’s drive system, now made from cast aluminum, includes calibrated tension control and tool-less roller changes, thus improving both reliability and ease of use.

Business owners who have used the Lotos MIG140 highlight the efficiency and reliability of its wire feeder. An especially noteworthy feature is the 2T/4T switch, which offers convenience for continuous welding without the need to hold the trigger constantly – a boon for extended welding sessions. The welder also simplifies polarity changes with tool-less front panel connectors, making the process much more streamlined.

While the MIG torch is generic, it is commendably functional with its 10-foot length and compatibility with Lincoln-style contact tips, providing sufficient flexibility for various welding tasks. However, it’s important to note that the accessories included with the Lotos MIG140 are of basic quality. In my evaluation, these accessories don’t significantly enhance the overall value of the welder, and prospective buyers should consider the welder’s core performance and features over these ancillary items. The Lotos MIG140 presents itself as a practical and economical choice for both amateur and professional welders, offering advanced functionalities typically found in more expensive models.

Pros

- Quality MIG Torch: Comes with a well-made MIG torch, improving the welding experience.

- Spool Gun Compatibility: The welder is prepared for use with a spool gun.

- Digital Displays: Features digital read-outs for precise control and settings adjustments.

- Simple Polarity Changes: Allows for easy and quick polarity adjustments.

Cons

- Inferior Accessories: The included accessories are of poor quality.

- Warranty Shipping Costs: The customer is responsible for shipping costs both to and from the service center for warranty claims.

5. Forney Easy Weld 140 MP – Best Value Multi-Process 110V MIG Welder for Budget Buyers

Specifications

- Process Type: MIG, Flux Core, Stick, TIG

- Input Voltage: 110V/115V/120V

- Output Amperage: 10 – 140A

- Duty Cycle: 30% at 90A

- Weldable Material Thickness: 22 gauge to 1/4 inch

- MIG Cable Length: 10 feet

- Work Cable Length: 8 feet

- Weight: 20 pounds

- Dimensions: 12 inches (height) x 8.125 inches (width) x 16.75 inches (depth)

If you’re in the market for a highly mobile welding machine, akin to the Forney FC-I discussed earlier, but require a tool with more capabilities than what a flux core welder can offer, the Easy Weld 140 MP might be your perfect match.

This model presents itself in a package strikingly similar to its Forney counterpart, yet it elevates the game as a 110V multi-process welder. It arrives ready to handle both flux core and stick welding. Moreover, it goes a step further by offering the capacity for genuine 110V MIG welding, provided you use solid wire coupled with shielding gas.

However, it’s important to note that you would need to purchase the gas regulator and hose separately, as these are not included with the welder itself.

One limitation of the 140 MP is that it is not designed for use with a spool gun. On the flip side, this machine opens the door to TIG welding adventures. To embark on TIG welding, all you need is to acquire a TIG torch and supply it with 100% Argon gas. The 140 MP utilizes a lift arc start technique for TIG welding. It’s crucial to remember, though, that this is DC TIG welding, which means it isn’t suitable for welding aluminum.

Pros

- Multi-Process Versatility: Ready for flux core and stick welding right out of the box. MIG and TIG welding capabilities are also available with the purchase of additional accessories.

- Portability: Compact and lightweight, making it easy to carry and store.

- Convenience: Can be used anywhere with a 110V power source.

- Generator Compatibility: Rated for use with a 4500-watt generator.

Cons

- Additional Purchases Required: Gas regulator and hose are not included and must be bought separately.

- Limited Welding Scope: Does not have the capability to weld aluminum.

6. PowerMIG 210 MP – Lincoln’s Best 110V MIG Welder

Specifications

- Process Type: MIG, Flux Core, Stick, DC TIG

- Input Voltage: 110/115/120V & 230V

- Output Amperage: At 120V: 20 – 140A

- Duty Cycle: At 120V: 40% at 100A/19V

- Weldable Material Thickness: MIG: 24 gauge to 5/16 inch

- MIG Cable Length: 10 feet

- Work Cable Length: 10 feet

- Weight: 40 pounds

- Dimensions: 14 inches (height) x 10.8 inches (width) x 19 inches (depth)

The Lincoln Electric 210 MP stands out as one of the finest MIG welders available, though its higher price point places it slightly outside the range for the overall top choice. However, for those devoted to the Lincoln brand, the extra cost is often seen as a worthwhile investment for the quality and reliability synonymous with Lincoln’s equipment.

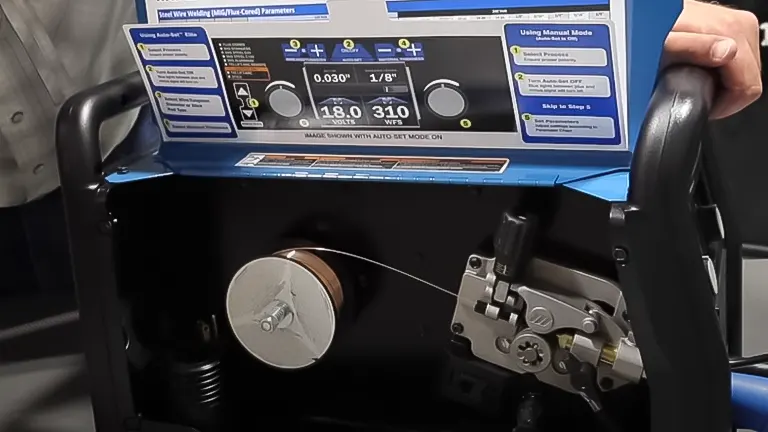

What makes the 210 MP particularly appealing to hobbyist welders is a multitude of user-centric features. One of the most notable is its color LCD screen, which simplifies the setup process significantly. This feature is designed to guide users through various procedures, making the welder extremely user-friendly and obviating the need to constantly refer to the owner’s manual for basic operations.

The interface of the 210 MP is not just intuitive for beginners, but also enjoyable for more advanced users, adding to its overall appeal. As a multi-process welder, it comes ready to handle MIG, flux core, and stick welding right out of the box.

For those looking to expand their welding capabilities to TIG, the 210 MP can accommodate this with the addition of a Lincoln K3690-1 TIG kit (sold separately). It’s important to note, however, that this is a DC-current TIG process, making it unsuitable for welding aluminum.

To counter this, Lincoln offers the K3269-1 Magnum PRO 100SG spool gun, which when connected, transforms the 210 MP into an efficient aluminum welder. The welder’s core is its robust wire drive system made of cast aluminum, featuring interchangeable wire guides that virtually eliminate issues like birdnesting.

Flexibility in power source is another key feature of the 210 MP. It can operate on both 120V and 230V inputs. Unlike the Hobart/Miller system which uses a plug change, the Lincoln requires swapping the entire power cord to switch voltages, resulting in an extra cord to manage and store.

If mobility is a factor in your decision, the Lincoln 210MP is impressively portable. Thanks to its lightweight inverter power source, the machine weighs just 40 pounds, making it a convenient option for transportation to various worksites.

Pros

- Portability: Lightweight, weighing only 40 lbs, easy to transport.

- User-Friendly Setup: Features an LCD screen for simplified setup procedures.

- Dual Cooling Fans: Enhanced cooling for efficient operation.

- Multi-Process Capability: Versatile, able to handle various welding processes.

- Dual Voltage: Can operate on both 120V and 230V power sources.

Cons

- High Cost: More expensive compared to similar models.

- Constant Fan Operation: The cooling fans are always on, which may be a drawback for some users.

7. Miller Multimatic 215 – Leading High-End 110V MIG Welder

Specifications

- Process Type: MIG, Flux Core, Stick, DC TIG

- Input Voltage: 110V/115V/120V & 240V

- Output Amperage: At 120V: 30 – 125A

- Duty Cycle: At 110V: 60% at 110A/19.5V

- Weldable Material Thickness: MIG: 24 gauge to 3/8 inch steel

- MIG Cable Length: 10 feet

- Work Cable Length: 10 feet

- Weight: 40 pounds

- Dimensions: 12.5 inches (height) x 11.25 inches (width) x 20.5 inches (depth)

If you find the Lincoln 210 MP lacking in sophistication, the Miller Multimatic 215 might just be the step-up you’re looking for. Sharing similar features and capabilities with the Lincoln, the 215 boasts a more polished and refined experience.

The Miller Multimatic 215 is arguably one of the easiest-to-use MIG welders, compatible with both 120V and 240V inputs. This multi-voltage capability means you can easily switch between different power sources. Similar to the Hobart 210 MVP, changing the voltage input is a hassle-free process involving only the swapping of the plug-end, and there’s no need for tools. The unused plug can be conveniently stored inside the welder, ensuring it’s always there when you need it and never misplaced.

As a versatile multi-process welder, the 215 is ready for MIG, flux core, and stick welding right out of the box. It can also handle DC-TIG welding with the addition of the Miller TIG kit. A particularly user-friendly feature is the inclusion of an extra gas port. This allows you to keep both your MIG gas and 100% Argon gas cylinders connected simultaneously, enabling seamless switching between processes without the need to stop and change tanks.

The Miller Spoolmate 100 and 150 spool guns are effortlessly compatible with the Multimatic 215. The welder automatically recognizes the spool gun, eliminating the need to remember to activate a switch. Additionally, the Auto-Set feature can be used with a spool gun, running a built-in program to synchronize the gun with the welder for straightforward and reliable aluminum welding.

One of my favorite features in the 215 is the fan-on-demand. This intelligent design means the cooling fans only operate when necessary, reducing the constant noise and minimizing the amount of smoke and dust pulled through the welder.

In terms of portability, the welder comes with a top-center mounted handle typical of portable welders. However, Miller enhances this with additional handles at each end, making it easier and more secure to move the machine. These extra handles are particularly useful for more controlled maneuvering when loading or unloading the welder from a vehicle.

Pros

- Portability: Lightweight design, weighing under 40 lbs, easy to transport.

- User-Friendly Setup: Equipped with an LCD screen for simplified setup.

- Fan-on-Demand: Cooling system operates only when necessary, reducing noise and dust intake.

- Dual Gas Ports: Allows simultaneous connection of two different gas types for easy process switching.

- Dual Voltage: Compatible with both 120V and 240V inputs, enhancing versatility.

Cons

- Costly: Higher price point compared to similar models.

- Higher Minimum Amperage: This may limit the welder’s control and precision on thinner metals.

When considering the Purchase of a 110-Volt MIG Welder, There are a Few Key Factors to Keep in Mind

Voltage Variations (110V, 115V, 120V)

- The difference between 110, 115, or 120 volts isn’t significant due to the ANSI C84.1 electrical power standard, which allows for an operating range of 108-126V for a nominal 120-volt circuit. Welder manufacturers rate their machines within this range based on independent decisions.

Circuit Amperage and Welder Performance

- Most 110V welders are designed for 20-amp circuits, but many household outlets are only 15-amps. Using a welder on a 15-amp circuit can lead to reduced performance, shorter duty cycles, or even tripped breakers.

Understanding Duty Cycles

- Duty cycle ratings indicate how long a welder can run at a specific power level before needing to cool down. For example, a duty cycle of 20% @90A (19V) means the welder can operate for 2 minutes at 90 amps and then needs an 8-minute cooling period in a 10-minute cycle.

- Exceeding the duty cycle can cause overheating and trigger the thermal overload relay, halting welding until the machine cools down.

Duty Cycles and Output Power

- The duty cycle inversely varies with the welder’s output power. Higher output reduces the duty cycle, while lower output increases it.

- Inverter-based welders, which are cooler and more efficient than traditional transformer machines, typically offer higher and more consistent duty cycles. For instance, the Multimatic 215 boasts a 60% duty cycle at 110A on 120V power.

Practical Tips for Hobbyists

- Many hobbyists rarely face duty cycle issues if the welder receives adequate power, which means using a dedicated 20-amp circuit.

- When using an extension cord, ensure it is properly sized to avoid power loss and maintain optimal welder performance.

Final Thoughts

In conclusion, when it comes to selecting the best 110v MIG welder, the decision ultimately hinges on a balance between functionality, ease of use, and budget considerations. The market offers a range of options, from the highly portable Forney Easy Weld 140 MP, ideal for hobbyists and DIY enthusiasts, to the more sophisticated and robust Miller Multimatic 215, suitable for those seeking advanced features and versatility. While budget options like the Lotos MIG140 provide a great starting point for beginners, it’s crucial to consider the long-term value and reliability, as seen in models like the Hobart Handler 210 MVP, which combines power with user-friendliness.

Furthermore, understanding the nuances of each welder, such as duty cycles, voltage requirements, and the necessity for additional accessories for processes like TIG welding, is essential. It’s also important to consider the electrical setup of your workspace, as many powerful welders require a 20-amp circuit. Ultimately, the best 110v MIG welder for you will align with your specific welding needs, skill level, and the types of projects you intend to undertake, ensuring a satisfying and productive welding experience.

Frequently Asked Questions

- What is a 110V MIG Welder Best Suited For?

110V MIG welders are ideal for home use, light fabrication, auto body work, and other DIY projects due to their portability and compatibility with standard household outlets. - Can 110V MIG Welders Handle Industrial-Level Work?

While some high-end 110V MIG welders can handle heavier tasks, they are generally more suited for light to medium-duty work due to their power limitations. - What Thickness of Metal Can a 110V MIG Welder Typically Handle?

Most 110V MIG welders can comfortably weld materials from 24 gauge up to 1/4 inch, depending on the model and settings. - Do I Need a Special Power Outlet for a 110V MIG Welder?

Most 110V MIG welders can be plugged into a standard household outlet, but it’s recommended to use a 20-amp circuit for optimal performance. - Can I Weld Aluminum with a 110V MIG Welder?

Yes, but it usually requires a spool gun and appropriate settings. Some models may not support aluminum welding, so it’s essential to check the welder’s specifications. - What is the Importance of Duty Cycle in a 110V MIG Welder?

The duty cycle indicates how long you can weld at a certain amperage before needing to let the welder cool down. It’s crucial for managing the welder’s workload and preventing overheating. - Are Inverter-Based 110V MIG Welders Better?

Inverter-based welders are generally more efficient, have better arc stability, and are lighter compared to transformer-based models, making them a popular choice. - Do I Need Additional Equipment to Start Welding with a 110V MIG Welder?

Besides the welder, you’ll typically need safety gear, MIG wire, and potentially a gas cylinder for MIG welding. Some models might require additional accessories for different welding processes. - How Do I Choose the Right Wire for My 110V MIG Welder?

The choice of wire depends on the material being welded and the welding process. For example, for mild steel, an ER70S-6 wire is commonly used. - Can I Upgrade My 110V MIG Welder for Better Performance?

Some models allow upgrades like installing a spool gun, larger wire spool capacity, or different drive rollers, which can enhance the welder’s versatility and performance.

We’d love to hear from you! Please share your personal experiences and insights about the best 110v MIG Welders in the comments section below. Whether you’re a seasoned welder or a beginner, your feedback could greatly assist others in making informed decisions. Tell us about your favorite models, the projects you’ve tackled, and any tips you have for using these welders effectively. Your contributions are invaluable to our community of welding enthusiasts!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment