Best Ways to Use Log Splitter Wedge

- March 1, 2024

- 0 comment

Log splitters have become essential for both personal and commercial wood splitting tasks, streamlining what was once a daunting and time-consuming activity. The advent of various splitter wedges has transformed wood splitting into a faster, more efficient, and significantly less labor-intensive process.

These wedges, ranging from standard, four-way, to six-way, are designed to meet different splitting needs, accommodating logs of varying sizes and types of wood. In this guide, we explore the optimal methods to employ these innovative splitter wedges, aiming to maximize the utility and efficiency of your log splitter.

By understanding how to effectively choose and use the right wedge for each task, operators can enhance their wood-splitting efficiency, reduce physical strain, and save valuable time, making the most of their log splitting equipment.

Table of Content List:

- Assess Log Size and Type

- Choose the Right Wedge for the Job

- Position Logs Correctly

- Manage Knots and Irregularities

- Keep Safety in Mind

Understanding Your Log Splitter Wedge Options

Before diving into the best practices, it’s crucial to familiarize yourself with the types of wedges available for log splitters. The standard wedge, four-way wedge, and the six-way wedge each serve unique purposes, tailored to different splitting needs.

- The Standard Wedge: Ideal for basic splitting, creating two halves from a single log. It’s the go-to for oversized logs or when precision is key.

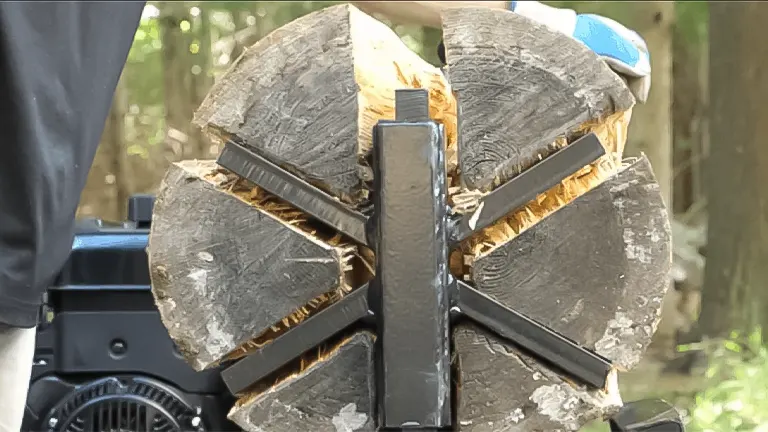

- The Four-Way Wedge: Designed for efficiency, the four-way wedge splits a log into four pieces in a single cycle. Perfect for medium-sized logs, this wedge is a time-saver.

- The Six-Way Wedge: The pinnacle of productivity, the six-way wedge splits logs into six parts at once. Best used on smaller, uniform logs for maximum output.

5 Ways Effective Strategies for Log Splitting

Leveraging the right techniques can significantly enhance your splitting efficiency. Here are the top strategies for using your log splitter wedges effectively:

1. Assess Log Size and Type

Selecting the appropriate wedge begins with a careful assessment of the log’s size and type of wood. Denser woods, such as oak or maple, typically necessitate the use of a standard wedge for a straightforward split, while softer woods are more amenable to splitting with four-way or six-way wedges.

Understanding the characteristics of the wood you’re working with enables you to choose the most effective tool for the job, ensuring efficient and effective splitting.

2. Choose the Right Wedge for the Job

The standard wedge is best suited for splitting large, challenging logs where precise control is paramount. For more routine splitting tasks, the four-way wedge offers a balance of efficiency and ease, splitting logs into four pieces in one go.

For smaller logs, where maximizing productivity is the goal, the six-way wedge is the ideal choice, enabling you to quickly process logs into multiple pieces, thus speeding up the entire splitting operation.

3. Position Logs Correctly

Proper log positioning is crucial for optimal splitting results. Placing the log on the splitter so that the wedge aligns with the wood’s grain not only ensures a cleaner, more consistent split but also minimizes wear and tear on the machine.

This technique leverages the natural lines of weakness in the wood, facilitating easier splitting and extending the lifespan of both the wedge and the splitter.

4. Manage Knots and Irregularities

Handling logs with knots or unusual shapes can pose significant challenges. In such cases, employing a standard wedge allows for targeted splitting, enabling you to isolate and manage these difficult sections more effectively.

This approach helps in avoiding the potential pitfalls that knots and irregularities present, ensuring a smoother, more uniform splitting process across a wide variety of wood types.

5. Keep Safety in Mind

Safety should always be the top priority when operating a log splitter. Ensuring the use of appropriate protective gear, such as gloves, eye protection, and sturdy footwear, and adhering strictly to the operational guidelines of your log splitter, are essential practices.

By maintaining a focus on safety, you can prevent accidents and injuries, making the wood-splitting experience safer and more enjoyable for everyone involved.

Optimizing Your Splitting Session

Maximizing your log splitter’s efficiency isn’t just about the splitting itself; preparation and post-splitting practices also play a crucial role.

- Prep Your Logs: Trim off any protruding branches or irregularities to ensure a smooth loading process onto the splitter.

- Stay Organized: Keep your splitting area organized, with clear zones for unsplit logs, the splitter, and split wood. This reduces downtime between splits and keeps the process flowing smoothly.

- Regular Maintenance: Keep your log splitter and wedges in top condition with regular maintenance. Sharpen the wedges as needed and ensure the splitter’s hydraulic system is functioning correctly.

Leveraging Technology for Enhanced Productivity

In the age of technological advancement, log splitters have seen significant improvements. Features like adjustable wedge positions, hydraulic log lifts, and automated splitting cycles can further enhance your efficiency. Investing in a splitter with these capabilities can save time and labor, making the wood-splitting process even more productive.

Additional Tips For Safety and Maintenance Tips

- Regular Inspection and Maintenance: Before each use, inspect your log splitter and wedges for any signs of wear, damage, or malfunction. Check hydraulic lines for leaks, ensure all nuts and bolts are tightened, and verify that the wedge is securely attached. Regular maintenance, such as changing the hydraulic fluid and filter as recommended by the manufacturer, can prevent breakdowns and extend the lifespan of your equipment.

- Use a Log Splitter Stand or Workbench: Operating your log splitter at a comfortable height can significantly reduce the risk of back strain and other injuries. If your model does not come with a stand, consider purchasing or building a sturdy workbench that brings the splitter to waist level. This not only improves safety but also enhances efficiency and comfort during long splitting sessions.

- Keep the Area Clear and Stable: Ensure the ground around your log splitter is stable, level, and free of debris. Slippery or uneven surfaces can lead to accidents. Keeping the area clean and organized also reduces tripping hazards and allows for a smoother workflow, contributing to a safer work environment.

- Implement a Two-Person Operation Protocol When Necessary: For particularly large or awkward logs, consider employing a two-person operation protocol, where one person operates the machine controls, and the other assists with positioning and removing the logs. This approach can improve safety by distributing the workload and ensuring that the operator can focus on managing the controls without distraction. Always communicate clearly and establish roles before starting to ensure both parties understand their responsibilities and actions during the splitting process.

Related Articles:

- Log Splitter Oil Change and Hydraulic Fluid Change

- Two Essential Log Splitter Modifications Every Owner Should Consider

- Best 3-Point Hitch Log Splitters

- Best Manual Log Splitters 2024

- Best Log Splitter for the Money 2024

- Wood Splitting Made Easy: The Tire Trick

Final Concluding Thoughts

Log splitters and their accompanying wedges are powerful tools that can significantly ease the labor of splitting wood. By understanding the different types of wedges and employing effective strategies, you can maximize your splitter’s efficiency, making your wood-splitting task quicker, easier, and more enjoyable. Remember, the key to successful log splitting lies in choosing the right wedge for the job, maintaining your equipment, and adhering to safety practices.

For those looking to delve deeper into strategies for boosting productivity in wood splitting or other areas, exploring SEO and online marketing techniques can offer additional insights. Enhancing your website’s visibility and traffic can be just as crucial for your business as optimizing your log-splitting process.

Frequently Asked Questions

- What types of wedges are available for log splitters?

There are primarily three types of wedges used in log splitters: the standard (single) wedge, the four-way wedge, and the six-way wedge. Each is designed for different splitting needs based on log size and type. - How do I choose the right wedge for my log splitting task?

Select the wedge based on the log’s size and the wood type. Use a standard wedge for large, tough logs, a four-way wedge for general tasks, and a six-way wedge for smaller logs to increase productivity. - Can I use a four-way wedge on any size log?

While a four-way wedge is versatile, it’s best used on medium-sized logs. Large logs may require more force than a four-way wedge can efficiently handle, and small logs may not be split evenly by the wider spread of the wedge. - Is it necessary to adjust the log’s position on the splitter?

Yes, aligning the log so that the wedge follows the grain ensures a cleaner split and reduces stress on the machine, prolonging its lifespan. - How do I deal with logs that have knots or are irregularly shaped?

For logs with knots or irregular shapes, using a standard wedge allows for more precise control over the split, helping to manage these challenging sections more effectively. - What safety precautions should I take when using a log splitter wedge?

Always wear appropriate safety gear, including gloves, eye protection, and sturdy boots. Follow the manufacturer’s operational guidelines closely to ensure safe use of the log splitter. - Can I switch wedges during a splitting session?

Yes, depending on the log splitter model, you can switch between wedge types to match the specific needs of each log, maximizing efficiency and productivity. - How do wood types affect the choice of wedge?

Dense hardwoods like oak or maple may split better with a standard wedge for a clean, controlled split, while softer woods can be efficiently processed with four-way or six-way wedges. - What maintenance is required for log splitter wedges?

Regularly inspect wedges for wear and tear, and sharpen them as needed to maintain efficient splitting capability. Also, ensure that the wedge attachment mechanism is secure and functioning correctly. - How can I improve the efficiency of my wood-splitting process using wedges?

Assess each log’s characteristics before splitting, choose the appropriate wedge, and position the log correctly. Keeping your equipment well-maintained and adhering to safety practices will also contribute to a more efficient and safe wood-splitting process.

We’re eager to learn from your experiences! Share your personal stories and insights on the best ways to use log splitter wedges in the comments section below. Your knowledge and tips could greatly assist fellow woodworkers and enthusiasts in optimizing their use of log splitter wedges, making their work more efficient and effective. Let’s help each other make informed choices and get the most out of our equipment!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment