10 Best Welding Clamps for 2024

- April 4, 2024

- 0 comment

10 Best Welding Clamps for 2024 demands not just skill and precision, but also the right set of tools. Among these, welding clamps play a pivotal role in ensuring workpieces are securely held together, leading to safer and more accurate welding outcomes. As technology and manufacturing processes evolve, so do the tools welders rely on. The year 2024 brings with it an array of welding clamps that stand out for their innovation, quality, and reliability. Here’s a closer look at the best welding clamps for 2024, each with its unique features designed to meet various welding needs.

We’ve got your welding covered! Find comfy, Best welding gloves, Best welding boots, Best welding jackets, Best welding carts, plus top picks for Best TIG Welder, Best MIG Welder & Best ARC Welders – all without breaking the bank!

List of Best Welding Clamps for 2024

- Hobart T-Style Brass Ground Clamp

- Lincoln Electric 300 Amp Ground Work Clamp

- Gimiton 800 Amp Arc Welding Ground Clamp

- Betooll Cast Iron Welders Angle Clamp

- Irwin Vise-Grip Locking Welding Clamp

- Tekton 11-Inch Locking C-Clamp

- Bessey Magnetic Ground Clamps

- Baytory Upgrade Magnetic Welding Ground Clamp

- MaxPower Thick Rail F Clamp

- Bessey Clutch Style Bar Clamps

Top Rated Welding Clamps

1. Hobart T-Style Brass Ground Clamp: Best Overall

Technical Specifications

- Material: High-grade brass

- Current Capacity: Up to 500 amps

- Design: T-Style for wide grip

- Features: Excellent conductivity; corrosion-resistant; suitable for various welding environments.

The Hobart T-Style Brass Ground Clamp is a testament to superior craftsmanship and material quality. Made from high-grade brass, this clamp offers excellent electrical conductivity, crucial for effective grounding. Its T-style design ensures a wide grip and easy handling, making it a go-to for welders looking for efficiency and durability.

Advantage

- Brass ensures optimal grounding for safer and more efficient welding.

- Resistant to corrosion and wear, making it a long-lasting investment.

- The T-style handle provides a comfortable grip, enhancing user experience during long welding sessions.

Disadvantage

- Premium materials and construction come with a higher price tag, potentially limiting accessibility for hobbyists or those on a tight budget.

- The durable brass construction adds to the weight, which may not be ideal for welders who prefer lightweight tools for ease of maneuverability.

About This Item

- Superior Conductivity Made from high-grade brass for optimal electrical conductivity and efficient grounding.

- Durable Design Corrosion-resistant brass construction ensures longevity and reliability in various welding environments.

- Versatile Use T-Style grip offers a comfortable and secure hold, suitable for a wide range of welding applications.

- High Current Capacity Capable of handling up to 500 amps, making it versatile for both light and heavy-duty welding tasks.

2. Lincoln Electric 300 Amp Ground Work Clamp: Most Innovative

Technical Specifications

- Material: Heavy-duty steel

- Current Capacity: 300 amps

- Jaw Opening: Up to 2 inches

- Features: Wide jaw for various applications; built for durability and easy handling.

A blend of strength and simplicity, the Lincoln Electric 300 Amp Ground Work Clamp is designed for welders who demand reliability. This clamp is built to support up to 300 amps, catering to a broad range of welding applications from automotive repairs to heavy machinery maintenance.

Advantage

- Known for its durability and reliability in providing a solid grounding connection.

- Suitable for a range of welding applications, from hobbyist projects to professional work.

Disadvantage

- While versatile, its fixed jaw opening may not accommodate all project sizes.

- Primarily designed for grounding, it may not be as multifunctional as some other clamps.

About This Item

- Strong and Reliable Heavy-duty steel construction designed to withstand tough welding conditions.

- Medium to Heavy-Duty With a 300 amp capacity, it’s ideal for a variety of welding jobs.

- Wide Jaw Opening Accommodates up to 2 inches, providing flexibility for different project sizes.

- Easy Handling Ergonomically designed for comfortable use and efficient operation.

3. Gimiton 800 Amp Arc Welding Ground Clamp: Best for High Amperage

Technical Specifications

- Material: Robust metal alloy

- Current Capacity: 800 amps

- Clamping Mechanism: Screw-type

- Features: High amperage capacity; designed for industrial use; ensures stable ground connection.

For those challenging projects that require high power, the Gimiton 800 Amp Arc Welding Ground Clamp stands ready. Its heavy-duty design is not just about handling high amperage; it’s about ensuring consistent, reliable performance where it matters most.

Advantage

- High Power Capability: Can handle high amperage, making it suitable for industrial and heavy-duty welding tasks.

- Constructed to endure tough working conditions and high temperatures without losing grip or conductivity.

Disadvantage

- The size and design may not be as convenient for smaller, more delicate jobs where finesse is required.

- Aimed at professional settings, the high amperage capacity can mean a higher upfront cost, potentially out of reach for casual users.

About This Item

- High Amperage Support Designed for industrial use with an 800 amp capacity for heavy-duty welding tasks.

- Robust Construction Made from durable metal alloy to ensure stability and longevity.

- Secure Grounding Ensures a reliable ground connection for safer, higher quality welding.

- Screw-Type Mechanism Offers a firm grip on workpieces for uninterrupted welding.

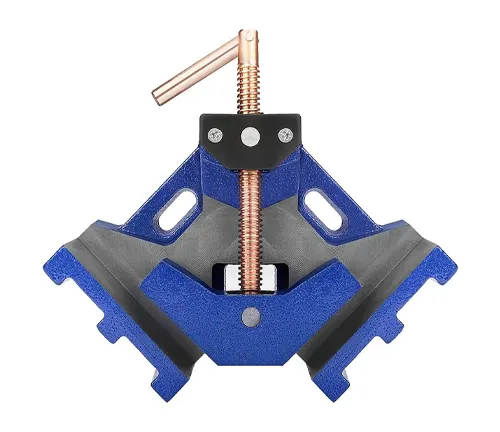

4. Betooll Cast Iron Welders Angle Clamp: Most Durable

Technical Specifications

- Material: Cast iron

- Clamping Angle: Adjustable up to 90 degrees

- Jaw Opening: Up to 2.5 inches

- Features: Designed for precision angle welding; durable construction; suitable for heavy-duty tasks.

Precision meets durability in the Betooll Cast Iron Welders Angle Clamp. Specifically designed for accurate angle welding, this tool is indispensable for fabricators and constructors who prioritize precision in their work. Its cast iron construction ensures it can withstand the rigors of the workshop.

Advantage

- Built to withstand the rigors of the workshop, providing reliability for heavy-duty applications.

- Allows for accurate alignment of workpieces at right angles, crucial for certain welding tasks.

- Offers a solid base that prevents movement during welding, ensuring consistency and quality.

Disadvantage

- Prone to rust if not properly cared for, necessitating regular maintenance.

- The significant weight and size of the clamp may make it cumbersome to move and adjust, particularly in tight spaces.

About This Item

- Precision Angle Welding Adjustable up to 90 degrees for accurate welds and joint work.

- Heavy-Duty Material Cast iron construction provides strength and durability for long-term use.

- Stability Offers a solid base that prevents movement during welding, enhancing workpiece consistency.

- Versatile Clamping Ideal for fabricating, welding, and repairing metal objects at precise angles.

5. Irwin Vise-Grip Locking Welding Clamp: Most Versatile

Technical Specifications

- Material: Alloy steel

- Length: 9 inches

- Clamping Force: Adjustable, with a quick-release mechanism

- Features: Locking mechanism for secure grip; ergonomic design for comfort; versatile for various projects.

Irwin’s Vise-Grip Locking Welding Clamp brings flexibility and security to your welding setup. With its patented locking mechanism, this clamp allows for easy adjustment while guaranteeing your workpiece remains immovable, offering peace of mind for detailed welding tasks.

Advantage

- Provides a secure grip that prevents slippage, enhancing safety and precision.

- Beyond welding, it’s versatile enough for a range of applications, making it a valuable tool in any workshop.

Disadvantage

- Requires some learning to adjust the pressure correctly without damaging materials.

- Frequent use of the locking mechanism may lead to wear, necessitating occasional maintenance or replacement.

About This Item

- Secure Locking Mechanism Features a patented locking mechanism for a firm hold on workpieces.

- Versatile Application Suitable for a wide range of welding, assembling, and repairing tasks.

- Ergonomic Design Designed for comfort and ease of use, reducing hand fatigue during extended periods.

- Adjustable Pressure Allows for precise pressure adjustments to suit different materials and thicknesses.

6. Tekton 11-Inch Locking C-Clamp: Best for Flexibility

Technical Specifications

- Material: Forged steel

- Length: 11 inches

- Jaw Opening: Up to 3.25 inches

- Features: Wide range of clamp sizes; adjustable pressure; durable and suitable for both light and heavy tasks.

The Tekton 11-Inch Locking C-Clamp is designed for versatility, with an adjustable screw mechanism that can accommodate a wide range of material sizes. Its robust build quality ensures longevity, making it a valuable addition to any welder’s toolkit.

Advantage

- Offers a wide range of adjustments, making it suitable for clamping various sizes and shapes of materials.

- Forged steel ensures it can withstand the demands of regular use.

Disadvantage

- Achieving the right balance of pressure requires practice, which might be challenging for beginners.

- Without proper padding, the strong grip can mar the surface of softer materials.

About This Item

- Wide Opening and Adjustable Offers up to 3.25 inches of jaw opening for clamping various sizes and shapes.

- Forged Steel Durability Constructed with durability in mind, ensuring longevity and reliability.

- Versatile Clamping Ideal for both light and heavy-duty projects across welding, carpentry, and metalworking.

- Easy Adjustment Features an adjustable screw for quick and precise pressure settings.

7. Bessey Magnetic Ground Clamps: Best for Precision

Technical Specifications

- Material: High-quality steel with magnetic base

- Current Capacity: Up to 300 amps

- Magnetic Force: Strong, for secure attachment

- Features: Quick setup and adjustment; eliminates the need for traditional grounding methods.

Innovative and efficient, Bessey Magnetic Ground Clamps introduce ease and speed into setting up for welding. The magnetic base allows for quick placement and adjustment, significantly reducing setup time while ensuring a strong ground connection.

Advantage

- The magnetic attachment allows for quick and easy setups, significantly reducing prep time.

- Can be used on any ferromagnetic surface, offering flexibility in welding setups.

Disadvantage

- Effectiveness can be diminished on non-magnetic or very thick materials, slightly limiting its versatility.

- Magnets must be handled with care to avoid accidental attachment to unintended objects or surfaces, which could pose safety risks.

About This Item

- Magnetic Convenience Quickly set up and adjust welding grounds with the strong magnetic base.

- Efficient Welding Eliminates the need for traditional clamping methods, streamlining the welding process.

- Suitable for Various Surfaces Works on any ferromagnetic material, offering versatility in application.

- Safe and Clean Provides a clean, reliable ground connection, enhancing welding safety and quality.

8. Baytory Upgrade Magnetic Welding Ground Clamp: Best Upgrade

Technical Specifications

- Material: Steel with upgraded magnetic technology

- Current Capacity: Up to 600 amps

- Magnetic Force: Enhanced for stronger grip

- Features: Improved design for efficiency; strong magnetic hold for secure welding; easy to attach and detach.

Taking magnetic technology a step further, the Baytory Upgrade Magnetic Welding Ground Clamp features enhanced magnetic strength for even more secure grounding. Its upgraded design focuses on user convenience and safety, making it an excellent choice for fast-paced work environments.

Advantage

- Provides a stronger and more secure connection than standard magnetic clamps, ensuring stability during welding.

- Easy to attach and detach, saving time and effort, especially in complex setups.

Disadvantage

- Optimal performance depends on clean, flat surfaces, which may not always be available in all welding scenarios.

- While offering upgraded features, the cost-benefit ratio should be considered, especially if the additional grip strength is not a necessity.

About This Item

- Enhanced Magnetic Strength Upgraded magnets offer a stronger and more secure connection than standard models.

- Quick and Easy Setup Designed for efficiency, allowing for fast attachment and detachment on workpieces.

- Improved Design Features an enhanced structure for better performance and durability.

- High Current Capacity Supports up to 600 amps, making it suitable for a range of welding applications.

9. MaxPower Thick Rail F Clamp: Best for Large Projects

Technical Specifications

- Material: Heavy-duty steel

- Length: Varies (available in multiple sizes)

- Clamping Force: High, with large clamping surface

- Features: Suitable for large projects; robust construction for added durability; wide opening for versatile use.

Designed for the toughest tasks, the MaxPower Thick Rail F Clamp boasts a large clamping surface and a sturdy frame. This clamp is ideal for handling large, heavy workpieces, providing the necessary force to keep them securely in place during welding.

Advantage

- Ideal for securing large workpieces, providing broad versatility in project scope.

- Designed to exert significant force without compromising on the clamp’s integrity over time.

Disadvantage

- Due to its size and strength, making precise adjustments can be time-consuming.

- Not the easiest to handle, especially in tight spaces or where quick repositioning is needed.

About This Item

- Large Clamping Capacity Ideal for securing large and heavy workpieces with its robust design.

- High Durability Constructed for strength, capable of exerting significant force without compromise.

- Versatile Use Suitable for woodworking, metalworking, and welding, providing broad utility.

- Precision Adjustment Offers precise control over clamping pressure for delicate or robust tasks.

10. Bessey Clutch Style Bar Clamps: Best Quick-Adjust

Technical Specifications

- Material: Steel

- Length: Available in various lengths

- Clamping Mechanism: Clutch style for quick adjustment

- Features: Quick-release mechanism; lightweight yet sturdy; ideal for fast-paced work environments.

The Bessey Clutch Style Bar Clamps are all about speed and simplicity. With a quick-release mechanism, these clamps are perfect for projects requiring frequent adjustments. They provide a reliable hold, ensuring that workpieces remain steady throughout the welding process.

Advantage

- Allows for quick and easy adjustments, ideal for projects requiring frequent repositioning.

- Easier to handle and maneuver, reducing fatigue during prolonged use.

Disadvantage

- While suitable for many applications, it may not provide enough force for very heavy-duty tasks.

- The clutch mechanism may wear over time, especially under heavy use, affecting performance.

About This Item

- Quick-Adjust Mechanism Features a clutch style for rapid adjustments, enhancing workflow efficiency.

- Lightweight and Strong Offers a perfect balance between strength and ease of handling.

- Versatile Clamping Solution Suitable for a wide range of projects, from woodworking to metal fabrication.

- Durable Construction Engineered for reliability and long-term use, ensuring consistent performance.

Comparison Table

| Clamp Type | Material | Jaw Opening | Key Feature | Best For |

|---|---|---|---|---|

| Hobart T-Style Brass Ground | Brass | N/A | High conductivity | Effective grounding |

| Lincoln Electric 300 Amp | Steel | Up to 2 inches | Wide jaw, durable | Medium to heavy-duty welding |

| Gimiton 800 Amp Arc | Metal Alloy | N/A | High amperage capacity | Industrial welding |

| Betooll Cast Iron Angle | Cast Iron | Adjustable | Precision angle welding | Fabrication and heavy-duty |

| Irwin Vise-Grip Locking | Alloy Steel | 9 inches | Secure locking mechanism | Versatile clamping |

| Tekton 11-Inch Locking C | Forged Steel | Up to 3.25 in | Wide opening, adjustable | Varied size projects |

| Bessey Magnetic Ground | Steel | N/A | Quick setup, magnetic base | Quick grounding setups |

| Baytory Upgrade Magnetic | Steel | N/A | Enhanced magnetic strength | Secure, fast-paced grounding |

| MaxPower Thick Rail F | Steel | Various | Large capacity, durability | Large, heavy workpieces |

| Bessey Clutch Style Bar | Steel | Various | Rapid adjustment, lightweight | Quick adjustments, versatile |

Choosing the Right Welding Clamp Type

Choosing the right type of welding clamp for your project is crucial for achieving the best results and ensuring safety. Here are five types of welding clamps and guidance on selecting the right one:

- Ground Clamps

Best for: Establishing a solid electrical connection to the workpiece, essential for arc welding.

Choosing Tips: Look for a clamp with a high current capacity that matches or exceeds your welder’s output. Materials like brass offer excellent conductivity. - Locking C-Clamps

Best for: Holding pieces in place with a firm grip. Ideal for projects requiring precision and where the workpiece might move during welding.

Choosing Tips: Consider the size and depth of the throat to ensure it fits your workpiece. Adjustable pressure settings can prevent distortion of the material. - Angle Clamps

Best for: Fabrication that requires welding at specific angles or corners, such as creating frames or boxes.

Choosing Tips: Look for an angle clamp that can adjust to various angles and securely hold different material thicknesses. - F-Clamps/Bar Clamps

Best for: Projects that need a wide opening and flexibility in the size of the workpieces being joined. Great for layout and fit-up before welding.

Choosing Tips: Pay attention to the clamp’s maximum opening and the length of the bar. A larger clamp can handle a wider range of project sizes. - Magnetic Clamps

Best for: Quick setups and when working with ferromagnetic materials. Useful for holding pieces in place without the need for physical adjustment.

Choosing Tips: Consider the strength of the magnet based on the weight of the workpiece. Ensure the clamp’s design allows for easy positioning and repositioning.

Conclusion

As we delve into the advancements of welding tools for 2024, it’s evident that the right welding clamp can significantly enhance project outcomes, offering a blend of efficiency, safety, and precision. The diverse selection, from the highly conductive Hobart T-Style Brass Ground Clamp to the innovative Bessey Magnetic Ground Clamps, caters to a broad spectrum of welding demands. We invite the welding community to share their experiences with these clamps, enriching our collective knowledge and guiding others in making informed tool choices for their unique projects.

FAQs

- What are welding clamps used for?

Welding clamps are used to hold workpieces in place during welding, ensuring stability, precision, and safety. - How do I choose the right welding clamp?

Choose based on the material, current capacity for grounding clamps, jaw opening size, and specific project requirements such as the need for precision or heavy-duty capacity. - Can I use any clamp for welding?

While many clamps can be adapted for welding, specialized welding clamps are designed for the high temperatures and specific demands of welding applications. - What is the difference between a regular clamp and a magnetic welding clamp?

Magnetic welding clamps use magnets to secure to workpieces, offering quick setup and adjustments, unlike regular clamps that require manual adjustment. - Why is brass used in some welding clamps?

Brass is used for its excellent electrical conductivity and corrosion resistance, ideal for grounding clamps. - How important is the jaw opening of a welding clamp?

Jaw opening is crucial for versatility, determining the range of workpiece sizes the clamp can securely hold. - What does the current capacity of a welding ground clamp indicate?

The current capacity indicates the maximum electrical current the clamp can safely conduct, important for effective grounding in arc welding. - Are heavier welding clamps better?

Not necessarily. The choice depends on the application. Heavier clamps offer stability for heavy-duty work, while lighter clamps are easier to handle and adjust. - How do I maintain my welding clamps?

Regular cleaning, checking for wear, and proper storage are key. For clamps like cast iron models, preventing rust is also important. - Can welding clamps be used for other purposes?

Yes, many welding clamps are versatile enough to be used in other applications requiring material holding, such as in carpentry or metalworking.

We’re eager to connect with you! If you’ve had the chance to use any of the top 10 welding clamps for 2024, please share your experiences and thoughts in the comments section below. Your personal insights are invaluable, helping fellow welders and enthusiasts make well-informed choices. Whether it’s a favorite feature, a tip for optimal use, or general feedback, your contribution can greatly assist the welding community in selecting the right tools for their projects. Let’s help each other build better!

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment