Different Ways To Maintain Your Wood Lathe

- December 8, 2023

- 0 comment

Maintaining your wood lathe is essential for achieving optimal performance and longevity in your turning endeavors. In this comprehensive guide, we’ll delve into several distinct methods to effectively maintain your lathe, ensuring it remains operational and reliable for years to come. By acquainting yourself with preventative measures and potential solutions to common issues, you’ll be well-equipped to preemptively address problems and sustain the functionality of your lathe.

A thorough understanding of various maintenance techniques not only guarantees that your lathe functions as intended but also amplifies the factor of safety in your wood-turning pursuits. Prioritizing the well-being of your equipment is paramount, as it translates into a secure working environment. Remember, the pursuit of productivity should never compromise safety. By consistently implementing the right maintenance practices, you not only safeguard your equipment but also establish a reciprocal relationship where your lathe reliably takes care of your creative needs whenever you call upon it.

Ensure Your Lathe Is Fully Powered Down

It is imperative to prioritize safety when undertaking maintenance on your lathe, given its substantial weight and the potential hazards associated with its numerous high-speed moving parts, capable of exceeding 1,000 RPM. Before embarking on any cleaning or maintenance tasks, ensure that the lathe is completely turned off and unplugged.

This precautionary measure is crucial to prevent accidental activation of the lathe, mitigating the risk of damaging internal components and, more importantly, reducing the possibility of injury, such as getting hands entangled in the swiftly moving machinery. By consistently adhering to this practice, you establish a fundamental foundation for a safe working environment around your lathe.

Examine The Lathe Bed Thoroughly

Inspecting the lathe bed is a crucial step in maintaining your lathe’s optimal performance. Both before and after each lathe session, it is essential to meticulously clear any residual woodchips, dust, or debris that may have accumulated on the lathe bed. Conduct a thorough examination of the bed to identify any signs of rust or deterioration. If you detect minor corrosion, promptly apply a rust remover and utilize a steel wool cleaner to eliminate it.

Addressing rust in its early stages is crucial, as allowing it to persist can impede the smooth movement of the head and tailstock. In cases where the lathe bed exhibits extensive rust that compromises its safety and practicality, it may be necessary to consider replacement. Fortunately, replacing the bed does not entail replacing the entire lathe; the bed can be detached from the rest of the machine for a swift and secure replacement process.

It is essential not to overlook a severely rusted bed, as working with it beyond acceptable standards can detrimentally impact productivity and compromise the safety of your work environment. Prioritizing the condition of the lathe bed contributes significantly to a seamless and safe woodturning experience.

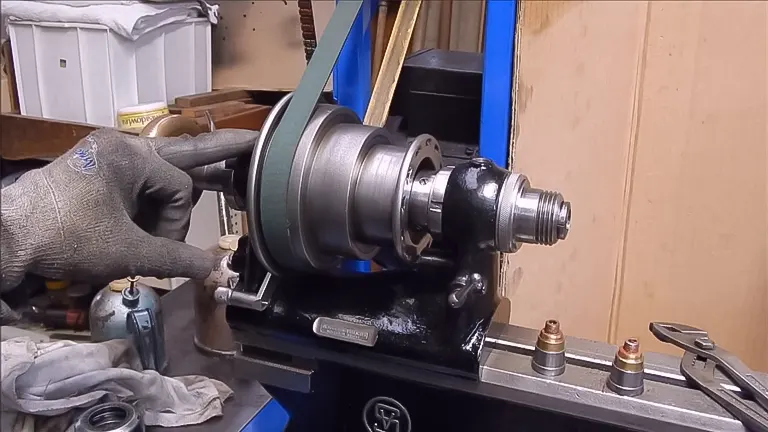

Checking And Adjusting Belt Tension

Ensuring the appropriate tension of the belts in your wood lathe is integral to its efficient operation and longevity. The belts play a pivotal role in transmitting power throughout the lathe’s components. Through my own experience, I’ve come to realize the significance of routinely inspecting and adjusting belt tension to uphold optimal performance.

If the belts are too loose, it can result in inefficient turning, compromising the precision and quality of your work. On the other hand, overly tight belts not only strain the motor but can also lead to long-term damage. Striking the right balance in belt tension is a key preventive measure, safeguarding the integrity of your lathe and ensuring smooth and effective woodturning sessions.

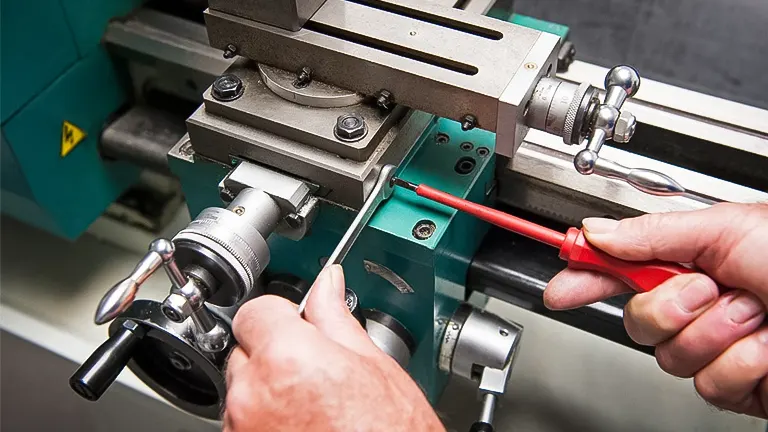

Give Proper Attention To The Morse Taper

The Morse taper, while a seemingly small component, is crucial for mounting tooling on your lathe. However, it is susceptible to clogging with metal filings and fine dust, necessitating regular cleaning to prevent blockages that could compromise its reliability. Failure to address this issue can result in damage to the mechanism, potentially scratching and scuffing the metal components.

In severe cases, neglecting routine cleaning may lead to difficulties in inserting and removing tools, and replacement may become unavoidable. To maintain the functionality and longevity of your lathe, it’s imperative to keep the Morse taper free from wood dust and debris through consistent and thorough cleaning.

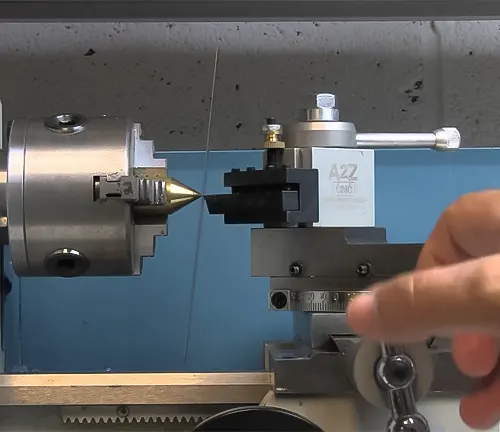

Remove Debris From The Lathe Spindle

The lathe spindle, a pivotal element facilitating the rotation of your workpiece, is exposed to constant debris due to its proximity to the turning and carving process. Accumulation of Morse taper residue, wood dust, oil, and debris in the spindle threads can impede the smooth insertion of the chuck, compromising its stability during woodturning.

To ensure optimal performance and prevent potential malfunctions, it is essential to regularly clean out the excess debris and remove any residual oil. This maintenance step not only ensures a secure fit for the chuck but also mitigates the risk of sudden malfunctions or reduced efficiency during your woodturning projects.

Clean Out The Headstock

The headstock of your lathe, housing the pulley system, is prone to debris accumulation, much like the Morse taper. Regular cleaning of the headstock is crucial to prevent wood shavings and other materials from clogging the intricate components within. Accessing the headstock through its designated panel and using compressed air to clear away debris is a recommended maintenance practice.

This method ensures that the sensitive internal components remain undamaged, as compressed air effectively dislodges stuck debris without exerting excessive pressure on the intricate machinery. By incorporating this cleaning routine into your lathe maintenance, you contribute to the overall cleanliness and safety of the headstock, enhancing the longevity and reliability of your woodturning equipment.

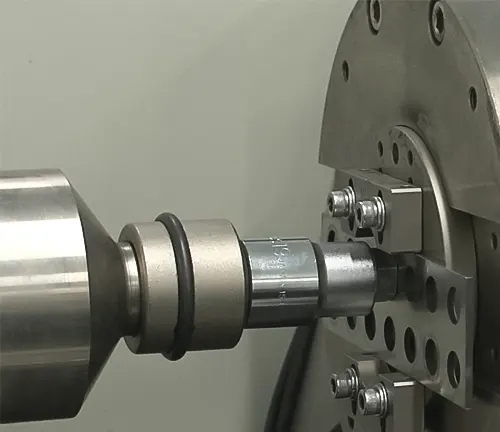

Check Out the Drive Belt

The drive belt is a fundamental component that plays a pivotal role in determining the speed and rotation of the lathe spindle. Regularly inspecting the drive belt is crucial for woodturners to ensure optimal performance. Look for any signs of wear and tear, including the formation of cracks.

It’s essential to examine both sides of the belt, as damage may be present on one side while remaining unnoticed on the other. A meticulous inspection helps identify potential issues before they escalate, ensuring the drive belt doesn’t fail unexpectedly during a project. Replace the belt promptly if you observe significant damage to maintain the efficiency and reliability of your lathe.

Check the Level of the Lathe

The proper alignment and level positioning of the lathe is vital for accurate turning and tool proficiency. Measuring and ensuring that the lathe sits level with the ground is a key maintenance practice. If the lathe is askew or if the floor itself is uneven, adjustments should be made to achieve a level position.

While maintaining a level lathe is not a critical safety concern, it significantly enhances the precision of shaving and increases proficiency with tools. Woodturners using an unlevel lathe may develop habits that negatively impact performance when transitioning to a level lathe, emphasizing the importance of maintaining proper alignment for consistent and accurate turning.

Tighten Any Loose Nuts or Bolts

The constant vibration generated during turning inevitably leads to the loosening of nuts and bolts in the lathe. To counteract this, it is essential to regularly inspect and tighten any loose nuts and bolts before and after each turning session. Properly securing these components is not only a matter of equipment integrity but also a crucial safety measure.

Neglecting to tighten nuts and bolts can result in an unsecured lathe, exposing the woodturner to avoidable dangers. Preventing the lathe from vibrating itself apart requires a proactive approach, involving the identification of all nuts and bolts and a consistent habit of tightening them as needed. This practice ensures a stable and secure lathe setup, promoting a safe and efficient woodturning environment.

MAINTENANCE MADE EASY: A STRAIGHTFORWARD LATHE CHECKLIST

A basic lathe maintenance checklist typically categorizes tasks by frequency, such as daily, weekly, monthly, or annually. While this guide provides a simple checklist, it’s essential to note that most lathe manufacturers offer more detailed maintenance instructions. Always refer to your lathe manufacturer for comprehensive guidelines when creating a maintenance plan.

DAILY CHECKLIST

Conducted at the start of each day or shift, these quick and straightforward tasks ensure the lathe operates smoothly without consuming much time or technical expertise.

- Check gauges, including hydraulics and water line pressure gauges.

- Verify air pressure levels.

- Allow the spindle to warm up at low speed for five minutes.

- Clear away chips from waycovers.

- Clean the chip filter.

WEEKLY CHECKLIST

This set of tasks, best performed every week, addresses slightly more in-depth aspects of lathe maintenance.

- Inspect all filters.

- Check coolant levels and concentration.

- Examine the lathe for any oil or grease buildup.

- Top up oil levels.

MONTHLY OR ANNUAL CHECKLIST

Tasks on this list are less frequent, with some requiring attention every month and others only once or twice a year. These encompass more comprehensive inspections and adjustments.

- Conduct a spindle bearing inspection.

- Inspect and adjust the drive belt.

- Check and, if necessary, change the oil.

- Verify the alignment of the lathe components.

GENERAL INSPECTION GUIDELINES

Maintaining a keen awareness of chips and debris is paramount in ensuring the optimal performance and longevity of your metal lathe. The accumulation of debris in the workspace poses a potential risk of obstruction and jamming, leading to significant damage. Therefore, a clean and organized workspace is essential, facilitating not only the ease of general inspections but also enhancing error detection.

It is advisable to remain vigilant about tidiness, as a clutter-free environment simplifies the execution of lathe inspections and aids in promptly identifying any issues. While routine inspections are crucial, it’s worth noting that some manufacturers or machinery dealers may offer more intricate technical maintenance services annually or semi-annually.

While this comprehensive maintenance may entail additional costs compared to self-conducted inspections, the heightened care and specialized knowledge can contribute significantly to the overall well-being of your lathe.

The implementation of maintenance schedules need not be rigid or overly strict to be effective; rather, consistency and adherence to the schedule are key. By adhering to a well-structured maintenance routine, there is every reason to anticipate the longevity of your lathe spanning decades. Thus, a combination of regular self-inspections, a tidy workspace, and occasional professional maintenance ensures that your metal lathe remains in top-notch condition for years to come.

Why is proper Cutting Speed important?

When set too high the tool breaks down quickly, time is lost by replacing or reconditioning the tool. Too low of a CS results in low production.

Know:

- Depth of cut for Roughing.

- Depth of cut for Finishing.

Notice the largest roughing cuts range from .010 to .030 depending on the material being machined, and .002 to .012 for the finished feed for the different materials.

- Feedrate for Roughing cut

- Feedrate for Finishing cut

Notice the feed rate for roughing cuts ranges from .005 to .020 depending on the material being machined, and .002 to .004 for the finished feed for the different materials.

Conclusion

Maintaining a wood lathe might seem like a chore, but trust me, the payoff is worth it. Through trial and error, I’ve discovered that a combination of regular cleaning, lubrication, and meticulous inspections keeps my wood lathe humming along smoothly. So, fellow woodturners, let’s show our lathes the love they deserve, and they’ll continue to help us create stunning works of art for years to come. Happy turning!

Frequently Asked Questions

- How often should I clean my wood lathe?

Regular cleaning is essential to prevent the accumulation of wood shavings and dust. Aim for a thorough cleaning session after each turning project and a more comprehensive cleaning routine at regular intervals. - What lubricant is best for my wood lathe?

It’s recommended to use a light machine oil for lubricating the moving parts of your wood lathe. Ensure that the lubricant is appropriate for woodworking machinery and apply it according to the manufacturer’s guidelines. - How do I know if my belts need adjustment?

- Pay attention to any unusual sounds or vibrations during operation. If you notice inefficiencies in turning or a decline in performance, it’s time to check and adjust the belt tension. Look for signs of wear and tear, and make adjustments as necessary.

- Can I replace the lathe bed if it becomes rusted?

Yes, in many cases, you can replace the lathe bed without replacing the entire lathe. If rust is beyond acceptable standards and compromises safety, consider replacing the bed for optimal performance. - What’s the importance of aligning the lathe?

Proper alignment ensures precision in turning. Misalignment can lead to inaccuracies in your work. Regularly check and align the lathe bed, tailstock, and tool rest to maintain optimal performance. - How often should I inspect the bearings?

Bearings should be inspected regularly for signs of wear or damage. If you hear unusual noises or experience vibrations, it’s crucial to check and replace the bearings as needed to maintain smooth operation. - Is rust prevention necessary for a wood lathe?

Yes, especially in humid environments. Applying a rust inhibitor to metal components helps prevent corrosion, ensuring the longevity of your wood lathe and preserving its aesthetic appeal. - Why is it essential to turn off the lathe before maintenance?

Turning off and unplugging the lathe before any cleaning or maintenance is crucial for safety. It prevents accidental activation and potential harm to both the lathe’s internal parts and the operator. Always prioritize safety during maintenance activities.

Got tips or personal insights on wood lathe maintenance? Feel free to drop them in the comments below! Whether you’ve discovered a unique trick or want to share your routine, your experiences could be a game-changer for fellow woodturners. Let’s build a community of knowledge and help each other keep our wood lathes in top-notch condition!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment