DIY Saw Guide for Perfect Straight Cuts on Plywood & Sheet Goods

- February 22, 2024

- 0 comment

In my experience, working with plywood and other sheet materials has consistently presented obstacles, especially when striving for accurate, straight cuts. Achieving such precision often seemed unattainable, a goal always just out of reach. However, the situation has now changed. I’ve discovered a practical solution that consistently delivers the exact results needed without costing a fortune.

This solution is a do-it-yourself saw guide designed to ensure straight cuts on every occasion. It’s an affordable, reliable tool that has transformed my woodworking projects, making precise cuts achievable and no longer just a wishful aspiration.

What is a Saw Guide?

A saw guide is an indispensable tool designed to enhance the accuracy and consistency of cuts made with a circular saw. It acts as a physical guide, ensuring that the saw blade follows a precise line on large pieces of wood, such as plywood or MDF (Medium Density Fiberboard). This tool is crucial for projects requiring exact measurements and straight edges, making it a valuable asset for both amateur and professional woodworkers. By providing a reliable path for the saw blade to follow, a saw guide greatly reduces the risk of errors and uneven cuts, facilitating the creation of high-quality woodwork.

Benefits of Using a Saw Guide

The advantages of using a saw guide extend beyond just achieving straight cuts. Firstly, it significantly enhances the safety of operating a circular saw by reducing the likelihood of the blade veering off course and causing potential injury. Secondly, it ensures precision in cutting, which is paramount in woodworking projects where accuracy can make or break the final outcome.

Lastly, minimizing mistakes helps conserve valuable materials that would otherwise be wasted on incorrect cuts. This efficiency is especially crucial given the cost of high-quality wood and sheet materials. Whether for a DIY hobbyist or a seasoned professional, the saw guide is a critical tool that promotes safety, accuracy, and material conservation in woodworking.

Method 1: Setting Up Your Plywood for the Saw Guide

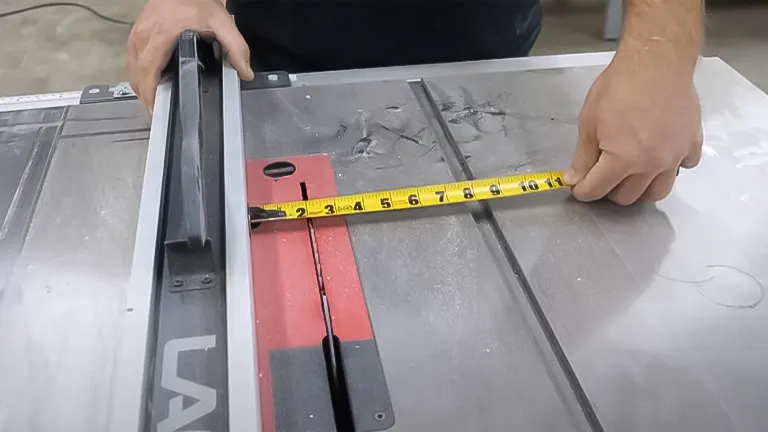

- Preparing the Plywood: Starting with a factory edge, cut a nine-inch strip from your plywood. This strip will be your guide for making a true cut.

- Cutting a Nine Inch Strip: Using the same saw you’ll use with the saw guide, measure and cut a nine-inch strip from your plywood. This will form the base of your saw guide.

Method 2: Assembling the Saw Guide

- Kerf Adjustment: Adjust your saw blade to about 3/16 to a quarter inch high to ensure the guide fits snugly in the groove.

- Screw Placement: Place screws an inch and a half from each end and then every 12 inches along the guide. Use a drill bit slightly larger than your screws to pre-drill through the aluminum.

Method 3: The Initial Cut

Making the initial cut with this saw guide is a moment of truth, showcasing its ability to deliver impeccably straight cuts. This first experience is often a revelation for users, as it proves the guide’s effectiveness and efficiency.

The precision of the cut achieved with this tool can rival professional standards, providing a confidence boost to DIY enthusiasts and craftsmen alike, and demonstrating that high-quality results are within reach for projects involving large wood panels or sheets.

Method 4: The DIY Saw Guide Kit

The DIY Saw Guide Kit is designed to cater to a wide range of cutting needs, offering a comprehensive solution right out of the box. The kit typically includes an eight-foot long saw guide, catering to the demands of cutting large sheets with ease.

To enhance versatility, an additional guide for crosscutting is also provided as part of the package. This inclusion ensures users have the necessary tools for a variety of cutting tasks, making it an indispensable asset for both casual and serious woodworking projects.

Method 5: Advantages Of Commercial Saw Guides

The DIY saw guide stands out from commercial options with its superior length, strength, and a unique lock-in mechanism.

This combination not only ensures safer, more reliable cuts but also enhances the tool’s durability and effectiveness across a range of woodworking tasks.

The guide’s design prioritizes user safety and precision, making it a preferred choice for those seeking an alternative to more expensive commercial products without compromising on quality or performance.

Method 6: Tips for Using the Saw Guide

To maximize the effectiveness of the saw guide, several pro tips can be invaluable. Proper preparation and setup are crucial; ensuring the guide is securely fastened and aligned with the cut line can make a significant difference in the accuracy of the cut.

Additionally, taking time to familiarize oneself with the guide’s features and practicing on scrap material can help refine technique, leading to consistently precise cuts. These practices are essential for achieving professional-quality results, regardless of the project’s complexity.

Method 7: Saving Money with a DIY Saw Guide

Investing in a DIY saw guide is not only a decision for precision but also for significant savings. The cost-effectiveness of this tool is one of its most appealing attributes, as it allows users to avoid the expensive mistakes commonly associated with freehand cuts or inferior guides.

By ensuring precise cuts the first time, the guide helps conserve materials and reduce waste, translating to considerable savings over time. This economic advantage, coupled with the guide’s reliability, makes it a wise investment for DIY enthusiasts and professionals aiming to maximize their resources.

Feedback and Reviews

The DIY saw guide has garnered enthusiastic praise from both amateur DIY enthusiasts and professional woodworkers alike, with particular commendation for its American-made quality and exceptional durability. Users across the spectrum report significant improvements in cutting precision, efficiency, and safety, highlighting the tool’s capacity to withstand the demands of frequent use. This positive feedback underlines the saw guide’s effectiveness and establishes it as an indispensable asset in woodworking projects, affirming its value and reliability for users aiming for professional-grade outcomes in their work.

Final Thoughts

The path to achieving flawlessly straight cuts on plywood and sheet goods is made accessible and cost-effective with our DIY saw guide. Designed to eliminate the frustration and high costs associated with precision cutting, this tool ensures quality and accuracy are within reach for all woodworkers, regardless of their experience level. The widespread positive feedback from our community accentuates the guide’s role in enhancing project outcomes, making it clear that superior craftsmanship is achievable with the right tools. This guide not only simplifies the woodworking process but also opens up new possibilities for creativity and excellence in the craft.

FAQs

- What is a DIY Saw Guide?

A DIY Saw Guide is a tool designed to help users make precise, straight cuts in plywood and other sheet goods, improving accuracy and safety during woodworking projects. - How does the DIY Saw Guide improve cutting accuracy?

The guide aligns with your saw, ensuring it travels in a straight path. This eliminates the wavering that often occurs when cutting freehand, resulting in perfectly straight cuts. - Can I use the DIY Saw Guide with any circular saw?

Yes, the DIY Saw Guide is designed to be compatible with most standard circular saws. Its adjustable nature allows it to fit various saw sizes and models. - Is the DIY Saw Guide suitable for professional use?

Absolutely. While it’s a favorite among DIY enthusiasts, its robust design and precise cutting capability also make it suitable for professional carpenters and contractors. - How long does it take to set up the DIY Saw Guide?

Setup time is minimal, often taking just a few minutes. Once you’re familiar with the guide, attaching it to your plywood and saw takes only a short time, allowing you to start cutting quickly. - Do I need special tools to install the DIY Saw Guide?

No special tools are required. You’ll need basic tools like a drill and screwdriver for assembly, which are commonly found in most DIYers’ toolkits. - What materials can I cut with the DIY Saw Guide?

While specifically designed for plywood and sheet goods, the saw guide can also be used with other materials like MDF, particle board, and even some types of plastics, provided you use the appropriate saw blade. - How do I maintain the DIY Saw Guide for longevity?

Maintenance is straightforward: keep the guide clean, check for loose components regularly, and store it in a dry place. Proper care ensures it remains reliable for many years. - Can the DIY Saw Guide be adjusted for different cut widths?

Yes, the guide can be adjusted to accommodate various cut widths, making it versatile for projects requiring different dimensions of straight cuts. - Where can I purchase the DIY Saw Guide, and what is included in the kit?

The DIY Saw Guide is available through various online platforms and woodworking shops. The standard kit typically includes the saw guide, clamps for securing the guide to your workpiece, and detailed instructions for setup and use.

We’re eager to hear from you! Share your experiences and thoughts about the DIY Saw Guide for Perfect Straight Cuts on Plywood & Sheet Goods in the comments section below. Whether you’ve crafted projects using this guide or have tips and tricks to enhance its use, your insights can greatly assist fellow DIY enthusiasts and woodworkers in making well-informed decisions. Your feedback not only enriches our community but also helps in refining DIY practices for everyone involved.

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment