Hydraulic Pump for Log Splitter: What You Need To Know

- September 4, 2024

- 0 comment

Hydraulic pump for log splitter are essential tools for anyone looking to split firewood efficiently. Whether you’re a homeowner preparing for winter or a professional working with firewood regularly, choosing the right hydraulic pump size for your log splitter is crucial. The size and power of the hydraulic pump significantly impact the splitter’s efficiency and performance. In this article, you are going to learn everything you need to know about hydraulic pump sizes for log splitter operations; its working principles, consideration, and tips for maintenance.

How Does a Hydraulic Pump Work in a Log Splitter?

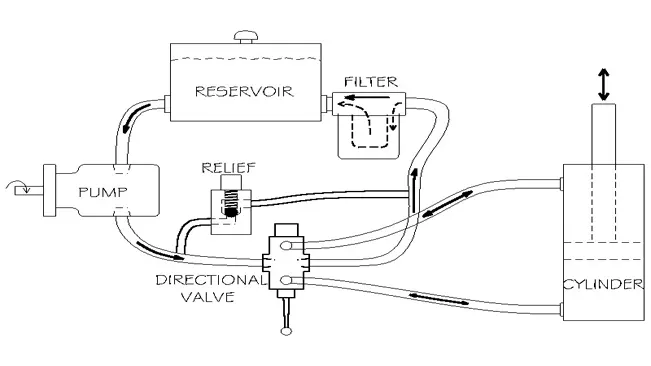

Hydraulic log splitters rely on pressurized fluid to generate the force needed to split logs. The hydraulic pump is the heart of this system, converting mechanical energy from the engine or motor into hydraulic energy. The pump pressurizes the hydraulic fluid, which is then transferred through hoses to the hydraulic cylinder. The pressurized fluid moves the piston in the cylinder, which exerts a force on the wedge, pushing it into the log to split it.

The power of the hydraulic pump, which is often measured in gallons per minute (GPM), directly affects the speed and efficiency of the log splitter. A larger pump can move more fluid, increasing the speed of the splitter’s cycle time, while a smaller pump may generate less force but could be more economical and easier to maintain.

Understanding Hydraulic Pump Sizes for log splitters

Hydraulic pump sizes for log splitters are typically rated based on their flow rate, usually measured in gallons per minute (GPM). The GPM rating determines how fast the hydraulic fluid moves through the system and, consequently, how quickly the log splitter operates. Higher GPM means faster splitting cycles, while lower GPM indicates slower operation.

Common Hydraulic Pump Sizes for Log Splitters:

- 2 GPM Pumps:

- Suitable for smaller, lighter-duty log splitters.

- Often used for splitting small logs with a diameter of less than 10 inches.

- Provides slower cycle times but is more energy-efficient.

- 11 GPM Pumps:

- Ideal for medium-duty log splitters.

- Can handle logs with a diameter of 12 to 18 inches.

- Provides a good balance between speed and power, suitable for both homeowners and professionals.

- 16 GPM Pumps:

- Found in more heavy-duty log splitters designed for larger logs.

- Capable of splitting logs with a diameter of over 18 inches.

- Offers faster cycle times and can be used in professional or commercial settings.

- 28 GPM Pumps:

- Designed for high-powered, commercial-grade log splitters.

- Capable of splitting extremely large and tough logs with diameters greater than 24 inches.

- Ensures the fastest cycle times but requires a powerful engine to operate effectively.

Factors to Consider When Choosing a Hydraulic Pump Size

When selecting a hydraulic pump size for your log splitter, several factors need to be considered. Choosing the right pump will not only improve your log splitter’s performance but also ensure that you get the best value for your money. Here are the key factors to keep in mind:

1. Log Size and Hardness

The size and type of wood you plan to split play a critical role in determining the appropriate hydraulic pump size. For smaller, softer logs like pine or cedar, a smaller pump (around 2 to 11 GPM) will suffice. However, if you’re dealing with large, hard logs such as oak or maple, a more powerful pump (16 to 28 GPM) is necessary to handle the additional force required.

2. Cycle Time

Cycle time refers to how quickly the log splitter completes one full operation—extending and retracting the piston to split a log. Faster cycle times allow you to split more logs in less time, increasing efficiency. A larger hydraulic pump size (with higher GPM) will result in faster cycle times, which is ideal for high-volume work. However, if you are a casual user or have smaller logs, a slower cycle time with a smaller pump may be sufficient.

3. Engine Power

The engine power of your log splitter must be compatible with the size of the hydraulic pump. A larger pump requires a more powerful engine to operate effectively. For example, a 16 GPM pump will need an engine with at least 8 to 11 horsepower (HP), while a 28 GPM pump may need 15 HP or more. If the engine isn’t powerful enough, the log splitter will struggle to achieve optimal performance, resulting in slower operation or potential mechanical failure.

4. Hydraulic Pressure (PSI)

The pressure rating of a hydraulic pump is measured in pounds per square inch (PSI). Higher pressure enables the splitter to exert more force on the log, which is crucial when working with tough or large logs. While GPM measures the speed of the splitter, PSI measures the strength. It’s important to balance both factors when choosing a pump with the right combination of GPM and PSI for the type of wood you’ll be splitting.

5. Efficiency and Fuel Consumption

Larger hydraulic pumps tend to consume more fuel or electricity, depending on whether your splitter is gas-powered or electric. If fuel efficiency is a priority, you might want to opt for a slightly smaller pump that balances performance with lower operational costs. However, if speed and power are more important, then fuel efficiency may be less of a concern.

6. Splitter Design and Configuration

Some log splitters are designed to accommodate specific pump sizes. Before upgrading or replacing your pump, make sure the hydraulic system in your splitter can handle the increased fluid flow and pressure. Overloading a system with an oversized pump can lead to damaged components and reduced lifespan of the equipment.

Maintaining Optimal Hydraulic Pump Performance

Once you’ve selected the right hydraulic pump size for your log splitter, it’s essential to maintain it properly to ensure peak performance and longevity. Regular maintenance not only enhances the efficiency of the splitter but also prevents costly repairs and downtime. Here are a few maintenance tips:

1. Check Hydraulic Fluid Levels

Low hydraulic fluid levels can reduce the power and efficiency of your log splitter. Regularly check the fluid reservoir and top it off as needed. Be sure to use the correct type of hydraulic fluid recommended by the manufacturer.

2. Inspect Hoses and Connections

Over time, hydraulic hoses can wear out, crack, or leak. Inspect hoses and connections regularly for any signs of damage or leaks, and replace them immediately to prevent accidents or loss of pressure.

3. Clean the Hydraulic Filter

Hydraulic systems have filters that trap dirt and debris from the fluid. A clogged filter can reduce fluid flow and pressure, leading to poor splitter performance. Clean or replace the filter according to the manufacturer’s guidelines.

4. Monitor Pump Temperature

Overheating can damage the hydraulic pump and shorten its lifespan. If you notice that the pump is running hot, check the fluid levels and ensure there’s no blockage in the hydraulic system. Some log splitters come equipped with cooling systems to help manage temperature, so make sure these are functioning properly.

5. Regular Engine Maintenance

Since the hydraulic pump is powered by the engine, keeping the engine in good condition is vital. Change the oil, clean the air filters, and inspect the spark plugs as recommended by the engine’s manufacturer. A well-maintained engine will help the hydraulic pump operate efficiently.

Upgrading Your Hydraulic Pump for Log Splitter: Is It Worth It?

If you already own a log splitter but find it too slow or underpowered, upgrading to a larger hydraulic pump might be a worthwhile investment. However, it’s essential to consider whether your current engine and hydraulic system can support the upgrade. Additionally, you’ll need to evaluate whether the increased performance will justify the cost of a new pump. If you’re frequently splitting large, tough logs, or if you run a commercial operation, a pump upgrade can significantly boost productivity.

Conclusion

Choosing the right hydraulic pump size for your log splitter is key to optimizing its performance and ensuring it meets your needs. By considering factors like log size, cycle time, engine power, and fuel efficiency, you can select a pump that strikes the perfect balance between speed and power. Regular maintenance is also critical in keeping your log splitter running smoothly and extending its lifespan.

Ultimately, the right hydraulic pump size depends on your specific requirements, whether you’re splitting logs for personal use or running a business. A well-chosen pump will make your log splitting tasks faster, easier, and more efficient.

FAQs

- What size hydraulic pump for log splitter?

The size depends on the log size and engine power, typically ranging from 11 to 28 GPM. - How does a hydraulic log splitter work?

It uses pressurized hydraulic fluid to push a piston that splits the log. - How to replace hydraulic pump on log splitter?

Disconnect the hoses, unbolt the old pump, and install the new one in reverse order. - How does hydraulic log splitter work?

A hydraulic cylinder pressurizes fluid to move a piston, splitting the log. - How do hydraulic log splitters work?

They use hydraulic pressure to move a wedge through the log, forcing it apart. - What hydraulic fluid to use in a log splitter?

Use ISO 32 or 46 hydraulic oil, depending on the manufacturer’s recommendations.

Charles Hayes

Forestry AuthorI'm Charles Hayes, I bring over 15 years of specialized expertise in landscaping and woodworking, blending artistic design with sustainable environmental stewardship. My career, fueled by a profound passion for the natural world, encompasses extensive education and hands-on experience in creating harmonious, eco-friendly outdoor spaces and responsibly managing forest resources. Recognized for my professional standing, I am committed to continuous learning and certification in cutting-edge practices. My expertise is not only reflected in my work but also in my contributions to community projects, educational workshops, and collaborations with industry leaders. As an authoritative voice in my field, I strive to share knowledge and promote environmentally conscious approaches, making me a trusted resource in landscaping and forestry.

Leave your comment