Underwater Welding: Techniques, Risks, and Impacts on Structural Durability

- January 3, 2024

- 0 comment

Explore underwater welding with key techniques, risks, and effects on structural durability. Essential insights for professional welders. Underwater welding, a specialized technique bridging the realms of welding and marine engineering, holds a pivotal role in ensuring the longevity and durability of various underwater structures. In this comprehensive exploration, we delve into the multifaceted impact of underwater welding on the lifespan of infrastructures, encompassing its challenges, techniques, case studies, advancements, training aspects, and future implications.

Insights for Aspiring Underwater Welders

If you’re intrigued by the idea of a profession that keeps you on your toes and is considering a path into underwater welding, this blog post aims to provide a comprehensive understanding of the challenges and strategies associated with this unique and captivating career choice.

Understanding Underwater Welding Life Expectancy

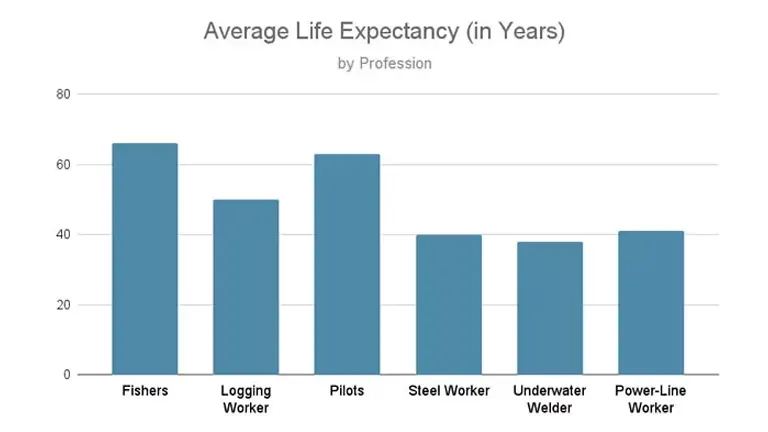

The life expectancy for underwater welders typically ranges from 50 to 60 years. This relatively lower life expectancy is attributed to the physically demanding nature of the job, which places a considerable strain on the body over time.

The challenging conditions and unique challenges posed by underwater welding contribute to the industry’s relatively higher risk factors, impacting the overall health and longevity of individuals pursuing this profession.

As a result, the average age of death for welders, particularly those engaged in underwater welding, tends to be around 56 years old. It underscores the importance of recognizing the demanding nature of the job and the need for comprehensive safety measures and health considerations in the field of underwater welding.

Factors Influencing Underwater Welders’ Lifespan

- Physical Strain: Welding is inherently physically demanding, requiring welders to handle heavy equipment and materials while contorting their bodies into uncomfortable positions. The repetitive bending and twisting associated with the job can result in chronic back problems and herniated discs, contributing to a shortened lifespan.

- Chemical Exposure: Welders face daily exposure to harmful chemicals and fumes, which pose a significant threat to their respiratory health. Prolonged inhalation of these fumes can lead to lung damage and respiratory problems, further impacting the overall well-being and longevity of welders.

- Electrocution Risks: The inherent risk of electrocution is a pervasive danger for welders, especially when working underwater where water conductivity increases the likelihood of electric shock. The combination of electrical currents and water presents a heightened risk that poses additional challenges to the safety of welders.

- Burn Hazards: Welders are constantly exposed to the intense heat generated by welding torches, reaching temperatures of up to 6,000 degrees Fahrenheit. This extreme heat not only increases the risk of immediate burns but can lead to severe third-degree burns, contributing to the occupational hazards that impact the health and life expectancy of welders.

- Explosion Threats: The sparks produced by welding torches pose a risk of igniting flammable materials in the vicinity, potentially leading to explosions. This added danger underscores the need for vigilant safety measures to prevent catastrophic incidents that could further jeopardize the safety and longevity of welders.

Decoding the Enigma of Underwater Welding

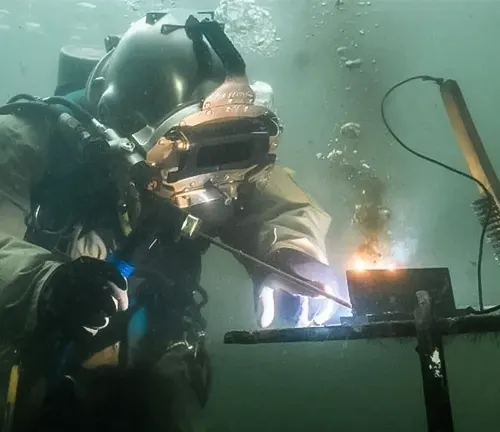

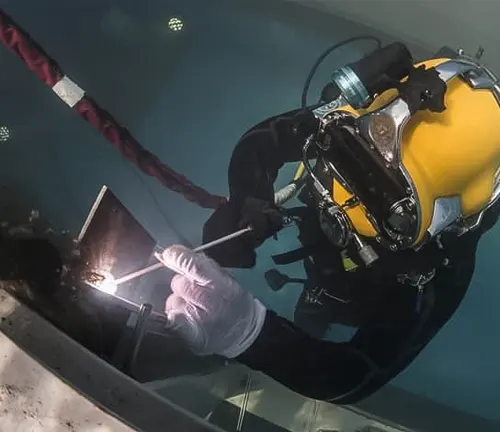

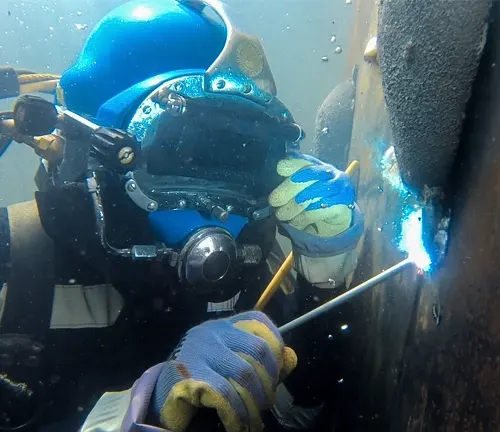

Underwater welding, often hailed as a marriage between metallurgy and marine exploration, is an intricate process that involves joining metal structures beneath the water’s surface. Whether it’s repairing an offshore oil rig or reinforcing the foundation of a submerged pipeline, underwater welders face a unique set of challenges that set them apart from their land-based counterparts.

Impact on Infrastructure Lifespan

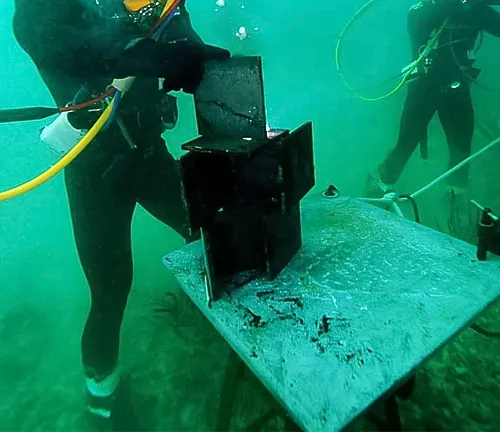

One of the key aspects of my exploration was understanding how underwater welding contributes to the longevity of underwater structures. The process is not just about fixing immediate issues but also preventing corrosion and degradation over time. By reinforcing joints and repairing damaged areas, underwater welders play a pivotal role in extending the lifespan of these structures, ensuring they can withstand the harsh marine environment.

Corrosion Control

The underwater environment is notorious for promoting corrosion due to the corrosive nature of saltwater. Through meticulous welding techniques and the use of specialized materials, underwater welders create durable bonds that act as a shield against corrosion. This proactive approach significantly enhances the resilience of underwater structures, ultimately leading to a longer lifespan.

Navigating Challenges in Underwater Welding

As I dived deeper into understanding the world of underwater welders, I found myself in complete admiration of their courage and expertise. These skilled professionals operate in environments where visibility is nearly nonexistent, grappling with powerful underwater currents and the formidable challenges posed by the aquatic realm itself. Their commitment to their craft is nothing short of remarkable, considering the harsh conditions they confront regularly. Yet, it’s their unwavering dedication that guarantees the integrity and strength of our crucial underwater infrastructure.

Human Element

Beyond the technicalities of the welding process, it’s essential to acknowledge the human aspect of this profession. Underwater welders undergo rigorous training to master the art of welding in challenging conditions. Their expertise not only safeguards the integrity of structures but also ensures their safety in an environment that can be unforgiving.

Impact of Underwater Welding on Life Expectancy

Indeed, underwater welding introduces health risks primarily linked to exposure to hazardous fumes and gases, leading to potential respiratory problems, skin irritation, and various other health issues. While welders, in general, tend to have a shorter life expectancy compared to the average population, it’s essential to recognize that not all welders face an early demise.

Numerous factors contribute to an individual’s lifespan, encompassing lifestyle choices and genetic predisposition. Underwater welders, specifically, can mitigate potential health hazards and anticipate a prolonged and healthy life by adopting precautionary measures to safeguard their well-being.

By prioritizing safety protocols and adhering to preventive practices, such as wearing appropriate protective gear and minimizing exposure to harmful substances, individuals in the underwater welding profession can positively influence their overall health outcomes.

This nuanced perspective underscores the importance of proactive health measures in shaping the longevity of underwater welders, emphasizing that a careful approach to safety can contribute significantly to a fulfilling and extended life.

Alarming Statistics: Underwater Welder Mortality Rates

The mortality rate among underwater welders is alarmingly high, placing it among the most perilous professions globally. The inherent dangers associated with this occupation make it notorious for its elevated risk factors, rendering it one of the most hazardous jobs worldwide. To provide a perspective, the fatality rate for underwater welders is approximately four times higher than that of the average worker.

Factors Leading to Fatalities

- Primarily, the environment itself poses an imminent threat, with the pervasive risk of drowning looming over the welders. Working submerged in water introduces a constant and formidable danger that significantly elevates the overall perils associated with the profession.

- Beyond the threat of drowning, another substantial risk arises from the proximity of underwater welders to high-voltage electrical equipment. The close interaction with such machinery introduces the potential for severe injuries or even fatal consequences should the welder accidentally come into contact with live wires during their operations.

- Furthermore, a distinct peril faced by underwater welders is the elevated risk of experiencing explosive decompression. This phenomenon occurs when a sudden loss of pressure induces the collapse of the lungs, posing a potentially fatal threat to those working in underwater environments. The nature of underwater welding operations makes individuals susceptible to this hazardous condition, further underscoring the precarious nature of their profession.

Despite the inherent risks, numerous individuals opt for a career in underwater welding due to its lucrative nature. Nevertheless, it is crucial to emphasize that prioritizing safety must always take precedence in this perilous profession.

Quantifying Fatalities among Underwater Welders

Engaging in welding is inherently perilous, and underwater welding compounds the risks further. According to the Bureau of Labor Statistics, the fatality rate for welders surpasses three times the average for all occupations. Within this challenging profession, underwater welders face an even more precarious scenario, and though the precise annual count of deaths remains elusive, it is presumed to be higher than reported.

The quest to quantify the annual fatalities among underwater welders proves challenging due to the absence of a centralized database dedicated to tracking these incidents, leading to underreporting. Despite this limitation, estimates suggest that approximately 5 to 10 underwater welders succumb to fatal incidents each year. While this figure may appear modest, it gains significance when considering the relatively small population of underwater welders in the United States, numbering only a few thousand.

This translates to a notably elevated death rate within this occupational group. The estimated fatality rate for underwater welders is approximately 100 times greater than the average for all occupations.

Understanding Underreported Incidents

The augmented risk of fatality faced by underwater welders stems from their work environment’s unique challenges, characterized by not only danger but also limited escape options in the event of an emergency.

Underwater welding introduces a myriad of hazards, including the looming threats of drowning, electrocution, and explosions. While certain precautions, such as donning proper safety gear, can mitigate some of these risks, they can never be entirely eradicated.

Given the inherent dangers, individuals opting for underwater welding must possess a comprehensive awareness of the associated risks and implement a robust contingency plan. Lack of adequate preparedness often contributes to fatalities among underwater welders.

To enhance safety, it is imperative for those involved in underwater welding to proactively educate themselves about potential risks and adopt effective mitigation strategies. A thorough understanding of the perils involved, coupled with stringent safety measures, is essential to fostering a secure working environment for underwater welders.

Dispelling Misconceptions about Underwater Welding

One notable characteristic conspicuously absent in underwater welders is an inclination towards seeking out high-risk occupations with a death wish. On the contrary, the overwhelming majority of underwater welders I have encountered approach their profession with a conservative mindset, placing a significant emphasis on maritime safety. They acknowledge the inherent dangers associated with their work and cultivate a profound respect for these risks. Starting from their initial training in diving school, hyperbaric welders are ingrained with the principles of safety as an integral aspect of their operations.

While the field of underwater welding may carry an adventurous allure, it is not synonymous with treasure-hunting escapades or working in subaquatic bomb shelters with great white sharks firing laser beams. Instead, the reality is far more straightforward – it involves underwater construction, plain and simple. The emphasis on safety and the pragmatic approach to their craft debunk the myth that underwater welders are thrill-seekers; rather, they are skilled professionals committed to executing their tasks with precision and precaution in an environment that demands a heightened awareness of safety protocols.

Evolution and Future Prospects of Underwater Welding

Welding, a time-honored process employed for centuries, has been instrumental in joining diverse metals together. This versatile technique employs heat to melt metals, allowing them to flow and merge seamlessly. Its applications span across various materials, encompassing metals, plastics, and even glass, showcasing its adaptability.

Despite its historical roots, welding remains at the forefront of technological advancements. Continuous innovations in both techniques and materials contribute to making welding progressively more accessible, efficient, and swift. Within this ever-evolving landscape, underwater welding emerges as a particularly exciting area of exploration.

While underwater welding is a relatively recent addition to the welding repertoire, its potential and promise are already evident. The unique challenges posed by working beneath the water’s surface have spurred innovation and research in this field. As underwater welding gains traction, it brings forth a transformative impact on the lifespan of submerged structures.

The specialized nature of underwater welding addresses the intricacies of joining metals in aquatic environments, providing solutions to challenges that traditional welding methods may not effectively navigate. The advancements in underwater welding technologies not only enhance the speed and efficiency of the welding process but also contribute to the longevity and durability of underwater structures.

The marriage of welding expertise with underwater challenges creates a synergy that extends beyond conventional welding applications. Underwater welding, with its continuous development and refinement, becomes a crucial element in the arsenal of techniques used to maintain and repair submerged structures. As the field matures, we can anticipate further breakthroughs that will not only make underwater welding more efficient but also contribute significantly to the overall lifespan and resilience of the critical infrastructure that exists beneath the waves.

Advantages Of Traditional Welding

- First, underwater welds are much less likely to be damaged by the forces of waves and currents.

- Second, underwater welds can be performed at depths that would be impossible to reach with traditional methods.

The potential applications of underwater welding are endless. The process could be used to repair pipelines, build offshore structures, and even explore the ocean floor. In the future, underwater welders may even be used to build homes and other structures on the moon or other planets.

The possibilities are truly endless. With continued research and development, underwater welding will become an increasingly important part of our world.

Conclusion

While the life expectancy of underwater welders may appear to be limited, implementing comprehensive safety measures can significantly contribute to the promotion of a prolonged and thriving career in underwater welding.

As the underwater welding industry undergoes continuous expansion, the working conditions for welders are poised to enhance, with a steadfast commitment to prioritizing their safety. The evolving landscape promises an environment where safety protocols are paramount, further establishing a foundation for a sustained and healthy career trajectory for underwater welders.

Have you ever contemplated venturing into the realm of underwater welding? It’s a dynamic field offering abundant opportunities for professional growth. Just remember, adhering to all requisite safety measures is imperative to ensuring a secure and flourishing career in this exhilarating industry!

Frequently Asked Questions

- What is the typical lifespan of a saturation diver?

Saturation diving, a technique that enables divers to remain submerged for prolonged durations without the need for decompression, involves breathing a gas mix to keep the diver saturated with nitrogen. The record for the longest time spent underwater by a saturation diver is an impressive 69 days. However, the average life expectancy for saturation divers hovers around 60 years. This relatively lower expectancy can be attributed to the inherent dangers of the job, often requiring work in extremely hostile and perilous environments. - At what age do welders typically retire?

Welders, on average, retire at the age of 56. The physical demands of welding, which can take a toll on the body over time, contribute to this relatively early retirement age. Some welders may choose to retire earlier due to health concerns or injuries related to their occupation. Given the challenges associated with the job, welders are advised to plan for their future retirement. - Is depression prevalent among welders?

Depression, a widespread mental health issue, can affect individuals across various professions, including welders. However, it is crucial to emphasize that depression is treatable, and numerous resources exist to assist individuals in coping with this condition. Anyone experiencing depressive symptoms, including welders, should not hesitate to seek help and support. - Do underwater welders face potential threats from sharks?

Yes, underwater welders do have to be cautious about the presence of sharks. While there have been no documented instances of sharks attacking underwater welders, the possibility of such an occurrence exists. Sharks are drawn to areas with high activity and noise, and there is a risk of them mistaking a person in a welding suit for prey. To mitigate this risk, welders must remain vigilant of their surroundings and take precautions to avoid potential shark encounters. - Is pursuing a career as an underwater welder worthwhile?

Becoming an underwater welder involves the specialized task of welding metal beneath the water’s surface, necessitating specific training and certification. Despite the associated risks, there are numerous advantages to this career path. One significant benefit is the potential for substantial earnings, with underwater welders earning up to $300 per hour, making it a lucrative profession. Additionally, the job offers opportunities to travel to intriguing locations globally. While the career can be challenging and thrilling, individuals considering this path should carefully weigh the pros and cons before making a decision.

Your input matters! Feel free to share your firsthand experiences and reflections on the impact of underwater welding on lifespan in the comments section. Your valuable insights may assist others in making well-informed decisions within the realm of this challenging and crucial profession!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment