Silver Maple Lumber

- June 6, 2023

- 0 comment

Silver Maple, scientifically known as Acer saccharinum, is a versatile hardwood that is widely recognized for its lightweight and ease of working. Native to Eastern North America, this deciduous tree grows to heights of 60 to 100 feet, with diameters ranging from 2 to 3 feet. The average dried weight of Silver Maple lumber is approximately 33 pounds per cubic foot (530 kilograms per cubic meter), giving it a specific gravity of 0.53.

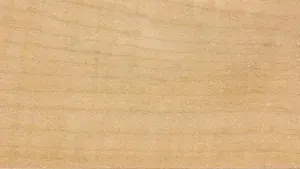

In terms of appearance, Silver Maple exhibits pale to light brown heartwood, occasionally with a reddish hue, while the sapwood is lighter, ranging from almost white to a pale yellow color. Its grain is typically straight, though it can display wavy or curly patterns. The texture of Silver Maple is generally fine and uniform, complemented by a low natural luster.

While Silver Maple is not inherently resistant to rot, proper treatment can help protect it from decay and insect infestation. This wood is relatively easy to work with, responding well to both hand and machine tools. It can be planned, turned, and shaped effortlessly, although care should be taken to minimize tear-out when dealing with interlocked grain. Silver Maple also demonstrates good gluing and finishing properties.

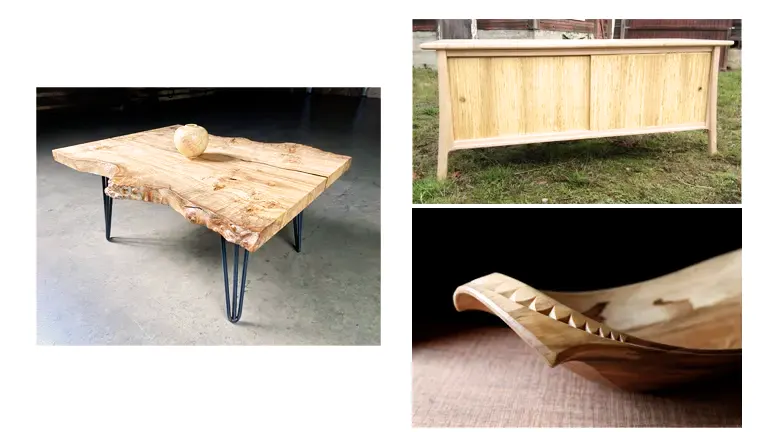

As for its common uses, Silver Maple finds its place in the manufacturing of furniture, cabinets, and veneer. It is frequently utilized for interior trim work, including moldings and window casings. This wood is also favored by woodturners for creating bowls and other turned objects. In addition, Silver Maple is utilized in the construction of musical instruments such as drum shells, owing to its lightweight nature and desirable tonal qualities.

With its affordability and wide availability within its native range, Silver Maple has become a popular choice for a range of woodworking projects. Its rapid growth and soft hardwood characteristics make it an attractive option for those seeking a lightweight and versatile material for indoor applications.

| Information | Description |

|---|---|

| Common Name(s) | Silver Maple |

| Scientific Name | Acer saccharinum |

| Distribution | Eastern North America |

| Tree Size | 60-100 ft tall, 2-3 ft in diameter |

| Average Dried Weight | 33 lbs/ft3 (530 kg/m3) |

| Specific Gravity | 0.53 |

| Janka Hardness | 700 lbf (3,110 N) |

| Modulus of Rupture | 9,500 lbf/in2 (65.5 MPa) |

| Elastic Modulus | 1,410,000 lbf/in2 (9.72 GPa) |

| Crushing Strength | 5,510 lbf/in2 (38.0 MPa) |

| Shrinkage | Radial: 5.8%, Tangential: 9.8%, Volumetric: 15.5% |

Color/Appearance: The heartwood of Silver Maple is commonly pale to light brown, sometimes with a reddish tinge. The sapwood is usually lighter in color, ranging from almost white to a pale yellow hue. It doesn’t have any distinct color patterns or features.

Grain/Texture: The grain of Silver Maple is usually straight, but it can also be wavy or curly. The texture is relatively fine and uniform, with a low natural luster.

Rot Resistance: Silver Maple is not naturally durable and is susceptible to decay. It is prone to fungal attack and insect infestation unless properly treated.

Workability: Silver Maple is generally easy to work with both hand and machine tools. It has good machining qualities and can be planned, turned, and shaped with ease. However, its softness can lead to some tear-out when working with interlocked grain. It glues and finishes well.

Odor: Silver Maple typically doesn’t have a distinct odor when being worked.

Allergies/Toxicity: There are no known allergies or toxic reactions associated with Silver Maple.

Pricing/Availability: Silver Maple is generally considered a low-cost hardwood. It is widely available within its native range and is commonly used as a utility wood.

Sustainability: Silver Maple is not listed in the CITES Appendices or the IUCN Red List of Threatened Species. However, as with any wood, it is important to source it from responsibly managed forests to ensure its sustainability.

Common Uses

- Furniture: Silver Maple is often used in the construction of furniture, particularly for pieces that require lightweight wood. Its relatively low density and ease of working make it suitable for chairs, tables, and other indoor furniture items.

- Cabinets: Due to their availability and affordability, Silver Maple is frequently utilized in cabinetmaking. It can be used for both the structural components and the visible surfaces of cabinets, providing a clean and light appearance.

- Veneer: The straight and sometimes wavy grain of Silver Maple lends itself well to the production of veneer. Veneer made from this wood is used to cover surfaces, providing an attractive finish to furniture, cabinetry, and interior paneling.

- Interior Trim: Silver Maple is commonly employed for interior trim work, such as baseboards, moldings, and window casings. Its fine texture allows for smooth finishes and clean lines, enhancing the overall aesthetics of a space.

- Musical Instruments: The lightweight nature and resonant properties of Silver Maple make it suitable for certain musical instruments. It is often used in the construction of drum shells, providing a bright and lively tone.

- Turned Objects: Woodturners appreciate Silver Maple for its ease of turning. It can be shaped into bowls, vases, and other decorative or functional turned objects.

- Utility Wood Products: Silver Maple’s availability and relatively low cost make it a popular choice for utility wood products. It is commonly used for boxes, crates, pallets, and other packaging materials that require a lightweight yet sturdy material.

Harvesting Silver Maple

Harvesting Silver Maple lumber typically involves several steps to ensure proper utilization and sustainability. Here’s some information about the process:

- Forest Management: Silver Maple is primarily harvested from managed forests. Forest management practices aim to maintain healthy and sustainable tree populations. This includes promoting the growth of desirable tree species, ensuring proper spacing between trees, and managing forest ecosystems to maintain biodiversity.

- Timber Harvesting: When it’s time to harvest Silver Maple trees, professional loggers or forestry experts carefully select individual trees for removal based on factors such as age, size, and overall health. Selective harvesting helps maintain the ecological balance of the forest and ensures the regeneration of the species.

- Logging Operations: Logging operations involve felling the selected Silver Maple trees using chainsaws or specialized equipment. The fallen trees are then delimbed, removing the branches, and cut into appropriate lengths for transportation.

- Transportation: Once the trees are cut and prepared, they are typically transported to a sawmill or lumber processing facility. This may involve loading the logs onto trucks or using other transportation methods such as barges or trains, depending on the location of the harvesting site and the destination of the lumber.

- Sawmilling: At the sawmill, the Silver Maple logs are processed into lumber. The logs are first debarked, and then they are cut into boards and planks of various dimensions. The sawmill may utilize different cutting techniques to maximize the yield and quality of the lumber.

- Drying and Processing: After sawmilling, the Silver Maple lumber is typically air-dried or kiln-dried to reduce its moisture content. Drying helps stabilize the wood and prepares it for further processing and use in woodworking projects.

- Distribution and Sales: The processed Silver Maple lumber is then distributed to retailers, woodworking businesses, and other end-users. It may be sold as rough-sawn lumber, dimensional lumber, or specialized products such as veneer or flooring.

Comments: Silver Maple is known for its rapid growth and its tendency to develop large limbs. It is considered a soft hardwood, which makes it suitable for certain applications but less durable than other hardwoods. Its affordability and availability make it a popular choice for various woodworking projects.

Leave your comment