Why Your Chainsaw Hard to Start and How to Fix It

- September 20, 2024

- 0 comment

Starting a chainsaw can sometimes be frustrating, especially when it doesn’t fire up right away. Many people face this chainsaw hard to start issue, and it usually comes down to a few common problems that can be easily fixed with some basic maintenance.

We’ll explore six reasons why your chainsaw might be hard to start and provide simple solutions to get it running smoothly again. Whether it’s the fuel mix, air filter, or something more complex like piston compression, you’ll find practical tips to fix these issues and get back to work.

6 Reasons why your chainsaw may be hard to start

- Fuel-Oil Mixture

- Air Filter

- Spark Plug & Ignition System

- Spark Arrestor & Muffler

- Piston Compression

- Fuel System & Carburetor

Why Your Chainsaw Hard to Start and How to Fix It

1. Fuel-Oil Mixture

One of the most common issues with chainsaw starting problems is related to the fuel-oil mixture. Most chainsaws require a specific blend of gasoline and oil to work properly. If this mixture is incorrect, your chainsaw might not start or run as it should.

Why this matters:

The engine in a chainsaw is a two-stroke engine, meaning it relies on both gasoline and oil for lubrication and power. If there is too little oil, the engine will overheat and seize. Too much oil, and the engine may fail to ignite or run rough.

How to fix:

Make sure you are using the correct fuel-oil ratio recommended by your chainsaw’s manufacturer. This is typically a 50:1 or 40:1 mix (50 parts gasoline to 1 part oil, or 40:1). Old fuel can also cause problems, so if the fuel has been sitting in the tank for months, drain it and replace it with fresh fuel.

2. Air Filter

A clogged or dirty air filter is another reason why your chainsaw may be hard to start. The air filter’s job is to prevent dust and debris from entering the engine. However, over time, it can become blocked, restricting airflow and making it harder for the engine to ignite.

Why this matters:

When the engine doesn’t receive enough air, the fuel-air ratio becomes unbalanced, making it difficult to start and causing the chainsaw to run poorly.

How to fix:

Regularly check and clean the air filter. If it’s clogged with dirt or sawdust, remove it and clean it with warm, soapy water or replace it if necessary. Make sure it’s completely dry before reinstalling it.

3. Spark Plug & Ignition System

A faulty spark plug or ignition system can also cause starting issues. The spark plug is responsible for igniting the fuel mixture in the engine. If the spark plug is damaged or the ignition system isn’t functioning correctly, the chainsaw won’t start.

Why this matters:

The spark plug delivers the spark needed to ignite the air-fuel mixture. If it’s worn out, dirty, or fouled with carbon buildup, the engine won’t fire up.

How to fix:

Remove the spark plug and inspect it for damage, dirt, or wear. If the spark plug looks dirty or fouled, clean it with a wire brush or replace it with a new one. Check the gap between the electrodes and adjust it according to the manufacturer’s specifications. Also, inspect the ignition system to ensure there are no loose wires or other issues.

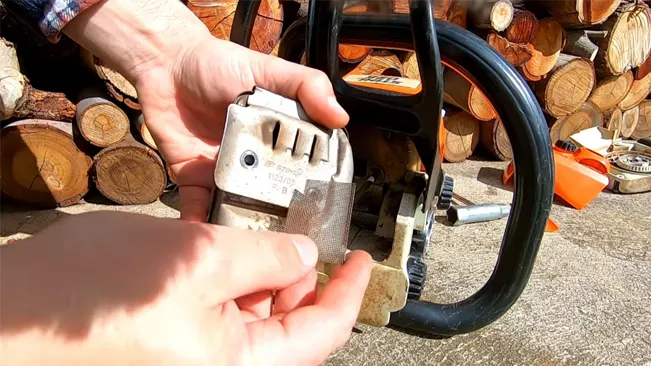

4. Spark Arrestor & Muffler

The spark arrestor and muffler help control the exhaust and reduce the risk of sparks igniting nearby materials. Over time, the spark arrestor can become clogged with carbon deposits, preventing proper exhaust flow and making it difficult for the chainsaw to start.

Why this matters:

A blocked spark arrestor can restrict exhaust flow, reducing engine power and making the chainsaw hard to start.

How to fix:

Locate the spark arrestor screen near the muffler. Remove it and inspect it for carbon buildup. If it’s dirty, clean it using a wire brush or replace it if it’s damaged. Cleaning the muffler and the exhaust ports may also improve performance.

5. Piston Compression

Low piston compression is a more serious issue but can also contribute to starting problems. Over time, wear and tear can cause the piston rings to wear out, leading to a loss of compression in the engine.

Why this matters:

When there’s insufficient compression, the engine may struggle to generate enough power to start. Compression issues can occur due to worn piston rings, scoring on the cylinder, or a blown head gasket.

How to fix:

Perform a compression test to check whether the compression is within the normal range. If it’s too low, the engine may need to be repaired by replacing the piston rings or other internal components. This may require professional repair, as it involves disassembling the engine.

6. Fuel System & Carburetor

The fuel system, including the carburetor, plays a crucial role in mixing the right amount of fuel with air for combustion. If the carburetor is dirty or clogged, the fuel won’t flow properly, leading to starting issues.

Why this matters:

A carburetor that isn’t functioning correctly can prevent the right mixture of fuel and air from reaching the engine, making it hard to start.

How to fix:

First, check the fuel lines for any blockages or cracks. Next, inspect the carburetor for dirt or damage. Clean the carburetor using a carburetor cleaner or rebuild it if necessary. Adjust the carburetor settings according to the manufacturer’s instructions to ensure the right fuel-air ratio is delivered.

Chainsaw Maintenance Tips

Proper maintenance can help ensure that your chainsaw starts easily and functions well over time. Regular maintenance keeps the engine clean, the components functioning smoothly, and the fuel system in good condition.

Here are a few important maintenance tasks:

1. Clean the Chainsaw Regularly

After each use, clean the chainsaw to remove sawdust, dirt, and debris. This prevents blockages in the air filter and carburetor, which can affect starting.

2. Check and Sharpen the Chain

A dull chain can increase the load on the engine, making it harder to start. Ensure the chain is sharp and well-lubricated to reduce the strain on the engine.

3. Inspect the Chain Tension

Ensure the chain tension is correct. A chain that is too loose or too tight can cause operational problems and may make the engine struggle.

4. Lubricate Moving Parts

Use proper lubrication on the chain and moving parts to prevent wear and tear. This helps the engine run smoothly and reduces friction-related issues.

Proper Storage for Long-Term Durability

Proper storage is key to keeping your chainsaw in good condition for a long time. Storing it in a dry place helps prevent rust and corrosion on the engine and chain, which can cause starting problems later. It’s also a good idea to use a chainsaw case to protect it from dust and moisture.

Before putting your chainsaw away for a long period, run the engine until all the fuel is gone. This prevents fuel from clogging the carburetor, which can make it hard to start the chainsaw the next time you need it. Regular, careful storage keeps your chainsaw ready to use whenever you need it.

Conclusion

Chainsaws can be hard to start for various reasons, ranging from simple issues like a clogged air filter or dirty spark plug to more complex problems like low piston compression or carburetor troubles. Understanding these common causes and performing regular maintenance can help prevent starting problems and extend the life of your chainsaw. By following the tips and solutions outlined in this guide, you can address most starting issues yourself and keep your chainsaw running smoothly.

Frequently Asked Questions

1. Why won’t my chainsaw start even with fresh fuel?

It could be due to a dirty air filter, spark plug issues, or problems with the ignition system. Check each of these components and clean or replace them as needed.

2. How do I know if my chainsaw’s fuel-oil mixture is correct?

Refer to your chainsaw’s manual for the recommended fuel-oil ratio. Most chainsaws require a 50:1 or 40:1 ratio. Always mix the fuel fresh, and avoid using old fuel.

3. How often should I clean the air filter on my chainsaw?

You should check and clean the air filter after every 5-10 hours of use, or more frequently if working in dusty conditions.

4. What causes low compression in a chainsaw, and how can I fix it?

Low compression is often caused by worn piston rings, a damaged cylinder, or a blown gasket. This usually requires professional repair or replacing the damaged parts.

5. Why is my chainsaw flooding when I try to start it?

A flooded engine occurs when there is too much fuel in the combustion chamber. To fix it, let the chainsaw sit for 15-20 minutes, remove and dry the spark plug, and then try starting it again.

6. How can I prevent my chainsaw from getting clogged with carbon deposits?

Regularly clean the spark arrestor and muffler, and use high-quality fuel to minimize carbon buildup in the exhaust system.

7. What should I do if my chainsaw starts but then stalls?

This could be due to a clogged fuel filter or carburetor, or an air-fuel mixture imbalance. Check the fuel lines and clean the carburetor.

8. How do I maintain my chainsaw’s carburetor?

Regularly clean the carburetor using a carburetor cleaner and check for blockages. If needed, rebuild the carburetor with a repair kit or have it professionally adjusted.

9. Can cold weather affect starting my chainsaw?

Yes, cold weather can make it harder to start your chainsaw due to thickened fuel or oil. Pre-warm the chainsaw, use winter-grade fuel, and store it in a warm place when not in use.

10. What’s the best way to store a chainsaw for long-term storage?

Run the engine dry before storing, clean the chainsaw thoroughly, and store it in a dry, well-ventilated area. Use a protective case to shield it from dust and moisture.

We hope this guide on why your chainsaw might be hard to start has helped you understand how to keep your tool in top working condition. Regular maintenance ensures better performance, a longer lifespan, and fewer frustrating starts for your chainsaw.

If you have any tips or experiences, feel free to share them in the comments below. Don’t forget to share this article with others who use chainsaws to help them avoid starting issues. Stay safe and keep cutting!

Leave your comment