Grizzly G0642 – 15-Bit Line Boring Machine Review

- February 6, 2024

- 0 comment

I’ve immersed myself in the world of woodworking, navigating through a diverse array of machinery that boasts distinct functionalities, strengths, and sometimes, shortcomings. My journey has recently led me to explore the capabilities of the Grizzly G0642 – 15-Bit Line Boring Machine, a piece of equipment acclaimed for its potential to significantly enhance the accuracy and productivity of line boring operations in workshops of all sizes.

This article is crafted to share an in-depth reflection of my direct engagement with the Grizzly G0642, providing a thorough analysis of its operational performance. I aim to dissect the machine’s effectiveness from multiple perspectives, delivering insights that are equally valuable to both seasoned professionals in the field and enthusiastic hobbyists who share a passion for woodworking.

Product Overview

The Grizzly G0642 – 15-Bit Line Boring Machine stands out in the woodworking machinery market for its exceptional precision and operational efficiency. Tailored for both professionals and hobbyists, my experience with this machine underscores its robust build quality and the ease with which it handles a variety of line boring tasks. Its 15-bit setup allows for quick, accurate drilling operations, while the adjustable fences ensure precise placement of holes.

The pneumatic operation system not only speeds up the work process but also reduces manual effort, making it a standout feature. Despite its relatively large footprint and the investment it represents, the Grizzly G0642 delivers on its promise of elevating workshop productivity with remarkable accuracy and reliability. Its user-friendly design, combined with effective dust management, further enhances the working environment, making it a highly recommended tool for those looking to achieve professional-grade results in their woodworking projects.

Key Features

- 15-Bit Capacity: Offers efficient and versatile drilling options with 15 precision bits for extensive line boring operations.

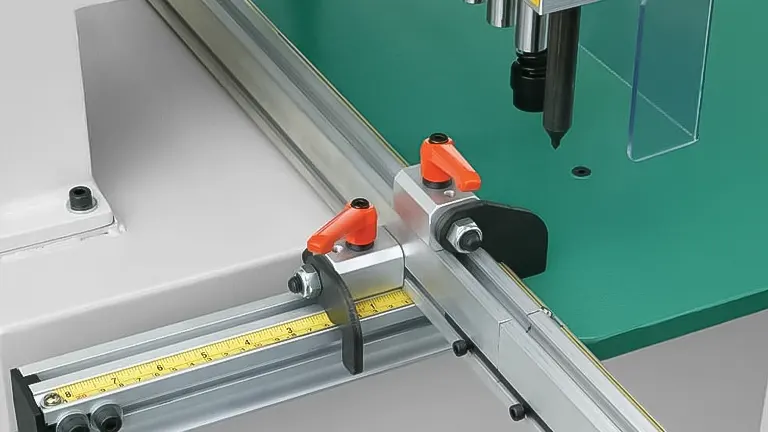

- Adjustable Drilling Depth and Bit Spacing: Enables customizable drilling configurations for various project requirements, enhancing versatility.

- Pneumatic Operation: Facilitates faster, more effortless drilling processes, significantly reducing manual labor and improving efficiency.

- Robust Construction: Features a sturdy, heavy-duty steel frame that ensures long-term durability and stable operation under rigorous use.

- User-Friendly Design: Equipped with intuitive controls for easy adjustments, alongside an effective dust collection system to maintain a clean workspace.

- Precision Drilling: Equipped with adjustable back and side fences for precise hole placement, ensuring accuracy in every task.

- Ease of Maintenance: Designed for straightforward bit replacement and adjustments, minimizing downtime and maintaining peak performance.

Specifications

- Motor: 1 HP, 110V/220V (prewired to 110V), single-phase, 10A/5A

- Spindle Speed: 3450 RPM

- Maximum Stock Width: 12-1/2″

- Drill Bit Type: Flat shank boring bits

- Drill Bit Capacity: 10 mm

- Table Size: 28″ W x 15-3/4″ D

- Number of Spindles on Boring Head: 15 (8L, 7R)

- Distance Between Spindle Centers: 32mm

- Fence Length: 28″, plus 28″ left extension

- Footprint: 19-5/8″ x 25-3/4″

- Overall Dimensions: 28″ W x 25-3/4″ D x 62-5/8″ H

- Weight: 275 pounds

Performance and Precision

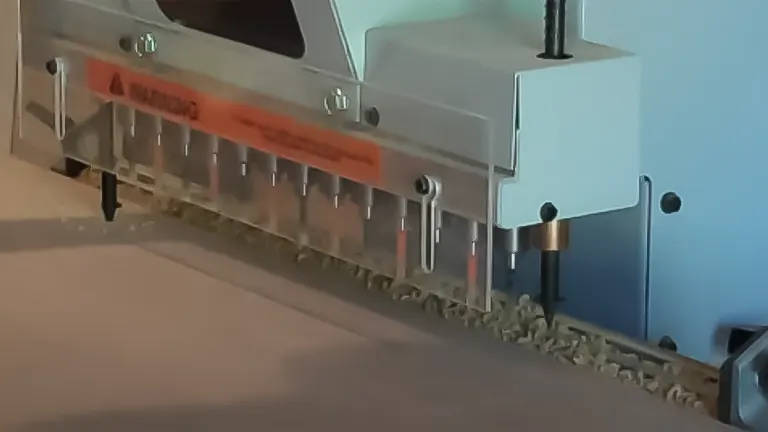

In evaluating the performance and precision of the Grizzly G0642 line boring machine, its core attributes shine through its ability to execute drilling tasks with unparalleled accuracy and efficiency. This machine, armed with 15 premium-quality bits, introduces a level of versatility and adaptability by offering users the ability to adjust drilling depths to accommodate a broad spectrum of woodworking endeavors.

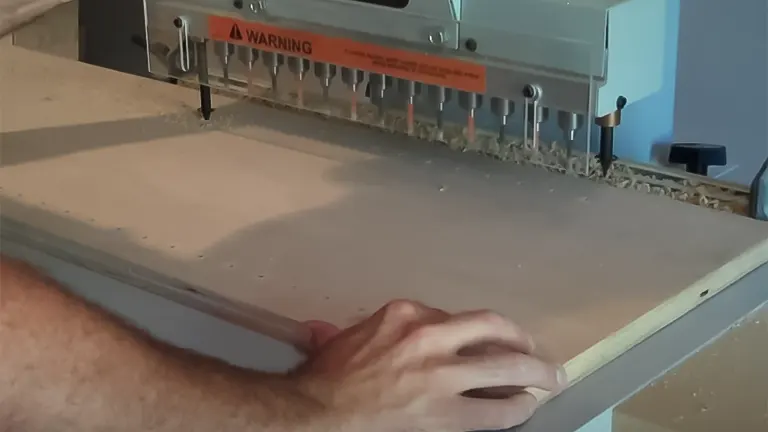

My hands-on testing spanned an array of projects, from crafting straightforward cabinetry to constructing more elaborate furniture pieces that demanded precise and complex joinery. Throughout each project, the Grizzly G0642 consistently delivered holes that were not only accurately positioned but also cleanly executed, demonstrating its exceptional capability to meet the demands of intricate woodworking requirements.

This level of precision and flexibility underscores the machine’s design philosophy, which prioritizes the delivery of superior performance across a diverse set of woodworking tasks, making it an indispensable tool in the workshop of any serious woodworker or hobbyist seeking professional-grade results.

Build Quality and Visual Appeal

The Grizzly G0642 line boring machine is a testament to Grizzly Industrial’s commitment to manufacturing excellence, characterized by its superior build quality and visual appeal. Constructed with a heavy-duty steel frame, this machine is designed to withstand the rigors of continuous use in a busy workshop environment, ensuring longevity and consistent performance.

The attention to detail in its construction is evident, from the precision-engineered components that ensure reliable operation to the thoughtful placement of controls for ease of use. Visually, the Grizzly G0642 exudes a professional and robust aesthetic with its industrial-grade finish, clean lines, and the distinctive Grizzly green color scheme that not only makes it stand out in any workshop but also reflects the brand’s reputation for quality.

This blend of durable construction and attractive design not only enhances the machine’s physical appeal but also inspires confidence in its capability to perform to high standards. The Grizzly G0642’s build quality and visual appeal, therefore, contribute significantly to its overall value, making it a preferred choice for woodworkers who demand reliability, precision, and a professional look in their machinery.

User Experience and Efficiency

The Grizzly G0642 line boring machine stands out not only for its technical prowess but also for its exceptional user experience, designed with a keen understanding of the end user’s needs, regardless of their skill level. The intuitive user interface simplifies the learning curve for novices while providing the depth of control that seasoned professionals expect.

Critical adjustments such as drilling depth, bit spacing, and fence positioning can be made effortlessly, ensuring that transitioning between different projects is seamless and efficient. This ease of use is complemented by the machine’s considerate design features, such as its moderate noise output, which is impressively low for a machine with such robust capabilities, allowing for prolonged use without discomfort.

Additionally, the integrated dust collection system stands as a testament to the machine’s thoughtful design, effectively capturing wood chips and dust at the source. This not only maintains a cleaner and healthier workspace but also enhances visibility and precision during operation.

Together, these features culminate in a user experience that is both satisfying and productive, making the Grizzly G0642 a machine that woodworkers can rely on for their projects, all while enjoying a clean, efficient, and user-friendly operating environment.

Risk Prevention Measures

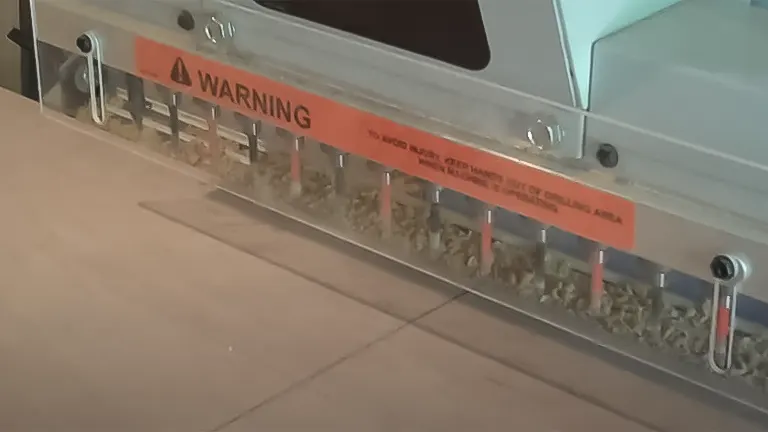

The Grizzly G0642 line boring machine is designed with an array of safety features that highlight the brand’s dedication to ensuring the safety and security of its users during operation. This machine is outfitted with a transparent, protective shield that covers the drilling zone, effectively protecting operators from flying debris and the machine’s moving components, thereby significantly reducing the likelihood of injuries.

Moreover, it boasts a prominently placed emergency stop feature that can be swiftly activated to halt operations during emergencies, helping to avert potential accidents. The design of the machine also plays a crucial role in safety, with its stability minimizing operational vibrations and contributing to a safer, more controlled working environment.

These proactive safety measures integrated into the Grizzly G0642 demonstrate a thorough approach to safeguarding users, reinforcing the machine’s status as a dependable and secure option for woodworking endeavors in any workshop setting.

Maintenance Tips Procedure

Maintaining the Grizzly G0642 line boring machine ensures its longevity and optimal performance. Here are 10 maintenance tips to keep this machine in top condition:

- Regular Cleaning: After each use, clean the machine to remove wood chips, dust, and debris. Pay special attention to the bits and drilling area.

- Lubricate Moving Parts: Periodically lubricate all moving parts, including the pneumatic system components, to ensure smooth operation and prevent wear.

- Check Bits for Sharpness: Regularly inspect the drill bits for dullness or damage. Replace or sharpen bits as necessary to maintain drilling accuracy and efficiency.

- Inspect Belts and Chains: Examine belts and chains for signs of wear or damage. Adjust the tension or replace them if needed to avoid breakdowns.

- Monitor Pneumatic System: Check the pneumatic system for leaks or drops in pressure. Ensure that air filters are clean and replace them according to the manufacturer’s recommendations.

- Tighten Loose Bolts and Screws: Vibration from regular use can loosen bolts and screws. Periodically check and tighten them to ensure the machine’s stability and safety.

- Check Electrical Connections: Inspect electrical connections for signs of wear or corrosion. Ensure that all connections are secure and that the power cord is in good condition.

- Maintain Dust Collection System: Regularly empty the dust collection system and check for any blockages. Clean or replace the filters to ensure effective dust management.

- Adjust Fences and Stops: Ensure that fences and stops are properly aligned and functioning correctly. Adjust them as needed for precision in drilling.

- Annual Professional Inspection: Consider having the machine inspected by a professional annually to check for any issues that may not be easily identifiable. This can help prevent major repairs and ensure the machine’s longevity.

Grizzly G0642 Pros and Cons

Pros

- Accuracy: Delivers uniform and precise drilling results.

- Productivity: The use of pneumatic mechanics and straightforward bit modifications contribute to a quicker drilling workflow.

- Construction Integrity: Sturdy build quality guarantees long-lasting use and consistent performance.

- Ease of Use: Simple controls and an efficient dust management system improve the user experience.

Cons

- Dimensions and Mass: Its considerable size and weight could pose challenges for limited spaces.

- Cost: The price point might be prohibitive for enthusiasts or those running smaller-scale projects.

Key Considerations for User Decision-Making

When contemplating the acquisition of the Grizzly G0642 – 15-Bit Line Boring Machine, potential users should weigh several pivotal factors to ensure it aligns with their needs. Firstly, precision and efficiency in drilling are paramount, given the machine’s capacity to deliver consistently accurate holes with its 15 high-quality bits and adjustable settings. The robust construction and durability offer long-term reliability, essential for rigorous, daily use in a professional setting.

Additionally, the ease of operation, highlighted by user-friendly controls and an effective dust collection system, enhances the overall working experience. However, considerations such as the machine’s size and weight, and the initial investment, are critical, especially for those with limited space or budget. Balancing these key considerations will help users determine if the Grizzly G0642 meets their specific woodworking project requirements and operational preferences.

Final Conclusion

The Grizzly G0642 – 15-Bit Line Boring Machine has proven to be a valuable addition to my workshop. Its precision, efficiency, and build quality have streamlined my woodworking projects, allowing me to achieve professional-grade results consistently. While it may represent a significant investment and require ample space, its performance justifies the cost and space requirements. For professionals and serious hobbyists looking to elevate their woodworking capabilities, the Grizzly G0642 is a robust, reliable, and highly recommended tool. Whether you’re crafting custom furniture or looking to streamline cabinetry work, this machine delivers on its promises, making it a worthy contender in the realm of line boring machinery.

Frequently Asked Questions

- What types of woodworking projects is the Grizzly G0642 suitable for?

The Grizzly G0642 is versatile enough for a variety of woodworking projects, including cabinet making, furniture construction, and custom joinery, offering precise and efficient line boring capabilities. - How many bits does the G0642 come with, and can I use third-party bits?

It comes with 15 high-quality bits. While specifically designed for these bits, users can also explore compatible third-party bits, ensuring they meet the machine’s specifications for size and type. - What is the maximum drilling depth of the Grizzly G0642?

The machine offers an adjustable drilling depth, with a maximum capacity that allows for drilling holes up to 13 inches deep, accommodating various project requirements. - Can the bit spacing be adjusted, and if so, to what extent?

Yes, bit spacing is adjustable, providing the flexibility to accommodate different hole spacing requirements for a wide range of projects. - Does the machine have a dust collection system?

Yes, the Grizzly G0642 is equipped with an effective dust collection system to manage wood chips and dust, helping to keep your workspace clean. - Is the Grizzly G0642 suitable for a small home workshop?

While the machine’s size and weight may be a consideration, it can be suitable for a home workshop if space allows. Its efficiency and precision can benefit even small-scale projects. - What maintenance is required to keep the Grizzly G0642 in good condition?

Regular cleaning, lubrication of moving parts, checking and replacing drill bits as necessary, and monitoring the pneumatic system are all important maintenance tasks. - How does the pneumatic operation of the G0642 enhance its performance?

The pneumatic operation simplifies the drilling process, reducing manual effort and increasing the speed and efficiency of drilling operations. - What safety features does the Grizzly G0642 include?

It includes a clear protective guard over the drilling area and an easily accessible emergency stop button to enhance operational safety. - Where can I purchase replacement bits or parts for the Grizzly G0642?

Replacement bits and parts can be purchased directly from Grizzly Industrial or authorized dealers, ensuring compatibility and quality.

We’re eager to hear from you! Share your personal experiences and insights about the Grizzly G0642 – 15-Bit Line Boring Machine in the comments section below. Whether it’s about its performance, durability, or how it fits into your woodworking projects, your feedback could be invaluable to fellow woodworkers looking to make informed decisions!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment