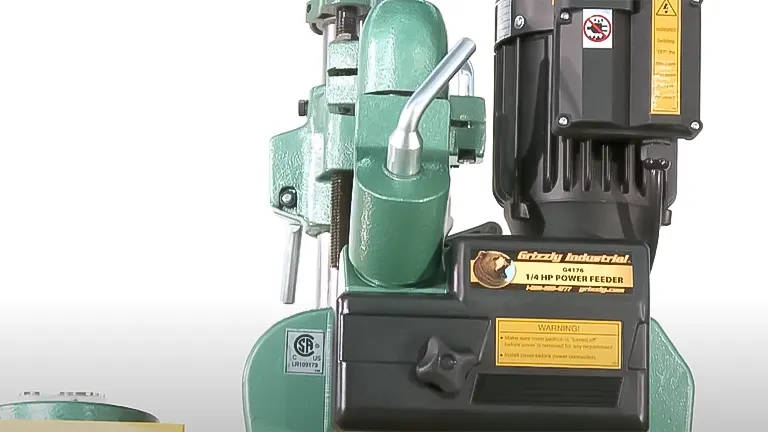

Grizzly G4176 – 1/4 HP Power Feeder Review

- February 8, 2024

- 0 comment

Throughout my woodworking journey, I’ve extensively engaged with various power feeders, understanding their pivotal role in the workshop. These tools are indispensable for achieving uniform, accurate cuts, and they play a crucial role in enhancing safety by maintaining a safe distance between our fingers and the sharp edges of blades and cutters.

In this exploration, I turn my focus to the Grizzly G4176 – 1/4 HP Power Feeder, an instrument that has become a staple in my array of equipment for numerous projects. Drawing from my personal use, I aim to provide an in-depth analysis of its operational efficiency, measure its performance against competing models, and lay out both its advantages and shortcomings.

Specifications

- Motor: 1/4 HP, 120V, single-phase, 2.5A

- Feed Speeds: 20, 26, 33, 43 FPM

- Rotation: Forward and reverse

- Vertical Travel: 6-1/2″

- Horizontal Travel: 10″

- Swing: 360°

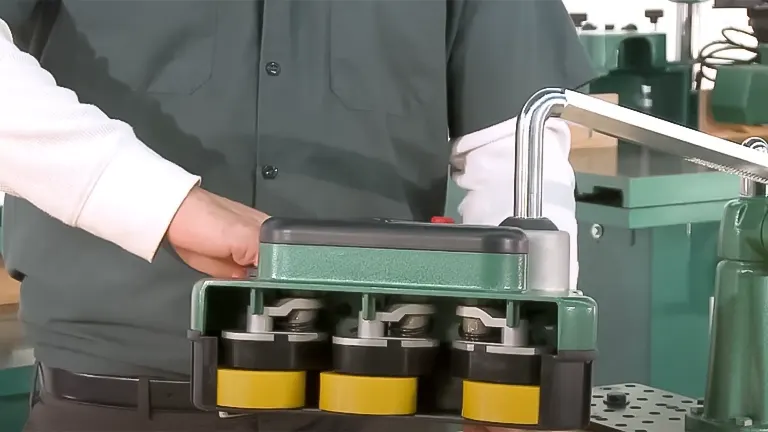

- Rollers: (3) synthetic rubber, 1-3/16″ wide x 3-1/8″ dia.

- Roller Suspension: 3/4″

- Item Weight: 77 pounds

- Product Dimensions: 23 x 23 x 11 Inches

Product Overview

This comprehensive review is grounded in my direct experiences with the Grizzly G4176. By meticulously examining its capabilities in a variety of scenarios, I intend to highlight how it measures up in terms of power, precision, and versatility.

Furthermore, this evaluation will include a comparative analysis with other market alternatives to give a well-rounded perspective on where it stands. My objective is to dissect the essential attributes of the Grizzly G4176, offering insights into its strengths and areas where it might fall short, all based on rigorous personal testing and observation.

Key Features:

- Forward/Reverse Feed: This feature allows the power feeder to push materials through in either direction, enhancing versatility in various operations and accommodating different cutting or shaping techniques.

- Multiple Feed Speeds: Having the option to adjust between multiple speeds provides the user with the flexibility to match the feed rate precisely with the material type and the specific operation, leading to optimal cutting results and improved safety.

- X-, Y-, Z-Axis Adjustment: This capability allows for precise positioning of the feeder in three dimensions: horizontally (X-axis), longitudinally (Y-axis), and vertically (Z-axis). Such adjustability ensures that the feeder can be perfectly aligned with the workpiece for accurate, consistent feeding.

- Rollers are Spring Tensioned: Spring-tensioned rollers automatically adjust to variations in workpiece thickness, maintaining consistent pressure and ensuring smooth, steady feeding without slipping or marking the material.

- Heavy-Duty Gear Reduction with Hardened Gears: This feature indicates the feeder is built with durability in mind. Gear reduction enhances torque, providing steady power even at lower speeds, while hardened gears ensure long-lasting performance and resistance to wear.

- Universal Positioning with Handle Locks: The feeder can be easily positioned at any angle or height, thanks to universal joints or mounts. Handle locks secure the feeder in the desired position, ensuring stability and precision during operation. This flexibility is crucial for custom setups and adapting to various machinery configurations.

Performance and Efficiency

The Grizzly G4176 is powered by a 1/4 HP, 120V motor, which may seem modest but is surprisingly effective for small to medium-sized woodworking tasks. It offers a variable speed control that ranges from 0 to 13 feet per minute, allowing for a great deal of flexibility depending on the workpiece and the operation being performed.

This feature is particularly beneficial when working with delicate pieces that require a gentle touch or when dealing with harder materials that demand slower feeding rates for accuracy.

In my experience, the feeder has consistently delivered smooth, even feeding on a variety of materials, from softwoods to hardwoods.

The three rubber rollers grip the workpiece firmly without leaving marks, which is a critical factor for finish-quality projects. Its ability to handle stock up to 2 inches thick and 6-1/2 inches wide covers a wide range of applications, from cabinet making to door construction.

Durability and Build Quality

Grizzly is known for its durable and well-constructed machinery, and the G4176 power feeder is no exception. The build quality is solid, with a heavy-duty cast iron base that ensures stability during operation. This sturdiness is crucial for maintaining precision in cuts and avoiding any movement that could compromise the workpiece’s integrity.

Over the months I’ve used it, the feeder has shown little sign of wear. The rollers maintain their grip without needing frequent adjustments, and the motor runs as smoothly as it did on day one. This longevity speaks to the quality of Grizzly’s manufacturing and their choice of materials.

Setup and Usability

Setting up the G4176 was straightforward, with clear instructions provided by Grizzly. Mounting it to my table saw took minimal effort, and adjusting it to various woodworking machines in my shop was equally simple. Its versatility is one of its strong suits, easily attaching to table saws, shapers, and jointers with little fuss.

The usability of this power feeder is enhanced by its simplicity. The speed control dial is intuitive, and making adjustments on the fly is hassle-free. This ease of use ensures that I can focus on the craftsmanship of my work rather than fiddling with equipment settings.

Safety Operations

Operating the Grizzly G4176 – 1/4 HP Power Feeder with safety in mind is paramount to ensure both the longevity of the tool and the well-being of the user. To maintain a safe working environment, it’s essential to always secure the power feeder firmly to the machine it is feeding into, preventing any movement that could lead to inaccuracies or accidents.

The operator should use the forward/reverse feed function judiciously, ensuring that the workpiece is always fed against the direction of the cutter for control and safety. Adjusting the X-, Y-, Z-axis carefully allows for precise alignment, minimizing the risk of kickback.

The spring-tensioned rollers should be checked regularly to ensure they apply consistent pressure without slipping, which could cause the workpiece to move unpredictably. Additionally, employing the heavy-duty gear reduction system and hardened gears provides a stable feed rate, reducing the chance of sudden jolts.

Always engage the universal positioning with handle locks securely to maintain the feeder’s position throughout the operation. Prioritizing these safety operations not only protects the user but also contributes to achieving optimal results in woodworking projects.

Comparable Alternatives

When comparing the Grizzly G4176 – 1/4 HP Power Feeder with the Shop Fox W1764 1/8 HP Mini Power Feeder, several key distinctions become apparent, offering potential buyers a clear choice based on their specific needs. The Grizzly G4176 stands out for its slightly more powerful motor, providing enhanced capability for handling a broader range of materials and project sizes.

Its 1/4 HP motor offers a bit more robustness compared to the 1/8 HP motor of the Shop Fox W1764, making the Grizzly better suited for medium-scale projects where additional power and versatility are required.

On the other hand, the Shop Fox W1764, with its smaller motor and compact design, is tailored for lighter-duty tasks and excels in environments where space is at a premium and portability is key. While the Grizzly G4176 offers a bit more in terms of speed control and material handling capacity, the Shop Fox W1764 counters with its ease of setup and maneuverability, making it an ideal choice for hobbyists or workshops with limited space.

Table of Comparisons vs. Competitor

Here’s a comparison table that outlines the key features and specifications of the Grizzly G4176 – 1/4 HP Power Feeder and the Shop Fox W1764 1/8 HP Mini Power Feeder:

| Feature | Grizzly G4176 | Shop Fox W1764 |

|---|---|---|

| Motor Power | 1/4 HP | 1/8 HP |

| Voltage | 120V | 120V |

| Speed Control | Variable, 0 to 13 feet per minute | Variable, speeds not specified |

| Roller Size | Not specified | Not specified |

| Material Capacity | Up to 2 inches thick, 6-1/2 inches wide | Suitable for light-duty tasks |

| Construction | Heavy-duty cast iron | Compact design for portability |

| Usage | Medium-sized projects, more robust tasks | Light-duty, precision work; ideal for small shops |

| Price Range | Generally higher due to larger motor and capacity | Usually more affordable, targeting hobbyists and smaller projects |

| Portability | Less portable, designed for stationary use | More portable, designed for ease of movement and storage |

This table highlights the differences in power, design, and intended use between the two models, providing a clear basis for decision-making depending on the specific needs of your projects and workshop environment. The Grizzly G4176 is better suited for those requiring a bit more power and material handling capability, while the Shop Fox W1764 caters to users looking for a compact, easy-to-handle feeder for smaller-scale tasks.

Maintenance Procedures

To ensure the Grizzly G4176 – 1/4 HP Power Feeder operates efficiently and lasts for years, adhering to regular maintenance procedures is crucial. Here are eight essential maintenance steps:

- Lubrication: Regularly lubricate all moving parts, including gears and bearings, to reduce friction and wear. Use the recommended lubricant as specified by the manufacturer to prevent buildup and ensure smooth operation.

- Cleaning: Keep the power feeder clean from sawdust, debris, and any other material that could accumulate. A buildup of debris can impair the feeder’s functionality and potentially become a safety hazard.

- Inspection of Rollers: Check the rollers for wear and tear, ensuring they maintain proper grip and tension. Replace them if they show signs of significant wear or damage to prevent slippage or marking of the workpiece.

- Gear and Motor Check: Inspect the gear reduction system and motor for signs of wear or damage. Listen for unusual noises that might indicate internal issues, and ensure the gears remain well-lubricated and free of debris.

- Tightening Loose Components: Periodically check all bolts, screws, and fasteners to ensure they are tight. Vibration from regular use can loosen these components, leading to instability or misalignment.

- Electrical System Check: Safely inspect the feeder’s electrical connections and cords for wear or damage. Ensure all connections are secure and replace any frayed or damaged wires to prevent electrical hazards.

- Adjustment Mechanisms: Regularly check the X-, Y-, Z-axis adjustment mechanisms to ensure they move freely and lock securely. Keeping these mechanisms well-lubricated and free of debris allows for precise positioning and stability during operation.

- Safety Features Inspection: Regularly test all safety features, including forward/reverse functionality and emergency stops, to ensure they are working correctly. This not only ensures operational safety but also helps in preventing accidental damage to the machine or workpiece.

Pros and Cons

Pros

- Versatile Speed Control: Tailor the feeding rate to the task at hand, enhancing both safety and precision.

- Solid Construction: Ensures longevity and consistent performance.

- Ease of Setup and Use: Makes it accessible even to those less experienced with power feeders.

- Excellent Grip with No Marking: Protects the workpiece while ensuring steady feeding.

Cons

- Limited to Smaller Projects: The 1/4 HP motor might not suffice for very large or heavy-duty operations.

- Weight and Portability: Its solid build makes it less portable than some may prefer.

Recommendations

For small to medium-sized workshops focusing on precision woodworking, the Grizzly G4176 – 1/4 HP Power Feeder is an excellent choice. Its combination of performance, durability, and ease of use make it a valuable asset. While it may not be the best fit for industrial-scale work, it’s the perfect companion for detailed, high-quality projects where control and safety are paramount.

Final Conclusion

In conclusion, the Grizzly G4176 – 1/4 HP Power Feeder emerges as a highly competent and versatile addition to any workshop, striking a balance between power and precision. With its 1/4 HP motor, it comfortably handles a wide range of materials and project sizes, making it particularly well-suited for medium-sized woodworking tasks that demand reliability and consistency.

The variable speed control, coupled with a robust build quality and the capacity to accommodate materials up to 2 inches thick and 6-1/2 inches wide, underscores its utility in producing precise cuts while enhancing safety. Although its size and power may not be tailored for the smallest of workshops or lightest-duty tasks, for enthusiasts and professionals seeking a dependable, versatile power feeder that bridges the gap between compact hobbyist models and industrial-grade machines, the Grizzly G4176 stands out as a compelling choice.

Frequently Asked Questions

- What types of woodworking machines is the Grizzly G4176 compatible with?

The Grizzly G4176 is versatile and can be mounted on various woodworking machines including table saws, shapers, jointers, and planers, making it suitable for a wide range of woodworking tasks. - Can the speed of the Grizzly G4176 be adjusted?

Yes, the Grizzly G4176 features variable speed control, allowing users to adjust the feeding speed from 0 to 13 feet per minute to match the specific requirements of each project. - What is the maximum material thickness and width the Grizzly G4176 can handle?

This power feeder can handle material up to 2 inches thick and 6-1/2 inches wide, accommodating a broad array of project sizes and types. - Is the Grizzly G4176 easy to set up and use?

Yes, the Grizzly G4176 is designed for straightforward setup and ease of use, with clear instructions provided. Its mounting and operation are user-friendly, catering to both seasoned woodworkers and novices. - How durable is the Grizzly G4176?

Built with a heavy-duty cast iron base and quality components, the Grizzly G4176 is highly durable and designed to withstand the rigors of frequent use in a woodworking workshop. - Does the Grizzly G4176 leave marks on the workpiece?

The rubber rollers are designed to grip the workpiece firmly without marking, ensuring the integrity of your materials during the feeding process. - What is the power source requirement for the Grizzly G4176?

The Grizzly G4176 operates on a standard 120V power source, making it compatible with typical workshop electrical setups. - How heavy is the Grizzly G4176, and is it portable?

While built for stability and durability, the Grizzly G4176 is less portable than smaller units due to its solid construction. Its weight is substantial, ensuring stability during operation, but it may require effort to move between machines if needed. - Can I use the Grizzly G4176 for very large or industrial-scale projects?

While the Grizzly G4176 is perfect for medium-sized projects, its 1/4 HP motor may not be sufficient for very large or industrial-scale operations that require higher power feeders. - Where can I purchase replacement parts or accessories for the Grizzly G4176?

Replacement parts and accessories for the Grizzly G4176 can be purchased directly from Grizzly Industrial’s official website or authorized dealers, ensuring you can maintain and extend the life of your power feeder as needed.

We’re eager to know what you think! If you’ve had the chance to use the Grizzly G4176 – 1/4 HP Power Feeder, please share your experiences and insights in the comments section below. Your personal stories and feedback are invaluable to fellow woodworkers looking to make well-informed decisions about this tool. Whether it’s about its performance, ease of use, or how it measures up in your projects, your input could be the deciding factor for someone on the fence. Let’s build a helpful community together!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment