JEGS Plasma Cutter Review

- April 5, 2024

- 0 comment

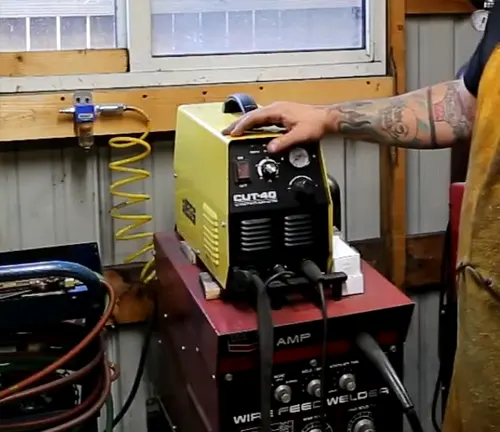

The JEGS Plasma Cutter is a compact, lightweight plasma cutter designed for both home DIY projects and professional use. It’s a part of JEGS’ lineup of high-performance tools and equipment, known for their reliability and efficiency. The Plasma Cut-40, in particular, is celebrated for its ease of use, portability, and cutting precision.

We’ve got your welding covered! Find comfy, Best welding gloves, Best welding carts, Best welding jackets, plus top picks for Best TIG Welder, Best MIG Welder & Best ARC Welders – all without breaking the bank!

Specifications

- Model: JEGS Plasma Cut-40

- Power Output: 40 amps

- Maximum Cut Thickness: Up to 3/8″ (approximately 9.5 mm)

- Duty Cycle: 60% at 40 amps

- Weight: Under 20 pounds (approximately 9 kg)

- Portability: Compact design with a comfortable carrying handle

- Material Compatibility: Cuts through steel, stainless steel, aluminum, copper, and more

- Power Source: Electric

- Display: Clear digital display

- Starting Mechanism: Pilot arc for easy start on painted or rusted surfaces

- Dimensions: Compact size for enhanced portability (specific dimensions may vary)

Usability

The Plasma Cut-40 is designed with the user in mind. Its setup is straightforward, requiring minimal adjustments to get started.

The inclusion of a pilot arc makes it easier to start cuts on painted or rusted surfaces without directly touching the metal, enhancing both safety and convenience. Moreover, its lightweight and compact size do not compromise its power, making it a versatile tool for both indoor and outdoor projects.

Power and Performance

The JEGS Plasma Cut-40 operates with a maximum output of 40 amps, which is quite potent for a unit of its size. This allows it to cut through metals up to 3/8” thick with precision and speed, making it suitable for a variety of applications, including automotive repairs, light industrial work, and metal art projects.

Portability

Weighing in at just under 20 pounds, its lightweight design is complemented by a comfortable handle, making it easy to transport from job to job.

Ease of Use

It features a user-friendly interface with a clear digital display and minimal control knobs, simplifying the setup process for both beginners and experienced users.

Versatility

The Plasma Cut-40 can cut through various types of metal, including steel, stainless steel, aluminum, copper, and more, offering flexibility across projects.

Duty Cycle

With a duty cycle of 60% at 40 amps, it provides a good balance between power and efficiency, allowing for prolonged use without overheating.

Performance

In terms of performance, the JEGS Plasma Cut-40 excels in delivering clean and precise cuts through a variety of metals.

The quality of the cuts is comparable to more expensive models, making it a cost-effective option for hobbyists and professionals alike. The machine’s reliability and efficiency are frequently highlighted by users, who appreciate its smooth operation and minimal maintenance requirements.

Pros and Cons

Pros

- Excellent value for its performance, appealing to budget-conscious users.

- Easy to transport and handle, ideal for various locations.

- User-friendly interface, suitable for beginners and experienced users alike.

- Capable of cutting a range of metals, offering flexibility for different tasks.

- Supports prolonged use with a 60% duty cycle at 40 amps.

Cons

- Maximum cut thickness of 3/8” may not suffice for thicker materials.

- Lacks the advanced features and precision controls found in some competitors.

Safety and Maintenance

Safety Precautions

- Wear Appropriate PPE: Always wear personal protective equipment, including safety glasses, gloves, and flame-resistant clothing to protect against sparks, heat, and UV radiation.

- Proper Ventilation: Ensure adequate ventilation in the workspace to avoid inhaling harmful fumes and dust generated during cutting.

- Electrical Safety: Check all electrical connections and cords for damage before use to prevent electric shocks.

- Avoid Flammable Materials: Keep the cutting area clear of flammable materials and liquids to prevent fires.

- Use a Fire Extinguisher: Have a suitable fire extinguisher nearby in case of emergencies.

Maintenance Tips

- Regular Inspection: Periodically inspect the plasma cutter for wear and tear, especially the torch and consumables, replacing any damaged parts immediately.

- Clean Air Supply: Ensure the air compressor is providing clean, dry air to prevent internal corrosion and ensure quality cuts.

- Torch Care: Regularly clean the torch’s exterior and check the electrode and nozzle for signs of wear, replacing them as needed to maintain cutting efficiency.

- Software Updates: If your plasma cutter uses software, keep it updated for optimal performance and new features.

- Secure Connections: Regularly check all connections, including the ground clamp, for tightness and security to ensure consistent performance and reduce electrical hazards.

Review of Visual Aspects

The JEGS Plasma Cutter presents a visually appealing design that combines functionality with an industrial aesthetic. Its sleek, compact form factor is accentuated by the distinctive JEGS yellow and black color scheme, which not only makes it stand out in any workshop but also aligns with the brand’s identity of robustness and reliability.

The intuitive layout of the control panel, with clear markings and a digital display, enhances its user-friendly nature, ensuring that even those new to plasma cutting can approach their projects with confidence. Overall, the visual aspects of the JEGS Plasma Cutter reflect a thoughtful design that prioritizes ease of use without compromising on professional appearance, making it a standout choice for both hobbyists and professionals seeking efficiency and style in their tools.

Comparison Table

When compared to similar models in its price range, the Plasma Cut-40 stands out for its balance of power, portability, and price. While some competitors may offer additional features or higher power outputs, the Plasma Cut-40 provides a solid performance that meets the needs of most typical applications without the extra cost.

| Feature | JEGS Plasma Cut-40 | Hobart Airforce 27i |

|---|---|---|

| Power Output | 40 amps | Up to 27 amps (but offers higher cutting capacity) |

| Maximum Cut Thickness | 3/8″ | 5/8″ |

| Duty Cycle | 60% at 40 amps | Varies, generally efficient for extended use |

| Weight | Under 20 pounds | Slightly heavier, specific weight not mentioned |

| Portability | Highly portable with carrying handle | Portable, designed for ease of transport |

| User Interface | Simple, user-friendly with digital display | Intuitive controls with more advanced settings |

| Material Compatibility | Cuts various metals like steel, stainless steel, aluminum, etc. | Broad compatibility with similar range of metals |

| Price | More cost-effective, aimed at budget-conscious users | Higher, reflecting the brand’s reputation and additional features |

| Ideal User | DIY enthusiasts, light industrial use, budget-conscious professionals | Users needing to cut thicker materials, willing to invest in a higher-end model |

| Additional Features | Pilot arc for easy starts on painted/rusted surfaces | May include more advanced features and settings for precision control |

Hobart Airforce 27i Specifications

- Model: Hobart Airforce 27i

- Power Source: 120V or 240V (Dual Voltage)

- Output Power: Up to 27 amps

- Maximum Cut Thickness: Up to 5/8″ (at optimal performance)

- Duty Cycle: 35% at 27 amps (240V), higher on 120V with reduced output

- Weight: Approximately 32 pounds

- Dimensions: Compact and portable, specific dimensions vary

- Technology: Inverter-based design for efficient power use

- User Interface: LED indicators for pressure, power, and cup status; pressure gauge for easy monitoring

- Cutting Capability: Can cut steel, stainless steel, aluminum, and more

Final Verdict

The JEGS Plasma Cut-40 is an impressive plasma cutter that offers great value for its price. It’s suited for users looking for a reliable, easy-to-use, and versatile cutting tool. Whether for home DIY projects, automotive repairs, or light industrial work, it provides the performance and quality expected from a higher-priced unit. While it may lack some of the advanced features found in more expensive models, its affordability, combined with its solid performance, makes it an excellent choice for both novices and seasoned professionals.

FAQs

- What Metals Can It Cut?

The JEGS Plasma Cutter can cut a variety of conductive metals, including steel, stainless steel, aluminum, copper, and brass. - Maximum Cutting Thickness?

It is capable of cutting materials up to 3/8 inch thick, though performance may vary with different materials. - Voltage Requirements?

Check the specific model’s specifications for voltage requirements, as some models may support dual voltage (120V and 240V). - Benefits of Pilot Arc?

The pilot arc feature allows for cutting without direct contact with the material, ideal for painted or rusted surfaces. - Is It Portable?

Yes, designed for ease of transport, it’s lightweight and includes a carrying handle. - Recommended Safety Equipment?

Wear safety glasses, gloves, and flame-resistant clothing to protect against sparks, heat, and UV radiation. - Consumables Replacement Frequency?

Replace consumables as needed based on wear, which varies by use intensity and duration. - CNC Compatibility?

Some models may be compatible with CNC setups. Check product specifications or contact JEGS for details. - Maintenance Requirements?

Maintain optimal performance through regular consumable checks, air filter maintenance, and inspection of electrical components. - Where to Find Replacement Parts?

Purchase genuine replacement parts directly from JEGS or authorized dealers to ensure compatibility and safety.

We’d love to hear from you! If you’ve used the JEGS Plasma Cutter, please share your personal experiences and thoughts in the comments section below. Your insights could greatly assist fellow craftsmen and DIY enthusiasts in making informed decisions. Whether it’s about its performance, ease of use, or any tips you have for getting the best out of it, your input is invaluable!

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment