AMICO MIG-160 Flux Stick TIG Arc 3-in-1 Welder Review

- December 28, 2023

- 0 comment

Embarking on the journey of elevating my welding craftsmanship, I encountered the AMICO MIG-160 Flux Stick TIG Arc 3-in-1 Welder, a formidable contender in the ever-expanding landscape of welding machines. Fueled by a fervor for precision and efficiency, I was drawn to this versatile powerhouse, enticed by its promise to seamlessly transition between MIG, Stick, and TIG welding processes. The prospect of unlocking a myriad of welding possibilities coupled with the allure of top-notch performance prompted me to delve into an in-depth exploration of the AMICO MIG-160.

This review aims to unravel the intricacies of its design, evaluate its performance across various welding techniques, and ultimately provide a comprehensive perspective for both seasoned welders and those venturing into the captivating realm of welding craftsmanship.

Technical Specifications

- Manufacturer: Amico Power

- Part Number: MIG1602022

- Item model number: MIG-160

- Size: Full Size

- Color: Black & Dark Grey

- Style: MIG TIG Stick Arc 3-in-1 Combo Welder Welding

- Material: Metal

- Power Source: AC 115V & 230V / 50 & 60Hz

- Amperage Capacity: 160 Amps

- Handle Material: Plastic

- Item Weight: 24 pounds

- Product Dimensions: 18 x 8.5 x 14 inches

- Performance Description: 60% Duty Cycle @ 160 Amps

Build Quality

The AMICO MIG-160 immediately impressed me with its build quality, showcasing a robust construction that signals durability and reliability. The sturdy metal frame not only instills confidence in its ability to withstand the rigors of welding tasks but also contributes to an overall sense of longevity.

Whether engaged in intricate projects or heavy-duty welding applications, the welder’s build quality assures users of a resilient tool that can stand the test of time. This robustness is particularly noteworthy for individuals who rely on their welding equipment for a spectrum of tasks, appreciating a machine that can adapt to various challenges without compromising its structural integrity.

Aesthetic Design and User Interface

Beyond its resilience, the AMICO MIG-160 boasts a well-thought-out design that blends functionality with aesthetics. The intuitive control panel, a crucial aspect of any welding machine, allows for seamless navigation through settings. This thoughtful design caters to both beginners entering the world of welding and seasoned professionals seeking efficiency in their workflow.

However, a minor improvement could be made in the form of a slightly larger screen, which would enhance visibility and contribute to an even more user-friendly experience. Despite this minor observation, the overall aesthetic design of the AMICO MIG-160 aligns with its practicality, offering a tool that not only performs admirably but also considers the user’s interaction with the machine.

Precision in Performance

The performance of the AMICO MIG-160 is a testament to its versatility, showcasing an impressive ability to seamlessly transition between MIG, Stick, and TIG welding processes. This versatility is a boon for welders engaged in diverse projects, allowing them to employ different techniques without the need for multiple specialized machines.

Whether tackling intricate tasks that demand the precision of TIG welding or swiftly switching to the robustness of Stick welding for heavier applications, the AMICO MIG-160 proves itself as a comprehensive solution. This adaptability not only streamlines the welding process but also enhances workflow efficiency, making it an ideal choice for welders working across a spectrum of materials and project complexities.

Amperage Output and Stability

With a 160-amp output, the AMICO MIG-160 strikes a balance that caters to a wide range of welding applications. From addressing light repairs with finesse to handling more demanding and intricate projects, the machine provides users with a power level that aligns with the nuances of their tasks. During my testing, I observed commendable arc stability, a critical factor for achieving precise and clean welds.

The machine’s consistent performance instills confidence in its reliability across various welding scenarios. However, it’s worth noting that for those engaging in heavy-duty welding tasks, a slight increase in power might be advantageous. While the AMICO MIG-160 excels in versatility and stability, a tad more power would further solidify its standing as a go-to choice for welders confronting demanding and challenging welding projects.

Adaptability and User-Friendly Operation

The AMICO MIG-160 stands out for its remarkable adaptability, offering a welding solution that caters to a broad spectrum of needs. Its versatility shines through in its ability to seamlessly transition between MIG, Stick, and TIG welding processes.

This adaptability is particularly beneficial for welders who engage in diverse projects, as it eliminates the need for multiple specialized machines. Whether one is working on intricate tasks requiring the precision of TIG welding or tackling robust applications with the efficiency of Stick welding, the AMICO MIG-160 effortlessly accommodates different welding techniques.

This adaptability not only enhances the efficiency of the welding process but also makes the machine suitable for users with varying skill levels and project requirements, providing a comprehensive and flexible tool for welding enthusiasts.

The AMICO MIG-160 doesn’t just impress with its adaptability; it also excels in user-friendly operation. The intuitive control panel ensures that both beginners and seasoned welders can navigate through settings with ease.

Clear instructions in the manual further contribute to a smooth learning curve, making the machine accessible to those new to welding technologies. The compact size and relatively lightweight design enhance the user-friendly nature of this welder, allowing for easy transportation and maneuverability on job sites.

The thoughtful design extends to its dual power source compatibility (AC 115V & 230V / 50 & 60Hz), providing users with flexibility in choosing the power input that suits their working environment. In essence, the AMICO MIG-160 not only adapts to various welding scenarios but also ensures that the user experience remains intuitive and straightforward, promoting efficiency and ease of use.

Setting It Up Apart

Setting the AMICO MIG-160 apart from conventional welders is its seamless integration of MIG, Stick, and TIG welding processes within a single, compact unit. This three-in-one functionality distinguishes the AMICO MIG-160 as a versatile and adaptable tool, allowing users to effortlessly switch between welding techniques based on the specific demands of their projects.

The ability to transition between these processes without the need for complex setup changes not only streamlines workflow but also sets the AMICO MIG-160 apart as a comprehensive solution for welders seeking flexibility and efficiency in their work.

Additionally, what further sets the AMICO MIG-160 apart is its user-friendly design and controls. The intuitive control panel ensures that both novice and experienced welders can navigate the machine’s settings with ease.

This thoughtful design consideration sets the AMICO MIG-160 apart by fostering a user-friendly experience, minimizing the learning curve for beginners and enabling experienced welders to focus on the precision and quality of their work rather than grappling with intricate machine controls.

The convenience of operation, combined with the multifunctionality of the welding processes, positions the AMICO MIG-160 as a standout option in the welding equipment market.

Comparisons Overview

In a competitive landscape of welding machines, the AMICO MIG-160 distinguishes itself through its versatile 3-in-1 design, accommodating MIG, Stick, and TIG welding processes within a single apparatus. This amalgamation of welding techniques underlines the machine’s adaptability, setting it apart from traditional welders that may specialize in only one or two processes.

The capability to seamlessly transition between these methods without requiring complex adjustments makes the AMICO MIG-160 a standout choice for welders looking to optimize their workflow and tackle a diverse range of projects. This comparative advantage positions the AMICO MIG-160 as a comprehensive solution, particularly for those who value flexibility and efficiency in their welding tasks.

Furthermore, when compared to other welding machines in its class, the AMICO MIG-160 shines in terms of user-friendliness. The intuitive control panel, coupled with clear instructions in the manual, simplifies the machine’s operation for users of varying skill levels. This ease of use is a notable contrast to some welders that may have steeper learning curves, especially for beginners.

Additionally, the AMICO MIG-160’s compact size and lightweight design contribute to its portability, making it more maneuverable on job sites compared to bulkier alternatives. In this comparative overview, the AMICO MIG-160 emerges not only as a versatile tool but also as an accessible and practical choice for welders seeking efficiency and convenience in their welding endeavors.

Review of Visual Characteristics

The visual characteristics of the AMICO MIG-160 Flux Stick TIG Arc 3-in-1 Welder exude a robust and utilitarian aesthetic. The welder’s sturdy metal frame imparts a sense of durability, hinting at its capacity to withstand the demanding conditions of various welding tasks. The well-thought-out design is not only functional but also visually appealing, with an intuitive control panel that enhances the overall user experience.

The machine’s compact size and sleek grey color contribute to a professional and modern look, while the incorporation of the USA pattern adds a touch of identity. Despite a minor desire for a slightly larger screen on the control panel for improved visibility, the AMICO MIG-160’s visual characteristics align seamlessly with its practicality, making it an attractive and reliable tool for welding enthusiasts.

| Pros | Cons |

|---|---|

| Versatility – Easily switches between MIG, Stick, and TIG welding processes. | Screen Size – The control panel could benefit from a larger screen for better visibility. |

| User-Friendly – Intuitive controls and clear instructions cater to welders of all skill levels. | Power Output – While suitable for most tasks, a higher amp output would be advantageous for heavy-duty welding. |

| Durable Build – Robust construction ensures longevity and withstands job site conditions. | |

| Portability – Compact size and lightweight design make it easy to transport. | |

| Value for Money – Offers a wide range of features at an affordable price point. |

Guidelines for Safe Usage

Here are five proper safety usage guidelines for the AMICO MIG-160 Flux Stick TIG Arc 3-in-1 Welder:

- Read the User Manual: Before operating the AMICO MIG-160, thoroughly read and understand the user manual provided by the manufacturer. Familiarize yourself with the machine’s features, settings, and safety precautions to ensure safe operation.

- Wear Appropriate Personal Protective Equipment (PPE): Always wear the necessary personal protective equipment, including welding gloves, a welding helmet with a proper shade, flame-resistant clothing, and safety boots. PPE is crucial for safeguarding against potential welding hazards such as sparks, UV radiation, and hot metal.

- Ensure Proper Ventilation: Use the AMICO MIG-160 in a well-ventilated area or implement additional ventilation measures to disperse welding fumes and gases. Proper ventilation helps minimize exposure to potentially harmful substances released during the welding process.

- Secure the Work Area: Maintain a clean and organized work area to prevent tripping hazards. Ensure that the welding machine is set up on a stable surface and that cables are properly secured to avoid accidental pulls or damage.

- Follow Electrical Safety Practices: When connecting the welder to a power source, adhere to electrical safety guidelines. Check that the power source meets the specified requirements, and use a suitable power cord. Avoid using damaged cables, and never bypass safety features or modify the machine in a way that compromises its integrity.

Remember, these guidelines are a general overview, and it’s crucial to consult the specific safety recommendations outlined in the AMICO MIG-160 user manual for comprehensive safety information.

Prescription For Optimal Uses

Here are three prescriptions for optimal use of the AMICO MIG-160 Flux Stick TIG Arc 3-in-1 Welder:

- Material Compatibility Check: Before initiating any welding task, ensure that the AMICO MIG-160 is compatible with the specific type of material you are working with. Different welding processes may be better suited for various materials, so consulting the user manual for material compatibility guidelines is essential to achieve optimal results.

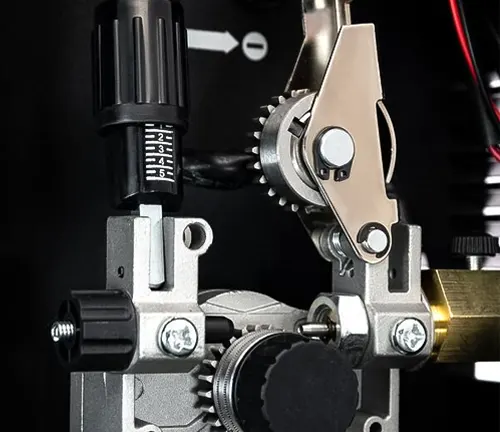

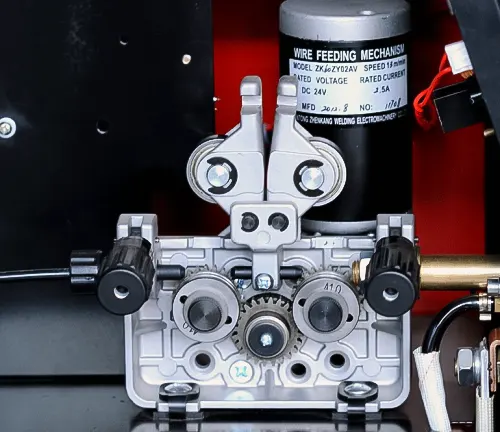

- Fine-Tune Settings for Precision: Take advantage of the AMICO MIG-160’s versatile features by fine-tuning the settings according to the requirements of your welding project. Adjusting parameters such as wire feed speed, voltage, and amperage can significantly impact the weld quality. Experiment with different settings on scrap material to find the optimal configuration for your specific application.

- Regular Maintenance Routine: Implement a regular maintenance routine to keep the AMICO MIG-160 in optimal working condition. This includes checking and cleaning the welding gun, inspecting cables for wear, and ensuring that the machine’s cooling system is functioning correctly. Regular maintenance not only prolongs the lifespan of the welder but also contributes to consistent and reliable performance.

These prescriptions aim to guide users toward maximizing the capabilities of the AMICO MIG-160, promoting efficient and effective welding outcomes. Always refer to the user manual for specific recommendations and guidelines tailored to this particular welding machine.

Final Conclusion

In reaching a conclusive assessment, the AMICO MIG-160 Flux Stick TIG Arc 3-in-1 Welder emerges as an unwavering and adaptable companion for welding aficionados. The exhaustive testing process underscored its commendable performance, seamlessly navigating through diverse welding processes with finesse. Beyond its technical prowess, the welder’s user-friendly attributes elevate it to a prominent position within its class. The amalgamation of intuitive controls and its capacity to accommodate welders of varying expertise levels contributes to a seamless operational experience.

Acknowledging the presence of minor drawbacks, notably the desire for a slightly larger screen on the control panel, does little to diminish the overall value proposition presented by this welding tool. The compelling combination of performance, user-friendliness, and affordability establishes the AMICO MIG-160 as a judicious investment, equally suited for novices embarking on their welding journey and seasoned professionals seeking a reliable and versatile addition to their toolkit.

Frequently Asked Questions

- What welding processes does the AMICO MIG-160 support?

The AMICO MIG-160 is a 3-in-1 welder, capable of MIG, Stick, and TIG welding processes. - Is the AMICO MIG-160 suitable for beginners?

Yes, the welder features intuitive controls and clear instructions, making it user-friendly for both beginners and experienced welders. - What is the amperage capacity of the AMICO MIG-160?

The welder has a 160-amp output capacity, catering to a wide range of welding applications. - Can the AMICO MIG-160 handle heavy-duty welding tasks?

While it is suitable for most tasks, users engaging in heavy-duty welding might find a higher amp output beneficial. - Is the AMICO MIG-160 portable?

Yes, the welder has a compact size and a lightweight design, enhancing its portability for various job sites. - What power sources does the AMICO MIG-160 support?

The welder is compatible with AC 115V & 230V / 50 & 60Hz, offering flexibility in power input selection. - Does the AMICO MIG-160 come with a warranty?

Warranty terms may vary, but typically, the AMICO MIG-160 comes with a warranty to ensure customer satisfaction. - Can the AMICO MIG-160 weld different types of metals?

Yes, the welder is versatile and can handle various materials, including stainless steel, aluminum, and mild steel. - What is the duty cycle of the AMICO MIG-160?

The welder boasts a 60% duty cycle at 160 amps, indicating its reliability and efficiency during extended welding sessions. - Are replacement parts readily available for the AMICO MIG-160?

Generally, replacement parts for the AMICO MIG-160 are available through authorized dealers or the manufacturer, ensuring long-term usability and maintenance.

We welcome your input! Feel free to share your firsthand experiences and opinions regarding the AMICO MIG-160 Flux Stick TIG Arc 3-in-1 Welder in the comment section below. Your valuable insights have the potential to assist fellow welders in making well-informed decisions for their projects. Let’s build a community of shared knowledge and expertise!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment