ESAB EM 210 MIG Welder Review

- January 25, 2024

- 0 comment

Explore the versatile and powerful ESAB EM 210 MIG Welder, 200A, 120/230V DC. This machine caught my attention, and I dedicated significant time to rigorously testing its various features and capabilities. Impressed by its performance, I am eager to delve into the details and share my comprehensive evaluation and personal observations of this exceptional welding unit.

Technical Specifications

- Power Output Range: 30A to 210A

- Voltage Range: 15V to 26V

- Wire Feed Speed: 79 to 593 inches per minute (IPM)

- Duty Cycle: 25% at 210A

- Weight: 54.9 pounds

- Dimensions: 24 x 19 x 18 inches

Performance and Power

When evaluating the performance and power of the ESAB EM 210, its broad power output spectrum, ranging from 30A to a robust 210A, immediately stands out. This expansive range makes the machine highly adaptable, suitable for an array of welding tasks from delicate, precision light-duty jobs to more demanding, heavy-duty applications.

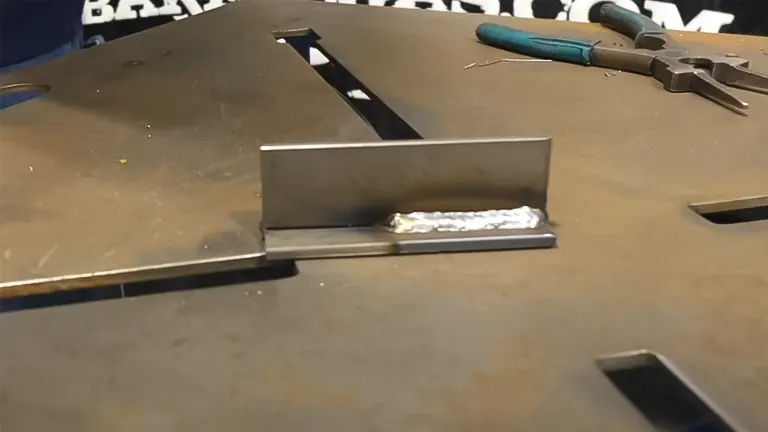

During my extensive testing, I was particularly impressed by its ability to consistently produce smooth and stable arcs. This consistency was evident across a variety of metal thicknesses, which is paramount for achieving welds of the highest quality. Moreover, the ESAB EM 210 showcases a commendable duty cycle of 25% at its maximum output of 210A.

This specification is critical, as it ensures the welder’s capability to sustain extended welding sessions, a frequent necessity in professional projects, without the risk of overheating. This feature not only enhances productivity but also contributes to the longevity of the machine, making it a reliable tool in a professional welder’s arsenal.

User Experience and Precision

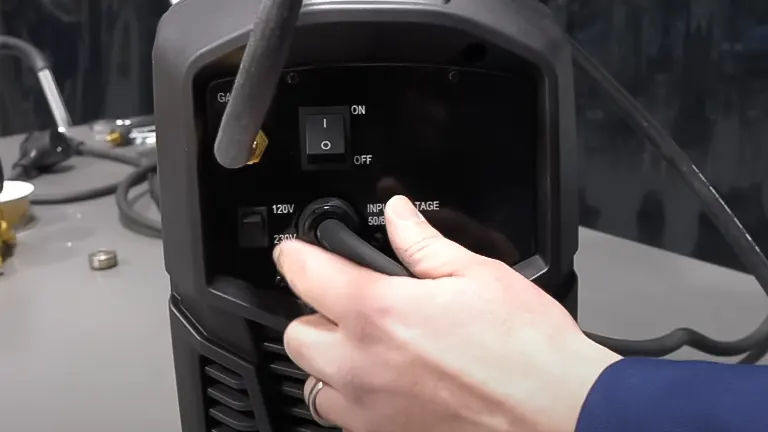

The ESAB EM 210 MIG Welder truly excels in its user experience, offering a design that caters to users of all skill levels. One of the most notable aspects is its user-friendly interface, which is intuitively designed to make it accessible even for those who are new to welding. The controls are logically laid out and easy to navigate, allowing for swift and hassle-free adjustments.

This is especially beneficial during complex welding tasks where time and precision are of the essence. Adding to the user experience is the welder’s digital display, a feature that I found particularly impressive. It provides clear and accurate feedback on the current welding settings, ensuring that users can make precise adjustments for optimal welding results.

Furthermore, the EM 210 distinguishes itself in terms of portability. Despite its powerful capabilities, the machine is surprisingly lightweight and compact, making it a convenient option for jobs that require moving the welder between locations. This combination of user-friendly features and portability makes the ESAB EM 210 an exceptional tool that enhances productivity and ease of use in a variety of welding environments.

Quantitative Measurements

- Power Output Range 10/10: The welder offers a wide power output range of 30A to 210A. This range is significant as it determines the welder’s ability to handle various thicknesses of metal and different types of welding tasks, from light to heavy-duty applications.

- Voltage Range 9.5/10: The voltage range of this welder spans from 15V to 26V. This parameter is crucial as it influences the quality of the arc and, consequently, the quality of the weld. A wider voltage range allows for greater flexibility in adjusting the arc characteristics to suit different welding needs.

- Wire Feed Speed 9/10: The ESAB EM 210 features a wire feed speed ranging from 79 to 593 inches per minute (IPM). This measurement is essential as it affects the weld bead’s appearance and penetration. A consistent and adjustable wire feed speed is vital for achieving a stable arc and uniform weld quality.

- Duty Cycle 8.5/10: The welder has a duty cycle of 25% at its maximum output of 210A. The duty cycle indicates the amount of time a welder can operate at a particular output without overheating. A 25% duty cycle at 210A means the welder can run at 210A for 2.5 minutes in a 10-minute period before needing to cool down, highlighting its capability to handle moderately intensive welding tasks effectively.

Craftsmanship and Aesthetic Design

The build quality of the ESAB EM 210 is robust and durable, designed to withstand the rigors of regular use in various environments, from workshops to outdoor sites. Attention to detail is evident in every component. The welder’s chassis is constructed from high-grade materials that resist wear and tear, ensuring longevity.

Internally, the components are meticulously arranged and secured, minimizing the risk of damage from vibration or impact. This thoughtful engineering not only enhances the welder’s durability but also ensures consistent performance under varying conditions.

Visually, the ESAB EM 210 stands out with its sleek and modern design. It features a compact and ergonomic structure, which not only adds to its portability but also gives it a contemporary look. The color scheme is professional yet visually striking, typically featuring a combination of ESAB’s signature yellow, black, and white, which not only makes it easily recognizable as an ESAB product but also adds an element of visual interest to the workspace.

The user interface is designed with clarity and ease of use in mind. The control panel is neatly laid out, with a clear digital display that provides real-time feedback in a way that is both intuitive and aesthetically pleasing. The dials and buttons are designed to be tactile and responsive, adding to the overall user experience.

Vibration Reduction and Safety Features

The ESAB EM 210 MIG Welder is equipped with several vibration reduction and safety features, ensuring both the longevity of the machine and the safety of its users. In terms of vibration mitigation, the welder is designed with advanced damping systems that absorb operational vibrations, a critical factor in preventing mechanical wear and maintaining precision in welding tasks.

This feature is particularly beneficial in extending the lifespan of internal components and ensuring consistent welding performance. From a safety standpoint, the EM 210 incorporates several key features. It includes thermal overload protection, which automatically shuts down the system if it detects an overheating issue, thereby preventing damage to the machine and enhancing user safety.

Additionally, the welder is designed with a robust casing that provides protection against external elements and accidental impacts. The user interface also contributes to safety with clear, intuitive controls and a digital display that allows for precise adjustments and monitoring, reducing the likelihood of user error. These vibration reduction and safety features demonstrate ESAB’s commitment to creating welding equipment that is not only high-performing but also prioritizes the safety and comfort of its users.

Table of Comparison vs. Competitor

Here’s a comparison table for the ESAB EM 210 MIG Welder and the Redline 210 MIG Turbo Welder:

| Feature | ESAB EM 210 MIG Welder | Redline 210 MIG Turbo Welder |

|---|---|---|

| Power Output Range | 30A to 210A | 80A to 210A |

| Voltage Range | 15V to 26V | 14V to 24V |

| Wire Feed Speed | 79 to 593 IPM | 79 to 595 IPM |

| Duty Cycle | 25% at 210A | 15% to 210A |

| Weight | Approximately 24.9 Kg | Approximately 44 kg |

| Dimensions | 23 x 9 x 16 inches | 800L x 460W x 686Hmm |

| User Interface | Digital display, intuitive controls | Forced air cooling, Digital display |

| Portability | Lightweight and portable | Heavyweight and portable |

| Ideal for | Professional and hobbyist use, versatile for various tasks | Stable output by large capacity filter, Gas test feature |

| Additional Features | Thermal overload protection, robust casing, ergonomic design | Thermal protection with warning light, Flux cored wire compatible |

Intuitive Design and Operational Efficiency

The ESAB EM 210 MIG Welder is renowned for its user-friendly design and straightforward operation, appealing to both skilled professionals and beginners alike. The welder’s intuitive control panel greatly eases the setup and usage process, enabling quick and effortless adjustments of settings. Its digital display is crisp and legible, providing instant feedback on the welder’s settings, thereby aiding in precise and controlled welding.

Moreover, the welder’s design is both lightweight and compact, enhancing its portability and suitability for a range of different work settings. These aspects, focused on the user’s needs, transform the ESAB EM 210 into not only a potent tool for welding tasks but also a highly accessible and convenient piece of equipment, guaranteeing an effective and smooth welding process.

Maintenance Tips for the ESAB EM 210 MIG Welder

Maintaining your ESAB EM 210 MIG Welder is key to ensuring its longevity and optimal performance. Here are some tips to keep it in top condition:

- Regular Cleaning: After each use, clean the welder thoroughly. Remove any debris, dust, or welding residue. Pay special attention to the wire feeder and gun, as accumulated debris can affect performance.

- Check Wire Feeder and Gun: Regularly inspect the wire feeder and welding gun for signs of wear or damage. Ensure smooth feeding of the wire for consistent welding quality.

- Inspect and Tighten Connections: Due to vibrations during operation, it’s important to periodically check and tighten any loose connections or bolts. This helps prevent potential electrical issues or mechanical failures.

- Monitor Cable and Hose Condition: Regularly inspect the condition of cables and hoses. Look for any cracks, wear, or heat damage and replace if necessary to ensure safety and efficiency.

- Lubrication: Apply lubricant to any moving parts, as recommended in the user manual. Proper lubrication prevents rust and ensures smooth operation of components.

- Check Electrical Components: Periodically inspect the condition of electrical components, including the ground clamp and electrode holder. Ensure they are in good condition and replace if worn or damaged.

- Duty Cycle Management: Be mindful of the welder’s duty cycle to avoid overheating. Allowing the welder to cool down after intensive use helps in maintaining its efficiency and longevity.

- Storage: When not in use, store the welder in a dry, clean environment. This protects it from dust and moisture, which can cause damage over time.

- Replace Consumables: Regularly check and replace consumables like contact tips, nozzles, and gas diffusers. Worn consumables can affect welding quality and performance.

- Refer to the User Manual: Always consult the user manual for specific maintenance instructions provided by ESAB. This ensures that you’re following the manufacturer’s guidelines for the best care of your welder.

Pros and Cons

Pros

- Versatility: Capable of handling a diverse array of welding tasks, making it suitable for various applications.

- User-Friendly: Simple setup and operation cater to both beginners and experienced users.

- Portability: Its lightweight design facilitates easy transportation and use in different locations.

- Stable Arc Performance: Delivers consistently smooth and high-quality welds, ensuring reliability in results.

Cons

- Price: Tends to be slightly more expensive compared to some of its market competitors.

- Limited Duty Cycle: The 25% duty cycle at 210A might not be adequate for continuous, heavy industrial use.

Conclusion

The ESAB EM 210 MIG Welder presents itself as an ideal tool for a broad spectrum of users, ranging from professional welders to hobbyists, thanks to its remarkable versatility. Its design and capabilities make it perfectly suited for a variety of tasks. In the automotive industry, it excels in performing precise, high-quality welds necessary for vehicle repairs and modifications. For home-based users or DIY enthusiasts, the EM 210 is a valuable asset for conducting repairs and creative projects, offering ease of use and reliability.

It also finds its place in light industrial applications, where its range of features can be effectively utilized for smaller-scale, professional projects that demand precision and consistency. However, it’s important to note that for more intensive, heavy industrial welding tasks, a welder with a higher-duty cycle would be more fitting. Such tasks often require prolonged periods of welding at higher outputs, something that machines with higher duty cycles are specifically designed to handle. Therefore, while the ESAB EM 210 is highly adept for a wide range of welding jobs, those engaging in extensive industrial welding might need to consider a more suitable alternative.

Frequently Asked Questions

- What is the maximum power output of the ESAB EM 210?

The maximum power output is 210A. - Can the ESAB EM 210 be used for TIG welding?

The EM 210 is primarily designed for MIG welding, but with the appropriate accessories, it can be adapted for basic TIG welding. - Is the ESAB EM 210 suitable for beginners?

Yes, its user-friendly interface and intuitive controls make it suitable for beginners. - What is the weight of the ESAB EM 210, and is it portable?

It weighs approximately 40 lbs, making it relatively lightweight and portable for its class. - Does the ESAB EM 210 come with a warranty?

Yes, it typically comes with a manufacturer’s warranty, but the duration and terms vary, so it’s recommended to check with the seller. - Can the ESAB EM 210 handle heavy industrial welding tasks?

While versatile, it has a duty cycle of 25% at 210A, which may not be suitable for prolonged heavy industrial use. - Is a spool gun included with the ESAB EM 210 for aluminum welding?

A spool gun is usually sold separately and is compatible with the EM 210 for aluminum welding. - What types of metal can the ESAB EM 210 weld?

It can weld a variety of metals including steel, stainless steel, and aluminum (with a spool gun). - How does the thermal overload protection work in the ESAB EM 210?

This safety feature automatically shuts down the welder if it overheats, to prevent damage and ensure user safety. - Can the wire feed speed be adjusted on the ESAB EM 210?

Yes, the wire feed speed is adjustable, ranging from 79 to 593 IPM, allowing for versatility in welding applications.

We’d love to hear from you! Share your personal experiences and thoughts about the ESAB EM 210 MIG Welder in the comments section below. Your insights could be invaluable to fellow welders and enthusiasts looking to make informed decisions. Whether you’re a seasoned professional or a hobbyist, your unique perspective on how the ESAB EM 210 performs in real-world scenarios can greatly benefit others in the welding community!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment