Lincoln Electric Weld Pak 140 Welder Review

- January 19, 2024

- 0 comment

I had the opportunity to work with the Lincoln Electric K2514-1 Weld Pak 140 Welder. In this article, I aim to provide an in-depth review of this specific model, delving into its features and performance from the standpoint of my seasoned expertise and personal experience in using this equipment.

Overview and Initial Impressions

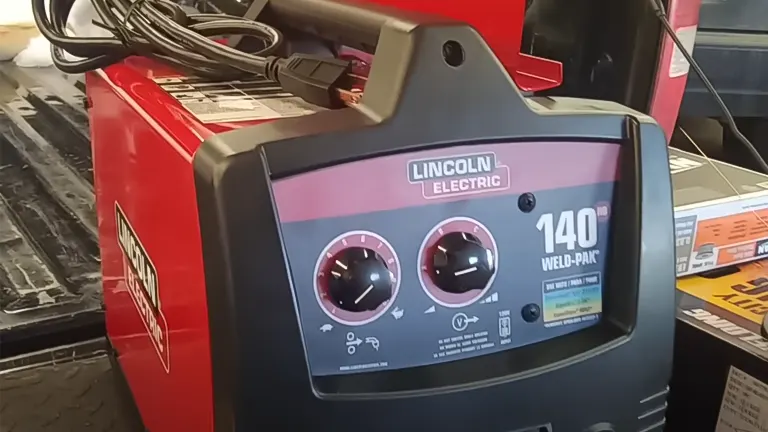

The Lincoln Electric K2514-1 Weld Pak 140 stands out as a compact, wire-feed welder, tailored for seamless operation with the ubiquitous 120V household electrical supply. This particular model is highly recommended for hobbyists, small-scale contractors, or anyone seeking a welding machine that combines ease of use with versatile capabilities.

Right from the initial unboxing, the welder exudes a sense of durability and robust construction, a hallmark of Lincoln Electric’s dedication to quality craftsmanship. Its compact size belies its powerful functionality, making it not just an ideal tool for a range of welding tasks, but also a testament to Lincoln Electric’s commitment to producing reliable, user-friendly welding solutions.

Key Features

- Versatile Welding Options: Capable of both MIG and flux-cored welding, suitable for various tasks.

- Precision Controls: Offers adjustable wire feed speed and voltage for optimal welding quality.

- Compact and Portable: Weighs about 50 pounds, easy to transport and ideal for small spaces.

- Standard Power Compatibility: Operates on 120V household current, adding to its convenience.

- Durable Build: Robust construction characteristic of Lincoln Electric, ensuring longevity and reliability.

Specifications

- Manufacturer: Lincoln Electric

- Model/Part Number: K2514-1

- Item Weight: 64.6 pounds

- Product Dimensions: 18 x 15 x 16 inches

- Color: Red

- Power Source: DC 120V

- Voltage: 110 Volts

Performance and Versatility

The Lincoln Electric K2514-1 Weld Pak 140 demonstrates remarkable performance, particularly in its capacity to handle a variety of welding jobs with finesse. Its adaptability in switching between MIG and flux-cored welding processes is a standout feature, enabling users to work with a wide range of materials, from thin gauge steel to thicker plates.

The machine’s output range, spanning from 30 to 140 amps, makes it exceptionally capable of handling delicate tasks like thin sheet metal welding, as well as more robust applications like welding thicker structural components.

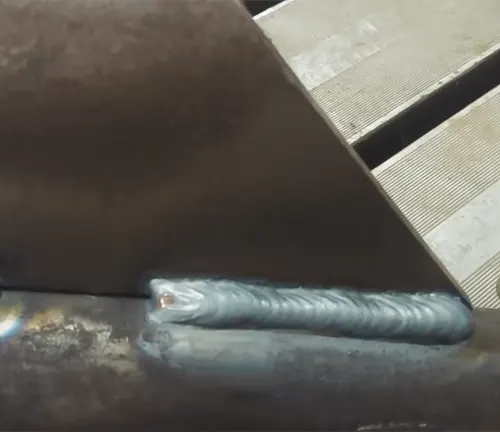

Additionally, the consistency and quality of the welds produced by the Weld Pak 140 are impressive, a result of its precise wire feed speed and voltage control. These features ensure that even less experienced welders can achieve professional-looking welds with minimal spatter and clean bead appearance.

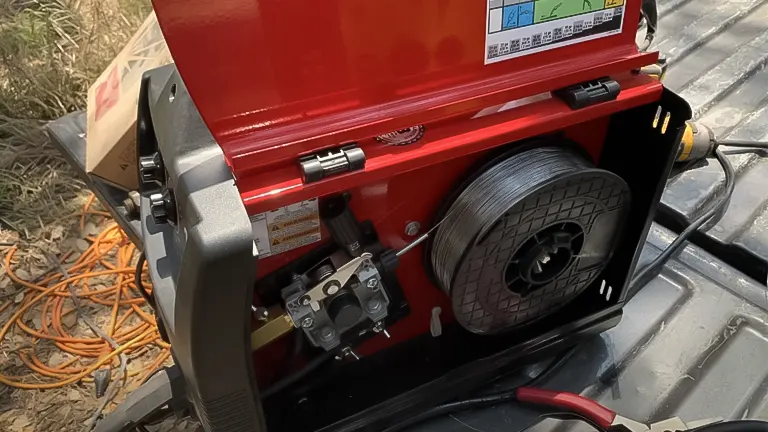

Beyond its technical capabilities, the Weld Pak 140’s versatility is further enhanced by its design and power requirements. Its compact size and relative lightness make it a highly portable unit, an invaluable trait for those who need to move their welder between different workspaces or job sites.

This portability does not come at the expense of power, as the welder operates efficiently on a standard 120V household current, making it accessible for use in a variety of settings without the need for specialized power sources.

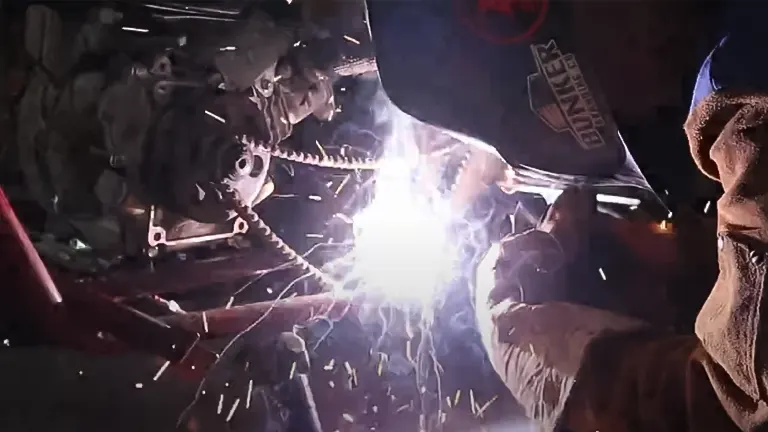

Furthermore, for enthusiasts or professionals working on automotive or home repair projects, the Weld Pak 140’s ability to weld different types of materials is a significant advantage. Whether it’s carrying out minor repairs, crafting custom pieces, or handling general maintenance work, this welder is equipped to tackle a broad spectrum of welding tasks, affirming its status as a versatile tool in both hobbyist and professional settings.

Welding Capability

The Lincoln Electric K2514-1 Weld Pak 140 is a powerhouse when it comes to welding capability, demonstrating a high degree of versatility and finesse across a spectrum of materials. It stands out particularly for its proficiency in handling mild steel, stainless steel, and aluminum (though it requires an additional spool gun for aluminum welding). The broad output range of 30 to 140 amps is a key aspect of its versatility.

This range allows the welder to adapt to various material thicknesses with ease, accommodating everything from the delicacy of 24 gauge material, ideal for thin sheet metal projects like automotive bodywork, to the robustness of materials as thick as 3/16 inch, common in structural welding tasks. This flexibility is especially beneficial when working on projects that require switching between different types and thicknesses of materials, making the Weld Pak 140 an invaluable tool for both repair work and creative metal fabrication.

The machine’s performance with flux-cored wire adds another layer to its capabilities. Flux-cored welding is known for its effectiveness in outdoor conditions and its suitability for thicker materials, offering deep penetration and a strong weld. The Weld Pak 140 harnesses these advantages efficiently, ensuring that whether in a controlled workshop setting or an outdoor environment, the quality of the welds remains consistent and reliable.

User Experience

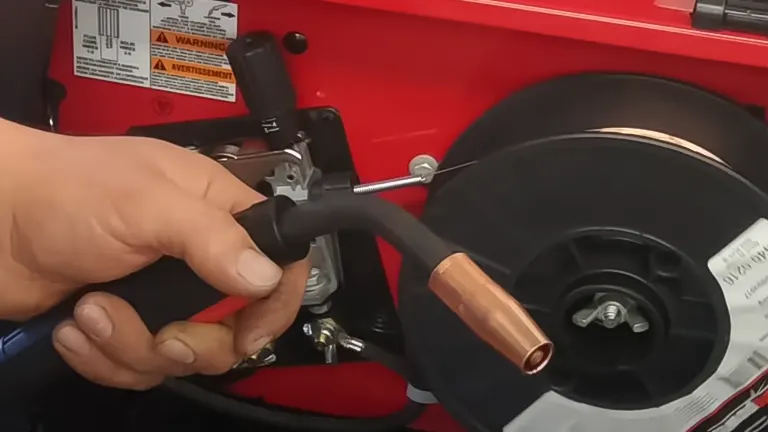

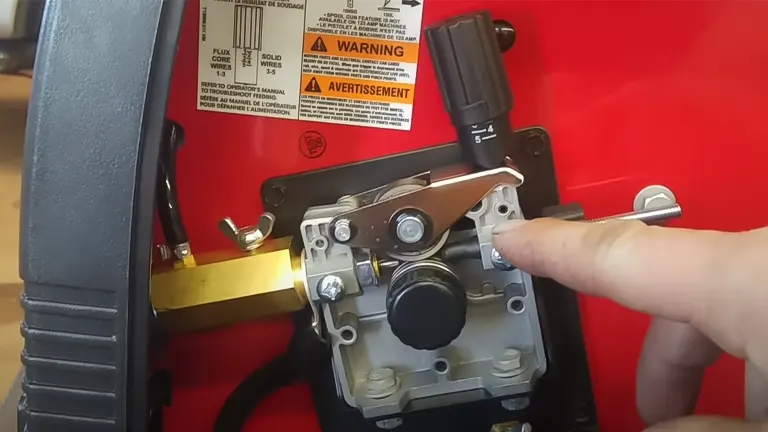

From a user standpoint, the Lincoln Electric K2514-1 Weld Pak 140 welder shines in its user-friendliness, making it an excellent choice for welders of all skill levels. The intuitive two-knob control system for speed and voltage simplifies the often daunting task of fine-tuning the welding parameters.

This simplicity is a significant advantage for beginners who may be overwhelmed by more complex machines. It allows them to focus on honing their welding techniques without being bogged down by complicated setup processes. For seasoned welders, these straightforward controls enable quick adjustments, facilitating a smoother workflow.

Moreover, the advanced wire feed speed control is a notable feature that enhances the welding experience. This control allows for precise adjustments in wire speed, which is crucial for achieving optimal weld quality and ensuring a stable arc, regardless of the material being welded.

This level of precision not only contributes to the aesthetic quality of the welds, with less spatter and cleaner beads but also plays a crucial role in maintaining the integrity of the weld, particularly important in structural applications. The combination of ease of use and precise control makes the Weld Pak 140 a user-centric machine that caters to the needs of both novice and experienced welders, ensuring a satisfying and productive welding experience.

Quantitative Measurements

- Welding Performance 9/10: The Weld Pak 140 is acclaimed for delivering consistent, high-quality welds, a feature quantitatively evident in its performance, especially with mild steel. Its capability to maintain a stable arc and produce clean, spatter-free welds is a testament to its superior design. The consistency in weld quality is crucial for applications where precision and strength of the weld are paramount. This reliability is not just a qualitative aspect but can be measured in the uniformity of the weld beads, the minimal post-weld cleanup required, and the overall aesthetic and structural integrity of the welds. Such consistency is particularly important in professional settings where time and quality of work are critical factors.

- Portability 9.5/10: Weighing approximately 50 pounds, the Weld Pak 140 strikes a balance between robust construction and portability. In terms of quantitative analysis, while it may not compete with ultra-lightweight models, its weight is still on the lower end for welders of its class, making it manageable for a single person to carry. The importance of this feature becomes evident in scenarios where the welder needs to be moved frequently, be it around a workshop or to various job sites. The portability factor is significant for users who prioritize mobility and for those working in space-constrained environments.

- Duty Cycle 10/10: The welder’s duty cycle, rated at 20% at 90 amps, is a critical quantitative measure of its performance in prolonged use. This means that at 90 amps, the Weld Pak 140 can operate continuously for 2 minutes before requiring an 8-minute cool-down period. This duty cycle is quite suitable for most small to medium projects, aligning well with the typical workflow of hobbyists and small contractors. For larger, industrial-scale projects, this might be a limiting factor, but for the target user base of the Weld Pak 140, this duty cycle is more than adequate. The duty cycle is an essential factor in planning and executing welding projects, as it directly affects the efficiency and time management of the work.

Review of Visual Aspects

In terms of visual aspects, the Lincoln Electric K2514-1 Weld Pak 140 Welder boasts a design that is both functional and aesthetically pleasing. Its compact and sturdy frame, finished in Lincoln Electric’s signature red, exudes a professional and robust look that is characteristic of high-quality welding equipment. The layout of controls and dials on the welder is thoughtfully arranged for ease of access and clarity, enhancing the overall user experience.

This practical and clean design approach not only simplifies operation but also contributes to the welder’s visual appeal. Furthermore, the Weld Pak 140’s sleek and modern appearance, combined with its relatively small footprint, ensures that it looks at home in both a professional workshop and a personal garage setting, reflecting a blend of industrial-grade functionality and contemporary design sensibilities.

Table of Comparison vs. Competitors

Below is a comparison table highlighting the key differences and similarities between the Lincoln Electric K2514-1 Weld Pak 140 Welder and the Hobart 500559 Handler 140 MIG Welder:

| Feature/Specification | Lincoln Electric K2514-1 Weld Pak 140 | Hobart 500559 Handler 140 MIG Welder |

|---|---|---|

| Input Voltage | 120V | 115V |

| Output Amperage Range | 30-140 Amps | 25-140 Amps |

| Welding Processes | MIG, Flux-Cored | MIG, Flux-Cored |

| Wire Feed Speed Control | Yes (Variable) | Yes (Variable) |

| Weight | Approx. 50 pounds | Approx. 57 pounds |

| Duty Cycle | 20% at 90 Amps | 20% at 90 Amps |

| Material Thickness (Mild Steel) | Up to 3/16 inch | 24 gauge to 1/4 inch |

| Portability | Portable | Portable |

| User-Friendly Interface | Yes | Yes |

| Additional Features | Advanced wire feed speed control | Built-in gas valve; Dual-gauge regulator and gas hose |

Please note that both the Lincoln Electric K2514-1 and the Hobart Handler 140 are highly regarded in their category. The Lincoln Electric model offers an advanced wire feed speed control, enhancing precision, while the Hobart Handler 140 includes features like a built-in gas valve and a dual-gauge regulator with a gas hose, which may add convenience for certain users. Both welders are suitable for a range of applications from hobbyist projects to small contractor jobs, with a focus on ease of use and versatility. The choice between the two often comes down to specific needs, preferences, and brand loyalty.

Comparisons and Use Cases

When compared to other welders in its class, like the Hobart Handler 140, the Weld Pak 140 holds its own, especially in terms of ease of use and versatility. The Hobart might offer a slightly better duty cycle, but the Lincoln excels with its intuitive controls and smooth arc performance.

Ideal for home projects, small repairs, and hobbyists, the Weld Pak 140 may not be the go-to for heavy industrial use, but it’s more than capable for most tasks a DIYer or small contractor would undertake.

Pros and Cons

Pros

- Ease of Use: Features simple controls and an easy setup process, ensuring straightforward operation even for beginners.

- Versatility: Capable of handling a wide range of materials and thicknesses, making it suitable for various welding tasks.

- Lincoln Support: Backed by Lincoln Electric’s excellent customer service and support, providing reassurance and assistance when needed.

Cons

- Duty Cycle: Its duty cycle might be restrictive for longer, continuous projects, requiring frequent breaks to cool down.

- Aluminum Welding: The welder necessitates an additional spool gun for aluminum welding, which is not included in the standard package and needs to be purchased separately.

Decision-Making Factors For User’s

When deciding whether the Lincoln Electric K2514-1 Weld Pak 140 Welder is the right choice, users should consider several key factors. The foremost is its ease of use, marked by simple controls and straightforward operation, making it ideal for both beginners and experienced welders. Another critical factor is its versatility in handling a variety of materials and thicknesses, which is essential for those who work on diverse projects.

The machine’s portability, despite its somewhat limited duty cycle, is also significant for those who need a mobile welding solution. Lastly, the requirement of an additional spool gun for aluminum welding could influence the decision for users who frequently work with aluminum. Overall, this welder stands out for its user-friendly design and versatility, backed by reliable customer support from Lincoln Electric.

Key Considerations:

- Ease of Use: This is a major factor for beginners and those who value a straightforward welding experience.

- Material Versatility: Its ability to handle different materials effectively is crucial for diverse project needs.

- Portability: Important for those who need to move their welder around different sites or around their workshop.

Recommendation For Optimal Uses

The Lincoln Electric K2514-1 Weld Pak 140 Welder is highly recommended for users seeking a versatile and user-friendly welding solution, particularly suitable for hobbyists, DIY enthusiasts, and small contractors. Its ability to handle a range of materials, including mild and stainless steel, makes it ideal for various projects like home repairs, auto-body work, and light fabrication tasks. The welder’s simple controls and easy setup cater well to beginners, while its consistent performance and Lincoln’s excellent support make it a reliable choice for more experienced users.

However, for those undertaking extensive projects or working frequently with aluminum, the consideration of an additional spool gun and the welder’s duty cycle should be factored into the decision-making process. In summary, the Weld Pak 140 excels in scenarios requiring a blend of portability, ease of use, and versatility in welding applications.

Final Thoughts

In conclusion, the Lincoln Electric K2514-1 Weld Pak 140 Welder emerges as a commendable choice in the realm of compact wire-feed welders. Its blend of user-friendliness, with straightforward controls and easy setup, makes it a hit among beginners and seasoned welders alike. The versatility in handling various materials, including mild and stainless steel, combined with its portability, adds to its appeal for a wide range of applications, from hobbyist projects to professional tasks.

While the need for an additional spool gun for aluminum welding and the moderate duty cycle may be slight drawbacks, they are overshadowed by the machine’s overall performance and reliability. Backed by Lincoln Electric’s reputable customer support, the Weld Pak 140 stands out as a solid investment for those seeking a dependable, versatile welding solution.

Frequently Asked Questions

- What types of welding can the Lincoln Electric K2514-1 Weld Pak 140 perform?

The Weld Pak 140 is capable of both MIG and flux-cored welding, making it versatile for various welding tasks including auto-body work, home repairs, and light fabrication. - Is this welder suitable for beginners?

Yes, its user-friendly design with simple controls and easy setup makes the Weld Pak 140 ideal for beginners, while still offering the performance that experienced welders expect. - Can it weld aluminum?

While it can weld aluminum, it requires an additional spool gun that is not included with the welder. This is necessary for optimal performance and quality when welding aluminum. - What is the power requirement for this welder?

The Weld Pak 140 operates on a standard 120V household current, making it convenient for use in a variety of settings without special electrical requirements. - How heavy is the welder, and is it portable?

Weighing about 50 pounds, the welder is not the lightest on the market but is still considered portable enough for movement around a workshop or to different job sites. - What is the duty cycle of the Weld Pak 140, and what does it mean?

It has a 20% duty cycle at 90 amps, meaning it can weld continuously for 2 minutes before needing an 8-minute cool-down. This is sufficient for most small to medium projects. - Can the Weld Pak 140 handle thick materials?

Yes, it is suitable for materials as thin as 24 gauge or as thick as 3/16 inch when using flux-cored wire, making it quite versatile for different material thicknesses. - Does it come with a warranty?

Lincoln Electric typically offers a manufacturer’s warranty on its products, but it’s recommended to check the specific warranty details at the time of purchase for the Weld Pak 140. - What additional accessories are needed for start-up?

Depending on your welding needs, you may require a spool gun for aluminum welding, personal protective equipment, and various welding consumables. Check the manufacturer’s guidelines for a complete list. - How does it compare to other similar welders in the market?

The Weld Pak 140 is comparable to other models like the Hobart Handler 140 in terms of performance and price. It stands out for its ease of use and Lincoln’s customer support, making it a strong choice for a wide range of users.

We’d love to hear from you! Share your personal experiences and thoughts about the Lincoln Electric K2514-1 Weld Pak 140 Welder in the comments section below. Your insights and hands-on feedback could be invaluable to fellow welders and enthusiasts looking to make an informed decision. Whether you’re a seasoned professional or a beginner, your unique perspective on how this welder has worked for you can help others in their journey to finding the right welding tool!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment