Revco GM1611 Welding Gloves Review

- March 22, 2024

- 0 comment

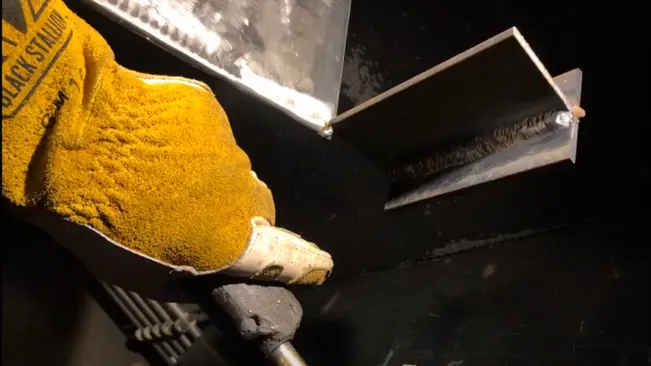

The Revco GM1611 Welding Gloves set the standard for protection, durability, and comfort in the demanding world of welding. Crafted from premium grain leather, these gloves offer an unmatched blend of heat resistance and tactile sensitivity, essential for precision welding tasks. Designed with the welder’s needs in mind, they provide superior performance and safety, making them an indispensable tool for professionals and hobbyists alike.

We’ve got your welding covered! Find comfy, Best welding gloves, Best welding carts, plus top picks for Best TIG Welder, Best MIG Welder & Best ARC Welders – all without breaking the bank!

Revco GM1611 Specifications

- Brand Revco

- Material Premium grain leather

- Reinforcement Reinforced palm

- Lining Soft interior

- Sizes Multiple

- Type Suitability TIG, MIG, Stick

- Protection Heat, spatter, sparks

- Cuff Long

- Usage Professional and hobbyist

Design and Materials

The Revco GM1611 Welding Gloves are a testament to the thoughtful design and material selection essential for high-quality welding gloves. These gloves are constructed from premium grain leather, which is renowned for its durability and resistance to heat and sparks. The choice of leather not only ensures longevity but also provides a superior level of protection against the harsh conditions encountered in welding.

A key feature of the GM1611 model is the reinforced palm area, which adds an extra layer of protection in a zone that frequently encounters high stress and exposure to heat. This reinforcement ensures that welders can handle materials and welding tools with confidence and safety.

Durability is another hallmark of these gloves. The quality of the stitching and the reinforced areas are designed to withstand the rigors of daily use in various welding environments, from TIG welding, where precision and dexterity are paramount, to MIG and stick welding, which require higher levels of protection due to the increased spatter and heat.

Thumb & Index Finger Reinforcement

This area is crucial for both protection and dexterity, designed with high-quality, resistant materials that withstand extreme conditions without compromising flexibility.

The reinforcement not only protects against cuts and burns but also ensures a firm grip on tools and materials, reducing the risk of slips and accidents. It’s perfect for precision tasks where detail and safety are paramount, providing a balance of protection and tactile sensitivity.

Dragpatch Side Padding

Positioned on the outer side of the hand, the Dragpatch side padding is a robust layer of protection against friction and thermal hazards, crafted from materials selected for their resistance to wear and heat.

This feature is particularly beneficial for tasks involving dragging or extended contact with rough surfaces, acting as a shield to preserve the integrity of the glove and the safety of the user. The padding is designed to not only protect but also to maintain flexibility, ensuring it doesn’t hinder hand movements.

Wrist Padding

The ergonomic design of the wrist padding encompasses more than just safety; it’s about ensuring lasting comfort and reducing strain on one of the most vulnerable parts of the hand.

Made from cushioning materials that absorb shock and insulate against heat, the padding extends coverage to the lower wrist, offering a safeguard against impacts, splashes, and radiant heat. Additionally, it supports the wrist in a natural position, minimizing the risk of strain injuries during repetitive movements or prolonged periods of work.

Pros and Cons

Pros

- The use of high-quality leather ensures durability and offers excellent protection against heat, spatter, and sparks, making these gloves ideal for various welding processes.

- With a soft interior lining and available in multiple sizes, these gloves offer superior comfort and a snug fit, enhancing dexterity and control during welding tasks.

- The reinforced palm provides additional protection in high-wear areas, increasing the gloves’ lifespan and safety during handling of materials and tools.

Cons

- The premium materials and construction quality may make these gloves more expensive than some other options available on the market.

- Welders looking for gloves with specific aesthetic preferences may find the options limited with the GM1611 model.

Cleaning Tips for Revco GM1611 Welding Gloves

- Regular Dusting After each use, gently brush off any dust and particulate matter from the gloves using a soft-bristled brush. This prevents buildup that can harden over time.

- Spot Cleaning For minor spots or spills, use a damp cloth to blot the affected area. Avoid rubbing, as this can push the contaminant deeper into the material.

- Dry Cleaning for Tough Stains If the gloves are heavily soiled, consider professional dry cleaning, especially if the gloves are made of materials that might be damaged by water or harsh detergents.

- Avoid Harsh Chemicals Use only mild soap and water for cleaning. Harsh chemicals can degrade the protective materials and coatings on the gloves.

- Air Dry Only Never use a direct heat source to dry your gloves. Instead, let them air dry away from direct sunlight and heat to prevent shrinking and stiffness.

- Deodorize Naturally To remove odors, sprinkle the inside of the gloves with baking soda, leave overnight, and then shake out the excess powder. Avoid using perfumed deodorizers that can irritate skin.

- Leather Conditioner for Leather Gloves If your gloves are leather, apply a leather conditioner after cleaning to keep them soft and pliable. This helps prevent cracking and drying out.

- Storage Store your gloves in a cool, dry place away from direct sunlight. UV rays can degrade the material over time.

- Avoid Water for Leather Gloves If your gloves are primarily leather, avoid getting them wet. Water can cause leather to warp, stiffen, or crack once it dries.

- Check for Damage Regularly inspect your gloves for signs of wear or damage, such as thinning material or tears. Early detection can prevent further deterioration.

Comparison Table with Other Models

| Feature | Revco GM1611 Welding Gloves | Lincoln Electric KH641 Welding Gloves |

|---|---|---|

| Material | High-quality leather with reinforcements in critical areas | Durable leather construction |

| Design | Ergonomic design for flexibility and comfort | Traditional design with a focus on comfort and protection |

| Heat Resistance | Excellent heat resistance suitable for high-temperature welding | Good heat resistance for general welding tasks |

| Durability | Enhanced durability with reinforced stitching | Durable with strong stitching for longevity |

| Flexibility | Designed for superior dexterity and control | Flexible design for ease of movement |

| Protection | Extended cuff for forearm protection; additional padding in key areas | Full hand protection with a focus on palm and finger safety |

| Size Availability | Various sizes available to fit different hand sizes | Comes in multiple sizes for a comfortable fit |

| Suitable Welding Type | Ideal for a wide range of welding types, including MIG, TIG, and Stick | Suitable for stick welding and other high-heat applications |

| Additional Features | Dragpatch side padding for extra protection; ergonomic thumb design for better tool control | Soft cotton lining for added comfort during long welding sessions |

| Price Point | Varies by retailer, generally positioned as a premium option | Often found to be cost-effective while offering reliable protection |

Lincoln Electric KH641 Welding Gloves Specifications

- Brand Lincoln Electric

- Material Durable leather

- Heat Resistance Suitable for general welding

- Durability Strong stitching for longevity

- Flexibility Designed for ease of movement

- Protection Emphasizes palm and finger safety

- Lining Soft cotton for comfort

- Sizes Multiple sizes available

- Cuff Long for wrist and forearm protection

- Usage Ideal for stick welding

About this Item

- Durable Construction Crafted from high-quality leather, these gloves are designed to withstand the rigors of welding, providing both durability and comfort during use.

- Heat and Spark Protection Engineered for welding tasks, they offer significant protection against heat, sparks, and spatter, making them ideal for stick welding and other high-heat applications.

- Enhanced Comfort Featuring a soft cotton lining, the gloves ensure comfort during prolonged welding sessions, reducing hand fatigue and improving overall user experience.

- Flexible Design The gloves are made with flexibility in mind, allowing for ease of movement and better control of welding tools, which is essential for precision work.

- Comprehensive Coverage A long cuff design extends protection to the wrist and lower forearm, safeguarding against burns and abrasions from welding operations.

Conclusion

The Revco GM1611 Welding Gloves are a standout choice for welders looking for a blend of durability, functionality, and comfort. Their thoughtful design, premium materials, and versatility make them suitable for various welding tasks, offering both protection and the precision required for high-quality welding work. Whether you’re a professional welder or a hobbyist, these gloves represent a wise investment in your welding gear, providing both safety and performance enhancements on the job.

FAQs

- What material are the Lincoln Electric KH641 Welding Gloves made from?

They’re crafted from durable leather, offering a balance of protection and dexterity for welding tasks. - Are these gloves suitable for all types of welding?

Primarily designed for stick welding, they offer good heat resistance and protection suitable for various general welding applications. - Do the KH641 gloves come in different sizes?

Yes, they are available in multiple sizes to ensure a proper fit for different hand sizes. - How do the gloves protect against heat and sparks?

The leather construction and design features provide significant resistance to heat, sparks, and spatter, safeguarding the user’s hands during welding. - Is there any lining inside the gloves?

Yes, they feature a soft cotton lining for added comfort, especially during extended use. - Can the gloves be used for high-precision welding tasks?

While they offer good dexterity, the level of precision depends on the user’s skill and the specific task at hand. - How do I determine the right size for my hands?

Refer to the manufacturer’s sizing chart and measure your hand according to their guidelines to choose the most appropriate size. - Are the KH641 Welding Gloves easy to clean?

Due to the materials used, it’s best to spot clean them and avoid soaking or machine washing, to preserve the leather’s integrity. - How long do these gloves typically last?

The lifespan varies based on usage frequency and the types of welding performed, but their durable construction is designed for longevity. - Where can I purchase the Lincoln Electric KH641 Welding Gloves?

They are available through various retailers, including online marketplaces and stores specializing in welding supplies.

We’re excited to hear from you! Share your personal experiences and insights about the Revco GM1611 Welding Gloves in the comments section below. Whether it’s about their durability, comfort, or how they stand up to the heat and sparks of welding, your feedback is invaluable. Your thoughts could greatly assist fellow welders in making well-informed decisions. Let’s help each other find the best gear for our welding needs!

For more expert welding and advice, explore our guides, discover top recommendations in our best section, and delve into in-depth product reviews in our review section. Happy Welding.

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment