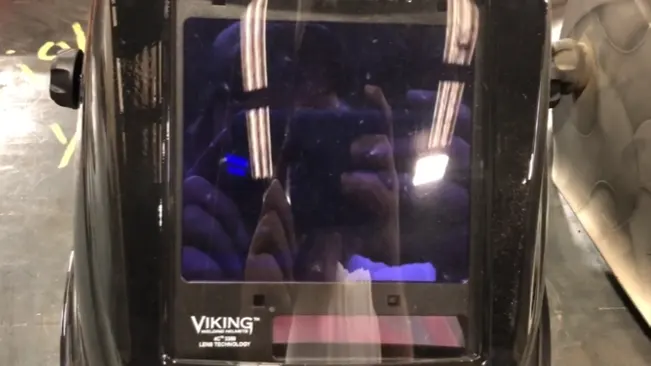

Lincoln Electric Viking 3350 Welding Helmet Review

- March 19, 2024

- 0 comment

The Lincoln Electric Viking 3350 welding helmet has garnered a solid reputation among welding professionals and enthusiasts for its exceptional features and performance. Here’s an overview based on collected reviews and technical evaluations

Lincoln Electric Viking 3350 Specifications

- Brand: Lincoln Electric

- Model: Viking 3350

- Lens Technology: 4C, offering 1/1/1/1 optical clarity

- Viewing Area: 3.74″ x 3.34″

- Arc Sensors: 4 sensors for comprehensive coverage

- Switching Speed: 1/25,000 second

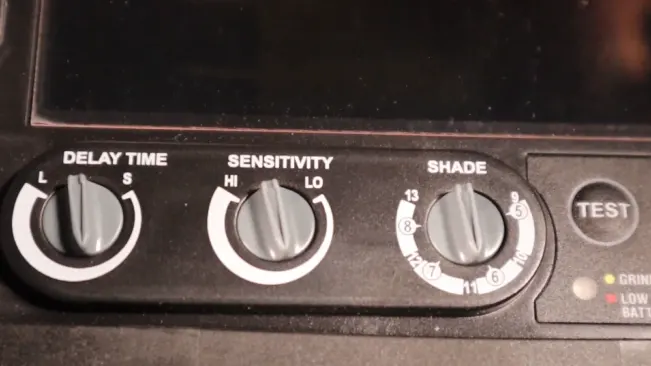

- Shade Levels: Variable, 5-13 for welding, 3.5 in light state

- Power: Solar with replaceable lithium battery

- Weight: Approximately 21 oz (595 grams)

- Comfort: X6 Headgear for improved fit and comfort

- Special Features: External grind button, auto-darkening, adjustable sensitivity and delay

Key Features and Benefits

4C Lens Technology

The 4C Lens Technology in the Lincoln Electric Viking 3350 welding helmet stands as a pinnacle of optical engineering, designed to significantly enhance the welder’s vision and comfort. With its premier 1/1/1/1 optical clarity rating, this technology dramatically reduces visual distortion and provides a true-color view of the welding area.

This clarity is paramount not only for achieving precision in welding tasks but also for minimizing eye strain during prolonged use. Such technological advancement ensures that welders can work with greater accuracy and comfort, a testament to Lincoln Electric’s commitment to enhancing user experience and safety in welding environments. This innovation represents a significant leap forward in welding helmet technology, making it a critical tool for professionals seeking the highest standards of visibility and protection.

Large Viewing Area

The Lincoln Electric Viking 3350 welding helmet’s large viewing area, measuring 3.74″ x 3.34″, is a game-changer for welders who demand both precision and efficiency in their work. This expansive field of view not only allows for an unobstructed view of the weld pool but also significantly aids in the execution of detailed and intricate welding projects.

By enhancing the welder’s ability to see more of the workpiece without the need to reposition the helmet, it effectively streamlines the welding process, contributing to improved workflow and productivity. Furthermore, this feature is invaluable in complex welding tasks where attention to detail is paramount, ensuring that even the most minute adjustments are visible. The Viking 3350’s large viewing area thus stands as a testament to Lincoln Electric’s commitment to providing welders with superior tools that meet the demands of modern welding applications, offering a perfect blend of functionality and user-centric design.

Comfort and Fit

The Lincoln Electric Viking 3350 welding helmet, renowned for its X6 Headgear, offers unparalleled comfort and fit, fundamentally changing the welding experience. This meticulously designed headgear system, celebrated by users, significantly extends the duration welders can work without experiencing discomfort.

With its lightweight construction, the helmet promises not only a secure and adjustable fit but also effectively minimizes pressure points and the risk of slippage. This innovative approach to helmet design ensures that professionals can focus on their work with enhanced comfort, thereby increasing productivity and overall work satisfaction. The Viking 3350’s commitment to comfort, combined with its advanced engineering, makes it a standout choice for welders who prioritize both performance and wearability in their protective gear.

Durability and Quality

The Viking 3350 welding helmet by Lincoln Electric exemplifies robustness and enduring quality, setting a high standard in protective gear for welders. Crafted from materials that meet the highest quality standards, this helmet is engineered to endure the demanding conditions typical of professional welding environments.

Its reputation for durability is not just about resisting wear and tear; it’s about offering consistent, reliable protection and functionality over time. This resilience ensures that welders can rely on their Viking 3350 helmet to perform day in and day out, minimizing the need for frequent replacements and thereby offering both economic and practical benefits. In the world of welding, where safety and precision are paramount, the Viking 3350’s durable construction becomes an indispensable ally, reflecting Lincoln Electric’s commitment to providing welders with gear that enhances their work without compromising on safety or quality.

Battery Life and Maintenance

The Viking 3350 boasts a solar-powered battery system supplemented by a replaceable lithium battery, ensuring extended battery life and reduced maintenance needs. It charges seamlessly during operation, guaranteeing uninterrupted usage.

With this innovative design, users can rely on sustained performance without frequent interruptions or the hassle of constantly replacing batteries. Enjoy prolonged productivity and convenience with the Viking 3350’s efficient power management system.

Sensitivity and Delay Adjustments

The helmet provides users with convenient controls for adjusting sensitivity and delay settings, allowing for personalized optimization to suit various welding conditions and techniques. Whether working in different environments or employing diverse welding processes, users can fine-tune these parameters effortlessly.

This feature enhances versatility and adaptability, ensuring optimal performance and safety while accommodating individual preferences and specific job requirements. Experience enhanced control and efficiency with the flexibility offered by the sensitivity and delay adjustments of the helmet.

User Feedback and Testimonials

Users consistently praise the Viking 3350 for its auto-darkening speed, large viewing area, optical clarity, and comfort. Many users, from professionals to hobbyists, recommend this helmet for its all-around performance and reliability in various welding situations.

Lincoln Electric Viking 3350 Pros and Cons

Pros

- Offers excellent vision with 1/1/1/1 clarity.

- Large visibility enhances work precision.

- Fast response protects eyes quickly.

- X6 Headgear ensures a comfortable fit.

- Made with high-quality, lasting materials.

- Adjustable settings for various welding jobs.

Cons

- Higher cost might deter some buyers.

- May feel heavy after long use.

- Features might overwhelm beginners.

- Occasionally needs new battery.

- Might need effort to fit perfectly, especially with glasses.

Comparison Table with Other Models

| Feature | Lincoln Electric Viking 3350 | Miller Digital Elite Black |

|---|---|---|

| Optical Clarity Rating | 1/1/1/1 | 1/1/1/2 |

| Lens Technology | 4C Lens Technology | ClearLight Lens Technology |

| Viewing Area | 3.74″ x 3.34″ | 9.22 sq in |

| Arc Sensors | 4 | 4 |

| Switching Speed | 1/25,000 sec | 1/20,000 sec |

| Shade Levels | Variable 5-13, Grind Mode | Variable #8-13, Cut Mode, X-Mode, Grind Mode |

| Weight | 21 oz (595 grams) | 18 oz (510 grams) |

| Power Supply | Solar with replaceable lithium battery | Solar cell with replaceable lithium battery |

| Comfort Features | X6 Headgear | Redesigned headgear |

| Special Features | External grind button, large viewing area | X-Mode, ClearLight Technology, InfoTrack |

| Price Range | Mid to high | High |

Miller Digital Elite Black Specifications

- Brand: Miller Electric

- Model: Digital Elite Black

- Lens Tech: ClearLight™ 2.0, high-definition optics.

- Viewing Area: 9.22 sq. in.

- Arc Sensors: 4, for superior response.

- Switching Speed: 1/20,000 sec.

- Shades: 5-8 (cut), 8-13 (weld).

- Power: Solar, CR2450 batteries, 3,000 hrs.

- Weight: 18 oz (510 g).

- Comfort: Redesigned headgear.

- Features: X-Mode™, Auto-On/Off, AutoSense™.

Quantitative Measurements of Lincoln Electric Viking 3350

- Optical Clarity: 1/1/1/1, ensuring top-tier visibility and minimal distortion.

- Viewing Area: 3.74″ x 3.34″, providing a broad perspective for welding tasks.

- Arc Sensors: Equipped with 4 sensors, offering comprehensive arc detection.

- Switching Speed: 1/25,000 of a second, for swift transition from light to dark.

- Shade Levels: Variable shade range from 5-13 for welding and 3.5 in the light state, accommodating different welding environments.

- Power Source: Solar-powered with an assist from a replaceable lithium battery, blending eco-friendliness with reliability.

- Weight: Approximately 21 oz (595 grams), balancing the need for durability with comfort during long welding sessions.

- TIG Rating: Effective for low amperage TIG welding down to 2 amps, suitable for high-precision welding jobs.

- Battery Life: Designed for extended use, with the solar assist ensuring the helmet is always ready for work.

- Grind Mode: Incorporates a grind mode, allowing for seamless transition between welding and grinding tasks without needing to change equipment.

Maintenance for Lincoln Electric Viking 3350

To ensure the helmet’s longevity and optimal performance, regular cleaning of the lens and adjustments to the headgear are recommended. Careful maintenance, including dust and debris removal and gentle cleaning with a mild soap solution, is essential to maintain optical clarity and functionality.

- Regular Inspection: Check the helmet and lens for any signs of damage, such as cracks or deep scratches, which could impair vision or protection. Replace any damaged parts as necessary.

- Cleaning the Lens: Use a soft, lint-free cloth with a mild soap solution to gently clean the lens. Avoid using abrasive materials that could scratch the lens.

- Dust and Debris Removal: Before wet cleaning, blow off or brush away any loose dust or debris from the lens and helmet to avoid scratching.

- Wiping with Clean Water: After cleaning with soap, use a damp cloth with clean water to remove soap residue, ensuring no streaks are left behind.

- Drying Gently: Pat the lens and helmet dry with a dry, lint-free cloth. Avoid vigorous rubbing that could cause scratches.

- Battery Maintenance: For models with a replaceable battery, ensure the battery is in good condition and replace it if necessary. The helmet uses a solar panel to charge the battery, so keeping both the panel and battery in good condition is crucial.

- Headgear Adjustment: Make sure the headgear is properly adjusted to fit comfortably. Adjust the tightness and positioning as needed to ensure the helmet is secure and does not slip during use.

- Lens Replacement: Over time, even with the best care, the lens may need to be replaced due to wear, scratches, or damage. This ensures continued optical clarity and protection.

- Storage: Store the helmet in a cool, dry place away from direct sunlight and extreme temperatures to prevent material degradation and to protect electronic components.

- Usage and Handling: Handle the helmet with care. Avoid dropping or placing heavy objects on the helmet to prevent damage to the lens and shell.

Overall Value

Despite being in the premium price range, the Viking 3350 is considered a worthwhile investment due to its blend of advanced features, superior comfort, and durability. Its versatility and protective capabilities make it a valuable asset for any welding project.

Conclusion

Conclusion, the Lincoln Electric Viking 3350 stands out for its excellent optical clarity, comfort, and robust build quality, offering significant value to both professional welders and hobbyists. Its comprehensive features and positive user feedback underscore its status as a top choice in welding helmets.

Frequently Asked Questions(FAQs)

- What is the optical clarity rating of the Viking 3350?

It has a 1/1/1/1 optical clarity rating, offering superior visibility and minimal distortion during welding tasks. - How large is the viewing area on the Viking 3350 helmet?

The viewing area is 3.74″ x 3.34″, providing a broad perspective for the welder. - What type of battery does the Viking 3350 use, and is it replaceable?

It uses a solar panel with an assist from a replaceable lithium battery, ensuring long operational life and easy maintenance. - Can the Viking 3350 be used for TIG welding?

Yes, it is effective for low amperage TIG welding down to 2 amps, making it suitable for precision welding jobs. - How many arc sensors does the Viking 3350 have?

The helmet is equipped with 4 arc sensors for comprehensive arc detection. - What is the switching speed from light to dark?

The switching speed is 1/25,000 of a second, allowing for swift protection from arc flashes. - What shade levels does the Viking 3350 offer?

It has variable shade levels from 5-13 for welding and a light state of 3.5, accommodating different environments. - Is there a grind mode available on the Viking 3350?

Yes, it includes a grind mode, enabling users to switch between welding and grinding tasks seamlessly. - How does the Viking 3350’s weight affect its usability?

Weighing approximately 21 oz (595 grams), it balances durability with comfort for extended use. - What special features does the Viking 3350 helmet include?

It boasts features like 4C lens technology for optical clarity, X6 Headgear for comfort, an external grind button, and adjustable sensitivity and delay settings

We’d love to hear from you! If you’ve had the chance to use the Lincoln Electric Viking 3350 welding helmet, please share your experiences and thoughts in the comments section below. Whether it’s about its comfort, optical clarity, or any feature you particularly loved or thought could be improved, your insights could greatly assist fellow welders in making well-informed decisions. Your feedback is invaluable!

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment