Grizzly G0694 – 20″ x 43″ Heavy-Duty Variable-Speed Wood Lathe Review

- February 9, 2024

- 0 comment

For a considerable time, my objective has been to find a lathe that satisfies the requirements of my varied woodworking projects while simultaneously pushing me to enhance my abilities. This search involved an extensive period of evaluating different models, engaging in practical testing, and generating a significant amount of wood waste in my workshop.

Ultimately, my choice has been the Grizzly G0694 – 20″ x 43″ Heavy-Duty Variable-Speed Wood Lathe. This decision comes after careful consideration and comparison against multiple alternatives. In the following detailed review, I will share insights from my experience as a user, outlining the specific features and performance aspects of the Grizzly G0694 that make it a potentially ideal option for those seeking a reliable and versatile tool for their woodworking endeavors.

Specifications

- Manufacturer: Grizzly

- Part Number: G0694

- Product Dimensions: 26 x 84 x 56 inches

- Power Source: Corded-electric

- Motor: 3 HP, 220V, 3-phase (with inverter for single-phase power), 9A

- Required Power Supply: 220V, single-phase, min. 20A circuit

- Swing Over Bed: 20″

- Spindle Speed: Variable, 100–3000 RPM

- Spindle Threads: 1-1/4″ x 8 TPI

- Tool Rest Width: 13-13/16″

- Footprint: 16-1/2″ x 77″

- Item Weight: 814 lbs.

Primary Attributes:

- Precision-Ground Cast-Iron Bed: This feature ensures a stable and vibration-resistant foundation for the lathe, enabling accurate and smooth operations. The precision-ground surface minimizes inaccuracies and enhances the quality of workpieces.

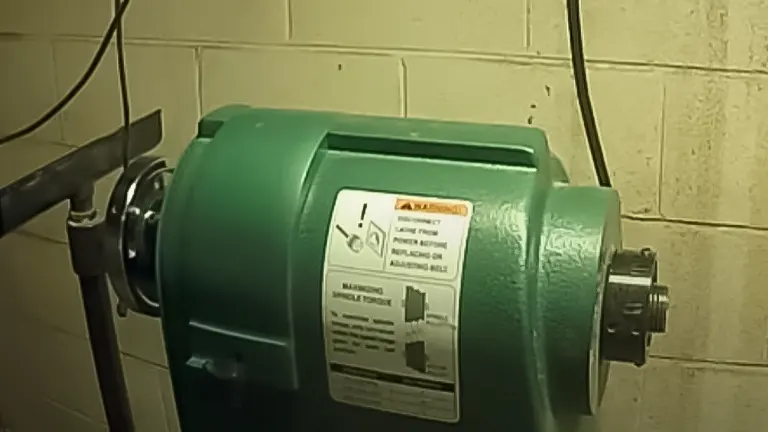

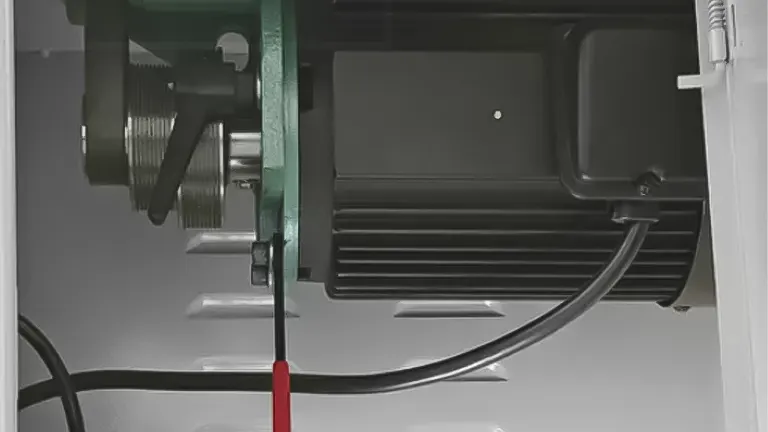

- Single-Phase Inverter for 3-Phase Variable-Speed Motor: This technology allows the lathe to use a standard single-phase power supply while delivering the performance benefits of a 3-phase motor, such as smoother operation and variable speed control.

- Low Speed Range of 100–1000 RPM: Ideal for tasks requiring high torque and precision, such as turning large diameter pieces or performing detailed work on harder materials.

- Mid Speed Range of 1000–2000 RPM: This range balances between torque and speed, suitable for a variety of turning projects, including both roughing and finishing work.

- High Speed Range of 2000–3000 RPM: Provides high-speed rotation for fine finishing and polishing tasks, allowing for a superior finish on workpieces.

- Quick-Release Belt Tension Lever: Enables swift and effortless changes between spindle speed ranges by simplifying the belt tension adjustment, thereby reducing downtime and increasing productivity.

- Digital Spindle Speed Readout: Offers real-time monitoring of the spindle speed, ensuring precise control over the turning process and allowing for adjustments to be made with accuracy.

- Forward/Reverse Spindle Control: This feature enhances the lathe’s versatility by allowing the user to easily switch the direction of spindle rotation, which is particularly useful for achieving a uniform finish or for certain specialized turning techniques.

- 13-3/4″ Wide Outboard Tool Rest: Provides ample support for tools when working on larger diameter projects outside the lathe bed, increasing control and safety during outboard turning operations.

- Spindle Indexed Every 15°: Facilitates precise drilling, fluting, and indexing operations by allowing the spindle to be locked in multiple positions, thereby expanding the lathe’s capability for detailed and decorative work.

Build Quality and Design

The Grizzly G0694 is characterized by its high-quality construction right from the moment it is unpacked. Constructed primarily from cast iron, including the bed, headstock, and tailstock, the lathe is designed to be exceptionally durable.

This choice of material is key for its ability to dampen vibrations effectively, a critical element in ensuring that finished projects are smooth and free of imperfections. Furthermore, the considerable weight of the lathe, standing at 792 pounds, plays a significant role in its stability.

Such heft guarantees that the machine remains firmly in place, resisting movement or wobbling even when subjected to the forces of aggressive turning activities. This solidity and built-in vibration control are indispensable for woodworkers who demand precision and longevity from their equipment.

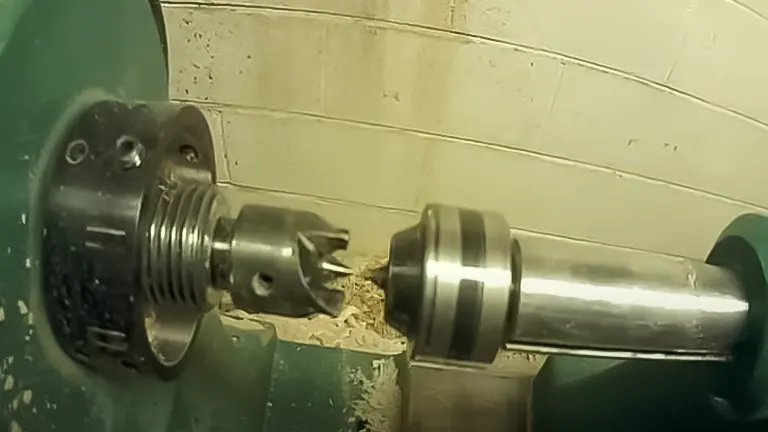

Power and Variable Speed

The motor of the G0694, a robust 3 HP, 220V unit, equips the lathe with the capability to handle demanding tasks without faltering. A standout feature of this model is its adjustable speed range, which can be set anywhere from 100 to 3200 RPM.

This flexibility is distributed across three separate speed settings, allowing users to tailor the machine’s operation to a broad spectrum of projects. Whether it’s executing finely detailed work or undertaking the hollowing of large vessels, the lathe’s speed can be finely adjusted to match the task at hand.

The integration of electronic variable speed control along with a digital readout for RPMs enhances the user’s ability to make precise speed adjustments. This precision is invaluable for achieving optimal results on each project, making it easier to produce work that meets high standards of quality.

Capacity and Capabilities

The G0694 showcases a generous turning capacity, with a 20-inch swing over the bed and a 43-inch distance between centers, accommodating a diverse range of project sizes. An important enhancement to this capacity is the lathe’s swiveling headstock, which facilitates outboard turning.

This feature is particularly beneficial for working on projects with larger diameters, expanding the machine’s versatility. Additionally, the design includes a headstock that can slide and pivot, increasing the lathe’s flexibility.

This allows for more precise positioning of workpieces, providing users with the ability to adjust the lathe to the specific requirements of each project, thereby enhancing the overall ease and efficiency of the woodworking process.

Performance in Use

When operating the Grizzly G0694, its capabilities become immediately apparent. The machine demonstrates a remarkable blend of power and precision, with the variable speed control offering smooth transitions that enable adjustments to be made in real-time, eliminating the need for halting work to change belt configurations.

Its performance remains consistent even when under significant load, a feature that benefits both novice and experienced turners by allowing for uninterrupted work on projects of all complexities. Exceptional vibration damping contributes further to the machine’s performance, ensuring that the quality of finish on turned pieces is consistently high.

This combination of features makes the G0694 an ideal choice for those seeking a lathe that performs reliably across a wide range of woodworking tasks, delivering both in terms of power and in the quality of the finished product.

Comparative and Alternatives

When comparing the Grizzly G0694 to other lathes in its class, such as the Jet JWL-1640EVS, a few considerations come to mind. The Grizzly’s price point is competitive, offering significant value given its features and build quality. While the Jet models offer similar capacities and features, the Grizzly stands out for its combination of power, capacity, and variable speed at a lower cost.

Table of Comparisons vs. Competitor

Below is a comparison table that outlines the key features and specifications of the Grizzly G0694 Wood Lathe and the JET JWL-1640EVS Wood Lathe.

| Features/Aspects | Grizzly G0694 | JET JWL-1640EVS |

|---|---|---|

| Motor | 3 HP, 220V, single-phase | 1.5 HP, 115V/230V, single-phase |

| Speed Range | 100–3200 RPM (Variable) | 40–3200 RPM (Variable) |

| Swing Over Bed | 20 inches | 16 inches |

| Distance Between Centers | 43 inches | 40 inches (with optional extension bed) |

| Bed Material | Precision-ground cast iron | Cast iron |

| Inverter | Single-phase for 3-phase variable speed | Yes |

| Speed Ranges | Low: 100–1000 RPM <br> Mid: 1000–2000 RPM <br> High: 2000–3200 RPM | Electronic variable speed control |

| Tension Lever | Quick-release belt tension lever | Easy access belt tension system |

| Spindle Speed Readout | Digital | Digital |

| Spindle Control | Forward/reverse | Forward/reverse |

| Outboard Tool Rest Width | 13-3/4 inches | Not specified |

| Spindle Indexing | Every 15° | 36 indexing positions |

| Weight | 792 pounds | Approximately 400 pounds |

| Power Source | Corded-electric | Corded-electric |

| Additional Features | Swiveling headstock for outboard turning | Sliding headstock for outboard turning |

This table aims to provide a clear comparison between the two wood lathes based on their motor capacity, speed variability, physical dimensions, construction material, and other features that might influence a woodworker’s choice.

The Grizzly G0694 offers a higher motor power and a larger swing over bed, making it suitable for larger projects, while the JET JWL-1640EVS provides a wider speed range starting from a lower RPM, which could be beneficial for intricate detail work. Each lathe has its unique set of features that cater to different user needs, making the choice dependent on specific project requirements, workshop space, and budget considerations.

Pros and Cons

Pros

- Durability and Stability: High-quality construction guarantees long-lasting use and steady performance.

- Variable Speed Range: Offers a broad range of speeds, accurately adjustable via a digital display for meticulous speed management.

- Turning Capacity: Capable of handling a wide variety of project sizes, with the ability to turn both within and outside the bed.

- Value for Money: Priced competitively, providing a good balance of features for its cost.

Cons

- Size and Weight: The machine’s considerable heft and dimensions necessitate ample, dedicated workshop space.

- Learning Curve: Beginners may find the setup and initial adjustments somewhat complex.

Maintenance and Troubleshooting Guide for the Grizzly G0694 Wood Lathe

To maintain the optimal functioning of your Grizzly G0694, regular maintenance and occasional troubleshooting are essential. Here’s an in-depth guide designed to assist you in keeping your wood lathe in top condition.

Maintenance Routines

- Regular Cleaning: After each use, clean the lathe to remove wood shavings, dust, and debris. Use a brush or compressed air for hard-to-reach areas. This prevents buildup that can affect performance or cause overheating.

- Lubrication: Periodically lubricate moving parts, such as the spindle and bearings, according to the manufacturer’s instructions. Use only the recommended lubricants to avoid damage or excessive wear.

- Inspection: Regularly inspect the lathe for signs of wear or damage, especially on critical components like the drive belts, bearings, and motor. Early detection of issues can prevent more significant problems down the line.

- Belt Tension: Check the tension of the drive belts periodically. Proper tension is crucial for effective power transmission and minimizing wear. Adjust as necessary following the manufacturer’s guidelines.

- Rust Prevention: Protect the lathe from rust by applying a light coat of machine oil on exposed metal surfaces, especially if you’re in a humid environment. Wipe down the bed, tool rest, and tailstock to keep them smooth and free of corrosion.

Troubleshooting Tips

- Vibration or Wobbling: If you notice excessive vibration or wobbling, check for unevenly mounted workpieces, unbalanced turning blanks, or loose parts. Ensure everything is securely fastened and balanced before proceeding.

- Motor Not Starting or Stopping: Verify the power supply, check the emergency stop switch and ensure it’s not engaged, and inspect the motor’s connections and fuses. Sometimes, a simple reset or reconnect can solve the issue.

- Difficulty Adjusting Speeds: If changing speeds is challenging, inspect the variable speed mechanism and belt tension. Ensure the belts are not worn out and that the speed control mechanism is functioning correctly.

- Poor Finish or Difficulty Cutting: Dull tools, incorrect tool rest position, or improper speed can cause this. Sharpen your tools, adjust the tool rest closer to the workpiece, and experiment with speed adjustments for better results.

- Noise from the Lathe: Unusual noises could indicate loose components, bearing wear, or issues with the motor. Tighten any loose parts and inspect bearings and the motor for signs of damage or wear. Replace parts as necessary.

Final Evaluation

Through rigorous evaluation and direct comparison with similar tools, the Grizzly G0694 – 20″ x 43″ Heavy-Duty Variable-Speed Wood Lathe has established itself as a dependable and multifaceted addition to my collection of woodworking tools. The lathe’s robust motor, exact speed control, and significant working capacity collectively position it as a top-tier choice for woodturners at any skill level.

It caters well to experienced craftsmen seeking an upgrade as well as novices aiming to undertake more ambitious projects. The G0694 distinguishes itself by providing the essential features and robust performance necessary to realize a wide array of woodworking visions. Based on my hands-on experience, this lathe emerges as the optimal choice for dedicated woodturners, offering the adaptability and strength required for a broad spectrum of tasks.

Frequently Asked Questions

- What motor power does the Grizzly G0694 wood lathe have?

The Grizzly G0694 is equipped with a 3 HP, 220V motor, providing substantial power for a variety of woodturning tasks. - What is the variable speed range of this lathe?

This lathe offers a variable speed range from 100 to 3200 RPM, allowing for precise control over your projects. The speed is adjustable across three distinct ranges: low (100–1000 RPM), mid (1000–2000 RPM), and high (2000–3200 RPM). - Can I turn large projects on the G0694 lathe?

Yes, the G0694 features a 20-inch swing over the bed and 43 inches between centers, accommodating large projects. It also supports outboard turning for even larger diameters. - How does the digital spindle speed readout benefit users?

The digital readout provides accurate and immediate feedback on the spindle speed, enabling users to make precise adjustments for optimal turning results. - Is it easy to change speeds on the G0694?

Yes, the lathe includes a quick-release belt tension lever that simplifies the process of changing spindle speed ranges, making adjustments quick and hassle-free. - Does the lathe offer both forward and reverse spindle control?

Indeed, the G0694 allows for forward and reverse spindle operation, enhancing the versatility of your turning techniques and finishes. - What is the weight of the Grizzly G0694, and what implications does this have for placement?

The G0694 weighs approximately 792 pounds. Its substantial weight aids in stability and vibration reduction but also means it requires a dedicated and sturdy space in your workshop. - What kind of projects can I undertake with the 13-3/4″ wide outboard tool rest?

The wide outboard tool rest provides support for a range of projects, especially those requiring outboard turning, such as large bowls or platters, offering greater control and safety. - How often do I need to maintain my G0694 lathe, and what does maintenance entail?

Regular maintenance is crucial for optimal performance. This includes cleaning dust and debris, lubricating moving parts, and checking for wear or damage. Consult the manual for specific maintenance schedules and procedures. - Can beginners use the Grizzly G0694 effectively, or is it aimed at experienced woodturners?

While the G0694’s features cater to all skill levels, its advanced capabilities and size make it particularly appealing for experienced woodturners. However, with proper learning and practice, beginners can also grow into using its features effectively.

We’d love to get your feedback! If you’ve used the Grizzly G0694 – 20″ x 43″ Heavy-Duty Variable-Speed Wood Lathe, please share your thoughts and experiences in the comments below. Your insights can help other woodturners make knowledgeable decisions!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment