Chicago Electric Flux 125 Welder Review

- January 9, 2024

- 1 comment

Excitement courses through me as I eagerly recount my firsthand encounters with the Chicago Electric Flux 125 Welder a trusty companion that has seamlessly integrated into my arsenal for a myriad of welding undertakings.

Technical Specifications

- Power Source: Corded Electric

- Input Voltage: 120 V

- Voltage: 110 V

- Amperage: 20 (Minimum), 125 (Maximum)

- Duty Cycle: 90A AC @17V, 20%

- Thermal Overload Protection: Yes

- MPN: Does not apply

- Item Weight: 37.5 pounds

- Item Length: 14-3/8 in

- Package Dimensions: 19.5 x 17.75 x 11 inches

- Welding Capacities: 18 gauge to 3/16 in. thick (0.047 in.– 0.187 in.)

- Wire Size: 0.030 in. (0.8mm), 0.035 in. (0.9mm)

Product Overview

The Chicago Electric Flux 125 Welder is a robust and versatile welding machine designed to meet the needs of both novice and experienced welders. Weighing 37.5 pounds, this compact yet powerful tool boasts an impressive maximum amperage output of 125 amps, making it suitable for a diverse range of welding projects.

Operating on a standard 120V input voltage, with a 110V output voltage, the welder features a minimum amperage output of 60 amps and comes equipped with thermal overload protection for enhanced safety. With a duty cycle of 90A AC @17V, 20%, it ensures consistent and reliable performance during operation. The machine’s welding capacities span from 18-gauge to 3/16-inch thick materials, offering flexibility for various applications.

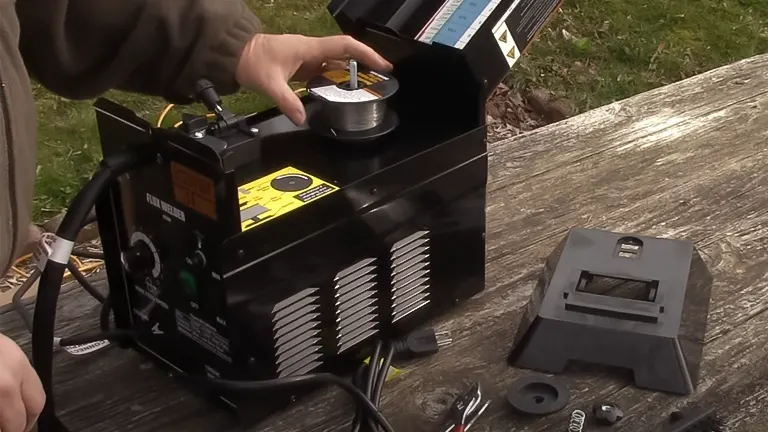

Its wire size compatibility of 0.030 in. (0.8mm) and 0.035 in. (0.9mm) caters to different welding needs. The package includes essential accessories such as a flux core gun, ground clamp, and spare contact tips, facilitating a seamless welding experience. Ideal for welding mild and low alloy steel, it’s important to note that this welder is not suitable for aluminum or stainless steel projects.

Overall, the Chicago Electric Flux 125 Welder stands out as a reliable, user-friendly, and versatile tool for welding enthusiasts and professionals alike.

Key Features:

- Versatile Amperage Range: The Chicago Electric Flux 125 Welder offers a versatile amperage range, with a minimum output of 60 amps and a maximum output of 125 amps, making it suitable for a wide array of welding tasks.

- Compact and Portable Design: Weighing in at 37.5 pounds and featuring dimensions of 19.5 x 17.75 x 11 inches, this welder is compact and portable, ensuring ease of transport and maneuverability in various workspaces.

- Durable Construction: Built with durability in mind, the welder’s construction is robust, ensuring longevity and reliability throughout its usage, making it a dependable tool for both amateur and professional welders.

- Thermal Overload Protection: Equipped with thermal overload protection, the machine automatically shuts down in the event of overheating, enhancing safety and preventing potential damage to the unit.

- User-Friendly Operation: With a straightforward setup and clear user manual, this welder is user-friendly, catering to both beginners and experienced welders, promoting ease of use and efficient operation.

- Welding Capabilities: The machine accommodates welding tasks ranging from 18-gauge to 3/16-inch thick materials, providing flexibility for various applications and ensuring it can handle a diverse range of projects.

- Dual Wire Size Compatibility: Supporting both 0.030 in. (0.8mm) and 0.035 in. (0.9mm) wire sizes, the welder allows users to choose the appropriate wire for different welding scenarios, enhancing adaptability and customization.

- Comprehensive Accessories: The package includes essential accessories such as a flux core gun, ground clamp, and spare contact tips, providing users with the necessary tools for a complete welding experience and minimizing the need for additional purchases.

Performance Accuracy

Delving into the crux of the matter – the performance accuracy of the Chicago Electric Flux 125 Welder is indeed noteworthy. Despite its compact design, this welding powerhouse delivers a robust 125-amp output, showcasing its prowess across a diverse spectrum of applications.

Whether navigating the intricacies of thin sheet metal or taking on more formidable materials, the welder exhibits a remarkable blend of precision and ease, rendering it a versatile tool for welders of various skill levels. In practical terms, the welder’s duty cycle of 20% at 90 amps emerges as a key indicator of its performance reliability.

From my hands-on experience, this implies the capability to weld continuously for two minutes within a 10-minute cycle, all while maintaining optimal temperature and avoiding overheating issues.

This feature proves to be particularly advantageous for DIY enthusiasts, offering a commendable performance level that aligns seamlessly with the demands of diverse projects.

Given its size and affordability, the Chicago Electric Flux 125 Welder stands out as an exceptional choice, catering to the precision needs of hobbyists and DIYers alike.

Duty Cycle and Versatility

The Chicago Electric Flux 125 distinguishes itself through its impressive combination of duty cycle and versatility. With a variable wire speed control and four distinct voltage settings, this welder stands as a paragon of adaptability, offering a nuanced approach to cater to the precise demands of any welding project.

The ability to fine-tune these settings becomes paramount when dealing with diverse materials such as mild steel, stainless steel, or aluminum, showcasing the Flux 125’s capacity to seamlessly transition between varying project requirements.

Moreover, its support for both flux-cored and MIG welding processes elevates its versatility even further, providing a multifaceted solution for different welding scenarios.

This proves exceptionally advantageous in practical applications, allowing users to switch between tasks effortlessly and eliminating the need for multiple machines.

The Flux 125’s capacity to accommodate various materials and welding techniques not only enhances its practicality but also positions it as a valuable asset for welders seeking efficiency and adaptability in their work.

Portability and Usability

Navigating the realms of portability and usability, the Chicago Electric Flux 125 Welder emerges as a stellar contender. Its user-friendly design is evident from the get-go, offering a straightforward setup process that is accessible even for beginners, thanks to the clarity provided by its user manual.

The thoughtfully engineered compact design and lightweight construction of the Flux 125 amplify its portability, allowing users to effortlessly transport and maneuver the machine within confined spaces, catering to the dynamic needs of diverse welding environments.

In addition to its ease of use, the Chicago Electric Flux 125 ensures a seamless welding experience through the quality construction of its welding gun and cable. The components exhibit a commendable level of durability, contributing to the overall reliability of the machine.

Furthermore, the incorporation of thermal overload protection stands as a testament to the manufacturer’s commitment to user safety. This feature acts as a fail-safe mechanism, automatically shutting down the welder in the event of overheating, safeguarding both the equipment and the user, and affirming Flux 125’s dedication to providing a hassle-free and secure welding environment.

Safety Management

Safety management is paramount when operating the Chicago Electric Flux 125 Welder. To ensure a secure working environment, it is imperative to adhere to recommended safety protocols. Always wear appropriate personal protective equipment (PPE), including welding gloves, a welding helmet with a proper shade, and flame-resistant clothing.

Adequate ventilation is crucial to dissipate welding fumes, so operate the machine in well-ventilated areas or use exhaust systems. Familiarize yourself with the machine’s thermal overload protection feature, which automatically shuts down the welder in case of overheating, preventing potential hazards. Additionally, be cautious of the short power cord and consider using extension cords judiciously to avoid tripping hazards.

Regularly inspect the welding gun, cable, and other components for wear or damage, and replace them promptly if needed. Prioritize a safe workspace by removing flammable materials and maintaining a clutter-free area to prevent accidents. Following these safety measures ensures that the Chicago Electric Flux 125 Welder can be harnessed effectively while minimizing risks and fostering a secure working environment.

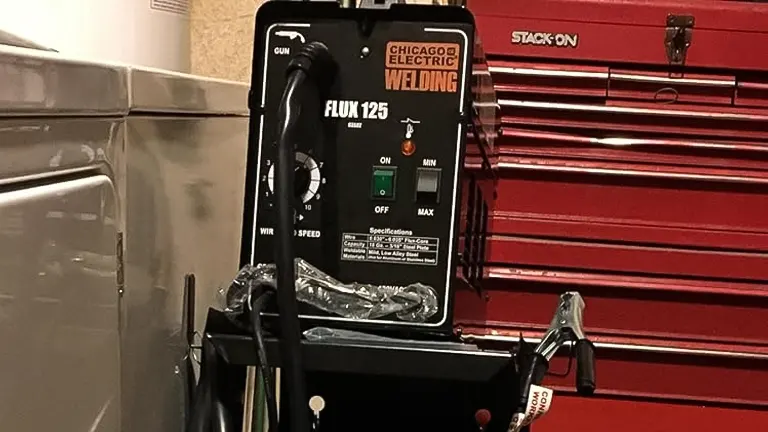

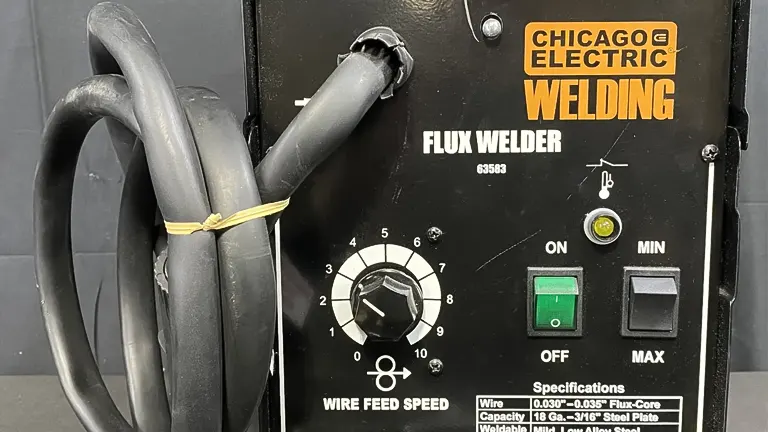

Review of Visual Assessment

The visual assessment of the Chicago Electric Flux 125 Welder reveals a well-crafted and thoughtfully designed machine. Its compact and lightweight form factor immediately stands out, allowing for easy portability and maneuverability in diverse workspaces. The machine’s control panel is intuitively laid out, featuring clearly marked settings for wire speed and voltage, contributing to its user-friendly nature.

The welding gun and cable exhibit a durable construction, instilling confidence in their ability to withstand the rigors of various welding tasks. The inclusion of thermal overload protection is visually reassuring, emphasizing a commitment to user safety.

The overall construction appears robust, and the machine’s matte finish gives it a professional and sleek aesthetic. From a visual standpoint, the Chicago Electric Flux 125 Welder presents itself as a well-engineered tool, aligning with its reputation for reliability and versatility.

Comparative Analysis and Consideration

When considering the Chicago Electric Flux 125 Welder and the HF Titanium Easy-Flux 125 Welder, both machines share notable similarities but present some distinctive features that might sway a user’s preference.

Both models offer a 125-amp output and a 20% duty cycle at 90 amps, making them suitable for a range of welding tasks. They share compatibility with 0.030 in. and 0.035 in. wire sizes, support flux-cored and MIG welding processes, and come with essential accessories like a flux core gun, ground clamp, and spare contact tips.

However, nuanced differences emerge in aspects such as voltage and weight. The Chicago Electric Flux 125 operates at 110V, whereas the HF Titanium Easy-Flux 125 runs at 120V. This distinction may impact the choice based on the user’s power supply capabilities.

Additionally, the Chicago Electric model weighs 37.5 pounds, slightly heavier than the HF Titanium at 32 pounds. The weight factor becomes crucial for users prioritizing portability and ease of transportation.

Both welders are priced affordably, catering to budget-conscious consumers. Ultimately, the choice between these two models hinges on the specific requirements of the user, with considerations ranging from power supply compatibility to the importance of machine weight in a given workspace.

Additional Features

- Variable Wire Speed Control: The Chicago Electric Flux 125 Welder boasts a variable wire speed control feature, allowing users to fine-tune the welding process based on the specific requirements of their project. This level of control enhances precision and adaptability, making it suitable for a diverse range of welding applications.

- Four Voltage Settings: With four distinct voltage settings, this welder provides users with the ability to customize the machine’s performance according to the thickness and type of material being welded. This versatility ensures optimal results and efficiency across various welding scenarios, contributing to the welder’s adaptability.

- Compact Design for Tight Spaces: The machine’s compact design, with dimensions of 19.5 x 17.75 x 11 inches, enhances its suitability for working in tight or confined spaces. This feature is particularly advantageous for users dealing with projects in areas where maneuverability is a crucial factor.

- Thermal Overload Protection: The inclusion of thermal overload protection is a critical safety feature. In the event of prolonged use or overheating, this safeguard automatically shuts down the welder, preventing potential damage to the machine and ensuring a secure working environment for the user. This feature adds an extra layer of reliability to the Chicago Electric Flux 125 Welder.

Table of Comparison vs. Competitors

Here’s a comparison table between the Chicago Electric Flux 125 Welder and the HF Titanium Easy-Flux 125 Welder:

| Feature | Chicago Electric Flux 125 Welder | HF Titanium Easy-Flux 125 Welder |

|---|---|---|

| Amperage Output | 125 amps | 125 amps |

| Duty Cycle | 20% at 90 amps | 20% at 90 amps |

| Power Source | Corded Electric | Corded Electric |

| Voltage | 110 V | 120 V |

| Wire Size Compatibility | 0.030 in. (0.8mm), 0.035 in. (0.9mm) | 0.030 in. (0.8mm), 0.035 in. (0.9mm) |

| Welding Processes | Flux-cored and MIG | Flux-cored and MIG |

| Weldable Metals | Mild, low alloy steel | Mild, low alloy steel |

| Thermal Overload Protection | Yes | Yes |

| Accessories Included | Flux core gun, ground clamp, spare contact tips | Flux core gun, ground clamp, spare contact tips |

| Weight | 37.5 pounds | 32 pounds |

| Dimensions | 19.5 x 17.75 x 11 inches | 20 x 17 x 12 inches |

| Price Range | $172.75 USD | $268.0 USD |

Pros and Cons

Pros

- Affordable: The Chicago Electric Flux 125 stands out for its affordability, providing an excellent balance between cost and performance, making it an attractive option for budget-conscious individuals without compromising on quality.

- Versatile: Its versatility shines through with variable settings and support for different welding processes. This adaptability makes it a versatile tool capable of handling various welding projects, catering to the needs of both beginners and experienced welders.

- Portable: The welder’s compact and lightweight design enhances its portability, allowing users to easily transport and maneuver the machine, making it an ideal choice for those working in tight or confined spaces.

- User-Friendly: Designed with user-friendliness in mind, the Chicago Electric Flux 125 is well-suited for both beginners and experienced welders. The straightforward setup process and clear user manual contribute to a seamless and hassle-free welding experience.

Cons

- Short Power Cord: One drawback is the relatively short power cord, which may necessitate the use of extension cords in certain situations. This limitation could be inconvenient for users working in larger or more expansive workspaces.

- Limited Duty Cycle: While the duty cycle of 20% at 90 amps is suitable for most DIY projects, professionals engaging in extended welding sessions might find it limiting. Continuous operation beyond the duty cycle may lead to overheating issues, prompting intermittent breaks to avoid potential equipment stress.

Chicago Electric Flux 125 Optimal Uses

- Material Selection and Thickness Matching: To optimize the performance of the Chicago Electric Flux 125 Welder, carefully select the appropriate welding materials. The machine excels in welding mild and low alloy steel, so ensure your chosen materials align with these specifications. Additionally, consider the thickness of the materials; the Flux 125 is well-suited for welding tasks ranging from 18-gauge to 3/16-inch thick materials, ensuring optimal results within this specified range.

- Fine-Tuning for Specific Projects: Leverage the Flux 125’s variable wire speed control and four voltage settings to fine-tune the machine according to the unique requirements of your welding project. Whether you’re working on intricate details or tackling larger structures, adjusting these settings allows for precision and customization. Moreover, take advantage of the machine’s support for both flux-cored and MIG welding processes, providing versatility that caters to a variety of welding scenarios. This adaptability ensures optimal performance and efficiency across different applications.

- Safety First: Prioritize safety measures for optimal use of the Chicago Electric Flux 125 Welder. Always wear the recommended personal protective equipment, including welding gloves and a helmet with the appropriate shade. Operate the welder in well-ventilated areas or employ exhaust systems to manage welding fumes. Regularly inspect the equipment for wear or damage, and replace any components as needed. Familiarize yourself with the thermal overload protection feature to prevent overheating, promoting a secure working environment. By adhering to safety protocols, you not only enhance the longevity of the machine but also ensure your well-being during welding operations.

Closing Thoughts

Summing up my assessment, the Chicago Electric Flux 125 Welder asserts itself as a dependable and multifaceted tool, delivering noteworthy performance without breaking the bank. Its compelling blend of power, versatility, and user-friendly features positions it as a standout option within its category. Whether you find yourself embarking on occasional weekend welding projects or are a seasoned professional in the field, the Chicago Electric Flux 125 caters to a spectrum of needs.

The machine’s prowess in handling diverse materials and welding processes, coupled with its ease of operation, elevates it to the forefront of welding equipment. Particularly appealing for budget-conscious DIY enthusiasts seeking a trustworthy companion for an array of welding tasks, the Chicago Electric Flux 125 Welder not only meets but exceeds expectations, earning my wholehearted endorsement.

Frequently Asked Questions

- What is the duty cycle of the Chicago Electric Flux 125 Welder?

The Flux 125 Welder has a duty cycle of 20% at 90 amps, meaning it can weld continuously for two minutes within a 10-minute cycle. - Can the Chicago Electric Flux 125 Welder handle aluminum or stainless steel welding?

No, the machine is primarily designed for welding mild and low alloy steel, making it unsuitable for aluminum or stainless steel projects. - Is the power cord of the Flux 125 Welder sufficient for most setups?

Some users might find the power cord relatively short, necessitating the use of extension cords in certain situations. - What welding processes does the Chicago Electric Flux 125 support?

The Flux 125 Welder supports both flux-cored and MIG welding processes, offering flexibility for various welding scenarios. - Is the welder suitable for professional use or more extensive projects?

While acceptable for most DIY projects, professionals may find the duty cycle limiting for extended use, prompting intermittent breaks to prevent overheating. - What wire sizes are compatible with the Chicago Electric Flux 125?

The welder supports wire sizes of 0.030 in. (0.8mm) and 0.035 in. (0.9mm), providing versatility for different welding needs. - Does the Flux 125 Welder come with thermal overload protection?

Yes, the machine is equipped with thermal overload protection, automatically shutting down in case of overheating for added safety. - How easy is it to set up the Chicago Electric Flux 125 Welder?

The welder is known for its user-friendly setup, catering to both beginners and experienced welders. The clear user manual enhances the ease of installation. - What welding capacities does the Flux 125 offer?

The machine can handle welding tasks ranging from 18-gauge to 3/16-inch thick materials, showcasing its adaptability for various applications. - Are spare contact tips included with the Chicago Electric Flux 125 Welder?

Yes, the package includes essential accessories, such as a flux core gun, ground clamp, and spare contact tips, providing users with the necessary tools for a complete welding experience.

We’re eager to learn from your firsthand experiences! Feel free to drop your comments and share your thoughts on the Chicago Electric Flux 125 Welder below. Your valuable insights could be the guiding light for fellow welders, aiding them in making informed decisions for their projects. Let’s build a community of shared knowledge and expertise!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Fuse on circuit board blows fuse. Where can I order a new 0Q055 circuit? Other numbers on the board: E232472 and SL-94V-0.

Bob Tusky

February 14, 2024 9:31 pm