10 Best Sawmill Bandsaw Blades

- July 13, 2023

- 1 comment

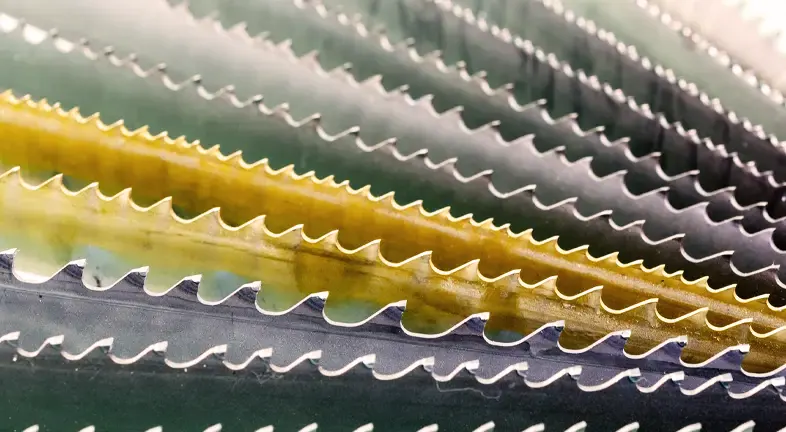

In the world of sawmilling, where precision, efficiency, and reliability are paramount, choosing the right bandsaw blade can make all the difference. A high-quality blade can help transform raw logs into valuable lumber with speed and accuracy, while a subpar blade can result in poor cuts, wasted material, and lost time. However, with numerous brands and styles on the market, finding the perfect blade for your needs can be a daunting task.

This comprehensive guide takes an in-depth look at ten of the best sawmill blades available. Each of these blades is revered for its unique strengths, offering a range of options to cater to different sawmill specifications and wood types. Whether you prioritize durability, precision, speed, or perhaps a combination of these, you’ll find a blade in this list that can elevate your sawmill operation to new heights.

Best Sawmill Bandsaw Blades List:

- Timber Wolf Bandsaw Blade

- Wood-Mizer DoubleHard Bandsaw Blade

- Lenox Woodmaster C Band Saw Blade

- Dakin-Flathers Ripper37 Bandsaw Blades

- Starrett Duratec SFB Bandsaw Blade

- Laguna ProForce Bandsaw Blade

- PS Wood Timber Wolf Bandsaw Blade

- Olson Hard Edge Flex Back Band Saw Blade

- M K Morse Bandsaw Blade

- Carter Accuright Bandsaw Blade

Prepare to explore the finest lumber mill bandsaw blades in the market has to offer, as we dive into the specifics of what makes each of these products stand out. From their construction material and design features to their performance and overall benefits, this guide will provide the essential information you need to make an informed decision about your next sawmill bandsaw blade purchase.

1. Timber Wolf Bandsaw Blade

Specifications

- Width: 1/8″ to 2-1/8″

- TPI (teeth per inch): 6 to 32

- Tooth style: Positive claw, skip tooth, raker tooth

- eBlade thickness: .025″ to .035″

- Kerf: .042″ to .060″

- Tooth hook angle: 6.5° to 10°

- Tooth set pattern: 5 raker set, alternating raker set

- Material: High silicon, low carbon steel

- Made in Sweden

These blades stand out in the market due to their silicon steel construction and unique manufacturing process that includes induction hardening. The low-tension feature is an innovative approach that reduces strain on your bandsaw, increasing its lifespan. Plus, with less heat generated during the cutting process, the blades remain sharper for longer, leading to increased precision in your cuts and reduced downtime for blade changes.

Pros

- Runs at low tension, reducing strain on the bandsaw

- Long-lasting sharpness due to silicon steel construction

- Suitable for a variety of sawmill tasks due to its precision

Cons

- Might not be as durable when cutting, particularly hardwoods

- Setting the correct tension might require a learning curve for some users

2. Wood-Mizer DoubleHard Bandsaw Blade

Specifications

- Width: 1/8″ to 1″

- TPI: 6 to 18

- Tooth style: Positive hook, skip tooth

- Blade thickness: .025″ to .035″

- Kerf: .042″ to .060″

- Tooth hook angle: 6.5° to 8°

- Tooth set pattern: 5 raker set, alternating raker set

- Material: High-carbon steel

- Made in the USA

Wood-Mizer’s DoubleHard blades are renowned in the sawmill industry for their high-quality high-alloy steel composition. Their induction-hardened teeth are a standout feature that promotes long-lasting sharpness and overall durability. A reduced need for frequent changes means you can focus more on cutting and less on blade maintenance, thus optimizing productivity in your sawmill.

Pros

- Robust high-alloy steel construction for durability

- Induction-hardened teeth maintain sharpness for a longer time

- Designed specifically for sawmill use

Cons

- Might be more expensive than other blades

- Could be overkill for less demanding, non-sawmill applications

3. Lenox Woodmaster C Band Saw Blade

Specifications

- Width: 1/8″ to 1″

- TPI: 6 to 18

- Tooth style: Positive hook, skip tooth

- Blade thickness: .025″ to .035″

- Kerf: .042″ to .060″

- Tooth hook angle: 6.5° to 8°

- Tooth set pattern: 5 raker set, alternating raker set

- Material: High-carbon steel

- Made in the USA

The Lenox Woodmaster C blade, made from high-carbon steel, is built to withstand demanding sawmill applications. Its design emphasizes tooth strength, and the unique tooth geometry leads to smooth and efficient cutting. The result is a bandsaw blade that can handle a wide variety of lumber types without compromising performance.

Pros

- High carbon steel body for excellent durability

- Unique tooth geometry for smooth and efficient cutting

- Can handle a variety of lumber types

Cons

- Higher price point than some other blades

- Might not be suitable for non-industrial, casual use

4. Dakin-Flathers Ripper37 Bandsaw Blades

Specifications

- Width: 1/4″ to 1″

- TPI: 6 to 18

- Tooth style: Positive hook, skip tooth

- Blade thickness: .025″ to .035″

- Kerf: .042″ to .060″

- Tooth hook angle: 6.5° to 8°

- Tooth set pattern: 5 raker set, alternating raker set

- Material: High-carbon steel

- Made in the USA

Dakin-Flathers has designed the Ripper37 to be a highly efficient and durable blade. Their claim of 37% longer life compared to other bandsaw blades is significant, and this could translate to a considerable reduction in maintenance costs for your sawmill operation. With a reputation for cleaner, faster cuts, this blade can help to enhance the overall efficiency and productivity of your sawmill.

Pros

- Claimed to last up to 37% longer than other blades

- Designed to deliver faster, cleaner cuts

- Can potentially reduce maintenance costs due to increased lifespan

Cons

- Might require a larger upfront investment

- Not all sawmill owners might see the claimed 37% lifespan increase, depending on their specific usage

5. Starrett Duratec SFB Bandsaw Blade

Specifications

- Width: 1/8″ to 1″

- TPI: 6 to 18

- Tooth style: Positive hook, skip tooth

- Blade thickness: .025″ to .035″

- Kerf: .042″ to .060″

- Tooth hook angle: 6.5° to 8°

- Tooth set pattern: 5 raker set, alternating raker set

- Material: High-carbon steel

- Made in the USA

A product of Starrett’s long-standing expertise in tool manufacturing, the Duratec SFB Bandsaw Blade is engineered for speed and precision. It is made from high carbon steel for added durability, while the unique tooth geometry reduces cutting resistance. The result is smoother, straighter cuts which contribute to the overall quality of the lumber you produce.

Pros

- Fast, precise cutting ability

- Made with high carbon steel for added durability

- Unique tooth geometry minimizes cutting resistance

Cons

- Might be more expensive than other options

- Some users may prefer a bi-metal blade for very heavy-duty sawmill tasks

6. Laguna ProForce Bandsaw Blade

Specifications

- Width: 1/8″ to 1″

- TPI: 6 to 18

- Tooth style: Positive hook, skip tooth

- Blade thickness: .025″ to .035″

- Kerf: .042″ to .060″

- Tooth hook angle: 6.5° to 8°

- Tooth set pattern: 5 raker set, alternating raker set

- Material: High-carbon steel

- Made in the USA

The ProForce blade from Laguna is designed for optimal performance in sawmill operations. Made from Swedish Silicon steel and featuring induction-hardened teeth, these blades offer both longevity and consistent performance. Moreover, the ProForce’s unique tooth shape enables cleaner and faster cuts, which can significantly enhance the efficiency of your sawmill operation.

Pros

- Induction-hardened teeth for durability and consistent performance

- Unique tooth shape provides cleaner, faster cuts

- Made from high-quality Swedish Silicon steel

Cons

- Some users might prefer a more aggressive tooth pattern for faster cutting

- Might not be ideal for cutting extremely hardwood species

7. PS Wood Timber Wolf Bandsaw Blade

Specifications

- Width: 1/8″ to 1″

- TPI: 6 to 18

- Tooth style: Positive hook, skip tooth

- Blade thickness: .025″ to .035″

- Kerf: .042″ to .060″

- Tooth hook angle: 6.5° to 8°

- Tooth set pattern: 5 raker set, alternating raker set

- Material: High silicon, low carbon steel

- Made in Sweden

The key feature of the PS Wood Timber Wolf blade is its ability to operate under low tension, which contributes to its long lifespan and reduced need for blade changes. Its silicon steel construction and design ensure a sharp and accurate cut, which makes it particularly suitable for sawmill tasks that require a high degree of precision.

Pros

- Operates under low tension for increased blade lifespan

- Silicon steel construction ensures sharp, accurate cuts

- Reduces heat during operation, prolonging its lifespan

Cons

- May not perform as well in very heavy-duty sawmill applications

- Some users might find the low-tension design challenging to set up initially

8. Olson Hard Edge Flex Back Band Saw Blade

Specifications

- Width: 1/8″ to 1″

- TPI: 6 to 18

- Tooth style: Positive hook, skip tooth

- Blade thickness: .025″ to .035″

- Kerf: .042″ to .060″

- Tooth hook angle: 6.5

- Tooth hook angle: 6.5° to 8°

- Tooth set pattern: 5 raker set, alternating raker set

- Material: High-carbon steel

- Made in the USA

Olson’s Hard Edge Flex Back blades offer an excellent combination of strength and flexibility, which are essential for demanding sawmill applications. Their carbon-rich steel construction contributes to superior hardness and durability. Additionally, the unique tooth geometry ensures efficient and accurate cutting, resulting in high-quality lumber.

Pros

- Combines strength and flexibility for optimal performance

- Carbon-rich steel construction contributes to superior hardness and durability

- Efficient and accurate cutting due to unique tooth geometry

Cons

- Might not be suitable for cutting very hardwoods

- May require more frequent changes in high-volume sawmills

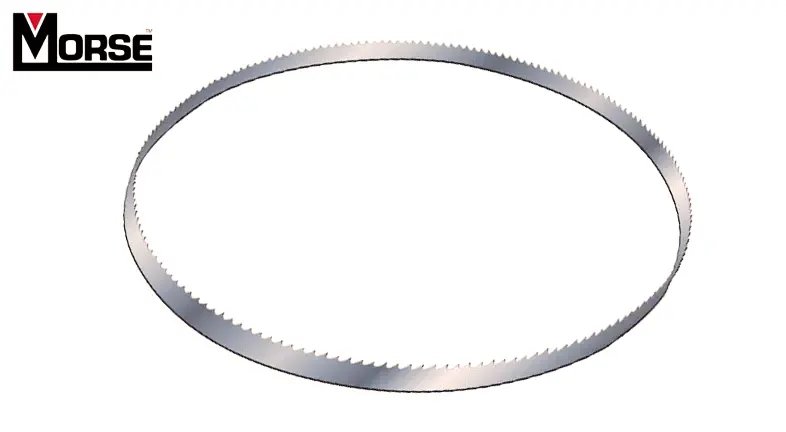

9. M K Morse Bandsaw Blade

Specifications

- Width: 1/8″ to 1″

- TPI: 6 to 18

- Tooth style: Positive hook, skip tooth

- Blade thickness: .025″ to .035″

- Kerf: .042″ to .060″

- Tooth hook angle: 6.5° to 8°

- Tooth set pattern: 5 raker set, alternating raker set

- Material: High-carbon steel

- Made in the USA

Known for producing high-quality cutting tools, M K Morse bandsaw blades offer durability and precise cutting. Their hardened teeth prolong the blade’s lifespan, ensuring consistent, high-quality performance over time. The Morse blade’s attention to detail and quality manufacturing ensure that they deliver top-notch performance every time.

Pros

- Durable and provides sharp, accurate cuts

- Hardened teeth prolong the blade’s lifespan

- The trusted brand known for high-quality cutting tools

Cons

- Might be pricier than some other bandsaw blades

- Might not be the best choice for casual or hobbyist woodworkers

10. Carter Accuright Bandsaw Blade

Specifications

- Width: 1/8″ to 1″

- TPI: 6 to 18

- Tooth style: Positive hook, skip tooth

- Blade thickness: .025″ to .035″

- Kerf: .042″ to .060″

- Tooth hook angle: 6.5° to 8°

- Tooth set pattern: 5 raker set, alternating raker set

- Material: High-carbon steel

- Made in the USA

Precision and performance are the main focuses of the Carter Accuright Bandsaw Blade. Constructed from high-carbon steel, these blades are designed to last long and stay sharp. The unique tooth design helps reduce waste and ensure a smoother cut, contributing to the overall quality of the final product. Carter Accuright blades are trusted by many sawmill operators due to their consistent performance and precision.

Pros

- Prioritizes precision and performance

- High carbon steel construction for longevity

- Unique tooth design ensures smoother cuts and reduced waste

Cons

- Might not be as durable as some other blades when cutting, particularly hardwoods

- Some users might prefer a more aggressive tooth pattern for faster cutting

Comparison Table

| Bandsaw Blade | Blade Type | TPI (Teeth Per Inch) | Blade Material | Suitable for | Durability | Cutting Performance | Price |

|---|---|---|---|---|---|---|---|

| Timber Wolf Bandsaw Blade | Premium Carbon Steel | Varied | High-Quality Steel | General Use | High | Smooth, Fine Cuts | Moderate |

| Wood-Mizer DoubleHard Blade | Premium Carbon Steel | Varied | High-Carbon Steel | High-Production | High | Precision Cutting | High |

| Lenox Woodmaster C Blade | Premium Carbon Steel | Varied | High-Speed Steel | Fine Woodworking | High | Clean, Accurate Cuts | High |

| Dakin-Flathers Ripper37 Blade | Carbide-Tipped | Varied | Carbide-Tipped Steel | Hardwood & Exotics | Very High | Extended Lifespan | Very High |

| Starrett Duratec SFB Blade | Bi-Metal | Varied | Bi-Metal | Versatile Use | High | Smooth, Efficient | Moderate |

| Laguna ProForce Blade | Carbide-Tipped | Varied | Carbide-Tipped Steel | Hardwood | Very High | Longevity, Precision | High |

| PS Wood Timber Wolf Blade | Premium Carbon Steel | Varied | High-Quality Steel | General Use | High | Smooth, Fine Cuts | Moderate |

| Olson Hard Edge Flex Back Blade | Carbon Steel Flex Back | Varied | Carbon Steel | Light Cutting | Moderate | Economical, Basic | Low |

| M K Morse Blade | Bi-Metal | Varied | Bi-Metal | Variety of Materials | High | Durable, Versatile | Moderate |

| Carter Accuright Blade | Carbon Steel Flex Back | Varied | Carbon Steel | General Purpose | Moderate | Reliable Cutting | Low |

Conclusion

The Timber Wolf Bandsaw Blade and PS Wood Timber Wolf Bandsaw Blade, with their silicon steel construction and low-tension operation, are standout choices for those prioritizing blade longevity and reduced wear on their sawmill equipment. For operators seeking extreme durability and efficient cutting in heavy-duty sawmill tasks, the high-alloy steel Wood-Mizer DoubleHard Bandsaw Blade and high carbon steel Lenox Woodmaster C Band Saw Blade excel.

For those targeting extended blade life to decrease downtime and maintenance costs, the Dakin-Flathers Ripper37 Bandsaw Blades and M K Morse Bandsaw Blade, with their impressive lifespan claims, would be formidable choices. Meanwhile, the precision and speed offered by the Starrett Duratec SFB Bandsaw Blade and Carter Accuright Bandsaw Blade would suit operations emphasizing productivity and fine-quality cuts.

Finally, for those seeking the perfect balance of strength, flexibility, and speed, the Laguna ProForce Bandsaw Blade and Olson Hard Edge Flex Back Band Saw Blade offer an excellent blend of these characteristics, ensuring optimal performance across a variety of cutting tasks.

In conclusion, these ten blades represent the apex of bandsaw blade design and manufacturing, each with its unique strengths catering to specific sawmill conditions and operator preferences. The key to selecting the ‘best’ blade lies in understanding your specific operational requirements and matching those to the features and benefits each blade offers. By doing so, you can transform your sawmill operation, elevating productivity, efficiency, and the quality of your cuts to unparalleled heights.

Related Articles:

- The Best Bandsaw Blades of 2023

- Best Sawmill Blades for Hardwood

- Best Bandsaw Blade Sharpener of 2024

Frequently Asked Questions

- What is the best sawmill bandsaw blade? The ‘best’ sawmill bandsaw blade will depend on your specific needs and the type of wood you’re cutting. This guide highlights some of the top choices, including the Timber Wolf Bandsaw Blade, Wood-Mizer DoubleHard Bandsaw Blade, Lenox Woodmaster C Band Saw Blade, and others.

- How often should I change my sawmill bandsaw blade? The frequency of changing your blade will depend on several factors, including the type of wood you’re cutting, the hardness of the wood, the sharpness of the blade, and how often you use the sawmill. Generally, it’s time to change the blade when you start to see a decrease in cutting performance or accuracy.

- How do I choose the right sawmill bandsaw blade? When choosing a bandsaw blade, consider factors like the type and hardness of the wood you’ll be cutting, the speed you want to cut at, and the level of precision you need. The blade’s material, tooth configuration, and size are also important considerations.

- Are more teeth on a bandsaw blade better? Not necessarily. Blades with more teeth can create smoother cuts, but they also cut more slowly. Blades with fewer teeth cut faster but may produce rougher cuts. The best choice depends on whether speed or finish quality is more important for your particular task.

- Can I sharpen my sawmill bandsaw blade? Yes, many sawmill bandsaw blades can be sharpened, which can extend their lifespan and save you money in the long run. However, sharpening should be done carefully to avoid damaging the blade.

- What makes a good sawmill bandsaw blade? A good sawmill bandsaw blade provides a balance between cutting speed, cut quality, and blade life. It should be durable enough to withstand the rigors of sawmill work, sharp enough to make clean, precise cuts, and designed in a way that matches the specific demands of your sawmill operation.

We’re eager to hear from you! Feel free to share your personal experiences and thoughts about the 10 Best Sawmill Bandsaw Blades in the comments section below. Your valuable insights could greatly assist others in making well-informed decisions when it comes to choosing the right bandsaw blade for their sawmill needs!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

I need the best hard wood cutting blade for wood Mizer LT20 Machine

Woodtech Engineers

November 22, 2023 4:20 pm