Best Sawmill Blades for Hardwood

- July 4, 2023

- 2 comment

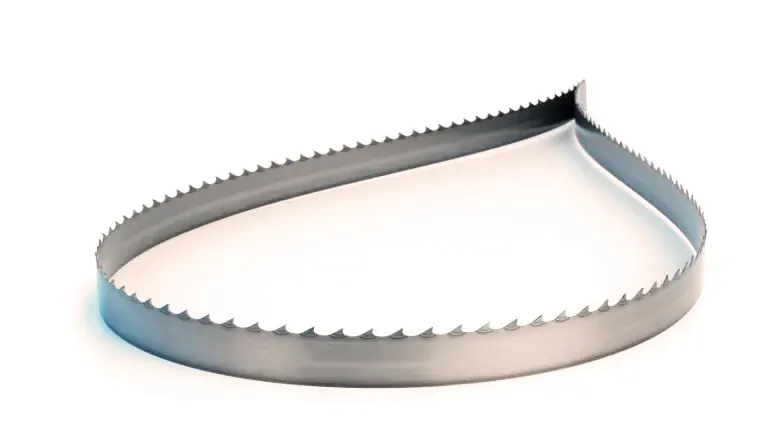

Hardwood is a material that has served humanity’s need for building and crafting for millennia, from constructing ships to fine furniture. Working with hardwood requires tools designed with precision, strength, and endurance in mind. This demand is especially true for sawmill blades, the essential tools that transform raw lumber into usable pieces.

When it comes to cutting hardwood, not all sawmill blades are created equal. The challenge lies in selecting the blade that can handle the density of hardwood while maintaining its sharpness over a long period. In this article, We dive deep into four leading sawmill blades perfect for hardwood!

Best Sawmill Blades List:

- Ripper37 Blades

- Wood-Mizer Turbo 747 Blades

- Lenox Woodmaster C Sawmill Blades

- Simonds Red Streak Carbon Bandsaw Blade

Things to consider when choosing a Sawmill Blade:

- Type of Wood: The type of wood you’re cutting is a crucial factor. Different woods have different hardness levels, and your blade needs to be able to handle that. Hardwoods typically require stronger, more durable blades than softwoods.

- Blade Material: Blades can be made from a variety of materials, each with its own pros and cons. Steel blades are quite common, but you may also find carbide-tipped blades that offer a longer lifespan and can endure tougher cutting tasks.

- Tooth Design: The design and arrangement of the teeth on a blade can have a significant impact on its cutting efficiency. The tooth count, angle, and size all play roles in how cleanly and quickly a blade cuts through wood.

- Blade Thickness (Kerf): The thickness of a blade, or its kerf, influences how much material is removed during each cut. Thinner blades remove less material, making them more efficient, especially when precision is needed.

- Band Wheel Diameter: The size of the wheels on your sawmill can determine the blade length and width you should use. Larger band wheels typically require wider and longer blades.

- Feed Speed: This refers to how quickly you can feed the wood into the sawmill during cutting. Some blades are designed to handle higher feed speeds than others.

- Maintenance and Sharpening: Over time, any blade will dull and require sharpening. Some blade materials and designs are easier to sharpen than others, and the ease and frequency of required sharpening could influence your blade choice.

Once you have considered all of these factors. Here is the Best Sawmill Blade on the market:

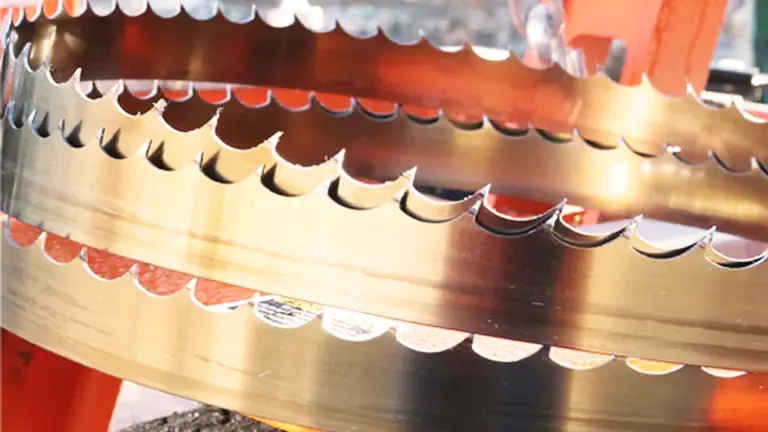

1. Ripper37 Blades

Product Specifications

- Size: 37 inches long, 1/4 inch thick

- Construction: High-carbon steel

- Tempering: Tempered and hardened

- Teeth: 6 teeth per inch, alternate hook, and rake

- Ideal for: Ripping through hardwoods and softwoods

Ripper37 Blades are a testament to exceptional strength, versatility, and longevity. Named for their ability to last up to 37% longer than most traditional bandsaw blades, these blades are a sound investment for any woodworker or sawmill operator.

Manufactured using high-grade steel, Ripper37 Blades are designed to handle the demands of cutting through hardwoods effortlessly. They feature a unique tooth profile that reduces cutting strain, resulting in smoother cuts with less wasted wood. Moreover, the improved blade body material ensures consistent performance over an extended period, minimizing downtime and ensuring cost-efficiency.

Pros:

- Longevity: Known for their durability, these blades are designed to last up to 37% longer than conventional blades.

- Versatility: These blades are able to handle a wide range of materials, including hardwoods, softwoods, and abrasive materials.

- Performance: Their unique tooth design enhances cutting performance, ensuring smooth cuts with less waste.

Cons:

- Cost: The high quality and extended life of these blades can make them more expensive than some other options.

- Maintenance: Like all blades, they require proper maintenance and care for best performance and extended life.

2. Wood-Mizer Turbo 747 Blades

Product Specifications

- Size: 747 inches long, 0.025 inches thick

- Construction: High-carbon steel

- Tempering: Tempered and hardened

- Teeth: Triple ground, 7 teeth per inch

- Ideal for: Resawing hardwoods and softwoods

The Wood-Mizer Turbo 747 blades have carved a niche for themselves in the woodworking world. Their performance, speed, and quality are second to none when it comes to cutting hardwood.

These blades incorporate a unique seven-tooth pattern and wide gullet design that delivers a faster and cleaner cut. The robust teeth configuration efficiently evacuates sawdust, maintaining the blade’s cutting efficiency even in dense hardwoods. Additionally, the high-grade steel combined with induction-hardened teeth ensures the blade’s longevity and consistent performance.

Pros:

- Speed: These blades are designed for high-speed cutting, enabling faster work completion.

- Efficiency: The unique seven-tooth pattern and wide gullet design ensure efficient sawdust evacuation and cleaner cuts.

- Durability: Made from high-quality steel, they’re designed to last.

Cons:

- Cost: Given their specialized design and high-performance capabilities, these blades might be more expensive than standard ones.

- Specialized Use: These blades are optimized for high-speed cutting and might not be suitable for slower, more delicate cutting needs.

3. Lenox Woodmaster C Sawmill Blades

Product Specifications

- Size: 72 inches long, 0.025 inches thick

- Construction: High-carbon steel

- Tempering: Tempered and hardened

- Teeth: Triple ground, 6 teeth per inch

- Ideal for: Resawing hardwoods and softwoods

Lenox Woodmaster C Blades is a trusted name in the woodworking industry. Known for their premium carbide-tipped design, these blades are particularly suited for hardwoods, which require a blade that can maintain sharpness and withstand high temperatures resulting from friction.

The carbide tips on the Woodmaster C Blades ensure a clean, smooth cut, minimizing the need for additional finishing. Additionally, they can maintain their sharpness over an extended period, even when cutting through the densest hardwoods. This resilience translates into less frequent blade changes, lower maintenance costs, and more uptime for the sawmill.

Pros:

- Sharpness: The carbide-tipped design ensures a sharp, smooth cut and maintains sharpness for a longer time, even with dense hardwoods.

- Heat Resistance: Carbide tips can withstand high levels of heat, which makes these blades ideal for heavy-duty cutting tasks.

- Reduced Maintenance: Their durability translates into less frequent blade changes, reducing maintenance costs and downtime.

Cons:

- Cost: The high-quality carbide tips make these blades a more expensive option.

- Brittleness: While carbide is incredibly hard and maintains sharpness well, it can be more brittle than steel and might chip if mishandled or used improperly.

4. Simonds Red Streak Carbon Bandsaw Blade

Product Specifications

- Size: 102 inches long, 0.025 inches thick

- Construction: High-carbon steel

- Tempering: Tempered and hardened

- Teeth: Triple ground, 7 teeth per inch

- Ideal for: Resawing hardwoods and softwoods

When durability meets efficiency, the result is the Simonds Red Streak Carbon Bandsaw Blade. The high carbon steel construction of the blade provides strength and durability, while the hardened teeth ensure a sharp and consistent cut.

The Red Streak blades stand out with their ability to maintain a straight and true cut, a critical factor when working with valuable hardwood. The blade’s design reduces stress on the sawmill equipment, which prolongs the life of both the blade and the machine. It offers a great balance of price, performance, and longevity, making it an excellent choice for hardwood applications.

Pros:

- Durability: Made with high-carbon steel, these blades are tough and long-lasting.

- Consistency: The blade’s design allows for straight, consistent cuts, which is vital when working with valuable hardwood.

- Balance: These blades offer a great balance of price, performance, and longevity.

Cons:

- Limited Versatility: These blades are designed primarily for hardwood, and their performance might not be as optimized with other materials.

- Maintenance: As with all carbon steel blades, proper maintenance is crucial to prevent rusting and ensure longevity.

Conclusion

Cutting hardwood requires sawmill blades that are tough, sharp, and durable. The Ripper37, Wood-Mizer Turbo 747, Lenox Woodmaster C, and Simonds Red Streak Carbon Bandsaw Blade each bring unique strengths to the table, allowing you to select the one that best fits your specific needs.

Whether you are dealing with the density of oak, the hardness of maple, or the uniqueness of exotic woods, these blades are equipped to handle the challenge. Each of these options offers a blend of speed, precision, and durability, providing you with the tools needed to transform raw hardwood into pieces of art. Their advanced designs and robust materials make them invaluable assets in the realm of hardwood cutting.

Frequently Asked Questions

- What’s the difference between carbide-tipped and Stellite-tipped blades? Carbide-tipped blades have tips made from carbide, a material known for its exceptional hardness and wear resistance. Stellite-tipped blades have tips made from Stellite, a cobalt-chromium alloy. Both materials are known for their durability and the ability to maintain sharpness over extended periods. The choice between the two often comes down to specific application requirements and personal preference.

- How often should I replace my sawmill blade? The frequency of blade replacement depends on several factors including the type of wood being cut, the volume of wood, and the blade’s quality. High-quality blades like the Ripper37 or the Lenox Woodmaster C can last longer than typical blades.

- Why is my sawmill blade dulling quickly? Several factors can cause a sawmill blade to dull quickly. These include cutting highly abrasive wood species, improper blade tension, inadequate lubrication, and feeding wood into the blade at an incorrect rate.

- How do I maintain my sawmill blades? Proper maintenance of sawmill blades involves regular cleaning to remove sap and resin buildup, proper tensioning to avoid overheating and warping, and regular inspection for any signs of wear or damage. Some blades may also require occasional sharpening.

- What does the tooth profile on a sawmill blade do? The tooth profile on a sawmill blade impacts how the blade cuts through the wood. For example, a tooth profile with more teeth or a more aggressive angle can cut through wood faster but might leave a rougher finish.

- What is the impact of blade width on the cutting process? Blade width can impact the stability of the cut and the minimum radius the blade can cut. Wider blades can provide more stability for straight cuts and are often used for resawing, while narrower blades can make tighter radius cuts.

- Why are some sawmill blades coated? Some sawmill blades have a special coating to reduce friction and heat build-up, which can prolong the life of the blade. The coating can also reduce resin and sap build-up, making the blades easier to clean.

- What type of sawmill blade is best for hardwood? High-quality blades, such as the Ripper37, Wood-Mizer Turbo 747, Lenox Woodmaster C, and Simonds Red Streak Carbon Bandsaw Blade, are all excellent choices for cutting hardwood due to their durability, sharpness, and design features that increase their cutting efficiency and lifespan.

Share Your Insights on the Best Sawmill Blades for Hardwood! At Chainsaw Length Guide, your expertise matters. We encourage you to take a moment and share your thoughts by leaving a comment. Your firsthand experiences and insights about the best sawmill blades for handling hardwood could be invaluable to others in our community. Let’s work together to create a valuable resource that assists those searching for optimal sawmill blade solutions for hardwood projects. Your input holds the power to shape the success of fellow sawmill enthusiasts.

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

2 comments

Ripper37 is the best!

I am after a suitable bandsaw blade that will handle Gidgee hardwood

Rob

December 23, 2023 4:18 am