Hidden Greasing Spot on a Chainsaw

- February 21, 2024

- 0 comment

Chainsaws are robust tools, essential for many outdoor tasks, from tree trimming to cutting firewood. However, like all mechanical devices, they require regular maintenance to function efficiently. One often overlooked aspect of chainsaw maintenance is the hidden greasing spot, crucial for preventing unexpected issues that could lead to damage or inefficient operation. This article delves into a common problem associated with chainsaw maintenance, its diagnosis, repair process, and preventive measures to ensure your chainsaw remains in top condition.

The Unexpected Issue: Chain Movement During Startup

When starting a chainsaw, the chain should remain stationary until the engine runs and the operator engages it. However, a situation may arise where pulling the starter rope causes the chain to move. While many might quickly attribute this issue to a broken clutch spring—a common diagnosis—this isn’t always the case.

Diagnosing the Problem: Beyond the Clutch Spring

Upon closer inspection, if you remove the side cover and the bar and chain, you can examine the clutch and its surrounding drum. In a properly functioning chainsaw, turning the drum should not rotate the clutch. If the drum is not turning freely, indicating that it’s stuck to the crankshaft, it suggests a problem beyond the clutch spring.

The Real Culprit: A Damaged Needle Bearing

The issue often lies with the clutch drum needle bearing. A damaged or destroyed needle bearing can cause the drum to stick to the crankshaft, preventing free movement. This was evidenced by the significant amount of metal shrapnel found upon removing the drum, which should have resembled a new, intact needle bearing.

Repairing the Chainsaw: Replacing the Needle Bearing

Repairing this issue involves cleaning out the metal shrapnel and replacing the damaged needle bearing with a new one. Ensuring the drum and the interior are clean and free from debris is crucial before fitting the new bearing. Once the new bearing is in place, the drum should spin freely around the crankshaft without engaging it directly, resolving the initial problem.

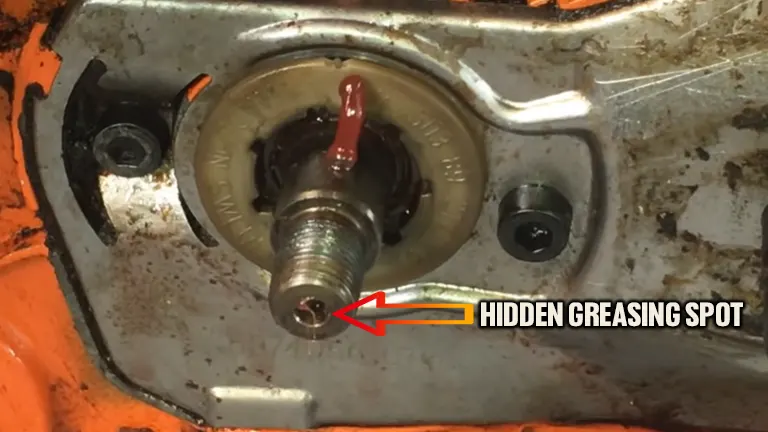

The Hidden Greasing Spot

The key to preventing such issues lies in regular maintenance, particularly greasing the hidden spot on the chainsaw. Not all chainsaws have this feature, but for those that do, a small hole at the end of the crankshaft can be found. This hole is designed for greasing; inserting a thin wire can check its presence. If the wire goes in, it indicates that your chainsaw has a greasing feature.

Using a grease gun, similar to the one used for the bar’s tip, you can inject grease directly into this hole. The grease then travels to the needle bearing, lubricating it and preventing the kind of damage seen in the case study. This simple yet effective maintenance step can significantly extend the life of your chainsaw’s components and ensure it operates smoothly.

Safety Tips for Chainsaw Maintenance

When performing maintenance tasks on your chainsaw, safety should always be your top priority. Here are essential safety tips to keep in mind:

- Always wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and ear protection. Consider wearing a long-sleeved shirt and pants to protect your skin.

- Before starting any maintenance, ensure the chainsaw is powered off and the spark plug is disconnected (for gas chainsaws) or the battery is removed (for electric chainsaws). This prevents the chainsaw from accidentally starting.

- If you’re working with a gas chainsaw, ensure your workspace is well-ventilated to avoid inhaling fumes.

- Employ the correct tools for each maintenance task to avoid damaging the chainsaw parts and to ensure your safety.

- A clutter-free and organized workspace helps prevent accidents, such as tripping or knocking over tools and parts.

- Always refer to your chainsaw’s manual for specific maintenance instructions and safety warnings.

Troubleshooting Guide: Common Post-Repair Issues

After performing repairs or maintenance on your chainsaw, encountering operational issues can be both common and frustrating. A well-structured troubleshooting guide can assist in identifying and resolving these issues effectively.

- A non-starting chainsaw can be due to several factors. Initially, check the spark plug to ensure it is connected and in good condition, as a faulty spark plug is a common culprit. For gas chainsaws, verify that the fuel mixture is correct and fresh to prevent ignition problems. Electric chainsaw users should ensure that the battery is fully charged or that the power cord is properly connected, as power issues are often the cause of starting failures.

- If the chain moves during startup, it’s essential to revisit the clutch and needle bearing installation. Incorrect assembly or a loose fit can lead to premature chain engagement. Additionally, inspect the chainsaw for any obstructions or damage that could inadvertently cause the chain to move, and address these issues accordingly to prevent recurrence.

- Rough operation in chainsaws can often be traced back to air and fuel system issues. Start by inspecting the air filter; a dirty filter can restrict airflow and should be cleaned or replaced. Similarly, check the fuel filter and lines for blockages or leaks that could affect performance. Ensuring that the carburetor is adjusted according to the manufacturer’s specifications can also rectify rough running by balancing the fuel-air mix correctly.

- A chain that fails to move upon engagement may be improperly tensioned or damaged. Verify that the chain tension is neither too tight nor too loose. Additionally, inspect the drive sprocket for wear, as a worn sprocket can impede chain movement. Checking for obstructions or damage in the chain path is also crucial, as these can prevent the chain from moving smoothly.

- Excessive vibration can be a sign of loose components or wear. Ensure that all bolts and nuts are securely tightened to mitigate vibration. Examine the condition of the anti-vibration mounts; worn mounts can increase vibration and should be replaced. Damage or uneven wear on the chain and bar can also contribute to excessive vibration and should be addressed.

Conclusion

The case of the hidden greasing spot on a chainsaw highlights the importance of thorough and regular maintenance. By understanding all aspects of your chainsaw’s operation and maintenance requirements, you can prevent common problems and ensure your tool remains reliable and efficient. Whether it’s replacing a needle bearing or regularly greasing the hidden spot, these steps can save you time, and money, and ensure your chainsaw is ready for action whenever you need it.

Related Articles:

- How To Fix A Stuck Chainsaw Brake: Practical Solutions and Tips

- How To Unflood Your Chainsaw Without Using Tools

- Hidden Risks of Cold Seizures in Chainsaws

- When to Replace Your Chainsaw Chain: Key Indicators and Tips

- Best Chainsaw Chaps 2024: Expert Reviews on Protective Gear

- 5 Chainsaw Maintenance Tips for Beginners

FAQs

- Why does my chainsaw chain move when I start it?

If your chainsaw chain moves upon starting, it’s often misdiagnosed as a broken clutch spring issue. However, it could actually be due to a damaged clutch drum needle bearing, which causes the drum to stick to the crankshaft. - How can I diagnose a stuck clutch drum without professional help?

Remove the chainsaw’s side cover and bar and chain to access the clutch and drum. If turning the drum also rotates the clutch, it indicates the drum is stuck to the crankshaft, likely due to a damaged needle bearing. - What tool do I need to remove the chainsaw clutch, and is there a specific technique?

An impact driver is ideal for removing the chainsaw clutch. Remember, the clutch has a left-hand thread, meaning it unscrews in the opposite direction to standard nuts and bolts. - What does a healthy clutch drum needle bearing look like, and how can I tell if mine is damaged?

A healthy needle bearing should allow the clutch drum to spin freely on the crankshaft. If removing the drum releases a lot of metal shrapnel, it indicates the bearing is severely damaged and was causing the drum to stick. - How can I prevent my chainsaw’s clutch drum needle bearing from getting damaged?

Regular maintenance is key. Some chainsaws feature a hidden grease spot at the end of the crankshaft. Greasing this spot can lubricate the needle bearing, preventing damage and extending the lifespan of your chainsaw. - What if my chainsaw doesn’t have the hidden grease spot feature?

If your chainsaw lacks this feature, focus on regular cleaning, and inspection of the bar, chain, and clutch components. Ensure they’re free of debris and adequately lubricated according to the manufacturer’s guidelines. - Can I replace a damaged needle bearing myself, and where can I find the replacement part?

Yes, with basic mechanical skills, you can replace a damaged needle bearing. Replacement bearings are available through chainsaw manufacturers, online retailers, or local repair shops. Be sure to check the description links of informative videos or the chainsaw’s manual for specific part numbers. - How often should I grease the hidden spot on my chainsaw?

The frequency depends on how often you use your chainsaw. For regular users, greasing the hidden spot before each heavy use session is a good practice. Occasional users might do it once at the beginning of the season or as part of a general maintenance routine. - What signs indicate I’ve properly greased the hidden spot on my chainsaw?

When greasing through the hidden spot, you should see excess grease escaping from the side hole near the needle bearing. This indicates that the grease has reached its destination and is lubricating the bearing effectively. - Are there any specific types of grease recommended for chainsaw maintenance?

It’s best to use grease specified by your chainsaw’s manufacturer for optimal performance. However, general-purpose grease designed for high-speed, high-temperature applications can also be effective for the bar tip and needle bearings.

And there you have it! We hope this guide not only enlightens you but also inspires you to keep your chainsaw in tip-top shape. Got any tips, experiences, or thoughts of your own? We’d love to hear from you! Drop a comment below and share your insights with the community. Let’s keep the conversation going and help each other out. Happy chainsawing!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment