Modifying Log Splitters for Low-Power Tractors

- March 4, 2024

- 0 comment

In the realm of agricultural and landscaping work, the synergy between equipment and necessity can’t be overstated. Particularly, when it comes to adapting heavy-duty machinery like log splitters for use with low-power tractors, the blend of innovation and practical knowledge is paramount.

This guide dives deep into the world of modifying log splitters for low-power tractors, ensuring you can tackle your wood-splitting tasks with efficiency, safety, and unparalleled ease.

Table of Content List:

- Hydraulic System Adjustments

- Power Take-Off (PTO) Considerations

- Custom Coupling Systems

- Weight Distribution and Stability

- Efficiency Boosting Modifications

- Safety Enhancements

Understanding the Basics of Log Splitter Modification

Log splitters are indispensable tools for processing firewood, transforming log cutting from a strenuous manual job into a quick, efficient mechanized operation. However, not all tractors possess the hydraulic power necessary to operate commercial log splitters. This discrepancy leads to the need for modifications, enabling these vital pieces of equipment to function seamlessly with lower horsepower tractors.

6 Methods for Modifying Log Splitters for Low-Power Tractors Guideline

Method 1: Hydraulic System Adjustments

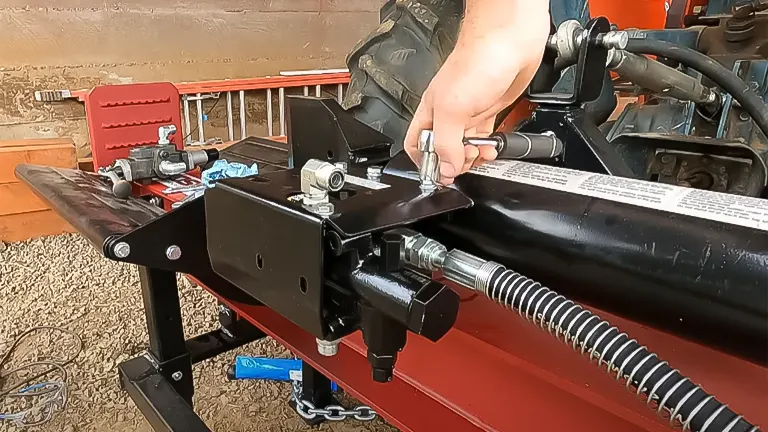

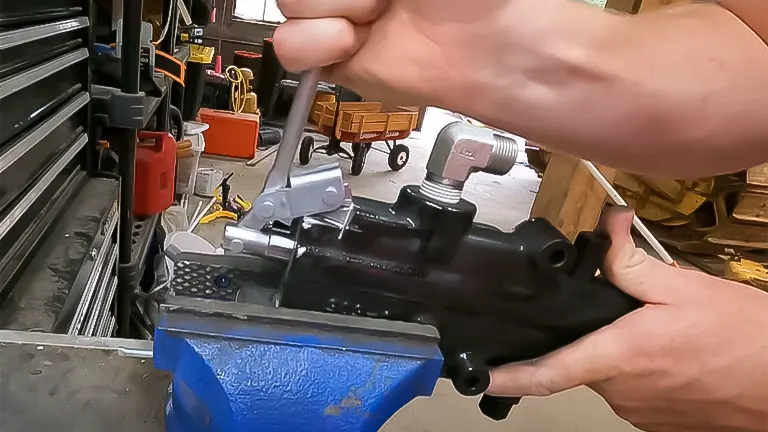

The heart of any log splitter modification lies in the hydraulic system. For low-power tractors, it’s crucial to adjust the hydraulic pump and control valve to match the tractor’s output capabilities. By recalibrating the flow rate and pressure settings, you can maintain operational efficiency without overburdening your tractor’s engine.

Method 2: Power Take-Off (PTO) Considerations

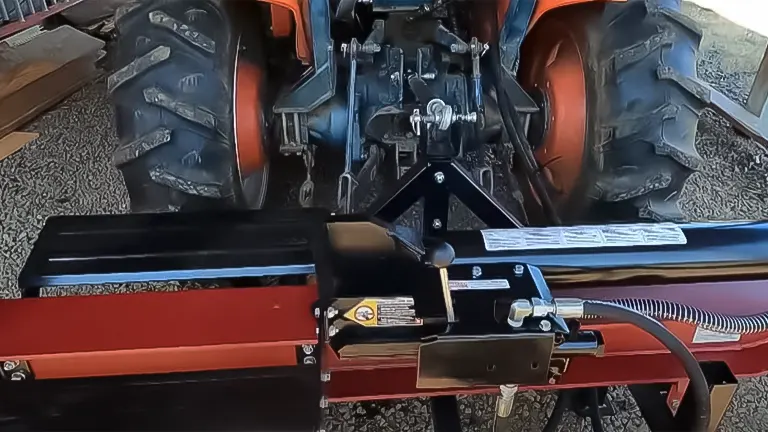

The PTO is an essential component for transferring the tractor’s mechanical power to the log splitter. When dealing with low-power tractors, selecting a PTO adapter that matches both the tractor’s output and the splitter’s input requirements is vital. This compatibility ensures a smooth transfer of power, mitigating any potential strain on the tractor’s engine.

Method 3: Custom Coupling Systems

Creating a custom coupling system can dramatically improve the connection between your tractor and the log splitter. This method involves fabricating or purchasing a coupling that precisely fits the dimensions and power specifications of both machines. A well-designed coupling system not only enhances performance but also significantly increases the safety of operations.

Method 4: Weight Distribution and Stability

Proper weight distribution is critical when modifying log splitters for low-power tractors. Implementing counterweights or adjusting the splitter’s mounting position can help balance the load, preventing undue stress on the tractor and ensuring stable operation. Stability is especially important when working on uneven terrain, as it reduces the risk of tipping and accidents.

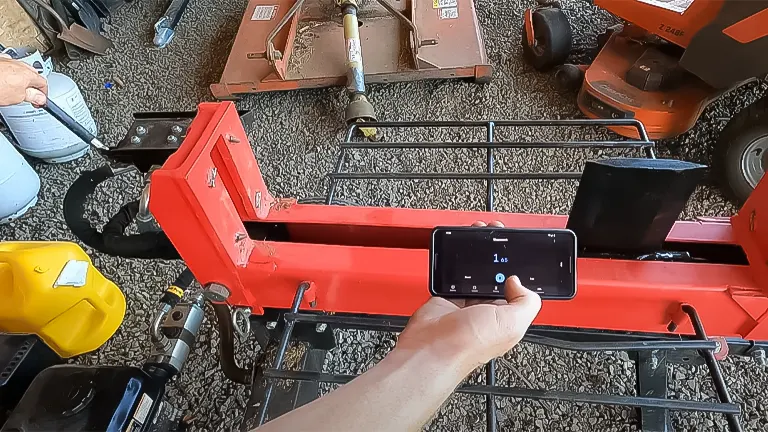

Method 5: Efficiency Boosting Modifications

To maximize efficiency, consider modifications that enhance the log splitter’s cycle time and fuel economy. This could involve upgrading the hydraulic fluid system for faster flow rates or installing more efficient blades that require less power to slice through logs. These improvements not only make the splitting process quicker but also extend the lifespan of both your tractor and the log splitter.

Method 6: Safety Enhancements

Safety should never be compromised in the pursuit of efficiency. When modifying your log splitter, it’s imperative to integrate features like emergency stop buttons, protective guards around moving parts, and enhanced visibility for the operator. These safety enhancements protect you and your equipment, ensuring that your wood-splitting tasks proceed without incident.

Pros and Cons of Log Splitter Modification

Modifying log splitters for low-power tractors presents a unique set of advantages and challenges:

Pros

- Customization: Tailoring the log splitter to your specific tractor model increases operational efficiency and safety.

- Cost-effectiveness: Modifying existing equipment is often more affordable than purchasing new, high-power machinery.

- Versatility: A modified log splitter can be optimized for various types of wood and splitting requirements, enhancing its utility.

Cons

- Technical Complexity: Modifications require a good understanding of hydraulics and mechanical systems, which might necessitate professional assistance.

- Time Investment: The process of modifying and fine-tuning the equipment can be time-consuming.

- Warranty Concerns: Alterations might void the warranty of your log splitter or tractor, leaving you responsible for any repairs or replacements.

Additional Tips for Log Splitter Modification Procedures

Here are 5 additional tips and procedures for modifying log splitters for low-power tractors:

- Prioritize Compatibility Assessments: Before starting any modifications, conduct a thorough compatibility assessment between your tractor and the log splitter. This involves understanding the hydraulic flow requirements of the splitter and ensuring your tractor’s hydraulic system can meet these needs without overexertion. Consider the tractor’s power take-off (PTO) capabilities, hydraulic pressure, and flow rate specifications.

- Implement a Two-Stage Hydraulic Pump: For tractors with limited hydraulic power, installing a two-stage hydraulic pump can be a game-changer. These pumps provide a high flow rate at lower pressures for faster cylinder movement at the start of the split and automatically switch to a lower flow rate at higher pressure when needed, optimizing efficiency without overburdening the tractor.

- Enhance Heat Dissipation: Hydraulic systems generate heat, and when modifying systems for compatibility, ensuring efficient heat dissipation becomes critical. Upgrading the hydraulic fluid cooler or adding one if not already present can prevent overheating, preserving the integrity of both your tractor and log splitter’s hydraulic systems.

- Regular Maintenance Checks: After modifications, the importance of regular maintenance checks cannot be overstated. Pay special attention to hydraulic lines, connections, and seals for leaks or wear. Check the hydraulic fluid level and quality regularly, and replace it according to the manufacturer’s recommendations or more frequently if operating under heavy use.

- Safety Modifications: Last but certainly not least, never overlook the importance of safety modifications. After any alteration, ensure all safety features of the log splitter are intact or enhanced. This can include adding or improving guards around moving parts, ensuring stable operation to prevent tipping, and possibly integrating an emergency stop feature. Always operate the machinery with protective gear and follow safety protocols.

Related Articles:

- Log Splitter Oil Change and Hydraulic Fluid Change

- Two Essential Log Splitter Modifications Every Owner Should Consider

- Best 3-Point Hitch Log Splitters

- Best Manual Log Splitters 2024

- Best Log Splitter for the Money 2024

- Wood Splitting Made Easy: The Tire Trick

Final Conclusion

Modifying log splitters for low-power tractors is a testament to the ingenuity and resourcefulness of those who work the land. By understanding and applying the principles outlined in this guide, you can ensure that your log splitting operations are as efficient, safe, and effective as possible. Remember, the key to successful modification lies in balancing the technical adjustments with an unwavering commitment to safety and performance.

Whether you’re a seasoned farmer, a weekend woodworker, or somewhere in between, the ability to adapt and optimize your equipment is invaluable. With the right modifications, your low-power tractor can become a powerhouse of productivity, proving that even the most formidable tasks can be tackled with intelligence and innovation.

Frequently Asked Questions

- What is a low-power tractor, and can it run a log splitter?

A low-power tractor is typically one with less horsepower, often ranging from 15 to 40 HP. Yes, it can run a log splitter, but modifications may be necessary to match the hydraulic power requirements of the log splitter with the tractor’s capabilities. - How do I modify a log splitter to work with my low-power tractor?

Modifying a log splitter usually involves adjusting the hydraulic system to ensure compatibility with your tractor’s power output. This can include changing the hydraulic pump, modifying the control valve for optimal flow rate, and ensuring the power take-off (PTO) setup matches the tractor’s specifications. - What are the key considerations when modifying a log splitter for a low-power tractor?

Key considerations include ensuring compatibility between the tractor’s hydraulic output and the log splitter’s requirements, proper PTO adaptation, efficient hydraulic fluid flow, safety enhancements, and maintaining stable and balanced operation. - Can I perform these modifications myself, or do I need professional help?

While some modifications can be done by individuals with mechanical and hydraulic systems knowledge, professional assistance is recommended for more complex adjustments, especially those involving the hydraulic system or custom fabrication. - Will modifying my log splitter void its warranty?

It’s possible. Modifying your log splitter, especially changes to the hydraulic system or structural modifications, can void the manufacturer’s warranty. It’s best to consult the warranty terms or contact the manufacturer before proceeding. - How can I ensure the modified log splitter is safe to use with my low-power tractor?

Safety measures include integrating emergency stop mechanisms, installing protective guards around moving parts, ensuring stable and balanced operation, and possibly adding visibility enhancements for the operator. Regular maintenance checks are also crucial for safety. - What is the cost range for modifying a log splitter for a low-power tractor?

The cost can vary widely based on the complexity of the modifications, ranging from a few hundred dollars for minor adjustments to several thousand for extensive modifications, including professional installation and custom parts. - How do modifications affect the efficiency and performance of the log splitter?

Properly executed modifications can enhance the efficiency and performance of the log splitter by ensuring it operates within the optimal power range of the low-power tractor, possibly improving cycle times and fuel efficiency. - Are there specific brands or models of log splitters that are easier to modify for low-power tractors?

Some log splitters are designed with adjustability in mind, making them easier to modify. It’s best to research and consult with manufacturers or professional modifiers to find models known for their compatibility and ease of modification. - What happens if the log splitter is too powerful for my tractor after modification?

If the log splitter demands more power than your tractor can provide, it may lead to inefficient operation, increased wear on the tractor, or even damage to both the tractor and the splitter. It’s crucial to ensure the modified setup matches the tractor’s capabilities to avoid these issues.

We’re eager to learn from your journey! Share your personal stories and insights on modifying log splitters for low-power tractors in the comments section below. Your experiences and advice could greatly assist fellow enthusiasts in navigating their own modifications. Let’s help each other make informed and effective decisions!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment