Top 5 Causes of a Loose or Detached Chainsaw Chain: How to Identify and Fix

- December 29, 2023

- 3 comment

Chainsaws, the powerhouse tools in your toolkit, are indispensable for efficiently tackling tough tasks. However, as potent as they are, they require meticulous care and understanding. A common, yet critical issue faced by many users is a loose or detached chain. In this article, we delve into the Top Five reasons for chain malfunctions in chainsaws and offer an additional, crucial insight.

Understanding the Chain Dynamics

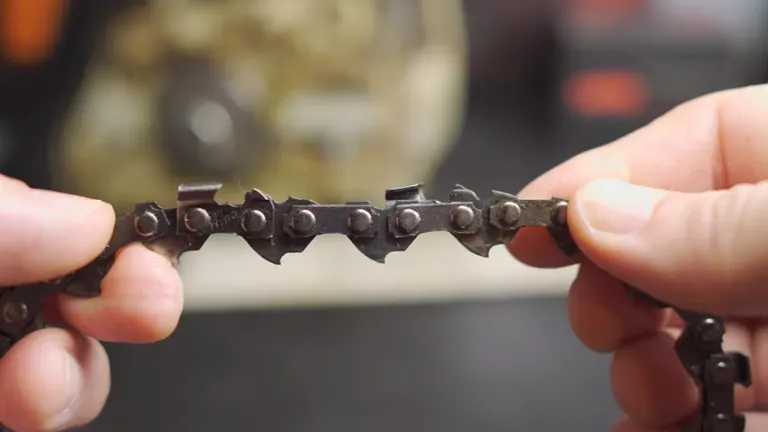

Before we delve into the specific causes, it’s essential to understand the dynamic nature of a chainsaw’s chain. The chain is more than just a cutting tool; it’s a complex assembly that requires precision in every aspect, from tension to fit. A slight deviation in any of these factors can compromise the chainsaw’s functionality and safety.

List of 5 Causes of a Loose or Detached Chainsaw Chain:

1. Incorrect Tension

The most common culprit behind chainsaw chain issues is improper tension. A chain that’s too loose poses the risk of slipping off, potentially causing dangerous kickbacks. Conversely, a chain that’s overtightened can bind or even snap, resulting in unnecessary strain on both the chainsaw and the operator. To avoid these pitfalls, it’s essential to meticulously follow the tension specifications outlined in your chainsaw’s manual. Regular tension checks and adjustments are not just a maintenance routine; they’re a critical safety practice that ensures the longevity of your chainsaw and protects you from potential hazards.

2. Wear and Tear

The relentless nature of a chainsaw’s task subjects its sprocket and bar to gradual but significant wear. This wear and tear, if left unchecked, can lead to a chain that becomes perilously loose. The key to managing this inevitable wear lies in proactive vigilance. Regularly inspect these components for signs of wear and replace them promptly when they start to show their age. This proactive approach goes beyond mere maintenance; it’s a commitment to operational safety and efficiency, ensuring that your chainsaw remains a dependable tool in your arsenal.

3. Chain Condition

A chainsaw’s chain might not readily reveal its wear and tear. Subtle issues like stretched links or minor damages can significantly impede its efficiency and safety. These nuances often require a discerning eye to identify. Conduct regular, thorough inspections of your chain, and be prepared to replace it at the first signs of significant wear, or even if you suspect it might be compromised. This strategy of erring on the side of caution is not just about maintaining an effective tool; it’s about ensuring your safety every time you power up your chainsaw.

4. Fit and Compatibility

The harmony between a chainsaw’s chain and its bar is pivotal for smooth operation. An incorrectly sized chain or an incompatible bar can lead to a host of issues, from reduced efficiency to increased risk of accidents. Always verify that the chain’s size precisely matches the bar’s specifications, typically etched or printed on modern bars for easy reference. In cases of uncertainty, the safest course of action is to replace either or both components. This attention to detail in ensuring compatibility is a small but significant step towards seamless operation and enhanced safety.

5. Tensioner Troubles

The chain tensioner, often unassuming yet vital, plays a crucial role in maintaining the appropriate tension of the chainsaw chain. A malfunctioning tensioner can lead to a chain that becomes loose during operation, even if it was correctly adjusted initially. This can lead to unsafe working conditions and decreased efficiency. Regular inspection and timely replacement of the tensioner are key. It’s not just about keeping the chain tight; it’s about ensuring the chainsaw operates safely and effectively, reducing the risk of accidents and downtime.

Bonus Insight

Lastly, user error is a significant factor in chainsaw chain mishaps. Incorrect operations, such as not guiding the chainsaw properly through a cut, can cause the chain to become pinched, bind, or come off entirely. Always keep your chainsaw sharp and follow the manufacturer’s guidelines for use and safety. Remember, chainsaws are powerful tools designed to do the hard work; never force a cut, as this can lead to dangerous situations.

Conclusion: Regular Checks for Optimal Performance

In conclusion, understanding these six factors – incorrect tension, wear and tear, chain condition, fit and compatibility, tensioner issues, and user error – is crucial for maintaining your chainsaw’s performance and safety. Regular maintenance, including proactive inspections and timely replacements, plays a significant role in ensuring your chainsaw remains a reliable and efficient tool.

Moreover, always prioritize safety by adhering to proper operating techniques and respecting the chainsaw’s capabilities. By doing so, you not only extend the life of your chainsaw but also protect yourself and others around you. Remember, a well-maintained chainsaw is a safe chainsaw. Stay vigilant, stay safe, and let every cut be as precise and secure as your maintenance routine.

Related Articles:

- STIHL 2 in 1 Chainsaw Chain Sharpener Review

- Chainsaw Safety Guide Tips

- Avoiding Common Mistakes When Using a Chainsaw

- 5 Step Plan for Safe Tree Felling with a Chainsaw

- How To Sharpen A Chainsaw Properly: Tips and Tricks

- Best Top Handle Chainsaw: Forestry Choice

FAQs

- How often should I check the tension of my chainsaw chain?

Ideally, you should check the tension every time before you use your chainsaw. Chains can loosen during use, so it’s crucial to ensure they’re correctly adjusted for each task. After adjusting, always do a quick test cut to confirm the tension is just right. - What are the signs that my chainsaw’s sprocket or bar needs replacing?

Look for signs of uneven wear, deep grooves, or visible damage on the bar. As for the sprocket, watch out for worn or broken teeth and any signs of free spinning without engaging the chain. If you notice any of these issues, it’s time for a replacement. - Can a dull chain affect the tension and overall performance of my chainsaw?

Absolutely! A dull chain makes the chainsaw work harder, which can lead to overheating and increased wear on both the chain and the chainsaw. This extra strain can also affect the tension. Regular sharpening ensures the chain cuts efficiently, reducing the strain on your chainsaw. - How do I know if I’m using the wrong size chain for my chainsaw?

A mismatched chain may not sit properly in the bar’s groove or may not align correctly with the drive sprocket. This misalignment can cause poor cutting performance, increased wear, and potential safety hazards. Always cross-reference the chain and bar specifications to ensure compatibility. - What are the consequences of ignoring tensioner maintenance?

Neglecting the tensioner can lead to a loose chain, which increases the risk of the chain jumping off the bar or causing uneven cuts. A faulty tensioner can also lead to excessive wear on the chainsaw’s bar and chain, shortening its lifespan. - Is there a way to prevent chainsaw chain issues proactively?

Regular maintenance is key. This includes keeping the chain sharp, ensuring correct tension, checking for wear and tear, and replacing any worn parts. Additionally, always use the chainsaw within its intended capacity and follow the manufacturer’s guidelines for use. - How tight should my chainsaw chain be?

The chain should be snug against the bar but still able to rotate freely without binding. A good rule of thumb is that you should be able to pull the chain slightly away from the bar, but not enough to disengage the drive links from the bar groove. - Can over-tightening the chain cause damage?

Yes, over-tightening can cause excessive wear on both the bar and chain. It can also increase the risk of chain snapping during use, which is a serious safety hazard. Always follow the manufacturer’s instructions for optimal tension. - How does user error affect chainsaw chain performance?

Improper use, such as forcing the chainsaw through a cut or using incorrect cutting techniques, can lead to the chain becoming pinched, binding, or coming off the bar. Familiarize yourself with proper chainsaw operation techniques to prevent these issues. - Where can I find the correct specifications for my chainsaw chain and bar?

Typically, the specifications are found in your chainsaw’s user manual or directly marked on the bar. If you’ve misplaced the manual, most manufacturers provide this information on their websites or through customer support.

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

3 comments

Never had that happen, but I agree that the quality of Stihl has declined as the price has increased. I own several Stihl saws (not the commercial series) and just recently bought a Husqvarna and an Echo Timber Wolf. I'm going to give the latter 2 a try this go around, because the Stihl Farm Boss saws are just high priced throw away saws too. So far I like the Echo (cuts good and is comparable to the Farm Boss) and the Husqvarna is the easiest starting saw I've owned. Unless you want to spend a grand, I would suggest trying a different brand.

Brian R.

January 1, 2024 2:17 pmI have a Stihl ms291c the chain adjuster mounting stud that holds the bar in place broke off in the housing. The remains of the stud could not be extracted from the housing. The end result is that the saw economically can not be repaired and is now a throw away. The saw is out of warranty and Stihl won’t do anything. The saw was used for cutting up downed limbs and only in the summer months. The saw has less than 25 hrs (approx). It will cost over $700.00 to replace. Stihl quality and reliability is disgraceful.

I have 13 chain saws ,one,s a 250 Canadian chainsaw , it,s a good old saw too , I have a 660 stihl , a huskvarne its a shit saw , the rest are all stihl saws , and I cut fence post out of gidgie timber, rosewood ,iron bark , and never had any trouble with any of my stihl chainsaws ,, I been using stihl saws for 48 years 😀 I have never and never will wear any of the poofter gear they want u to wear and I will never get one of the softcocked chainsaw licenses ..

Eddie Ebborn

January 2, 2024 1:38 am