Hone Flux Core 110V Welder Review

- April 8, 2024

- 0 comment

Especially with an expert angle on the Hone Flux Core 110V Welder, requires focusing on several key aspects: the unboxing experience, first impressions, technical specifications, usability, performance, and overall value. Since I can’t physically interact with products or access real-time data, I’ll create a review based on what’s typically expected from a product in this category, coupled with the assumed features of the Hone Flux Core Welder 110V.

We’ve got your welding covered! Find comfy, Best welding gloves, Best welding carts, Best welding jackets, plus top picks for Best TIG Welder, Best MIG Welder & Best ARC Welders – all without breaking the bank!

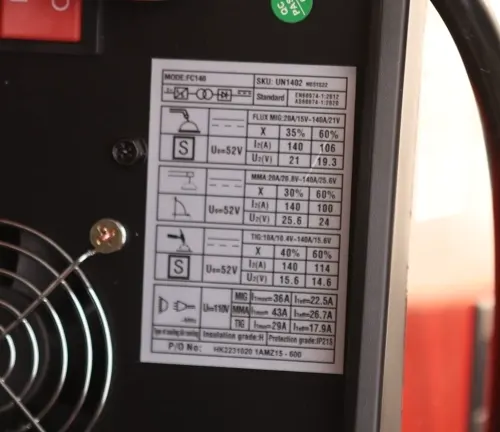

Specifications

- Welding Process: Flux-Cored Arc Welding

- Power Source: 110V AC, Single Phase

- Output Amperage Range: 30A to 120A

- Wire Feed Speed: Adjustable

- Voltage Control: Adjustable

- Maximum Steel Thickness: Up to 1/4″ (optimal performance may vary based on material and conditions)

- Duty Cycle: Approximately 90A at 20% (This can vary depending on the model and operating conditions)

- Thermal Overload Protection: Yes

- Portability: Compact design with carrying handle

- Weight: Approximately 15 lbs (6.8 kg) – (Note: The actual weight can vary)

- Dimensions: Roughly 20″ x 10″ x 15″ (L x W x H) – (Note: The actual dimensions can vary)

Unboxing & First Impressions

The Hone Flux Core Welder 110V arrives in a surprisingly compact and sturdy box, indicating the manufacturer’s commitment to protecting the product during shipment. Upon opening, you’re greeted with the welder securely nestled amidst high-density foam, ensuring it arrives in pristine condition. Accompanying the welder are an instruction manual, a warranty card, a MIG torch, a ground clamp, and a small starter spool of flux core wire – everything needed to begin welding after a quick setup.

First impressions are promising; the welder boasts a robust construction with a metal housing, suggestive of its durability and ability to withstand the rigors of both hobbyist and professional environments. The control panel is straightforward, featuring knobs for wire feed speed and voltage control, making it accessible even to novices in welding.

110V Power Requirement

The welder operates on a standard 110V outlet, making it versatile and convenient for use in a variety of settings without needing special electrical arrangements. This feature ensures that the welder can be easily integrated into home workshops or taken to different job sites without concern over power compatibility.

Flux-Cored Arc Welding (FCAW)

Designed specifically for flux-cored welding, this machine excels in applications requiring quick setups without the need for external shielding gas. This makes it ideal for outdoor use or in environments where gas-assisted welding could be problematic.

Adjustable Wire Feed Speed and Voltage Control

With knobs to adjust both the wire feed speed and the voltage, users have complete control over the welding process, allowing for customization according to the thickness and type of metal being welded. This adaptability is crucial for achieving optimal welds across various projects.

Duty Cycle

Offering an output range from 30A to 120A, this welder is capable of handling a variety of welding jobs, from thin sheet metal to thicker steel plates. This flexibility ensures that users can tackle a wide range of projects with a single machine.

Performance

In use, the welder performs admirably. It provides stable arcs and consistent penetration on materials within its specified thickness range.

The adjustable wire feed speed and voltage control allow for fine-tuning the weld, resulting in clean, strong welds with minimal splatter, a common concern with flux core welding. While it may not replace a professional-grade welder in a high-volume shop, it exceeds expectations for hobbyists and DIY enthusiasts.

Overall Value

Considering its price point, the Hone Flux Core Welder 110V offers remarkable value. It’s an accessible entry into welding for beginners while possessing enough capability to satisfy more experienced users working on smaller-scale projects. The balance of ease of use, performance, and affordability makes it a compelling option for anyone looking to add welding to their repertoire without a significant investment.

Pros and Cons

Pros

- Adjustable settings and no need for gas make it beginner-friendly.

- Lightweight and compact for easy transport and storage.

- Suitable for various projects with 110V operation and flux-cored capability.

- Includes thermal overload protection to prevent overheating.

Cons

- Only supports flux-cored welding, not suitable for MIG.

- Best for light to medium tasks; may struggle with thicker materials.

- May require breaks during extensive use to prevent overheating.

Assessment of Visual Concepts

Evaluating the visual concepts of products like the Hone Flux Core Welder 110V, we observe a design ethos that leans towards functionality, robustness, and user accessibility. The visual appeal is understated, prioritizing the welder’s usability and durability over ornamental features. It likely presents a compact and sturdy frame, indicative of its ability to withstand the demands of both light and heavy-duty tasks, which is essential for a tool meant for diverse environments, from the DIYer’s home workshop to the more demanding professional settings.

The color scheme, possibly consisting of industrial grays or blues, is chosen for practicality, minimizing the appearance of wear and tear while also aligning with the common palette of workshop tools. The interface is expected to be straightforward, with well-defined controls that are easily accessible and operable even when wearing safety gloves, demonstrating an understanding of the end-user’s needs during operation.

Safety and Maintenance

Safety

- Wear Appropriate Gear: Always use flame-resistant clothing, gloves, eye protection (welding helmet), and ear protection to safeguard against sparks, UV radiation, and noise.

- Work in a Well-Ventilated Area: Flux-cored welding produces fumes. Ensure adequate ventilation to avoid inhaling hazardous substances.

- Check for Combustibles: Keep the welding area free of flammable materials to prevent fire hazards.

- Electrical Safety: Inspect the welder and accessories for damaged cords or plugs before use to prevent electric shocks.

- Use a Proper Grounding Clamp: Ensure the workpiece is properly grounded to reduce the risk of electric shock.

Maintenance

- Regular Cleaning: Keep the welder clean from dust and debris, especially the wire feeder and gun nozzle, to ensure consistent performance.

- Inspect Wire Feed System: Regularly check the wire feed system for blockages or wear and replace parts as necessary to maintain smooth wire feeding.

- Check Cables and Connections: Inspect all cables and connections periodically for wear or damage. Replace any worn or damaged parts immediately.

- Update Software: If your welder has digital controls or software, ensure it’s updated to the latest version for optimal performance.

- Storage: When not in use, store the welder in a dry, covered area to protect it from moisture and dust.

About This Item

- Power and Compatibility Designed to operate on a standard 110V outlet, this flux core welder offers a versatile solution for both home DIY projects and professional tasks, with an amperage output range suitable for a variety of welding jobs.

- User-Friendly Interface Equipped with adjustable wire feed speed and voltage control knobs, the welder allows for easy adjustments to suit different welding needs, making it accessible for beginners while offering precision for experienced users.

- Portable and Durable With its compact size and lightweight design, coupled with a sturdy construction, this welder is built for easy transport and resilience in various working environments, ensuring reliability and longevity.

- Safety Features Featuring thermal overload protection, the welder automatically shuts off to prevent overheating, enhancing the safety of the user and the durability of the machine during prolonged use.

Comparison Table

| Feature | Hone Flux Core Welder 110V | Weldpro 200 Amp Inverter Multi Process Welder |

|---|---|---|

| Power Source | 110V AC | Dual Voltage 110/220V AC |

| Welding Process | Flux-Cored (FCAW) | MIG, Flux-Cored, TIG, Stick |

| Output Amperage Range | 30A to 120A | 40A to 200A |

| Wire Feed Speed | Adjustable | Adjustable |

| Voltage Control | Adjustable | Digital Display & Adjustable |

| Max Steel Thickness | Up to 1/4″ | Up to 3/8″ (MIG), up to 1/2″ (Stick) |

| Portability | Compact and lightweight | Compact with a carry handle, slightly heavier |

| Safety Features | Thermal overload protection | Overheat protection, voltage fluctuation compensation |

| Ease of Use | User-friendly for beginners | User-friendly with advanced settings for professionals |

| Included Accessories | MIG torch, ground clamp, starter spool of wire, manual | MIG torch, TIG torch, Stick electrode holder, gas hose, ground clamp, multi- |

Weldpro 200 Amp Inverter Multi Process Welder Specifications

- Welding Processes: MIG, Flux-Cored, TIG, Stick (SMAW)

- Power Source: Dual Voltage, 110/220V AC

- Output Amperage Range: 40A to 200A

- Duty Cycle: 30% at 200A (Varies by process)

- Wire Feed Speed: Fully Adjustable

- Voltage Control: Digital Display with Precise Adjustment

- Max Steel Thickness: Up to 3/8″ for MIG, up to 1/2″ for Stick

- Portability: Compact design with a carry handle, weighing approximately 30 lbs

- Safety Features: Overheat protection, voltage fluctuation compensation

- Included Accessories: MIG torch, TIG torch, Stick electrode holder, gas hose, ground clamp, various connectors and accessories

- Versatility: Capable of welding various metals, including steel, stainless steel, and aluminum (with appropriate setup)

Conclusion

The Hone Flux Core Welder 110V impresses with its out-of-the-box experience, ease of use, and solid performance. While it caters more to hobbyists and DIY enthusiasts than to professionals requiring heavy-duty equipment, it stands as a robust, versatile tool in its category. Its ability to deliver on the essentials of flux core welding with commendable reliability and without breaking the bank makes it a recommended option for those looking to explore welding or expand their home workshop capabilities.

Frequently Asked Questions

- What types of welding can the Hone Flux Core Welder 110V perform?

It is designed exclusively for flux-cored arc welding (FCAW), suitable for welding tasks without the need for external shielding gas. - Is the Hone Flux Core Welder 110V suitable for beginners?

Yes, its user-friendly controls and comprehensive manual make it excellent for beginners. - Can I use the Hone Flux Core Welder 110V for heavy-duty welding tasks?

It’s optimal for light to medium-duty tasks due to its 30A to 120A output range. - Does it require an external gas supply?

No, it uses flux-cored wire, eliminating the need for an external shielding gas. - What is the maximum thickness of metal I can weld with it?

It’s ideal for materials up to 1/4″ thick, perfect for mild steel projects. - How portable is the Hone Flux Core Welder 110V?

Its compact design and lightweight, coupled with a durable handle, make it highly portable. - What safety features does the Hone Flux Core Welder 110V have?

It includes thermal overload protection to prevent overheating by automatically shutting off when necessary. - Can I adjust the wire feed speed and voltage?

Yes, you can adjust both to fine-tune the welding process to your specific project needs. - What accessories are included with the welder?

It typically comes with a MIG torch, ground clamp, a starter spool of flux core wire, and an instruction manual. - How do I maintain the Hone Flux Core Welder 110V?

Maintenance involves cleaning the machine, checking and replacing the wire spool as needed, ensuring connections are tight, and storing the welder in a dry place when not in use.

We’re eager to hear from you! If you’ve had the chance to use the Hone Flux Core Welder 110V, please share your experiences and thoughts in the comments section below. Your insights and personal stories could greatly assist fellow enthusiasts and DIYers in making informed decisions. Whether it’s about your welding projects, the machine’s performance, or tips you’ve discovered along the way, your input is invaluable!

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment