Choosing the Right Skid Steer Tires

- November 3, 2023

- 0 comment

Selecting the right skid steer tires is a decision that should never be taken lightly. The choice of tires can significantly impact the performance and longevity of your skid steer, making it crucial to make an informed decision. Skid steer tires are not just rubber and tread; they are the interface between your machine and the ground, playing a pivotal role in how efficiently and effectively your skid steer operates. In this comprehensive guide, we will explore the importance of selecting the right skid steer tires and their impact on performance and longevity.

List of Skid Steer Tires

- Galaxy Beefy Baby II R-4 Skid Steer Pneumatic Tire 14-17.5

- TNT R4 Pattern Skid Steer Solid Tire

- GALAXY HULK L5 FOAM FILLED TUBLESS TIRE

- Michelin X Tweel SSL 2 All Terrain Airless Radial Tires

- Snow Wolf WolfPaws Snow Tires

What You Need To Know About Skid Steer Tires

Skid steer tires are a fundamental component that significantly influences the performance of these versatile machines, widely used in industries like construction and agriculture. The Tires that are commonly used are pneumatic, solid, and foam-filled, each with its unique set of advantages and drawbacks. Choosing the right type of tire largely hinges on your work environment and the specific tasks you’ll be tackling. Paying attention to the load capacity is essential, as exceeding it can lead to accelerated tire wear and diminished machine performance. Ensuring that the tire’s tread pattern aligns with your job requirements is crucial for efficient operation. Moreover, guaranteeing the correct tire size and compatibility with your skid steer is pivotal for stability and safety. Regular maintenance, encompassing tire inspection and proper inflation, is a must for maximizing their lifespan. While cost and budget constraints are important, investing in high-quality tires that suit your needs can yield long-term savings by reducing downtime and the frequency of tire replacements. Grasping these key aspects is essential for making informed decisions about skid steer tires, ultimately ensuring peak performance, safety, and cost-effectiveness in your operations.

Types of Skid Steer Tires

Before delving into the factors that influence your tire selection, it’s essential to understand the different types of skid steer tires available. Skid steer tires come in various types, each designed to suit different applications and terrains. Here are the primary kinds of skid steer tires:

1. Pneumatic Tires

Pneumatic tires offer a comfortable ride and are ideal for skid steers operating on softer terrains. Their air-filled design provides excellent traction and operator comfort. However, they are more vulnerable to punctures, which can result in downtime and maintenance costs. Regular air pressure maintenance is crucial to keep them performing at their best.

Galaxy Beefy Baby II R-4 Skid Steer Pneumatic Tire 14-17.5

The Beefy Baby II Tire is the most durable and versatile skid steer R-4 bias ply tires in the Galaxy skid steer range. It has been proven to be the lowest cost per hour R-4 tire in the market, making it the standard by which all other skid steer tires are measured. This leading market position was earned over many years of service thanks to the Beefy Baby II’s wear resistant compound, superior tread design, super sidewall and rim shield protector.

2. Solid Tires

Solid tires are known for their puncture resistance and durability. They excel in demanding environments with debris, making them suitable for construction sites and recycling centers. The trade-off is a less comfortable ride due to their rigidity, potentially leading to operator fatigue. They may not provide as much traction on softer terrains.

TNT R4 Pattern Skid Steer Solid Tire

The TNT R4 Pattern Skid Steer Solid Tire is a semi-pneumatic, flat-proof tire designed for skid steer loaders operating in a variety of demanding applications. It features a non-directional tread pattern with deep lugs that provide excellent traction on all surfaces, including mud, dirt, rocks, and concrete. The tire is also resistant to cuts and snags, making it ideal for use in harsh environments.

The TNT R4 Pattern Skid Steer Solid Tire is constructed from a durable rubber compound that provides long wear life and tear resistance. It also features a reinforced sidewall that helps to prevent punctures and blowouts. The tire is available in a variety of sizes to fit most skid steer loaders.

3. Foam-Filled Tires

Foam-filled tires combine the best of both worlds, offering a comfortable ride while being puncture-resistant and durable. These tires are versatile and suitable for various applications where operator comfort and tire longevity are essential. They are an excellent choice for balancing ride comfort and resilience, though they typically come at a slightly higher cost.

GALAXY HULK L5 FOAM FILLED TUBLESS TIRE

The Galaxy Hulk L5 Foam Filled Tubeless (TL) is a heavy-duty, industrial tire designed for the most demanding applications. It is made with a durable bias ply construction and features a deep tread pattern for excellent traction and performance in a variety of conditions. The tire is also foam filled, which makes it puncture-proof and eliminates the need for tubes. The Hulk L5 is ideal for use on skid steer loaders, compact track loaders, and other equipment that operates in harsh environments. It is well-suited for a variety of applications, including construction, landscaping, and mining.

4. All-Terrain Tires

All-terrain tires are versatile and adaptable, performing well on various surfaces, from soft dirt to hard pavement. They are designed for skid steers that need to transition between different terrains without compromising performance. However, they may not excel in extreme conditions and specialized terrains.

Michelin X Tweel SSL 2 All Terrain Airless Radial Tires

The Michelin X Tweel SSL 2 All Terrain Airless Radial Tire is a revolutionary new type of tire that eliminates the need for air. It is designed for use on a wide range of off-road vehicles, including skid steer loaders, forklifts, and agricultural equipment. The Tweel features a unique spoke design that provides excellent traction and stability, while also reducing bounce and driver fatigue.

One of the biggest advantages of the Tweel is that it is completely airless. This means that it is immune to flat tires, which can save businesses a significant amount of time and money in downtime costs. The Tweel is also more durable than traditional pneumatic tires, and it can be retreaded multiple times, extending its overall lifespan.

5. Winter/Snow Tires

Winter or snow tires feature unique tread patterns and rubber compounds tailored for excellent traction in snow and icy conditions. These tires are indispensable for winter operations like snow removal but may not perform optimally in other environments or seasons.

Snow Wolf WolfPaws Snow Tires

Snow Wolf WolfPaws snow tires are designed specifically for skid steers and other compact utility vehicles. They feature a narrow tread pattern that creates more down pressure, giving the tire a better grip on snow and ice. The tread pattern is also designed to self-clean, preventing snow and ice from building up in the grooves. WolfPaws tires are made from a soft rubber compound that further enhances traction in cold weather conditions.

WolfPaws tires are available in a variety of sizes to fit most skid steers and compact utility vehicles. They can be purchased with or without studs, depending on the level of traction required. Studded WolfPaws tires are ideal for use in extreme snow and ice conditions.

Factors to Consider

When choosing the right skid steer tires, several factors need to be considered. Terrain plays a pivotal role; different terrains require different tire types. Soft or muddy surfaces necessitate tires with deeper treads for improved traction, while solid surfaces may benefit from smoother, flatter treads.

Load capacity is another crucial factor; ensure that the tires can bear the weight you’ll be carrying. Tread patterns also play a significant role, with various designs suited to specific tasks like digging, lifting, or snow removal. Here are the critical factors to consider:

- Terrain and Surface Conditions: The type of terrain your skid steer will operate on is a pivotal factor. Different terrains require different tire types. Soft, muddy surfaces necessitate tires with deeper treads for traction, while solid surfaces like concrete or asphalt benefit from tires with flatter, smoother treads.

- Load Capacity: Understanding the weight your skid steer will carry is essential. Exceeding the load capacity of your tires can lead to premature wear, reduced stability, and safety concerns. Choose tires that can handle the weight of your intended loads.

- Tread Patterns: The tread pattern of the tires should match your specific tasks. For tasks requiring maximum traction, opt for tires with aggressive tread patterns. Smoother treads are better for jobs on hard surfaces, offering more stability and less wear.

- Puncture Resistance: If you’re working in environments with sharp debris, it’s wise to consider tires with puncture-resistant features. These tires can minimize downtime and reduce maintenance costs, making them a sound investment.

- Operator Comfort: Consider the comfort of the operator. Foam-filled tires, for example, offer a more comfortable ride, reducing operator fatigue during extended workdays. Comfort is vital for both productivity and safety.

- Versatility: Some tires are more versatile and can handle a variety of tasks and terrains. If your work involves transitioning between different environments, these all-terrain tires can be a practical choice.

- Durability and Longevity: Durable tires can save you money in the long run. Look for tires known for their longevity and ability to withstand the demands of your work environment. They may have a higher upfront cost but can result in fewer replacements and reduced downtime.

- Manufacturer Recommendations: Always consult the manufacturer’s recommendations for your skid steer model. They provide valuable information on the appropriate tire size, type, and load capacity for your specific machine. Following these guidelines ensures optimal performance and safety.

Sizing and Compatibility

Getting the right tire size for your skid steer is a crucial step in ensuring top-notch performance. Your skid steer’s manual or the manufacturer’s suggestions are your trusty guides in finding that perfect tire size. Opting for the wrong size can spell trouble, affecting how stable and efficient your machine is. Compatibility matters just as much. Double-check that the tires you pick are a seamless fit for your specific skid steer model to dodge any compatibility hiccups that might otherwise hinder your machine’s efficiency and safety.

Maintenance and Care

Maintaining and caring for your skid steer tires is vital for their longevity. Regular inspections should be a part of your routine, looking for signs of wear, damage, or punctures. Keeping your tires properly inflated to the recommended pressure is essential, as under-inflated tires can lead to premature wear and decreased performance. Avoid overloading your skid steer, as this can strain the tires and reduce their lifespan. A clean and debris-free work area can help prevent punctures and damage.

Here are some practical tips for keeping your skid steer tires in excellent shape:

- Regular Inspection: Make it a habit to inspect your tires routinely. Look for signs of wear, damage, or punctures. Identifying issues early can prevent more extensive damage and costly repairs.

- Proper Inflation: Keeping your tires at the correct air pressure is crucial. Under-inflated tires can lead to excessive wear and reduced stability. Over-inflated tires can cause a harsher ride and reduced traction. Consult your skid steer’s manual or the manufacturer’s recommendations for the right tire pressure.

- Tire Rotation: To promote even wear across all tires, consider rotating them regularly. This can extend their lifespan and ensure balanced performance. Check the manufacturer’s guidelines for the recommended rotation intervals.

- Cleanliness: Maintaining a clean work area is essential. Debris like nails, screws, or sharp objects can puncture tires. Regularly inspect and clean your tires to remove any embedded materials that could cause damage.

- Avoid Overloading: Exceeding your skid steer’s load capacity can strain the tires and lead to premature wear. Make sure you adhere to the weight limits to prevent damage and ensure safe operation.

- Timely Repairs: If you notice any issues with your tires, address them promptly. Ignoring problems can lead to more extensive damage and increased repair costs. Investing in a quality tire repair kit and ensuring your operators are trained to use it can be a smart preventive measure.

Cost and Budgeting

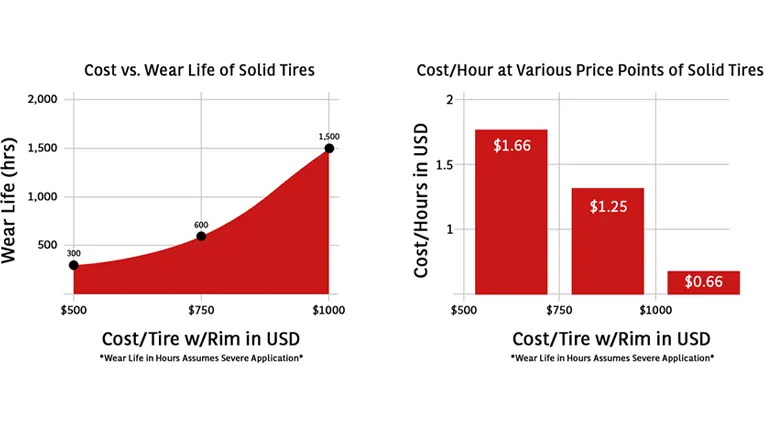

Skid steer tires can vary widely in price, and cost considerations are paramount. While it may be tempting to opt for the least expensive option, it’s crucial to strike a balance between cost and quality. Investing in high-quality tires that match your specific needs can ultimately save you money in the long run by reducing downtime and the frequency of tire replacements. Consider your budget and choose tires that offer the best value for your specific requirements.

Common Skid Steer Tire Problems and How to Avoid Them

As you venture into the world of skid steer operation, understanding common tire problems and how to avoid them is invaluable. Whether it’s encountering frequent punctures, uneven tire wear, or reduced traction, we’ll explore these issues and provide practical tips on how to prevent them, ensuring your skid steer tires stay in top condition. Here are some common issues and how to steer clear of them:

- Pesky Punctures and Damage: Rocks, nails, and debris can turn your skid steer tires into pincushions. To dodge this issue, always do a quick sweep of your work area to remove anything sharp. And consider switching to solid or foam-filled tires – they’re tougher cookies and less likely to get punctured.

- Uneven Tire Wear: If your tires wear unevenly, it’s like throwing money down the drain. Keep an eye on your wheels’ alignment and tire pressure. Make sure the pressure stays in the sweet spot recommended by the manufacturer, and balance your tires when needed.

- Overloading Oopsies: Trying to squeeze in too much stuff onto your skid steer is a recipe for tire trouble. Stick to the weight limits like your favorite recipe – don’t overdo it.

- Low-Pressure Problems: Running your skid steer with underinflated tires can be a real drag. It’ll wear your tires out faster and mess with your machine’s stability. So, make it a habit to check your tire pressure and keep it in the zone. You’ll save on fuel and keep things running smooth.

- Tire Storage Slip-up: Leaving your skid steer out in the elements for too long can spell disaster for the tires. Give it some shelter or use tire covers to protect those precious rubber buddies from harsh weather.

- Neglecting Maintenance: Skipping your regular tire checkup is a risky game. Clean your tires often, remove any gunk, and keep an eye out for wear and tear. If your tires look like they’ve seen better days, swap them out before things get worse.

- Traction Troubles: Lack of grip can turn your job site into a slip ‘n slide. Pick tires with the right tread pattern for your terrain and make sure they’ve got enough grip to avoid awkward slides, especially in mud or slippery spots.

- Load Lopsidedness: Unevenly distributed loads can put your tires through the wringer. When you’re carrying stuff, spread the load evenly across all four tires. It’s like sharing the load and spreading the love – keeps everyone happy.

Tips for Choosing the Right Skid Steer Tires

Delving deeper into the selection process, we’ll provide you with specific tips and guidelines on how to choose the right skid steer tires. From matching tire type to terrain to assessing load capacity, this section will serve as a practical toolkit to help you make the most informed decision possible. Here are some practical tips to guide you through the selection process as if we were picking out those ideal shoes:

- Consider Your Terrain: First things first, think about where you’ll be working most. If it’s on rough, rocky terrain, go for tires with deep, aggressive treads for added traction. For smoother surfaces, standard-duty tires may suffice.

- Tire Type: You’ve got options like pneumatic, solid, and foam-filled tires. If punctures are a constant headache, solid or foam-filled tires can be your saviors. Pneumatic tires offer a smoother ride but can puncture more easily.

- Tread Patterns: The tread pattern matters! For muddy or soft ground, look for tires with wide, self-cleaning treads. On hard surfaces, go for skid steer tires with tighter, non-directional treads for better wear resistance.

- Size Matters: Don’t play guessing games with tire size. Check your skid steer’s manual or existing tires to get the right measurements. You want them to fit perfectly.

- Load Capacity: Know how much weight you’ll be lifting. Choose tires with the appropriate load rating to handle your workload. Overloading can wear your tires out faster.

- Brand Reputation: Brands matter. Do a bit of research and read reviews to find tires from reputable manufacturers. Well-known brands tend to offer more reliable and durable options.

- Budget: Set a budget and stick to it. Skid steer tires come in a range of prices. While you want quality, you don’t want to break the bank.

- Maintenance Ease: Some tires are easier to maintain than others. If you prefer low-maintenance options, consider solid or foam-filled tires. They don’t go flat and require less upkeep.

- Weather Conditions: If you work in an area with extreme weather conditions, choose tires that can handle it. Some tires are better suited for hot, cold, or wet environments.

- Longevity: Think long term. While saving money is important, don’t compromise on tire quality. Durable, longer-lasting tires can save you more in the end.

- Warranty: Check if the tires come with a warranty. It’s a safety net in case you encounter unexpected issues.

- Consult an Expert: When in doubt, consult with a skid steer expert or tire specialist. They can offer valuable advice tailored to your specific needs.

Future Trends in Skid Steer Tire Technology

The world of skid steer tire technology is continually evolving. In this section, we’ll provide insights into the future trends and advancements in skid steer tire technology. From innovations in tire materials to enhanced tread designs, you’ll gain a glimpse of what lies ahead in the world of skid steer tires.

Here’s a glimpse of what we can expect:

- Cutting-Edge Tread Designs: Skid steer tires of the future will feature even more advanced tread designs. These patterns will be finely tuned to specific tasks and terrains, delivering better traction and durability.

- Smart Tire Technology: Just like our smartphones, tires are getting smarter. Future skid steer tires might come equipped with sensors that monitor tire pressure, temperature, and wear in real time. This data can help operators with proactive maintenance and reduce the risk of unexpected tire issues.

- Eco-Friendly Materials: Sustainability is a top priority, and the tires of the future will likely be crafted from eco-friendly materials. This shift towards greener options will reduce the environmental impact of tire production and disposal.

- Superior Puncture Resistance: Future tire technology will bring even better puncture resistance. Through advancements in tire compounds and construction methods, the risk of downtime and maintenance due to tire damage will be significantly reduced.

- Run-Flat Capability: Run-flat tires, which allow a machine to continue working safely even with a damaged tire, could become more common in skid steer applications. This will help minimize downtime and boost productivity.

- Unbeatable Durability: Tire technology will focus on maximizing durability, leading to less frequent replacements and lower operating costs. Fewer tire changes mean more uninterrupted work.

- Noise Reduction: Noise pollution is a concern in many work environments. The future of skid steer tires may include innovations to reduce noise levels, making operations quieter and more comfortable for workers.

- Energy Efficiency: With a growing emphasis on energy efficiency, skid steer tires will likely be designed to reduce rolling resistance. This, in turn, can lead to fuel savings and reduced carbon emissions.

The future of skid steer tire technology is all about enhancing performance, sustainability, and efficiency. These innovations will ultimately benefit operators, making their work more productive and environmentally responsible.

User Reviews and Recommendations

Learning from those who have hands-on experience with skid steer tires is invaluable. In this section, we’ll include real-world experiences and recommendations from skid steer operators. Their insights and feedback can provide you with a well-rounded view of how different tire choices have affected the performance of various skid steers. Here’s a collection of feedback and recommendations from skid steer users:

- Brand Reliability: Many skid steer operators emphasize the importance of choosing tires from well-established and reputable brands. They often cite brand reliability as a key factor in their decision-making process.

- Terrain-Specific Recommendations: Skid steer users who work in specific terrains, such as construction sites or farms, often offer recommendations for tire types and tread patterns that have proven effective in those environments. These insights can be particularly valuable when selecting tires for your specific application.

- Puncture Resistance: Operators working in areas with sharp debris or hazards often highlight the benefits of puncture-resistant tires or foam-filled tires. They emphasize how these options have reduced downtime and maintenance costs.

- Longevity and Durability: Reviews frequently mention the durability and longevity of certain tire models. Skid steer operators appreciate tires that can withstand the demands of their work environments and require fewer replacements.

- Operator Comfort: Feedback sometimes touches on the comfort of the ride. Foam-filled tires, for example, are often recommended for their combination of comfort and durability, leading to reduced operator fatigue during long workdays.

- Ease of Maintenance: Skid steer users value tires that are easy to maintain. Tires with accessible valve stems and straightforward maintenance requirements receive positive feedback.

- Adaptability to Different Tasks: Tires that perform well across a range of tasks, from digging to snow removal, tend to receive positive reviews. Skid steer operators appreciate tires that offer versatility.

- Cost-Effective Options: Some reviews provide insights into cost-effective tire choices that offer a good balance between price and performance, helping operators save on expenses without compromising quality.

- Recommendations for Specific Brands and Models: Skid steer users often offer specific recommendations for tire brands and models that have served them well in their operations. These firsthand experiences can be valuable when considering your tire options.

Conclusion

Selecting the right skid steer tires is a crucial decision that can significantly impact the performance and longevity of your equipment. By considering factors such as terrain, load capacity, tread patterns, and maintenance, you can make an informed choice. Pay close attention to sizing and compatibility, as well as your budget, to strike the right balance between cost and quality. Finally, seek advice from experienced operators to learn from their real-world experiences. With the right skid steer tires, you can ensure the efficiency and longevity of your skid steer, making it a reliable and productive asset for your projects.

FAQs

- Can I use the same skid steer tires for all types of terrains and tasks?

While some tires are designed for versatility, it’s often best to select tires tailored to your specific terrain and tasks. Tread patterns and tire types can significantly impact performance, so choosing the right one is crucial for efficiency and safety. - Are foam-filled tires worth the higher cost compared to pneumatic tires?

Foam-filled tires offer a balance between ride comfort and puncture resistance. The choice depends on your needs. If punctures are a common issue in your work environment, the added cost of foam-filled tires may be justified by reduced downtime and maintenance expenses. - What is the ideal tire pressure for skid steer tires?

The ideal tire pressure varies depending on the tire type and the skid steer’s load capacity. Always consult the manufacturer’s guidelines to determine the correct tire pressure for your specific tires. Regular pressure checks are essential to maintain performance and tire longevity. - Can I replace just one skid steer tire, or is it best to replace all four at once?

Ideally, it’s recommended to replace all four skid steer tires simultaneously. Mixing old and new tires can lead to uneven wear and affect the skid steer’s stability and performance. Replacing them as a set ensures consistent performance and longevity. - How do I know if I need winter/snow tires for my skid steer?

Consider winter/snow tires if you operate in cold climates with significant snow and ice. These specialized tires feature unique tread patterns and compounds to provide superior traction in such conditions. They are crucial for snow removal and winter tasks. - Are there any eco-friendly tire options for skid steers?

Yes, some manufacturers offer environmentally friendly tire options. Look for tires with low rolling resistance, which can reduce fuel consumption and minimize the skid steer’s carbon footprint. These tires can be a sustainable choice for environmentally conscious operators. - Can I use agricultural tractor tires on my skid steer?

While it is possible to use agricultural tractor tires, it’s not recommended. Skid steer tires are specifically designed to withstand the unique stresses and requirements of skid steer operation. Using the right tires ensures safety, stability, and optimal performance. - What are the consequences of using over-sized or under-sized tires on my skid steer?

Using over-sized or under-sized tires can significantly impact skid steer performance and safety. Over-sized tires may lead to stability issues and reduced maneuverability, while under-sized tires can reduce load capacity and overall efficiency. Always use the recommended tire size for your specific skid steer model.

In the broader perspective, the choice of the right skid steer tires takes on a significant role. These seemingly unremarkable components wield substantial influence over the effectiveness, endurance, and, above all, the safety of your skid steer, regardless of your industry. Delving into aspects like the terrain you traverse, the loads you handle, and the tread patterns suited to your tasks is not just wise; it’s an absolute necessity. Furthermore, ensuring a seamless fit between the tires and your skid steer’s size and compatibility is indispensable for maintaining stability and overall performance. When it comes to maintenance, you’ll find that regular care, inspection, and proper inflation are your dependable allies in extending tire life. As for financial considerations, there exists a delicate balance between making astute investments and reaping long-term advantages. Insights from the practical experiences and sincere recommendations of fellow skid steer operators offer a unique perspective that transcends monetary value. In a nutshell, the right choice of skid steer tires charts a path to enhanced efficiency and cost-effectiveness in your daily operations, making it a well-justified investment.

Benjamin Brooks

Forestry AuthorGreetings! I'm Benjamin Brooks, and my journey over the past 15 years has revolved around the fascinating realms of content creation, expertise in snow clearing, and the intricate world of lumberjacking and landscaping. What began as a simple curiosity about the natural world and heavy machinery has evolved into a passionate profession where my love for crafting words intertwines seamlessly with my lumberjacking and garden skills.

Leave your comment