Milwaukee M18 FUEL 30 Degree Framing Nailer Review

- March 29, 2024

- 0 comment

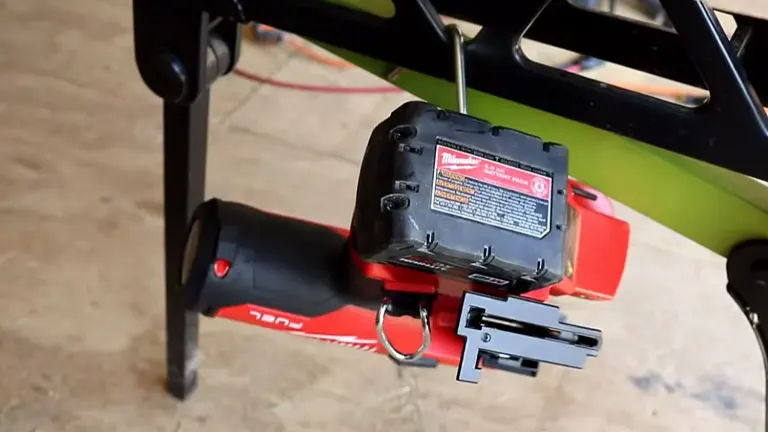

Today, we delve into the features and performance of the Milwaukee M18 FUEL 30 Degree Framing Nailer. This nailer has set a new benchmark in the cordless framing nailer category, leveraging advanced technology to offer pneumatic-like performance without the constraints of cords or gas cartridges.

Product Specifications

- Nailer Type: Framing

- Tool Warranty: 3 Year Limited Warranty

- Power Source: Cordless

- Length: 14.1 inches

- Weight: 9.4 pounds

- Height: 15.2 inches

- Width: 4.7 inches

- Nail Collation Angle: 30° to 34°

- Nail Length: 2 inches to 3 ½ inches

- Nail Shank Diameter: 0.113 inches to 0.131 inches

- Nail Head Style: Clipped Head Nails and Full Round Offset Head Nails

- Battery System: M18

Performance and Speed

The Milwaukee M18 FUEL Framing Nailer is a high-performance tool designed to meet the rigorous demands of professional framing tasks. Its ability to fire up to three nails per second with zero ramp-up time sets it apart in the market.

This feature ensures that the nailer responds instantly upon trigger activation, enabling fast and efficient work, especially in time-sensitive projects. The nailer’s capability to sink full round head nails into dense engineered lumber demonstrates its impressive power, derived from the combination of Milwaukee’s nitrogen spring mechanism and POWERSTATE brushless motor. This power is crucial for ensuring that nails are driven consistently and securely, even in challenging materials, which is essential for structural integrity in framing applications.

Cordless Convenience

A significant advantage of this framing nailer is its cordless operation, eliminating the need for gas cartridges, a compressor, or hose. This not only reduces the tool’s total weight and increases maneuverability but also cuts down on the operational costs and maintenance typically associated with gas-powered nailers.

The reliance on Milwaukee’s REDLITHIUM batteries ensures a long-lasting charge, allowing users to work for extended periods without the need for frequent recharging. The absence of a gas cartridge system means there’s no need to purchase and replace cartridges, offering long-term savings and environmental benefits. Additionally, the sealed compressed nitrogen driving mechanism enhances the tool’s efficiency and reliability, providing a consistent driving force for each nail.

Design and Ergonomics

Weighing in at 9.4 pounds, the M18 FUEL Framing Nailer is built for durability and performance. Although its weight contributes to a solid and robust feel, it may be perceived as top-heavy, which could affect handling during extended use. However, the tool’s design includes features that enhance its ergonomics and ease of use.

The comfortable grip is designed to reduce fatigue, and the tool’s balance is engineered to minimize strain on the user’s hand and wrist. The depth of nail drive can be adjusted easily, allowing for precise control over nail placement and countersink, which is particularly useful when working with varying materials and nail lengths. The on-board storage for a hex key adds a layer of convenience, enabling quick adjustments and maintenance without the need to carry additional tools.

Battery and Intelligence System

The integration of Milwaukee’s REDLITHIUM battery technology and REDLINK PLUS intelligence system is a key feature of this nailer. The REDLITHIUM battery is renowned for its superior pack construction, electronics, and performance, delivering more work per charge and more work over the life of the pack than other batteries in the market.

The REDLINK PLUS intelligence system provides optimized performance and overload protection, facilitating communication between the tool, battery, and charger. This synergy ensures that the nailer operates at its best, with efficient power usage and protection against overheating or overloading, which could otherwise lead to downtime or damage to the tool.

Additional Features

The M18 FUEL Framing Nailer comes equipped with a rafter hook, belt hook, dry fire lockout, and a no-mar tip cover, enhancing its functionality and versatility. The rafter hook allows for convenient hanging of the tool when not in use, while the belt hook offers easy portability on the job site.

The dry fire lockout feature prevents the tool from firing when there are no nails in the magazine, protecting the workpiece from damage and the tool from wear. The no-mar tip cover prevents damage to the work surface, ensuring a clean finish. These features, combined with the tool’s firing speed, power, and cordless convenience, make it an invaluable asset for professional carpenters and remodelers.

Pros

- I appreciate the cordless design, which eliminates the hassle of dragging around a compressor or dealing with tangled hoses. This freedom allows for easier maneuverability around the job site.

- The ability to fire up to three nails per second with zero ramp-up time significantly increases my productivity, especially on large framing projects. It’s powerful enough to drive nails into dense engineered lumbers, making it versatile for various tasks.

- Without the need for gas cartridges, I save on ongoing expenses and avoid the maintenance issues commonly associated with gas-powered nailers. This aspect is particularly beneficial for keeping long-term operational costs low.

- The three-year limited warranty provides peace of mind, ensuring that the tool is a durable investment. Given the robust construction of the nailer, I feel confident it can withstand the rigors of daily job site use.

Cons

- At 9.4 pounds, the nailer is relatively heavy, which can lead to fatigue during extended use or when working overhead. While it’s well-balanced, the weight might be a drawback for some users, especially in tight spaces or for prolonged periods.

- Since it operates on the M18 battery system, having multiple batteries is necessary to ensure continuous operation throughout the day. This could be a con if additional batteries are required, as it adds to the initial investment and the need to manage battery charging.

- The initial investment for the Milwaukee M18 FUEL Framing Nailer can be high, especially considering the need to purchase batteries and a charger separately if they are not already owned. This cost factor may be a significant consideration for individuals or small businesses on a tight budget.

Maintenance of Milwaukee M18 FUEL 30 Degree Framing Nailer

Regular Cleaning

- Regular cleaning is essential for maintaining the performance of the Milwaukee M18 FUEL Framing Nailer. After each use, the exterior of the nailer should be wiped down with a clean, damp cloth to remove dust, debris, and any residues from the work environment. It’s important to avoid using harsh solvents that could damage the tool’s plastic components. The magazine and nosepiece areas, prone to accumulating dust and debris, should be cleaned regularly using a brush or compressed air. This prevents potential jamming and ensures smooth operation.

Lubrication

- Unlike traditional pneumatic nailers that require frequent oiling, the Milwaukee M18 FUEL Nailer is designed to minimize the need for regular lubrication due to its advanced construction. However, it’s advisable to check the user manual for any specific lubrication recommendations. Periodically, certain moving parts or contact points might need a bit of lubrication to maintain smooth operation, although this is less frequent compared to other types of nailers.

Battery Care

- Proper battery care is crucial for cordless tools like the M18 FUEL Nailer. The tool uses Milwaukee’s REDLITHIUM batteries, which should be charged using compatible Milwaukee chargers to ensure optimal performance and longevity. Batteries should be stored in a cool, dry place and not exposed to extreme temperature conditions. Regular charging and adherence to the manufacturer’s guidelines for battery care will help maintain their efficiency and lifespan.

Inspection and Testing

- Routine inspection and testing of the nailer can prevent unexpected downtime and ensure safety. Regularly inspect the tool for loose screws, signs of wear, or any damage, especially focusing on the firing mechanism and safety features. Before beginning work, performing a test fire on scrap material can help verify that the nailer is operating correctly and that the depth adjustment is set appropriately for the task at hand.

Storage

- Storing the nailer properly when not in use is important to protect it from environmental damage and to keep it in good working condition. The nailer should be stored in a clean, dry environment, away from moisture and dust. If available, using the manufacturer-provided carrying case for storage can offer additional protection and help maintain the nailer’s condition.

Service and Repairs

- For service and repairs, it’s recommended to rely on authorized Milwaukee service centers or professional tool repair services. Attempting to perform complex repairs independently, especially if untrained, can lead to further damage and might void the warranty. Professional servicing ensures that any issues are addressed correctly and that the nailer remains reliable for future use.

Conclusion

The Milwaukee M18 FUEL 30 Degree Framing Nailer represents a significant advancement in cordless nailer technology, offering powerful, efficient, and convenient operation without the traditional limitations of corded or gas-powered models. Its design, which emphasizes speed, power, and user-friendly features, along with the cost-effective operation due to the elimination of gas cartridges, makes it an excellent choice for professionals looking for a reliable and high-performing framing nailer. With its robust construction and advanced technology, the M18 FUEL Framing Nailer is built to withstand the rigors of heavy-duty use, providing consistent and reliable performance that professionals can depend on.

FAQs

- What makes the Milwaukee M18 FUEL 30 Degree Framing Nailer stand out from pneumatic nailers?

The Milwaukee M18 FUEL Nailer combines the portability of cordless operation with the power typically associated with pneumatic nailers. Its advanced mechanism allows it to fire nails at a speed comparable to pneumatic models without the need for hoses or compressors. - Can the Milwaukee M18 FUEL Framing Nailer operate in extreme weather conditions?

Yes, it’s designed to perform reliably in various environmental conditions. The robust construction and battery technology ensure consistent operation in both hot and cold climates, providing flexibility for outdoor and indoor projects. - How does the REDLINK PLUS Intelligence system benefit the user of the M18 FUEL Framing Nailer?

REDLINK PLUS Intelligence ensures optimal performance by preventing damage due to overload or overheating. It enhances communication between the tool, battery, and charger, ensuring efficient power management and prolonged tool life. - Is the weight of the Milwaukee M18 FUEL Nailer a disadvantage for overhead or extended use? +

While the nailer is on the heavier side, it is designed with balance and ergonomics in mind to minimize user fatigue. Its efficient operation and rapid firing capability can offset the weight factor, especially in jobs requiring high nail volumes. - How does the absence of gas cartridges in the M18 FUEL Nailer impact the overall cost of ownership?

Eliminating the need for gas cartridges reduces the ongoing operational costs. Users save on the purchase of cartridges and avoid the downtime and maintenance associated with gas-powered nailers, leading to a lower total cost of ownership over time. - What types of nails can the Milwaukee M18 FUEL Framing Nailer use, and how does it affect its versatility?

It accommodates a range of nail sizes and types, from 2” to 3 ½” in length and 0.113” to 0.131” in diameter, including clipped head and full round offset head nails. This versatility allows it to be used in various framing applications, enhancing its utility across different projects. - Can the depth adjustment feature of the M18 FUEL Nailer be used on-the-fly, or does it require tool downtime?

The depth adjustment can be easily and quickly changed without tools, allowing for seamless transitions between tasks without significant downtime, making it efficient for projects requiring varied nail depths. - How does the dry fire lockout feature enhance the lifespan of the Milwaukee M18 FUEL Framing Nailer?

The dry fire lockout prevents the nailer from operating when out of nails, reducing unnecessary wear and tear on the tool’s internal components, thereby extending its lifespan and maintaining consistent performance.

We hope you found our deep dive into the Milwaukee M18 FUEL 30 Degree Framing Nailer both informative and enlightening. Your insights and experiences are invaluable to us, and we encourage you to share your thoughts and questions in the comments below. Have you used this nailer in your projects? What’s your take on its performance and features? Let’s discuss and help others make informed decisions.

For those of you passionate about crafting and DIY, or if you’re seeking expert gardening advice, our website is a treasure trove of information. Explore our comprehensive guides for tips and tricks, discover our top recommendations in the best products section, and delve into our in-depth reviews to find the perfect tools and equipment for your needs. Your journey to mastering the art of framing and beyond starts here. Share your thoughts, join our community discussion, and let’s cultivate a space for growth and learning together.

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment