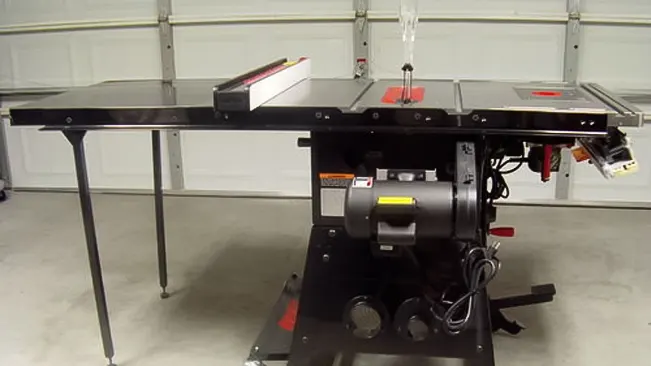

SawStop Contractor Saw Review: Performance, Safety Features, & Value

- April 4, 2024

- 0 comment

Take a closer look at the SawStop Contractor Saw. It packs a 1.75 HP motor and a 10-inch blade into a sturdy frame. With its sizeable cast iron table and weighing in at 335 lbs, this saw’s all about precision and keeping your projects safe.

Specifications

| Brand | SawStop |

| Motor | 1.75 HP |

| Blade Size | 10 inches |

| Cabinet Footprint | 25 3/4″ W x 27″ D |

| Cast Iron Table | 20″ W x 27″ D |

| Overall Weight | 335 lbs. |

Key Features of SawStop 10-inch Contractor Saw

- A patented safety system that stops the spinning blade upon contact with skin, minimizing the risk of life-altering injuries in less than 5 milliseconds

- T-Glide Fence System made of heavy-gauge steel for sure lockdown and reliably square cutting, ensuring accurate cuts for years without deflection

- Dust collection system for efficient debris management

- Durable construction with the trunnion and arbor built for precision, strength, and stability, ensuring a reliable and safe woodworking experience

Design and Build Quality

The design of the SawStop 10-inch Contractor Saw is strong and tough, guaranteeing that it can withstand heavy use without breaking. This sturdiness means that it will stay solid and steady while you’re using it, giving you confidence in its reliability. Additionally, the construction is built to last, so you can trust that it will hold up well over time, making it a good long-term investment for your woodworking needs.

Performance

The 1.75-HP motor in the SawStop 10-inch Contractor Saw provides plenty of strength and accuracy, allowing it to handle many different woodworking jobs with ease. This means you can use it for various tasks without worrying about it struggling to keep up.

Whether you’re cutting thick hardwood or making delicate, precise cuts, this saw’s motor is up to the challenge. With this level of power and precision, you can trust that the saw will help you accomplish your woodworking projects efficiently and accurately.

Ease of Use and Maneuverability

The SawStop 10-inch Contractor Saw is designed to be easy to use, with a layout that’s simple to understand and operate, making it hassle-free for woodworkers of all levels. Its smooth operation means you won’t encounter any rough or difficult movements when using it, further adding to its user-friendly nature.

This overall ease of use and smoothness make your woodworking tasks more efficient, allowing you to focus on your projects without struggling with the equipment.

SawStop Contractor Saw Pros and Cons

Pros

- Superior safety features

- Accurate and reliable cutting performance

- Solid construction for longevity

Cons

- Relatively heavy

- Assembly may require time and effort

Comparative Analysis of the SawStop 10-Inch Contractor Saw

| Features |  SawStop 10-Inch Contractor Saw |  Bosch 4100XC-10 10-Inch Worksite Table Saw |  Delta 36-5000T2 Contractor Table Saw |

|---|---|---|---|

| Model | CNS175-TGP252 | 4100XC-10 | 36-5000T2 |

| Motor Power | 1.75 HP | 4.0 HP | 1.75 HP |

| Blade Size | 10 inches | 10 inches | 10 inches |

| Fence System | 52-inch Professional T-Glide | SquareLock Rip Fence | 30-inch T-Square Fence System |

| Safety System | SawStop patented safety system | Smart Guard System | Blade Brake |

| Weight | 317 lbs | 92 lbs | 230 lbs |

| Dust Collection Port | 4-inch | 2.5-inch | 2.5-inch |

| Max Rip to Right of Blade | 52 inches | 30 inches | 30 inches |

| Max Depth of Cut at 90° | 3-1/8 inches | 3-1/8 inches | 3-1/2 inches |

| Max Depth of Cut at 45° | 2-1/4 inches | 2-1/4 inches | 2-1/2 inches |

| Key Features | Patented safety system, T-Glide Fence, Cast Iron Table | Gravity-Rise Stand, Soft Start, Constant Response Circuitry | Large ON/OFF switch, Blade Brake, Tubular Stand |

| Pros | Exceptional safety features, Precise cuts, High-quality construction | Portable, Powerful motor, Easy adjustments | Good safety features, Stable, Affordable |

| Cons | Higher price, Heavier, Mobility kit sold separately | Smaller rip capacity, Less robust safety system | Limited rip capacity, Noisy |

| Suitable for | Professional woodworkers, Safety-conscious users | Jobsite contractors, DIY enthusiasts | Home workshops, Budget-conscious users |

Summary

The SawStop 10-inch Contractor Saw CNS175-TGP252 is a high-end contractor saw with a focus on safety and precision. It is ideal for professional woodworkers and those who prioritize safety features in their tools. Its 52-inch T-Glide Fence and 1.75 HP motor make it suitable for a wide range of tasks, though it comes at a higher price and is heavier compared to other models.

The Bosch 4100XC-10 is a more portable option with a 4.0 HP motor, making it powerful for its size. It is equipped with a Gravity-Rise Stand and a SquareLock Rip Fence for easy adjustments and transport. This saw is well-suited for job site contractors and DIY enthusiasts who need a reliable and portable saw.

The Delta 36-5000T2 offers good safety features with its Blade Brake and a stable tubular stand. It is more affordable than the SawStop model and is suitable for home workshops and budget-conscious users. However, it has a limited rip capacity and can be noisier during operation.

Each of these contractor saws has its strengths and is suited to different types of users, from professionals to DIY enthusiasts and those working within a budget.

Maintenance

Proper maintenance of the SawStop 10-inch Contractor Saw is essential for ensuring its longevity and performance. Here are some key maintenance tips:

Daily Maintenance

- Clean the Saw: Wipe down the saw table, fence, and other surfaces to remove sawdust and debris. Use a soft cloth or brush to avoid scratching the surfaces.

- Check for Obstructions: Ensure that there are no obstructions in the path of the blade or the safety system. Remove any debris that may interfere with the operation of the saw.

- Inspect the Blade: Check the blade for any signs of wear, damage, or dullness. Replace the blade if necessary to ensure clean and precise cuts.

Weekly Maintenance

- Lubricate Moving Parts: Apply a light machine oil to the moving parts of the saw, such as the elevation and tilt mechanisms, to ensure smooth operation.

- Check the Alignment: Verify that the blade and fence are properly aligned. Use a square to check the alignment of the blade to the miter slots and the fence to the blade. Adjust as needed.

- Inspect the Safety System: Test the safety system to ensure that it is functioning correctly. Refer to the SawStop manual for instructions on how to perform a safety system test.

Monthly Maintenance

- Clean the Interior: Remove the blade and throat plate to access the interior of the saw. Vacuum out any accumulated sawdust and debris.

- Inspect Belts and Pulleys: Check the belts and pulleys for any signs of wear or damage. Replace them if necessary to prevent breakdowns.

- Check for Loose Hardware: Tighten any screws, bolts, or other hardware that may have become loose over time.

Annual Maintenance

- Service the Motor: Have the motor serviced by a qualified technician to ensure it is in good working condition.

- Calibrate the Saw: Perform a thorough calibration of the saw to ensure that all adjustments are accurate and that the saw is operating at its best.

Safety System Maintenance

- Replace the Brake Cartridge: If the safety system is activated, replace the brake cartridge immediately. Do not attempt to use the saw until the cartridge has been replaced.

- Test the Safety System Regularly: Even if the safety system has not been activated, test it regularly to ensure it is working correctly.

Practical Tips for Use

Using the SawStop 10-inch Contractor Saw efficiently and safely requires some practical knowledge. Here are some tips to help you get the most out of your saw:

Safety First

- Use the Safety System: Always ensure that the safety system is activated and functioning properly before starting the saw.

- Wear Appropriate Safety Gear: Use safety glasses, hearing protection, and a dust mask to protect yourself from sawdust and noise.

- Keep Hands Clear: Never place your hands near the blade while the saw is running. Use push sticks or featherboards to guide the workpiece.

Making Precise Cuts

- Use a Sharp Blade: A sharp blade ensures clean and precise cuts. Regularly inspect the blade and replace it if it becomes dull.

- Check Alignment: Make sure the blade and fence are properly aligned for accurate cuts. Use a square to check and adjust if necessary.

- Use a Zero Clearance Insert: A zero clearance insert helps support small pieces and reduces tear-out for cleaner cuts.

Efficient Operation

- Use the Right Blade for the Material: Different materials require different blades. Use a blade that is suitable for the material you are cutting.

- Adjust the Blade Height: Set the blade height so that it is just above the thickness of the material being cut. This reduces the risk of kickback and improves the quality of the cut.

- Support Large Workpieces: Use outfeed tables or roller stands to support large workpieces and ensure stable and accurate cuts.

Maintenance and Care

- Keep the Saw Clean: Regularly clean the saw table, fence, and other components to prevent the buildup of sawdust and debris.

- Lubricate Moving Parts: Apply light machine oil to moving parts to keep them operating smoothly.

- Inspect the Saw Regularly: Regularly inspect the saw for any signs of wear or damage. Address any issues promptly to ensure the safety and performance of the saw.

Additional Tips

- Use a Crosscut Sled for Crosscuts: A crosscut sled can improve the accuracy and safety of crosscuts.

- Use Featherboards for Consistent Pressure: Featherboards help maintain consistent pressure on the workpiece, resulting in smoother cuts.

- Avoid Overloading the Saw: Do not force the saw to cut material that is too thick or hard for its capacity. This can strain the motor and increase the risk of kickback.

Conclusion

The SawStop 10-inch Contractor Saw with a 1.75-HP motor and 52-inch Professional T-Glide Fence System is a top-of-the-line choice for woodworking enthusiasts and professionals. Its patented safety system sets it apart from competitors, providing unparalleled protection against accidents.

The saw’s durable construction, precise cutting capabilities, and ease of use make it a valuable addition to any workshop. While it may be heavier and require some assembly, the superior safety features and reliable performance justify the investment.

Whether you’re a professional woodworker or a safety-conscious hobbyist, the SawStop Contractor Saw is a solid choice for your woodworking needs.

Frequently Asked Questions (FAQs)

1. What makes the SawStop 10-inch Contractor Saw unique?

The SawStop 10-inch Contractor Saw features a patented safety system that stops the blade within milliseconds if it comes into contact with skin, significantly reducing the risk of serious injuries.

2. How does the T-Glide Fence System benefit users?

The T-Glide Fence System is made of heavy-gauge steel, ensuring sure lockdown and reliably square cutting. It provides smooth and precise adjustments for accurate cuts.

3. Is the saw suitable for heavy-duty use?

Yes, the SawStop 10-inch Contractor Saw is built for heavy-duty use with its 1.75-HP motor, cast iron table, and sturdy construction, making it suitable for various woodworking tasks.

4. How do I maintain the SawStop 10-inch Contractor Saw?

Regular maintenance includes cleaning the saw, lubricating moving parts, checking for obstructions, inspecting the blade, and testing the safety system. Refer to the maintenance section for detailed tips.

5. Can I adjust the blade height and angle on this saw?

Yes, the SawStop 10-inch Contractor Saw allows for easy adjustments of blade height and angle, ensuring versatility for different types of cuts.

6. Is the dust collection system effective?

The saw comes with a 4-inch dust collection port, which, when connected to a dust collection system, effectively manages sawdust and keeps the workspace clean.

7. How does the SawStop 10-inch Contractor Saw compare to other contractor saws?

Compared to other contractor saws like the Bosch 4100XC-10 and Delta 36-5000T2, the SawStop 10-Inch Contractor Saw stands out for its safety features, precision, and build quality, though it is heavier and pricier.

8. What materials can I cut with this saw?

The SawStop 10-inch Contractor Saw can handle a variety of materials, including hardwoods, softwoods, and composite materials, making it versatile for different woodworking projects.

9. Is the assembly process difficult?

The assembly may require some time and effort, but the instructions are clear, and the result is a sturdy and reliable saw. It’s recommended to have a helper for easier assembly.

10. Where can I purchase the SawStop 10-inch Contractor Saw?

The SawStop 10-inch Contractor Saw is available through various retailers, including online platforms like Amazon, as well as local woodworking and tool supply stores.

Leave your comment